Cutting tool for metal working and method for producing it

A cutting tool and metal processing technology, applied in the field of tool holder body, can solve the problem of not bringing about the fatigue strength of the tool holder body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

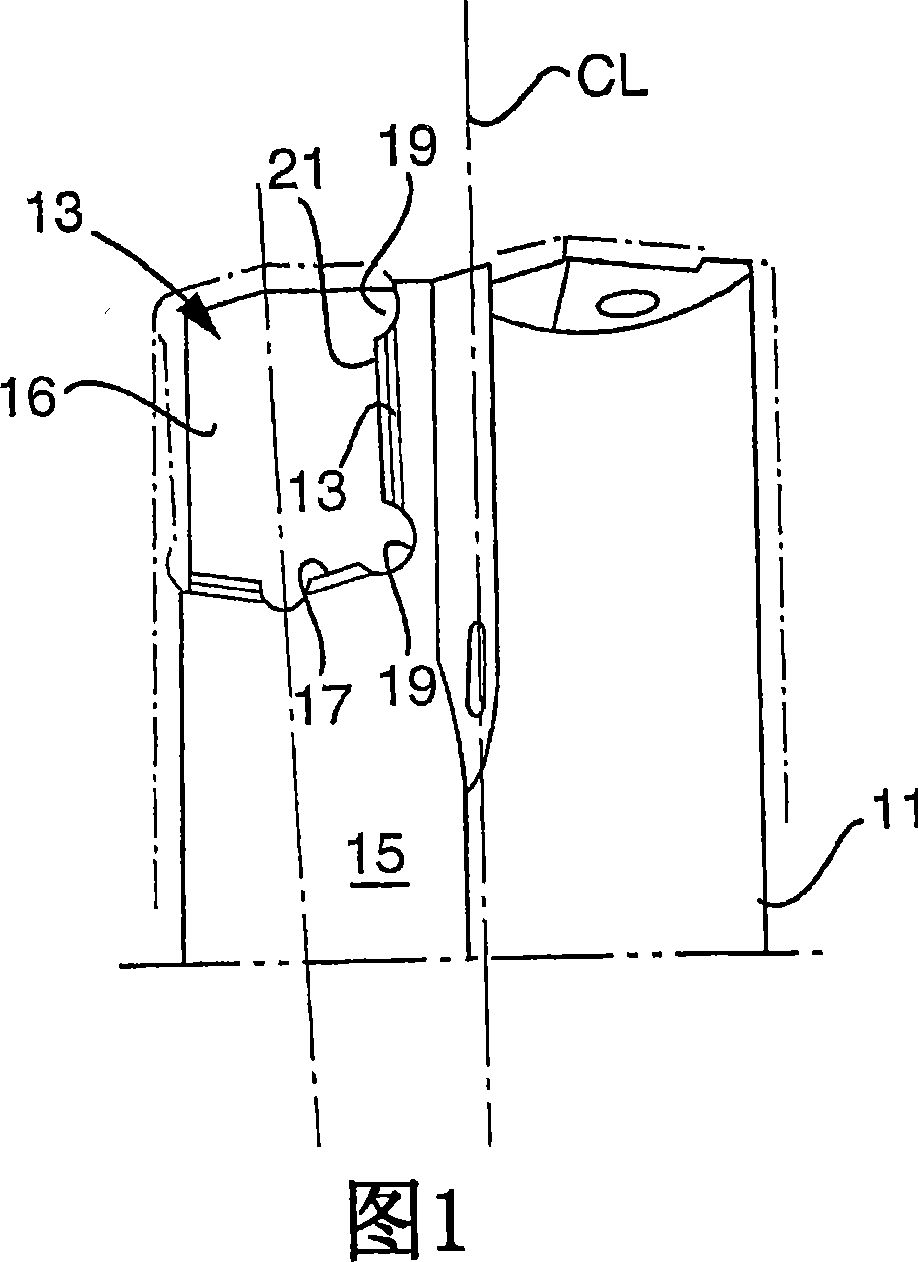

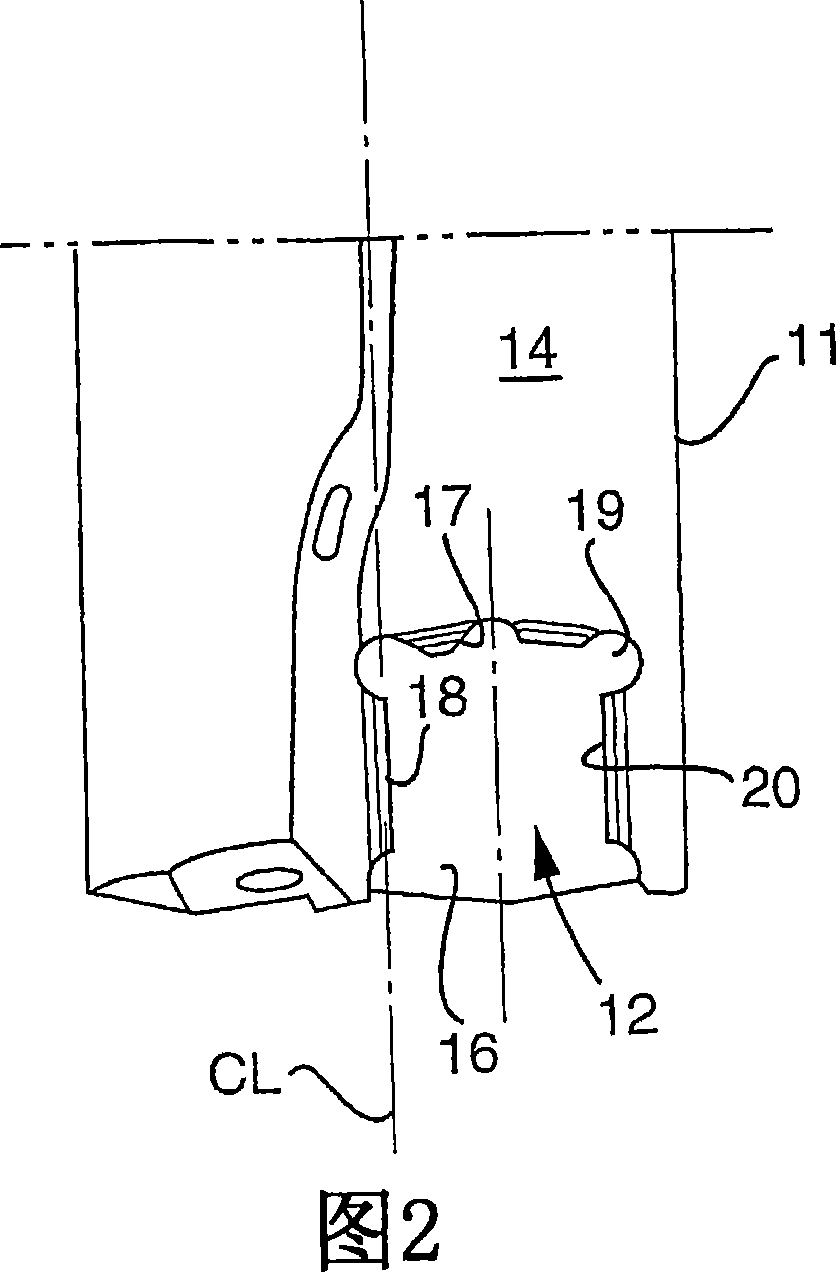

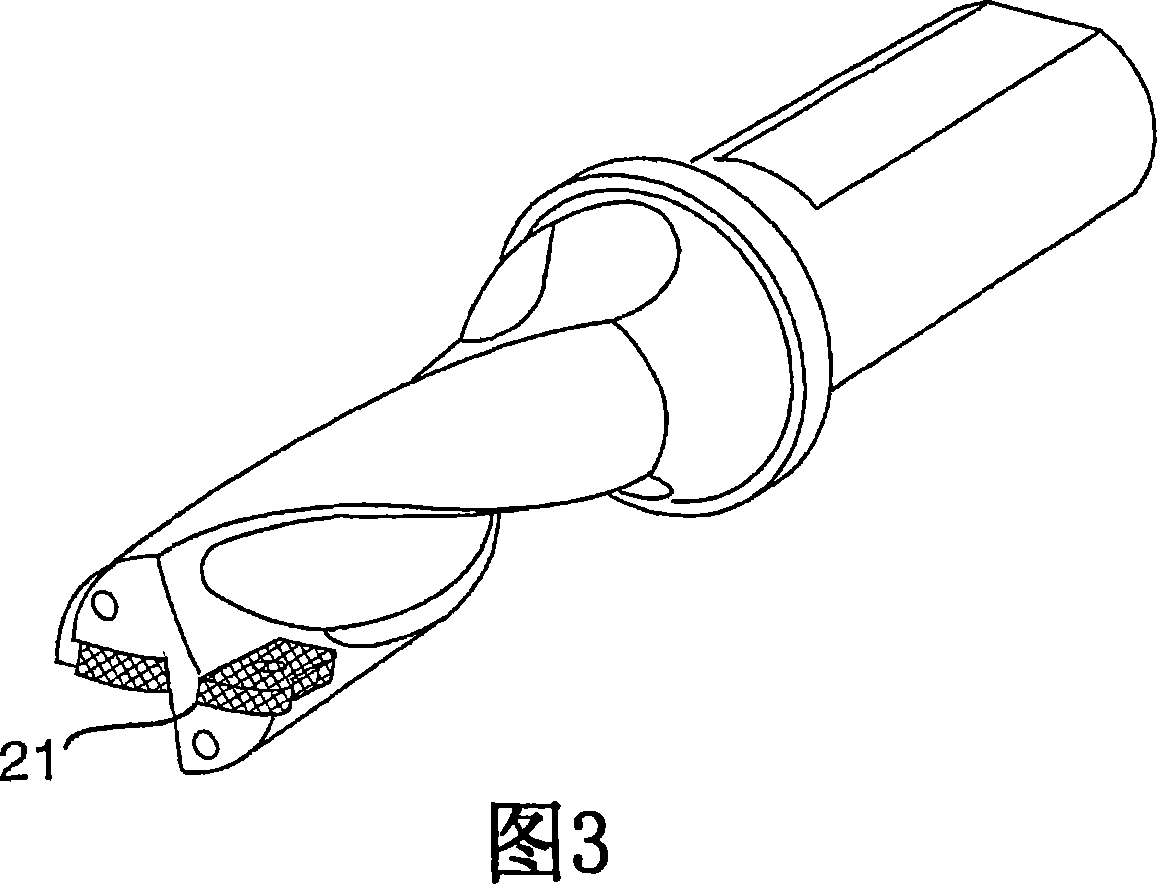

example 1

[0034] Tool steel SS2242 was prepared to the final shape and dimensions of the indexable short hole drill bit according to the present invention. The drill is deep hardened by heating to 960°C followed by air quenching, giving the tool a 1520N / mm 2 The yield point under tension and has a hardness of 50HRC. Subsequently, the entire holder body of the tool is shot peened under the following conditions:

[0035] Angle of incidence: 90 degrees relative to the longitudinal axis of the drill bit

[0036] Distance between nozzle and tool holder body: 100mm

[0037] Rotation speed of tool holder body: 30rev / min

[0038] Time: 60s

[0039] Medium: 52HRC round steel ball, 0.20mm

[0040] Adjust the pressure and flow to achieve an Almen value of 18A

example 2

[0042] Example 1 was repeated, and in addition to hardening a nitrocarburizing treatment as disclosed in US 2005 / 0002744 was performed.

example 3

[0044]The tool holder bodies of Examples 1 and 2 with cutting inserts made of cemented carbide were tested in a short hole drilling operation at a depth of 60 mm. Drill holes in the material SS2541300HB, the cutting data is: 200m / min speed and 0.20mm / rev feed rate. These cutting data yield the force at which the material yields and stretches 85%. As a further reference, the same type of deep-hardened and cold-work-blackened drill bit was tested as commercially available. The tool life is based on the damage of the tool holder body.

[0045] result:

[0046] Refer to 300m

[0047] Example 2 50m

[0048] Example 1 >1000m

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com