Patents

Literature

51results about How to "Reduce risk of formation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

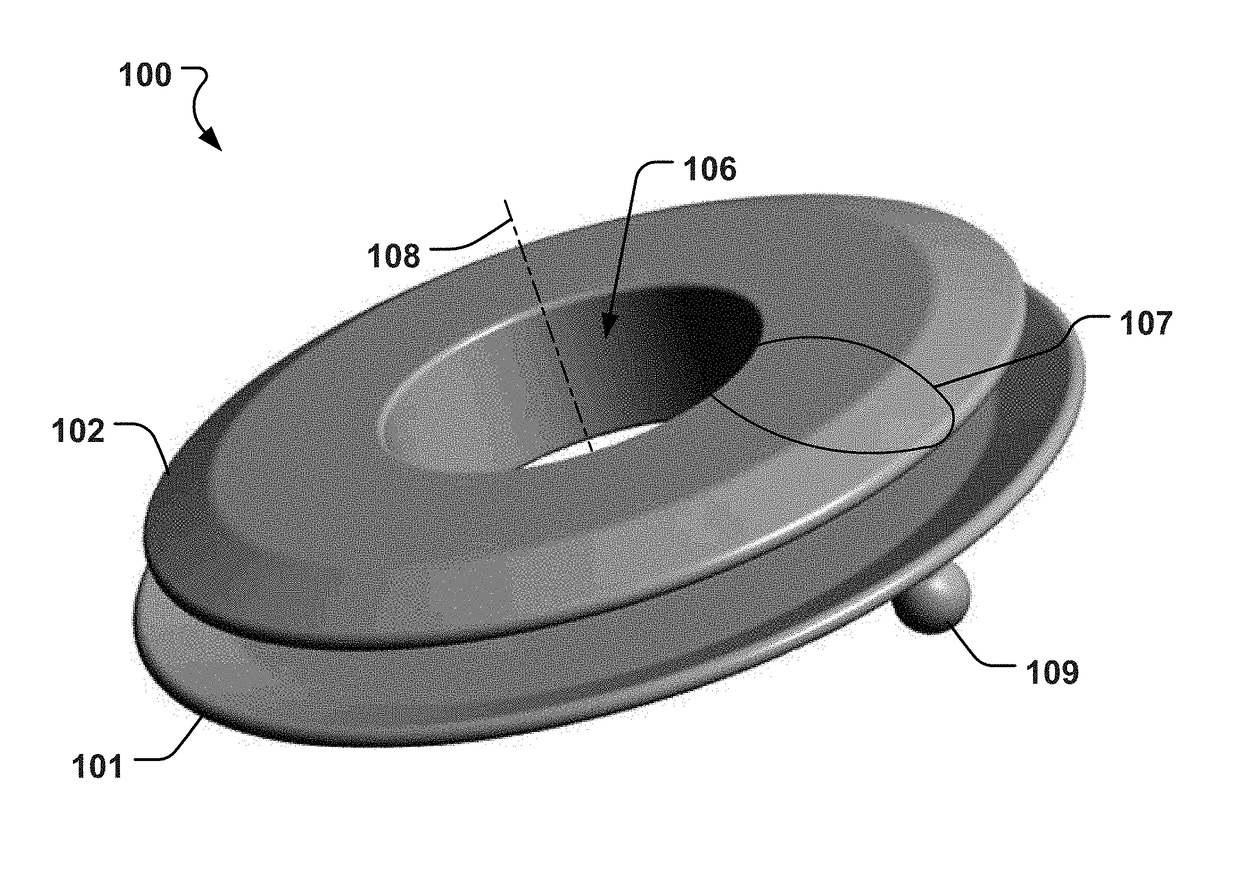

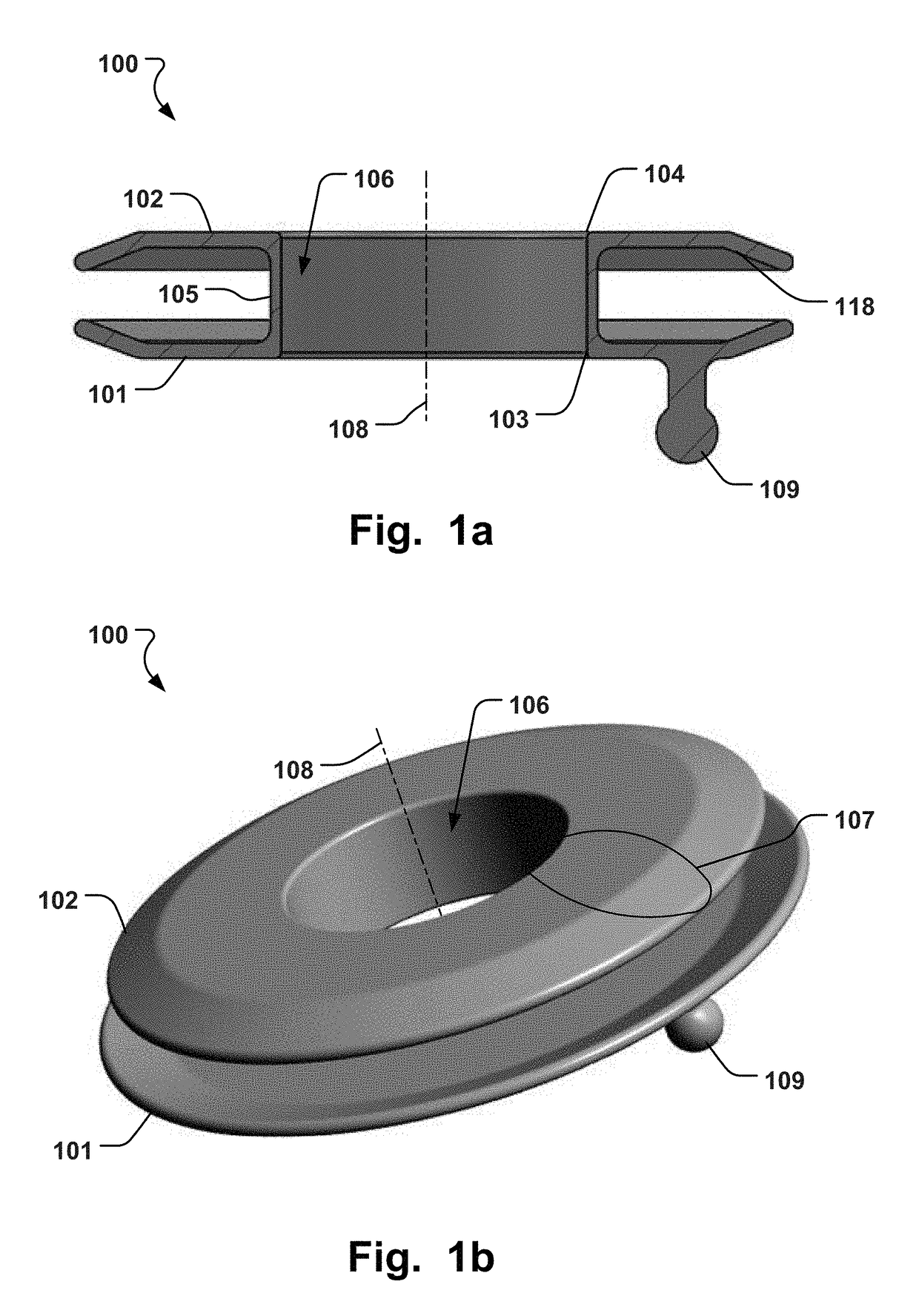

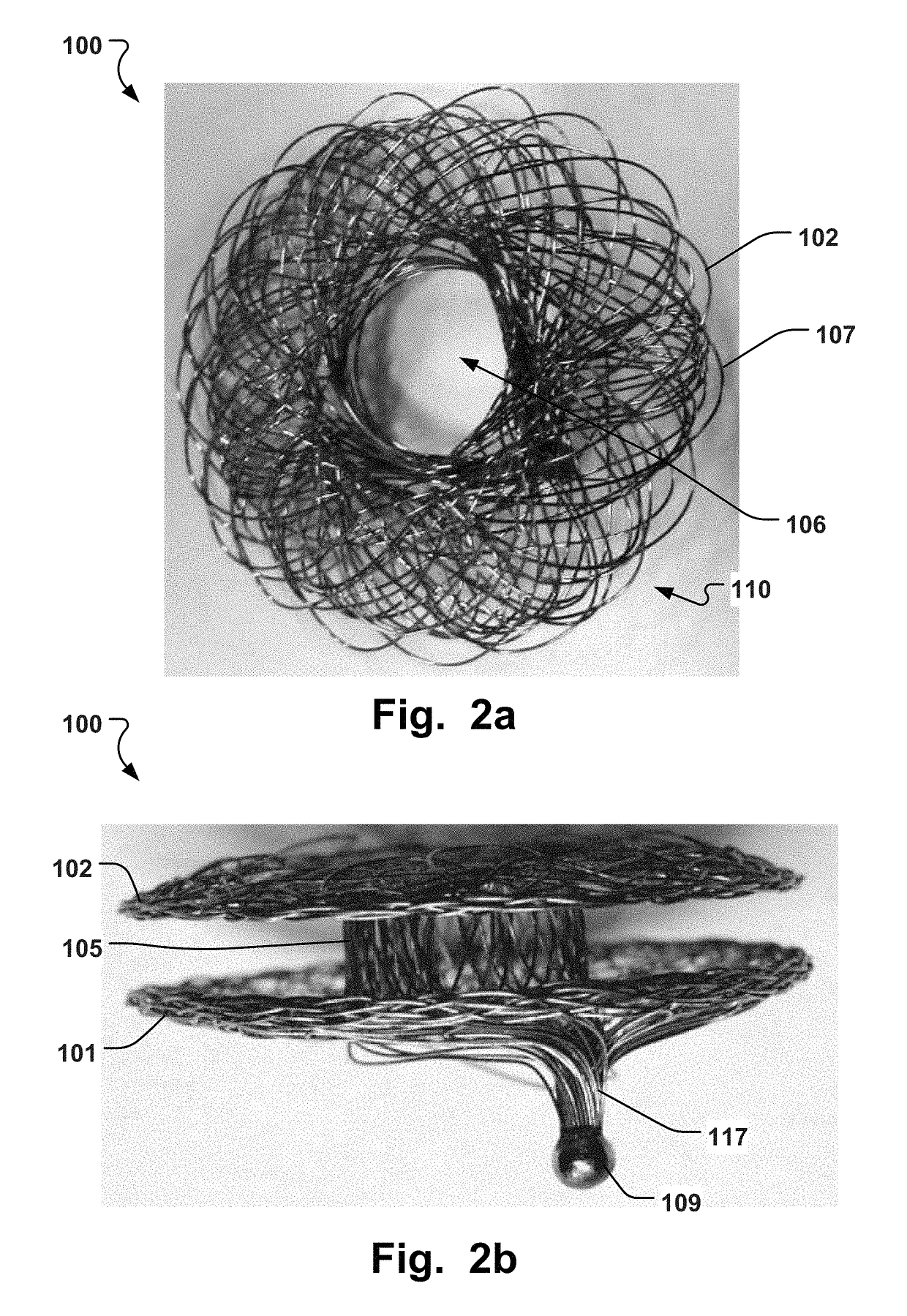

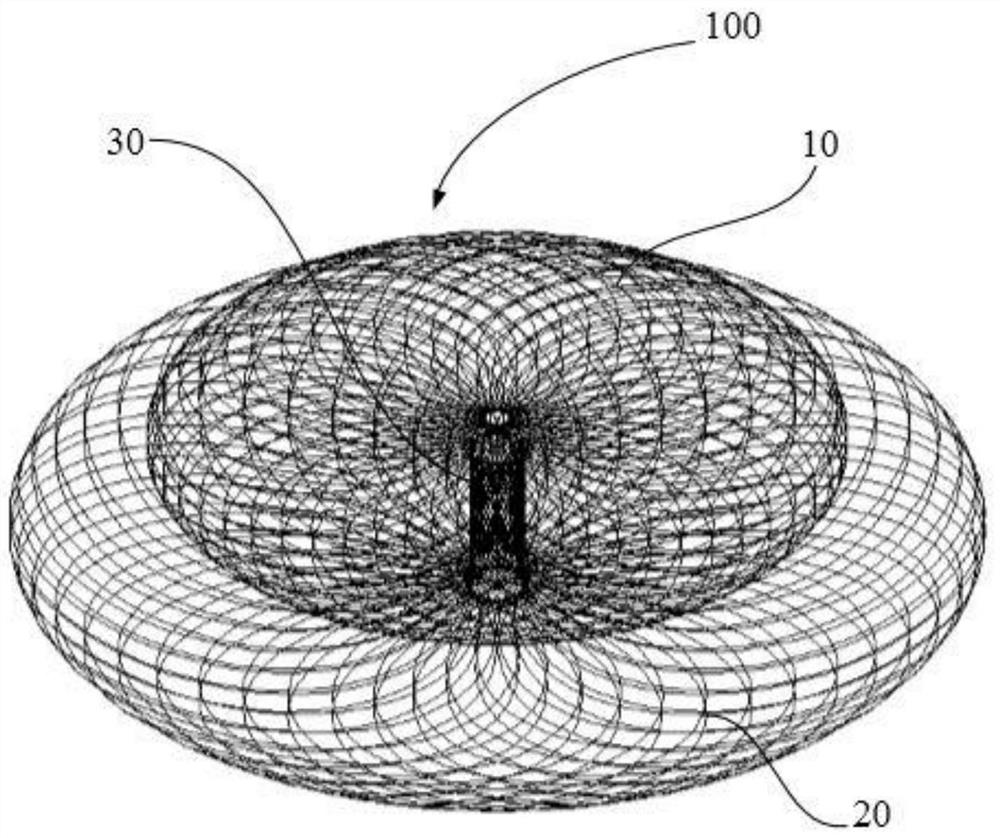

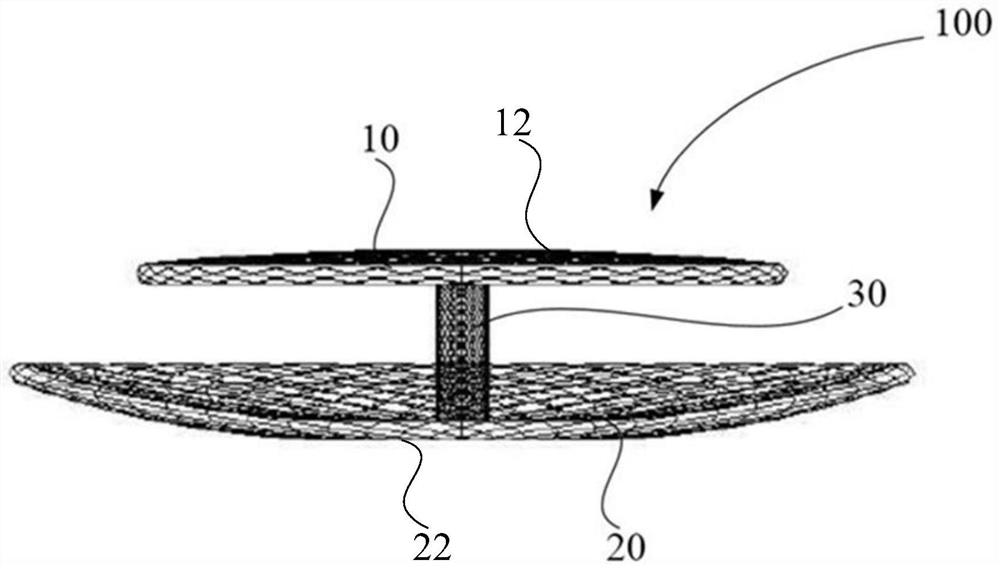

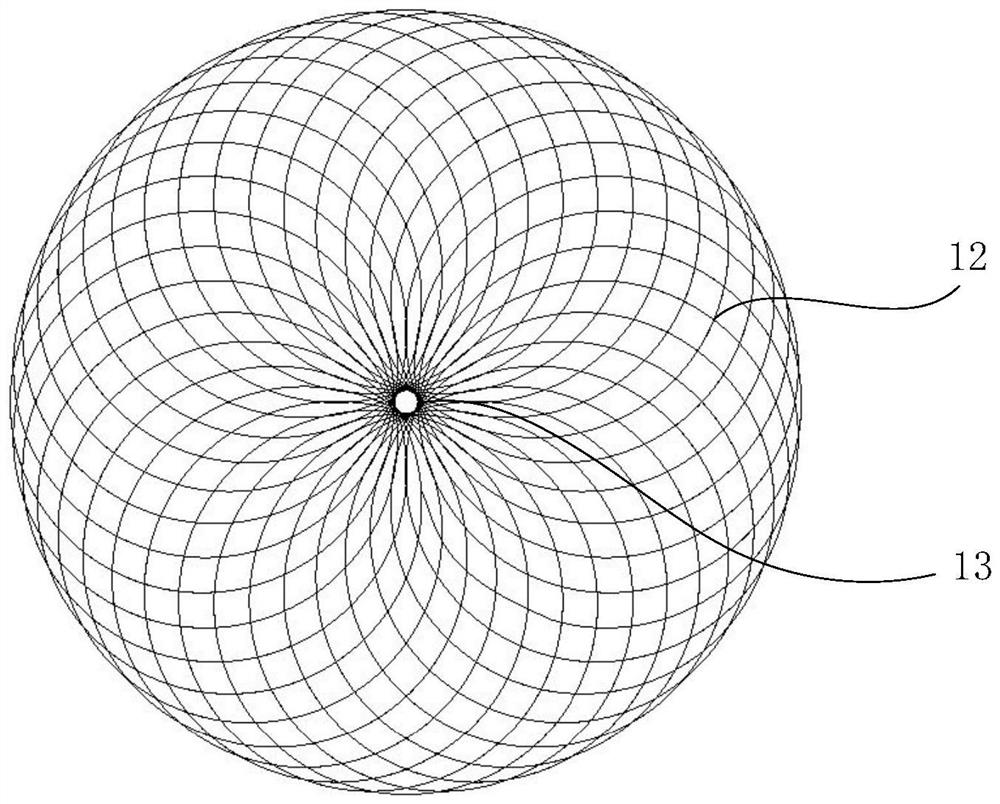

A Flow Regulating Device In The Heart

A blood flow regulator for creating a shunt in the heart, comprising; a proximal element having a general disc-shape, defined by a braid of one or more wires extending about a central aperture of the proximal element; a distal element having a general disc-shape, defined by a braid of one or more wires extending about a central aperture of the distal element; and a third element defining a neck section intermediate the proximal and distal elements and forming a cavity having a diameter no greater than a diameter of each of the distal and proximal elements, wherein said distal element comprises at least one loop of a wire extending radially outwardly from a center of the distal element and returning towards said center of said distal element.

Owner:OCCLUTECH GMBH

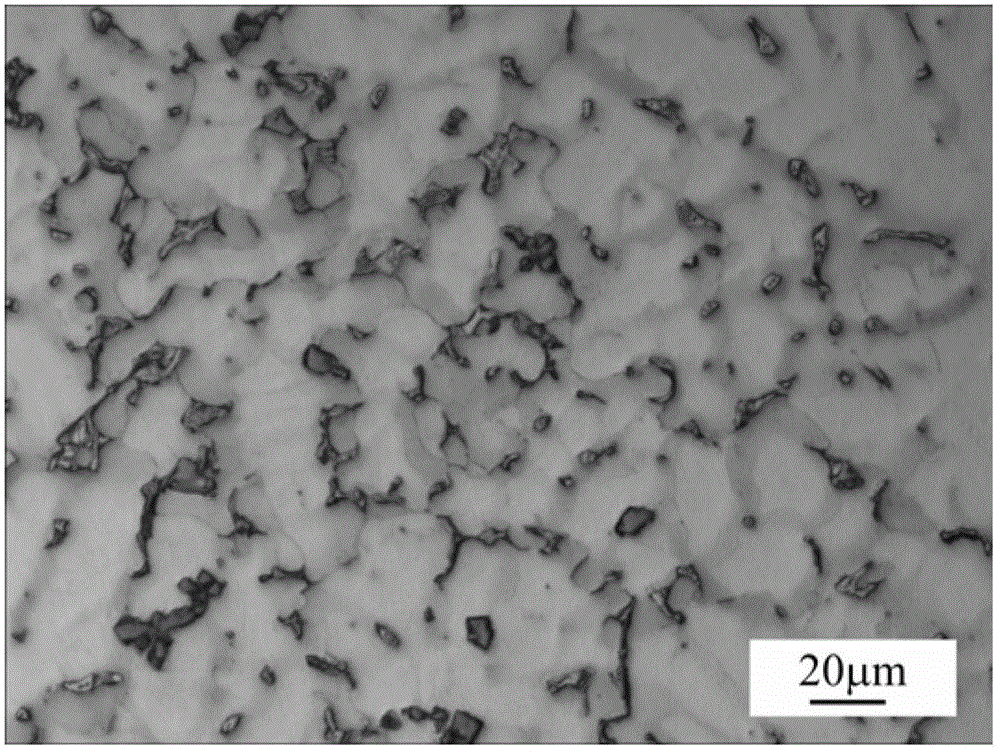

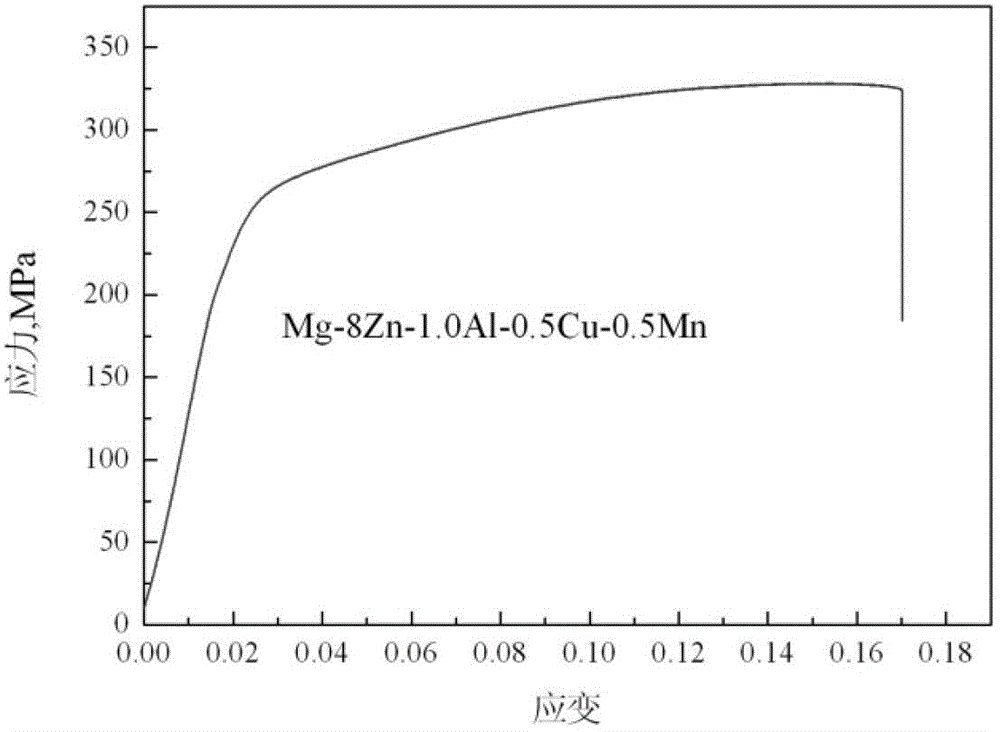

Casting magnesium alloy with high strength and toughness and preparation method thereof

ActiveCN102978497AGood comprehensive mechanical propertiesExcellent aging strengthening abilitySolution treatmentCrucible

The invention relates to the field of magnesium alloy of metal materials, and concretely relates to a casting magnesium alloy containing Zn, Al, Cu and Mn with high strength and toughness. The casting magnesium alloy comprises the following components in percentage by weight: 6.0-8.0% of Zn, 0.5-1.5% of Al, 0.5-1.0% of Cu, 0.3-0.7% of Mn and the balance of Mg and inevitable impurity elements, wherein the content of the impurity elements is less than 0.01%. A preparation method of the casting magnesium alloy comprises the steps of: smelting Mg at the temperature of 740-760 DEG C by using an iron crucible; after pure magnesium is completely smelted, sequentially adding preheated pure metal Zn, Al, Cu and Mg-10wt.% and Mg intermediate alloy for alloying, wherein mixed CO2 and SF6 are used as protective gases in the pure magnesium smelting and alloying processes; stirring, slagging off, standing for 15-20 minutes, adjusting the temperature of an alloy fusant to 700-720 DEG C, and casting into an ingot; and carrying out solution treatment on the alloy for 24-64 hours at 350-400 DEG C, quenching by warm water at 40-60 DEG C, then preageing for 8-24 hours at 50-70 DEG C, and finally preageing for 2-6 hours at 150-200 DEG C to obtain the casting magnesium alloy with high strength and toughness. In room temperature extension tests of the casting magnesium alloy, the yield strength is not less than 205MPa, the tensile strength is not less than 305MPa, the elongation rate is not less than 10%, and the casting magnesium alloy has excellent comprehensive mechanical property.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

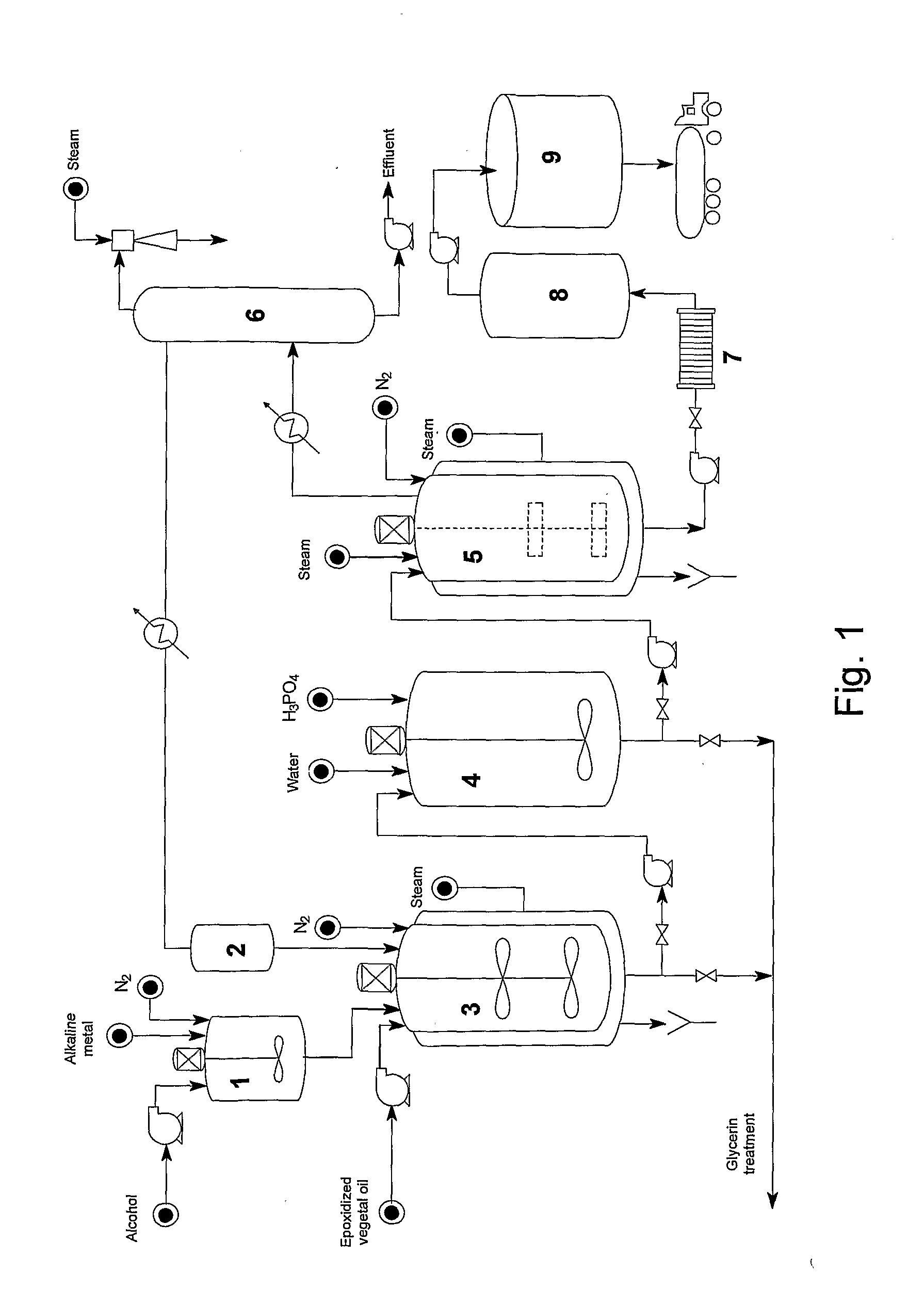

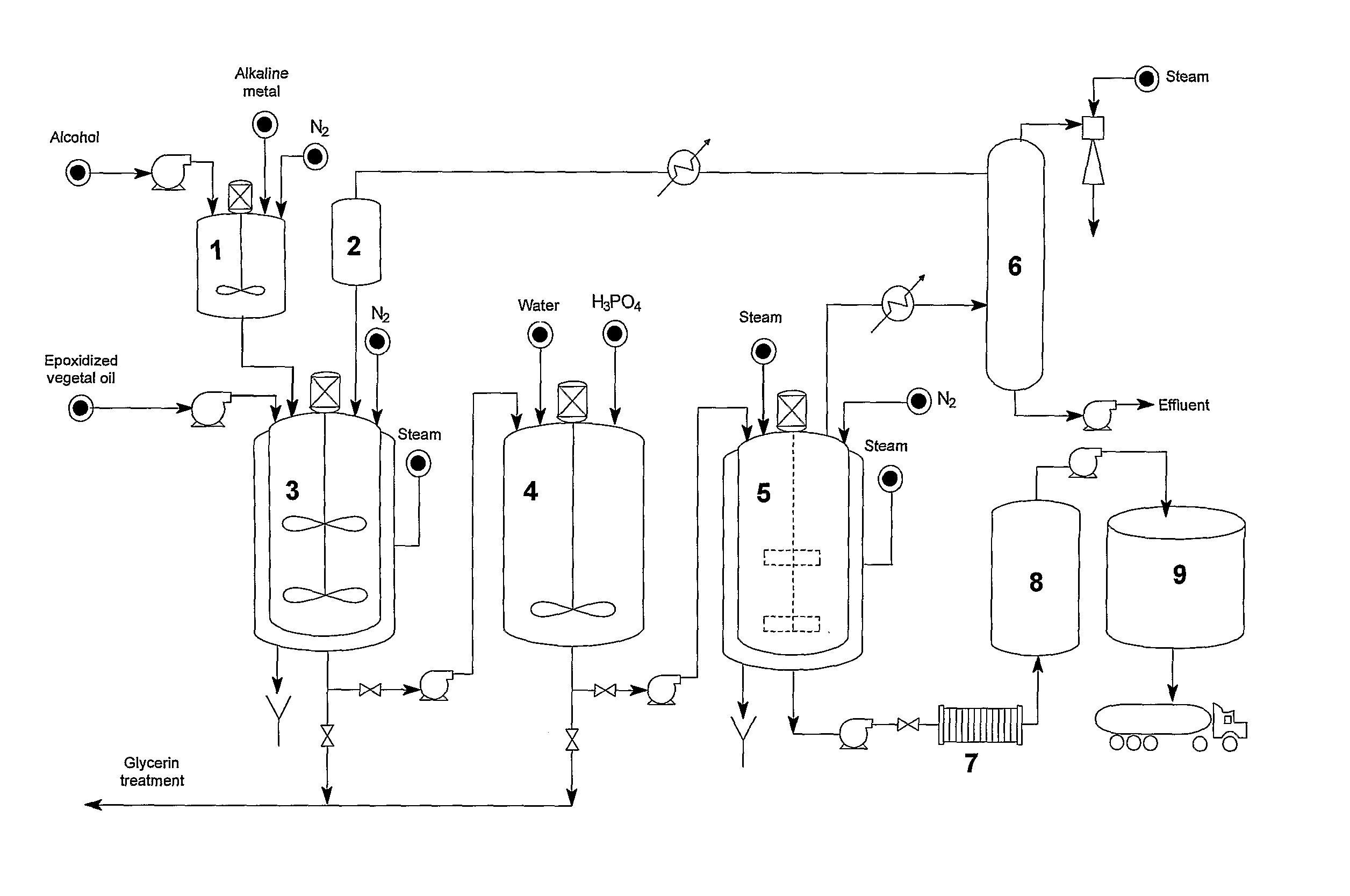

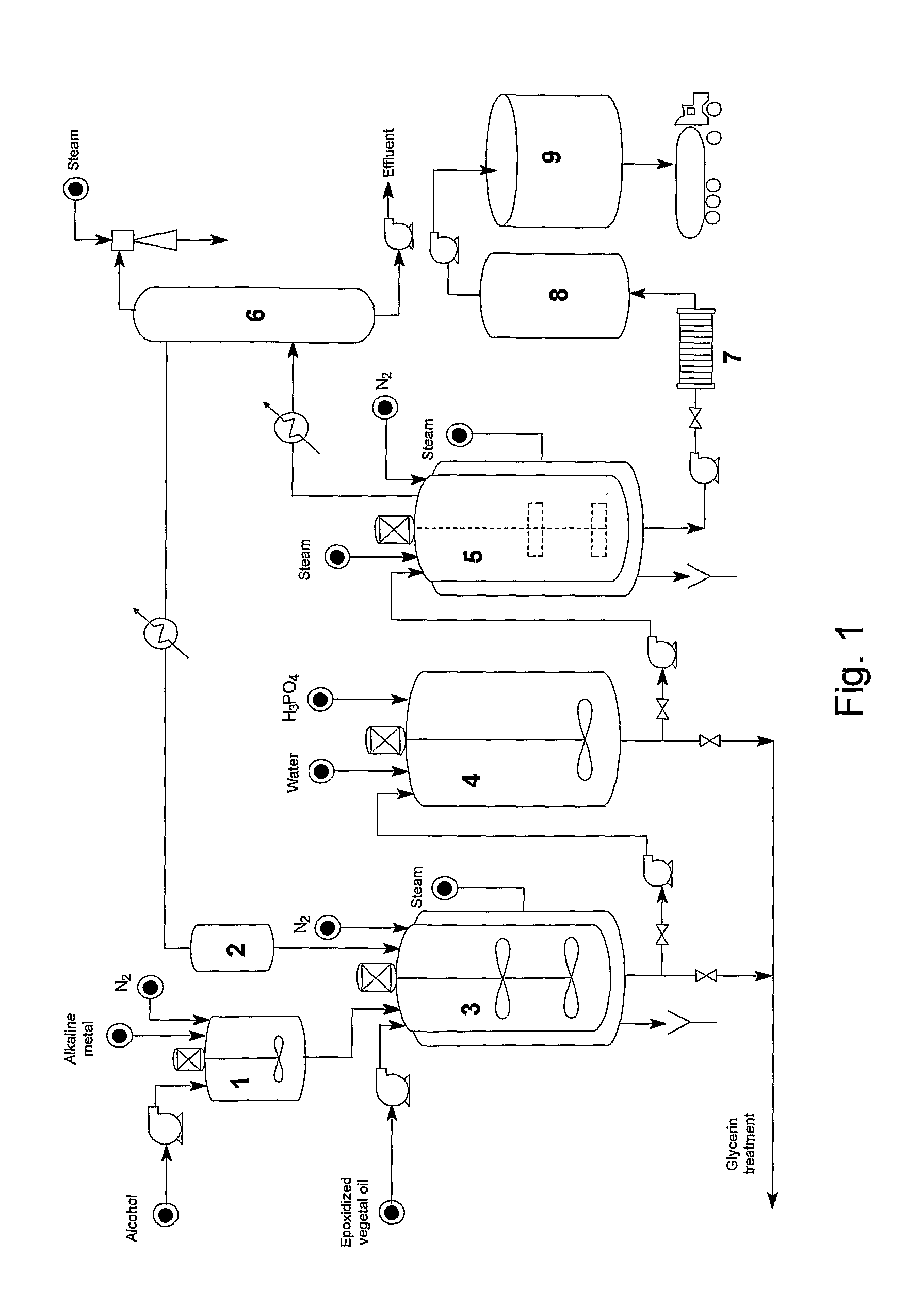

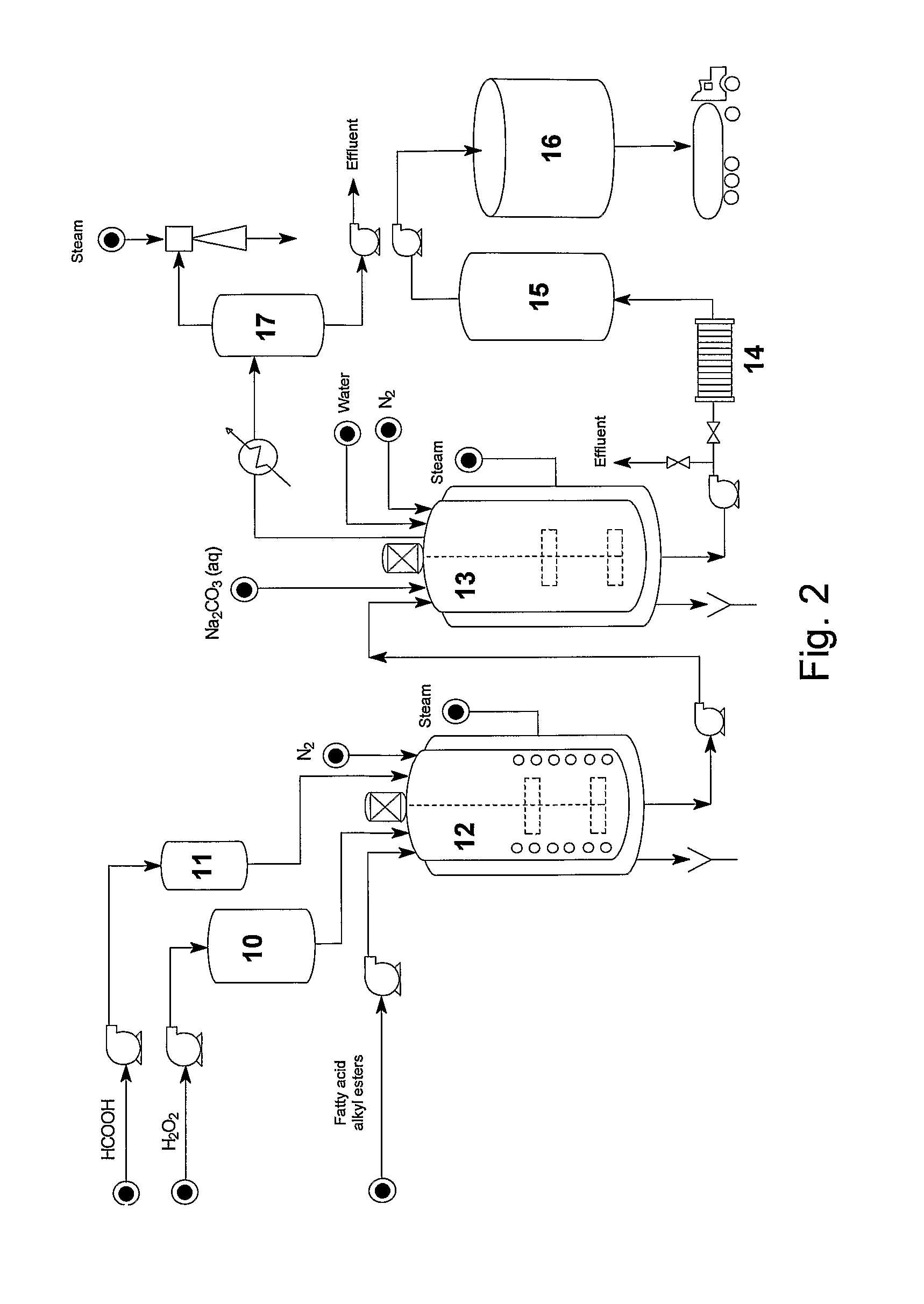

Process for modifying vegetable oils and primary plasticizer for vinyl polymers

ActiveUS20120289727A1Improve efficiencyReduce risk of formationFatty acid esterificationOrganic compound preparationAlcoholVegetable oil

The present invention refers to a process for modifying epoxidized or non-modified vegetable oils. More specifically, it refers to the process through which vegetable oils and alcohols are converted into fatty acid alkyl esters through transesterification. The present invention also refers to the products obtained through the process disclosed herein.

Owner:NPC IND QUIMICAS

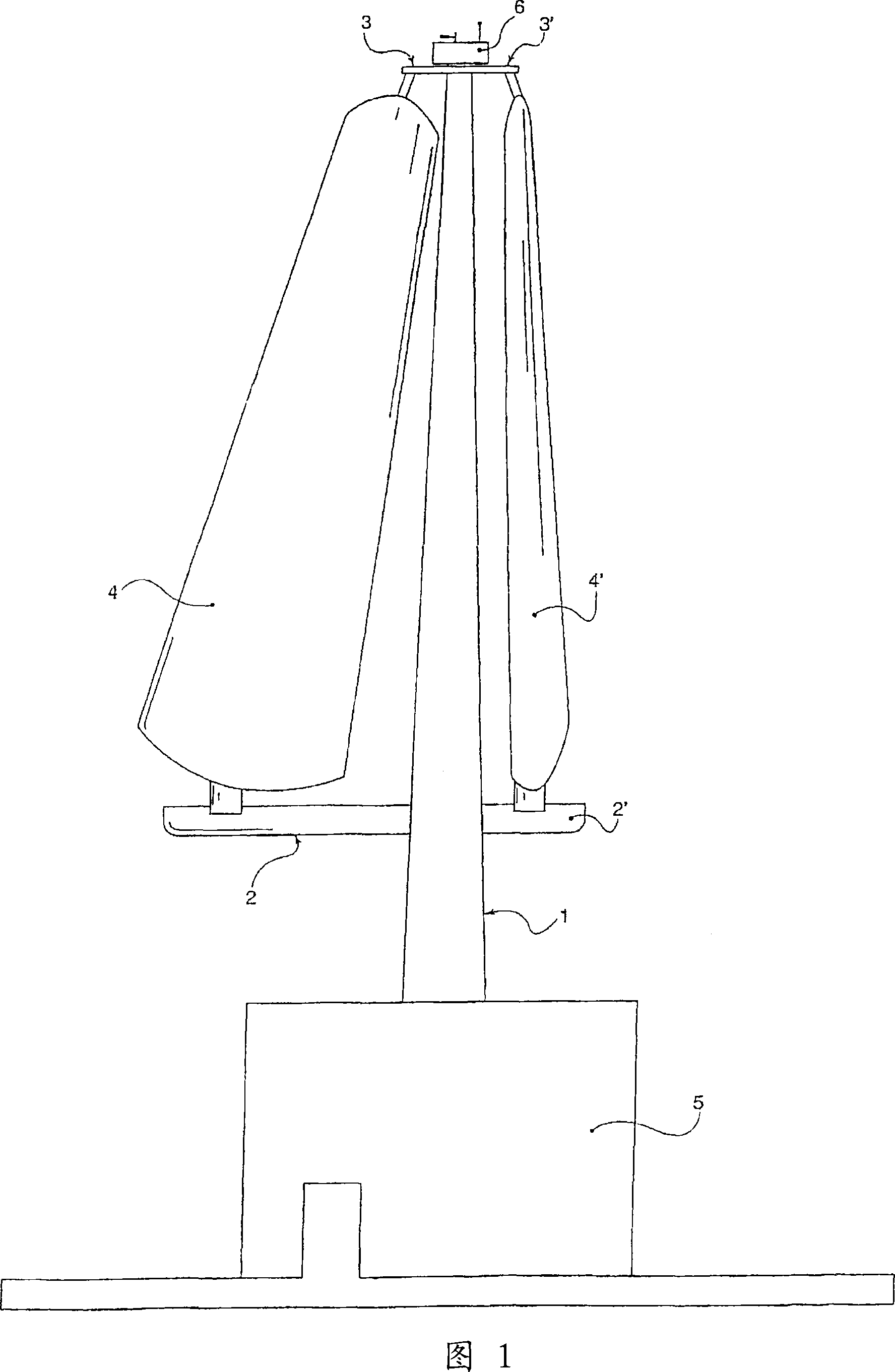

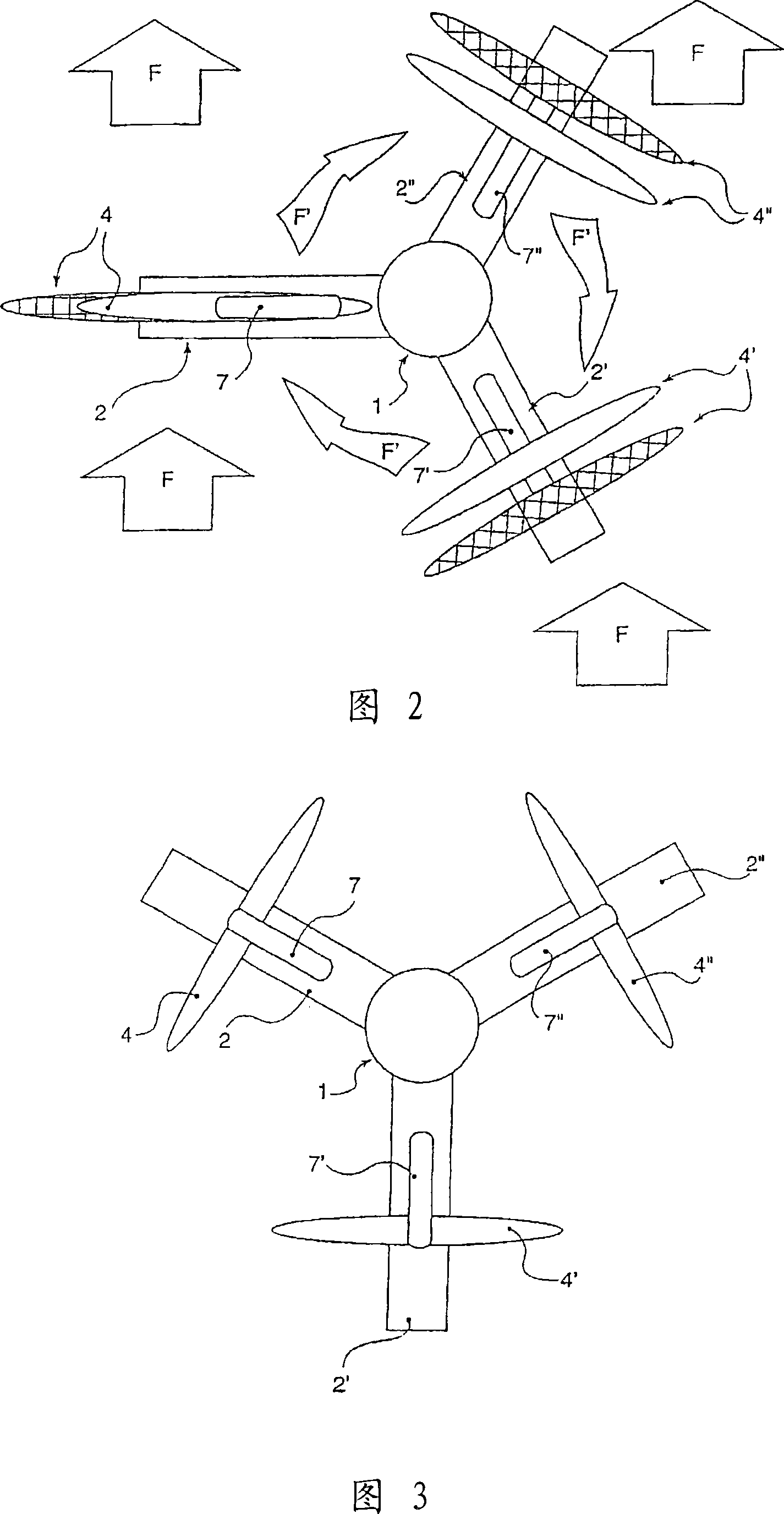

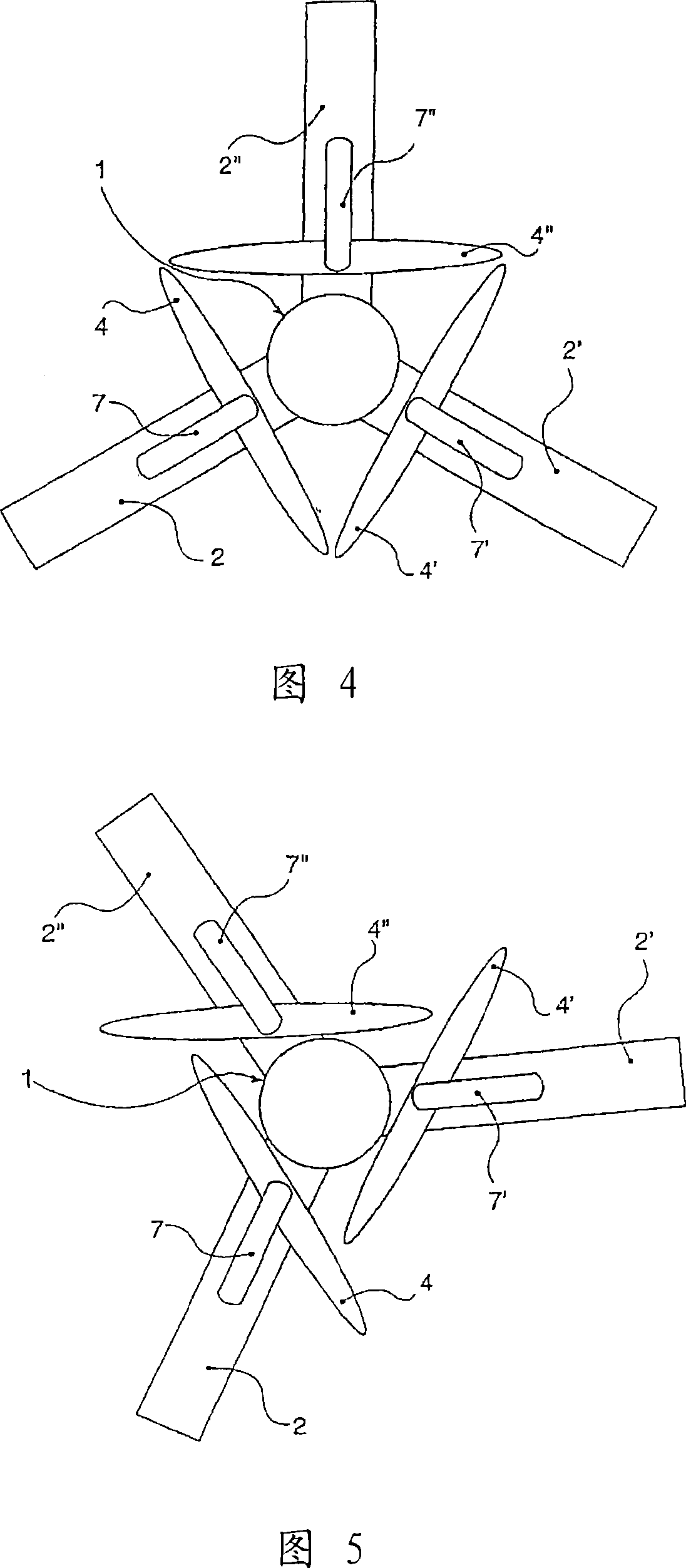

Vertical-axis wind turbine

InactiveCN101010505AImprove stabilityEffectively fixedWind motor controlMachines/enginesVertical axis wind turbineTower

The invention concerns a vertical-axis wind turbine comprising a central rotary tower whereto are fixed substantially vertical blades, said blades capable of rotating and moving radially relative to the central tower, the movement of each blade being independently controlled based on the conditions to which it is constantly subjected so as to optimize the overall performance of the wind turbine.

Owner:VIMAK CORP

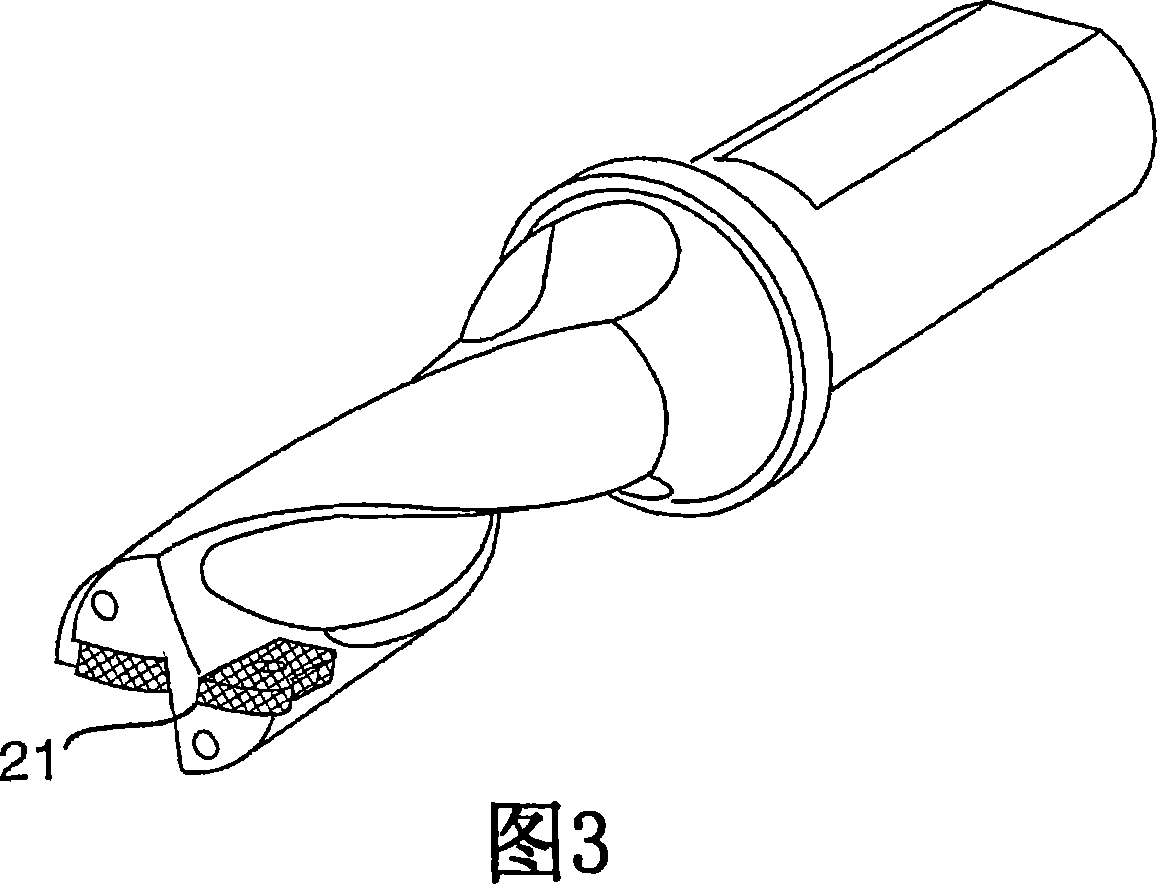

Cutting tool for metal working and method for producing it

InactiveCN101056996AImprove fatigue strengthReduced risk of crack formationTransportation and packagingMilling cuttersMetalworkingTreatment results

According to the invention, there is provided a cutting tool and a method in the production of a cutting tool for metalworking that results in a holder body having increased fatigue strength at loads over 60 % of the yield point in tension. The method and the tool are characterized in that the holder body of the tool is subjected to a hardening process resulting in deep hardening, and that the holder body then is subjected to a surface treatment resulting in a strain hardening of the surface in order to introduce compressive stresses in the surface zone of the holder body.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

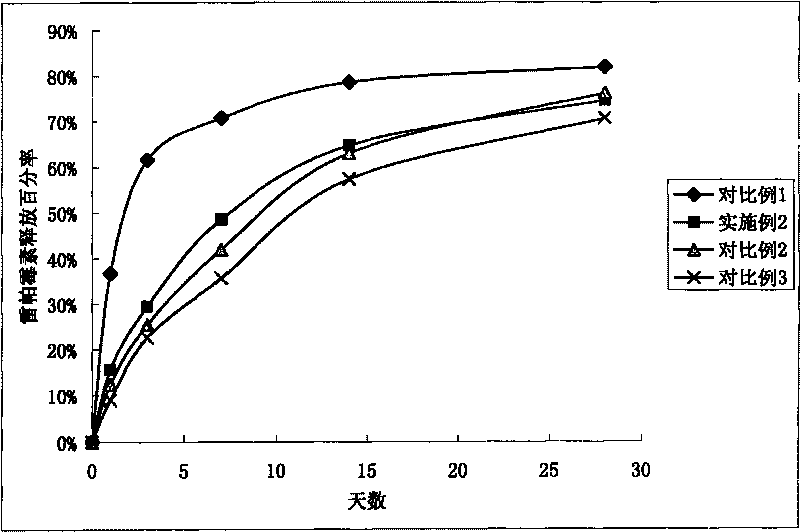

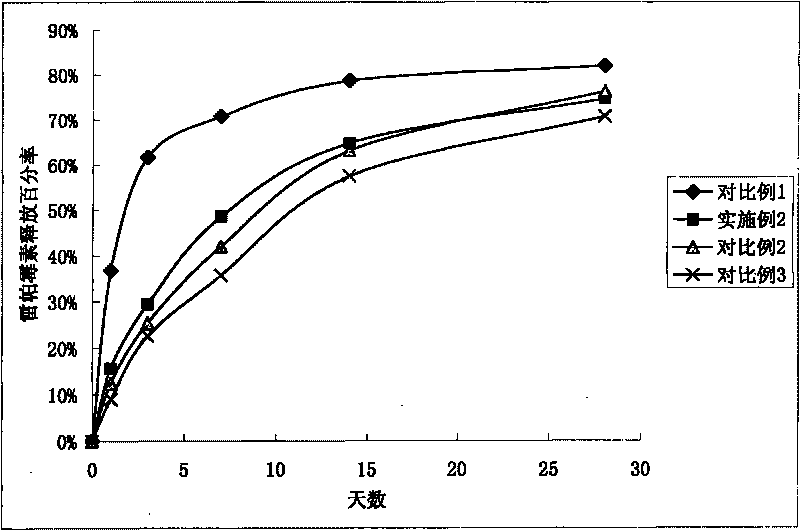

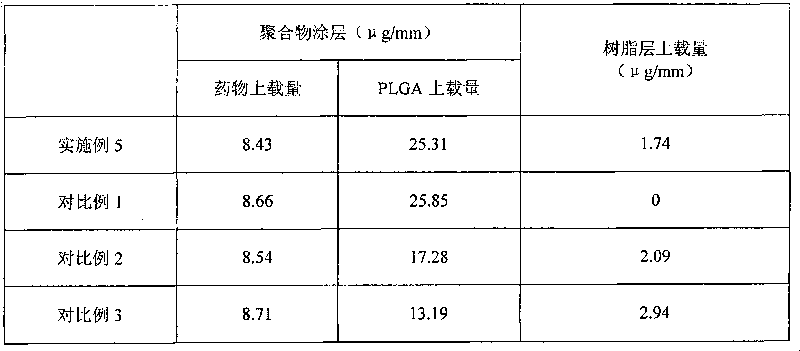

Medicament eluting stent and preparation method thereof

ActiveCN101711710AReduce dosageReduce adverse reactions such as restenosisStentsMedical devicesGlycolic acidMedicine

The invention relates to a medicament eluting stent, which consists of a bare stent and a coating coated on the bare stent. The medicament eluting stent is characterized in that the coating at least comprises a polymer layer and a resin layer, wherein the polymer layer comprises polylactic-co-glycolic acid (PLGA) and medicaments; and the resin layer is coated on the surface of the polymer layer. A resin of the invention is coated on the surface of the medicament-loaded polymer coating. Due to the sustained release effect of the resin, on the premise of guaranteeing medicament dosage, the dosage of the polymer is reduced so as to obvious reduce an inflammatory reaction, reduce the generation of adverse reactions such as late intravascular restenosis and the like, and avoid forming late thrombosis.

Owner:SHENZHEN SALUBRIS BIOMEDICAL ENG CO LTD

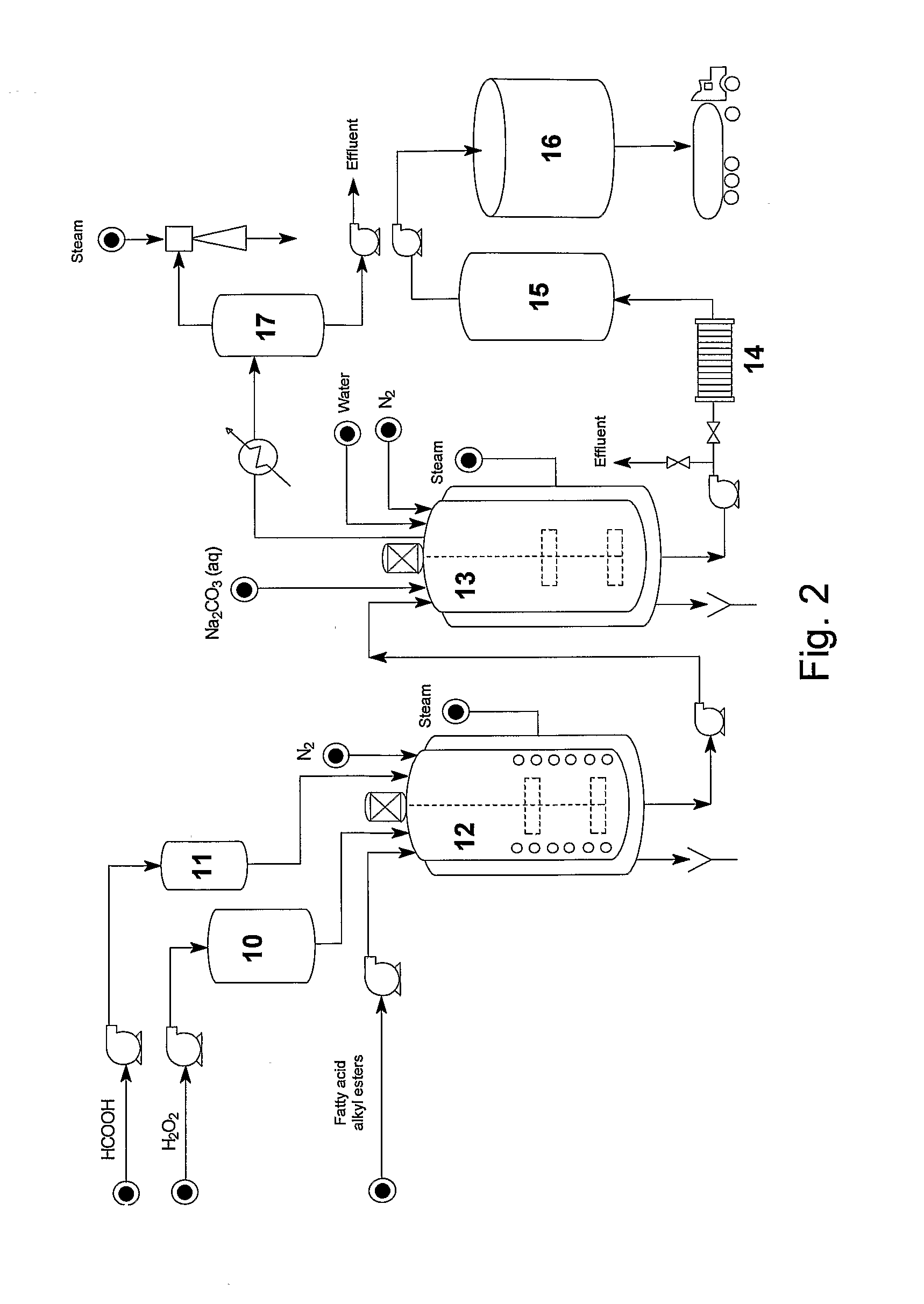

Process for modifying vegetable oils and primary plasticizer for vinyl polymers

ActiveUS8802877B2Improve efficiencyReduce risk of formationFatty acid esterificationPreparation by ester-hydroxy reactionAlcoholVegetable oil

Owner:NPC IND QUIMICAS

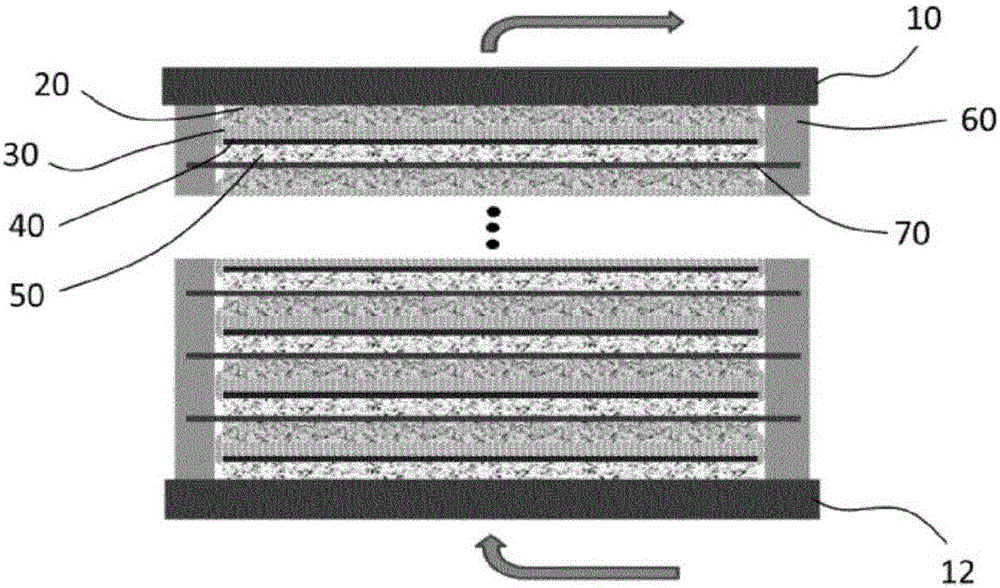

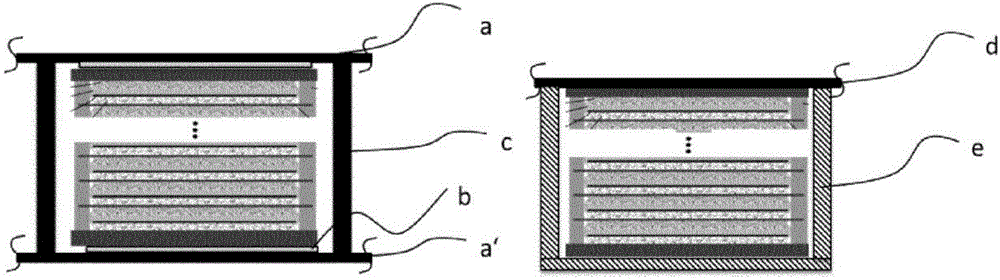

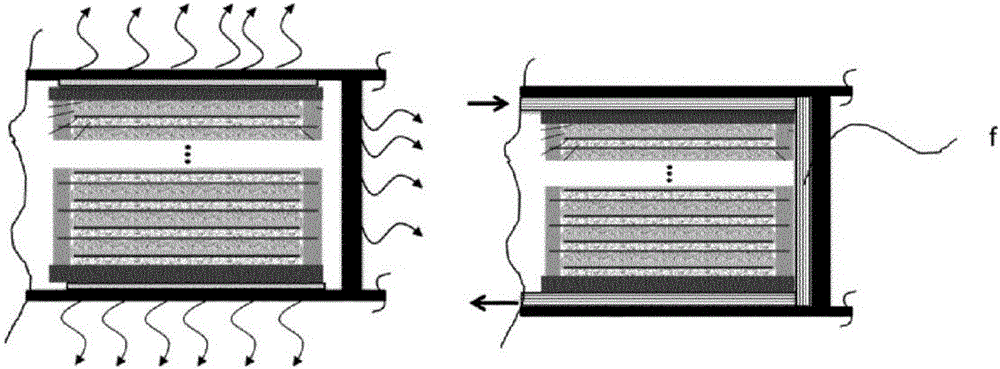

Electrical energy storage element, method and apparatus for producing said electrical energy storage element

InactiveCN106471666AImprove volume utilizationReduce paddingFinal product manufactureCell electrodesEngineeringHigh voltage cathode

In the electrical energy storage element according to the invention, a plurality of electrochemical cells, which are each formed with a cathode and an anode as electrodes and with an electrolyte, are arranged in a manner stacked one above the other. On one side, said electrochemical cells are surrounded by a cover plate which is formed from an electrically conductive material, in particular aluminium, and on the opposite side are surrounded by a base plate which is formed from an electrically conductive material, in particular aluminium. The base plate is coated with a cathode or an anode, and the cover plate is coated in a complementary manner with an anode or cathode. The anodes and cathodes are each formed on opposite surfaces of an electrically conductive carrier foil or film which is preferably composed of aluminium, copper, steel or electrically conductive plastic. An outer circumferential edge which is free of electrode material is present on the carrier foil or film, said edge connecting adjacent electrochemical cells to one another by means of a sealing and adhesive means such that they are hermetically sealed off from one another and from the surrounding area. The anodes are formed from a lithium titanate (LTO) having a spinel structure, and the high-voltage cathodes are formed from a lithium nickel manganate (LNMO) having a spinel structure or lithium phosphates (LP) in an olivine structure. A separator layer is in each case provided between the electrolyte and an electrode of an electrochemical cell in the case of a gel-like electrolyte, and no separator is provided in the case of a solid electrolyte.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV +2

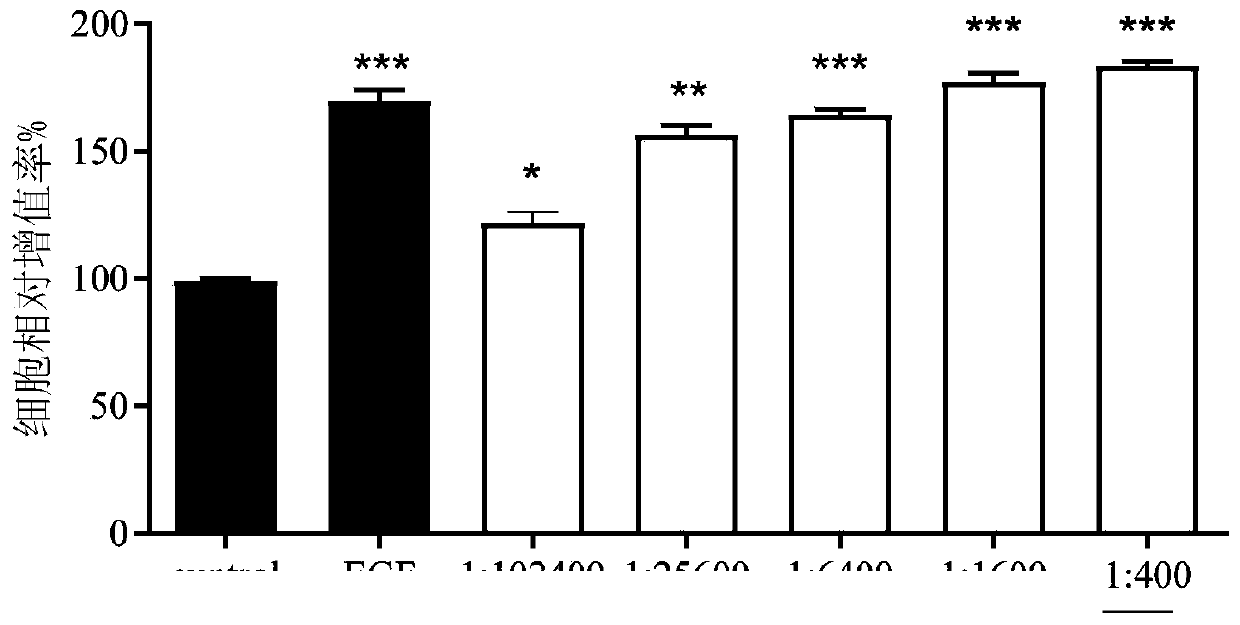

Composition for skin repair

ActiveCN110585054AHas anti-wrinkle effectWith regenerationCosmetic preparationsToilet preparationsHydroxyprolineArginine

The invention discloses a composition for skin repair. The composition is composed of active substances and auxiliary materials. The active substances comprise prolyl hydroxylase and arginine / lysine polypeptide. The active substances also comprise soluble collagen and tripeptide-1 copper. The arginine / lysine polypeptide has the function of promoting transdermal absorption of other active proteins;the polypeptide is used together with the prolyl hydroxylase to promote the prolyl hydroxylase to enter the body through the skin, and cooperates with prolyl hydroxylase in the body to hydroxylate proline on existing procollagen in the body into hydroxyproline, so that the formation of collagen with a triple helix structure is accelerated, wound repair is promoted, and pigmentation is reduced. Meanwhile, due to the existence of the prolyl hydroxylase, a triple helix structure can be well maintained, part of collagen is attached to the surface of the skin to form an isolating membrane protective layer, moisture is preserved and retained, and an internal environment for skin repair is provided.

Owner:GUANGZHOUJIDABIOLOGICAL TECH CO LTD +1

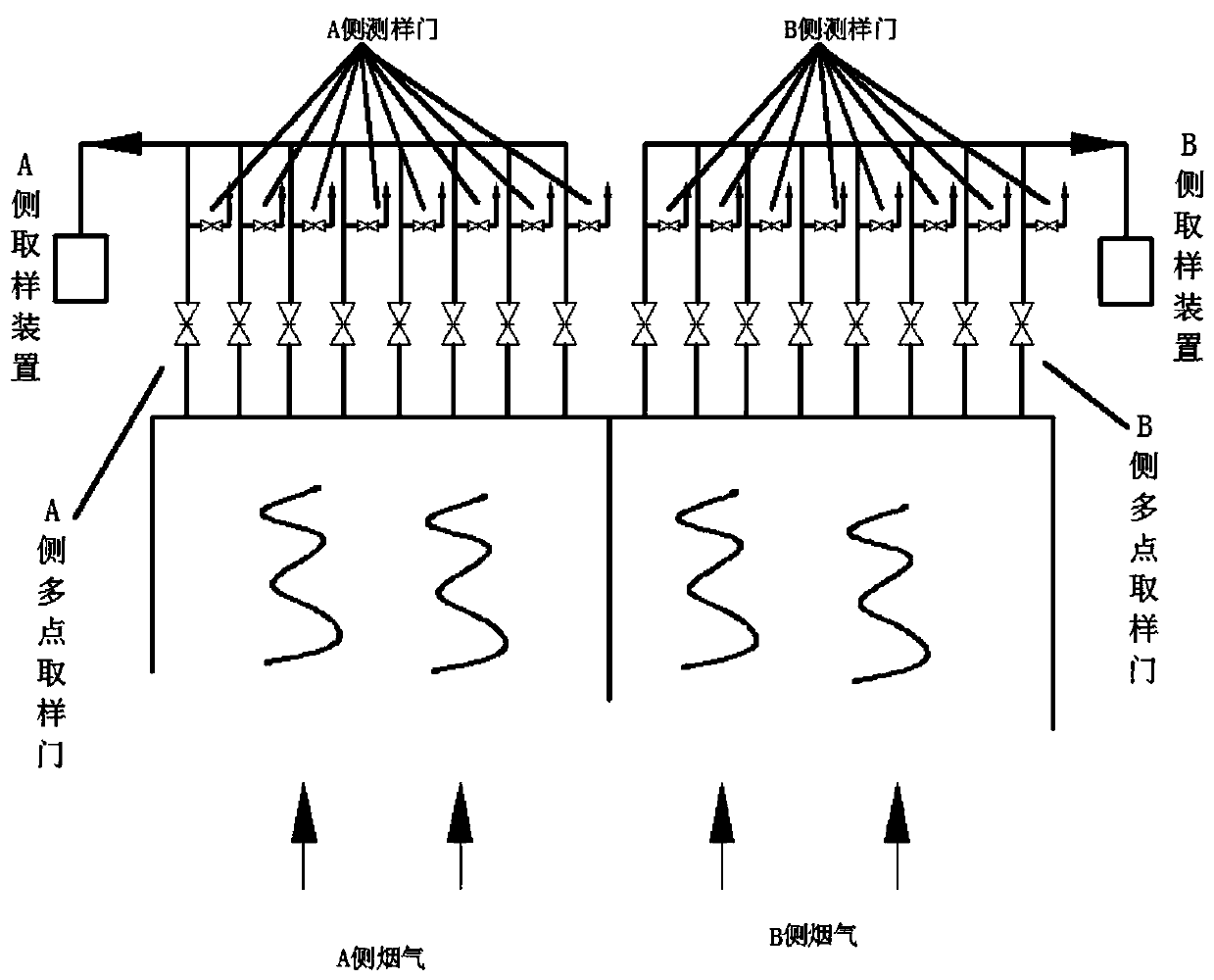

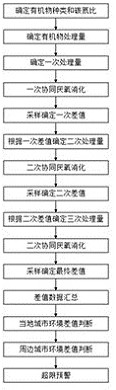

Optimizing system and method for denitration-system ammonia injection grating

InactiveCN109821417AEvenly distributedImprove mixing uniformityDispersed particle separationPtru catalystEnvironmental engineering

The invention provides an optimizing system and method for a denitration-system ammonia injection grating. The optimizing system comprises an A-side smoke outlet, a B-side smoke outlet, a sampling device and an ammonia injection control valve group; the ammonia injection control valve group is arranged in the A-side smoke outlet and the B-side smoke outlet, the sampling device is installed in theA-side smoke outlet and the B-side smoke outlet and located on the outer side of the ammonia injection control valve group, and comprises multiple sampling doors, and the sampling doors are evenly arranged in the A-side smoke outlet and the B-side smoke outlet. According to the optimizing system and method for the denitration-system ammonia injection grating, the multiple sampling doors are evenlyarranged at multiple sampling door outlets from the A side and the B side of a denitration outlet; through the adjusted denitration-reactor ammonia injection grating (AIG), the mixing uniformity of ammonia and smoke is improved, the using rate of a catalyst is increased, and the unit ammonia injection amount is decreased. By optimizing and adjusting the ammonia injection grating (AIG), outlets NOx are more evenly distributed, and denitration efficiency is better guaranteed; meanwhile, the ammonia consumption amount is decreased, the running cost is reduced, and the forming risk of ammonium bisulfate (ABS) is also reduced.

Owner:DATANG GUIZHOU FAER POWER GENERATION

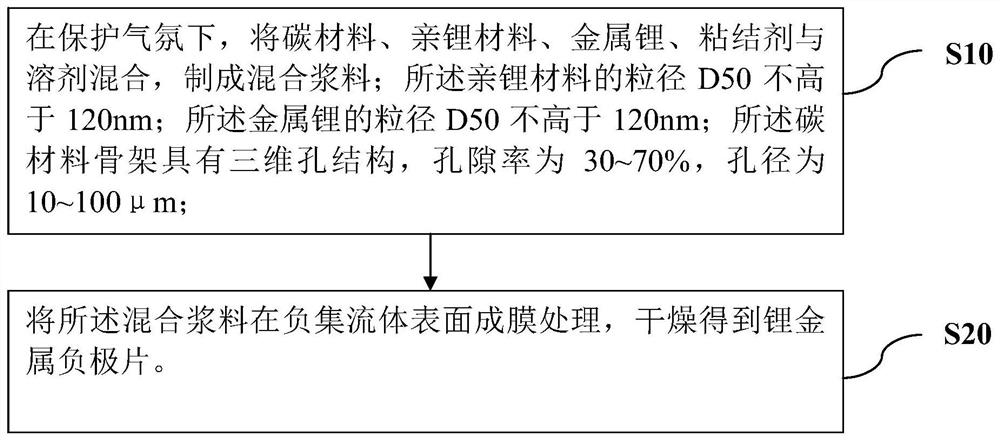

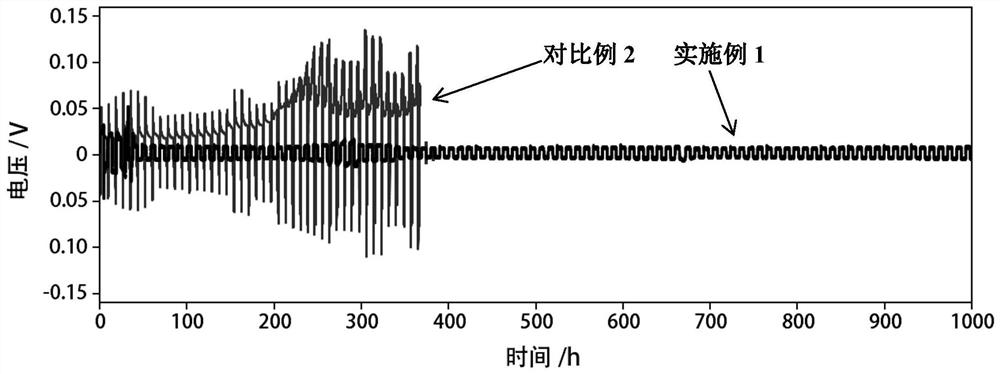

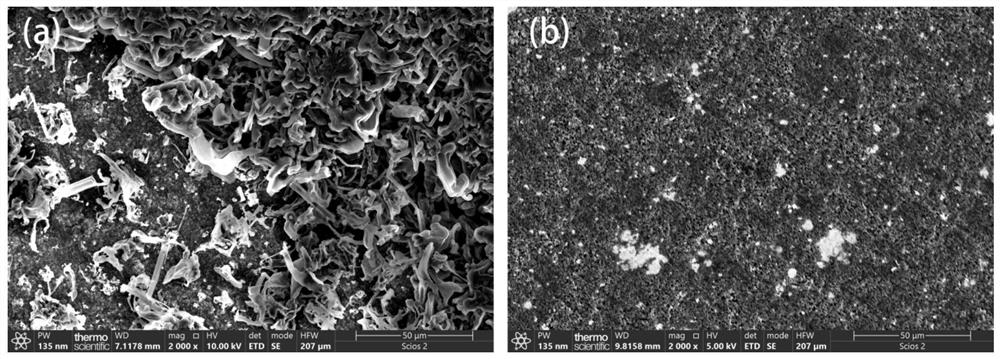

Lithium metal negative plate, preparation method thereof and secondary battery

PendingCN113871575AImprove cycle stabilityExtended service lifeNegative electrodesSecondary cellsMetallic lithiumPore diameter

The invention belongs to the technical field of batteries, and particularly relates to a lithium metal negative plate, a preparation method thereof and a secondary battery. The lithium metal negative electrode plate comprises a negative electrode active layer, the negative electrode active layer comprises a carbon material framework, the carbon material framework has a three-dimensional pore structure, and pores of the three-dimensional pore structure contain a lithium-loving material and metal lithium; the particle size D50 of the lithium-loving material is not higher than 120nm; the particle size D50 of the metal lithium is not higher than 120nm; the porosity of the three-dimensional pore structure is 30%-70%, and the pore diameter is 10-100 m. The lithium metal negative electrode plate provided by the invention comprises the carbon material skeleton with the three-dimensional pore structure, and the pores of the three-dimensional pore structure contain the lithium-loving material and the metal lithium, so that the risk that lithium dendrites are easy to grow on the surface of the lithium metal negative electrode plate is relieved, and meanwhile, the cycling stability and the safety performance of the lithium metal negative electrode plate are improved.

Owner:EVERGRANDE NEW ENERGY TECH SHENZHEN CO LTD

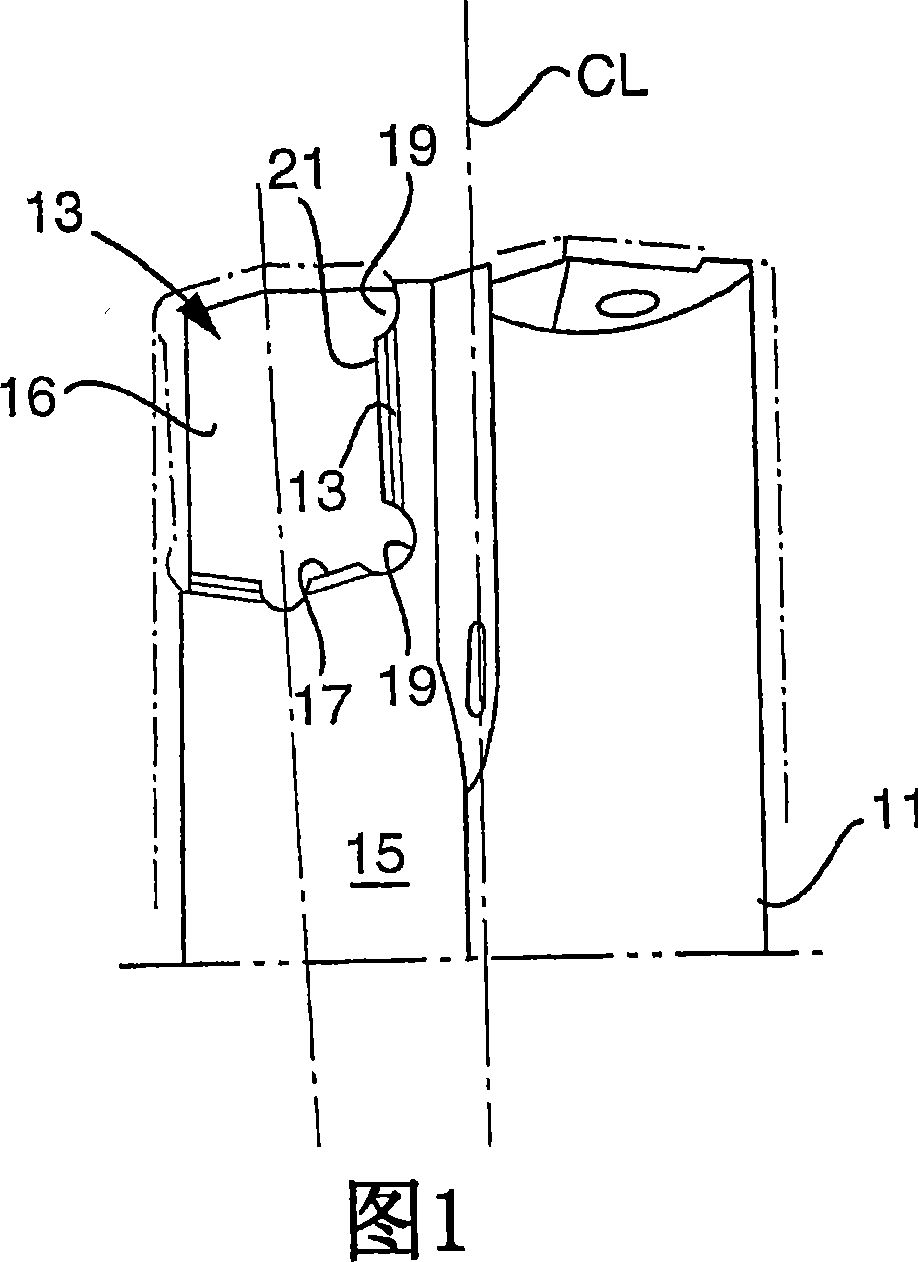

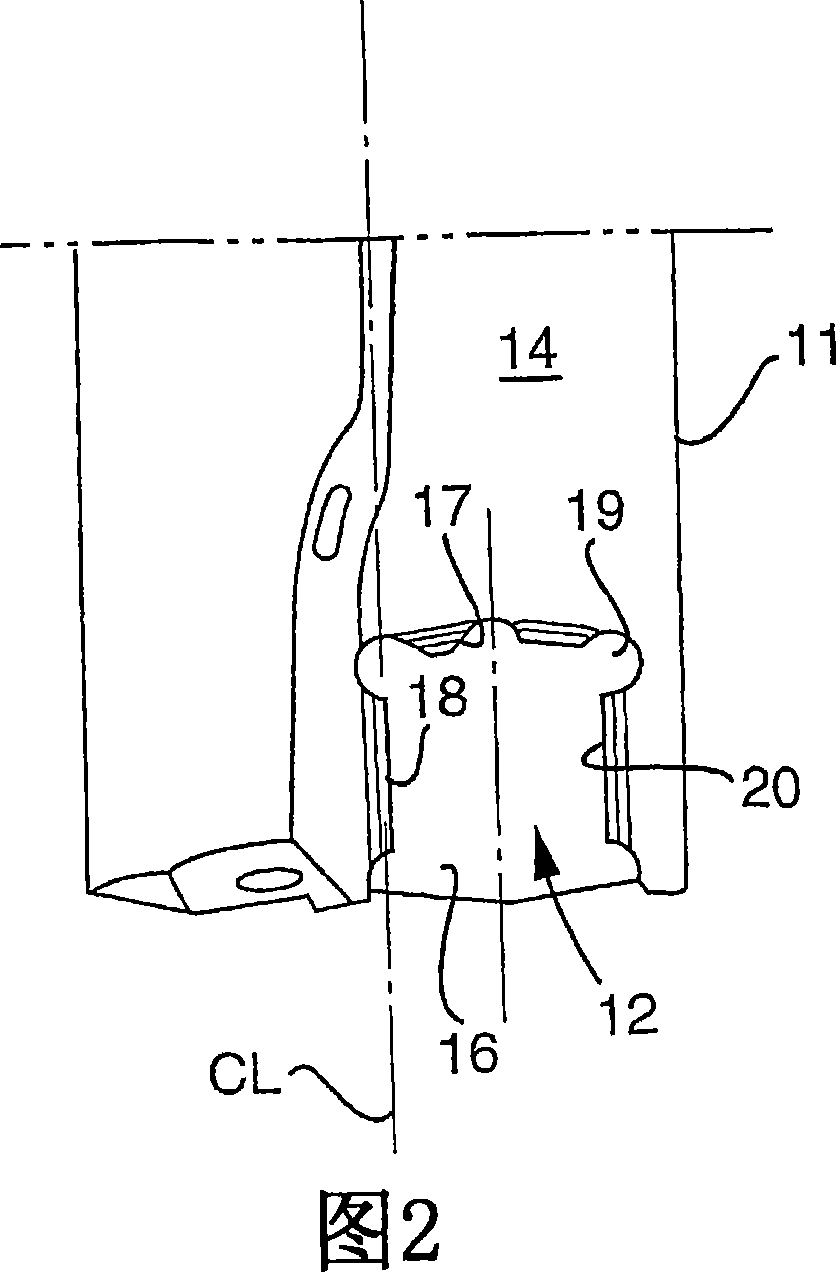

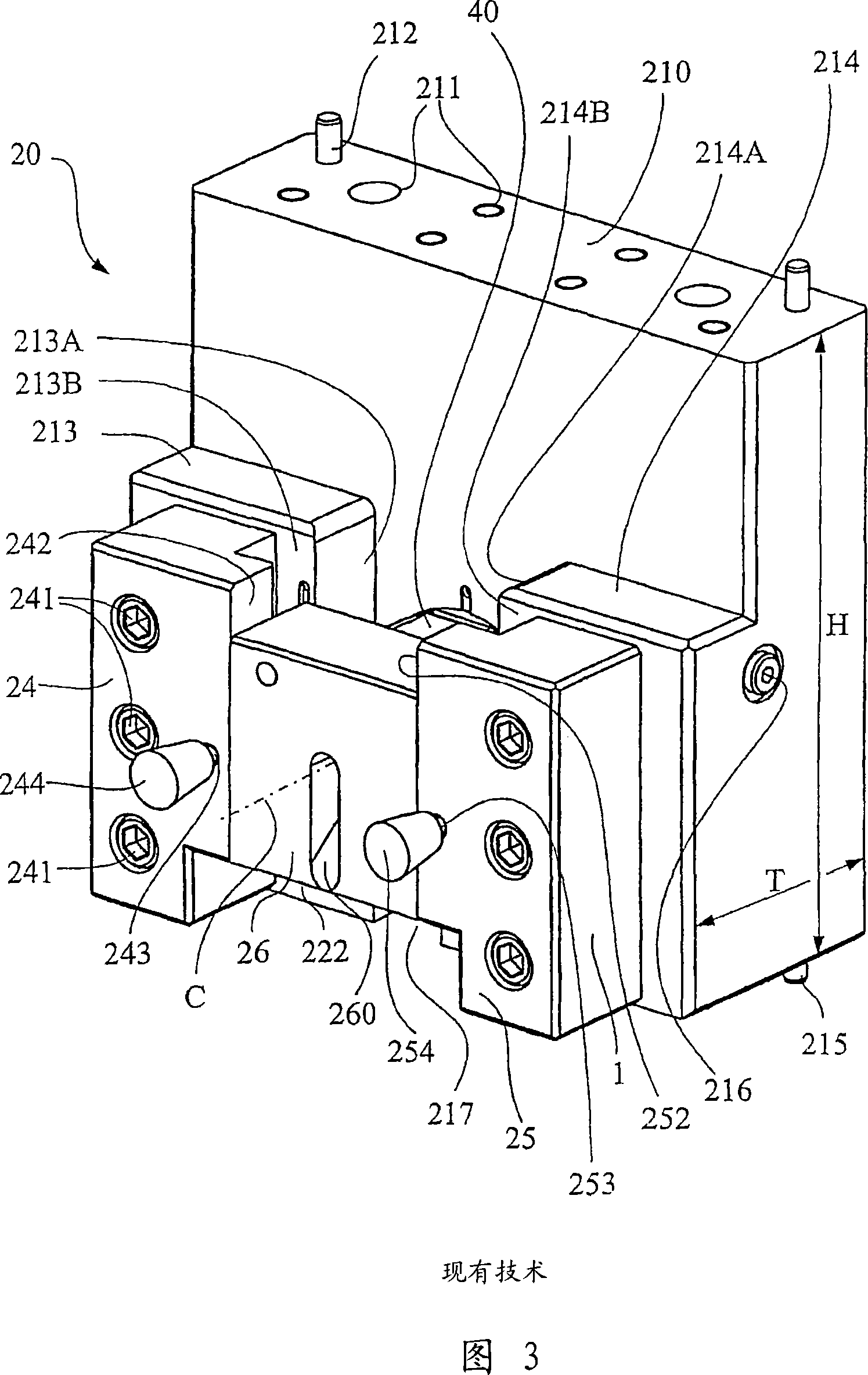

Crosscutting tool for high-speed crosscutting

InactiveCN101027144AReduce distortionReduce risk of formationShearing machinesShearing toolsMechanical engineeringEngineering

The present invention relates to a Crosscutting tool for high-speed crosscutting, which crosscutting tool (40; 50) comprises a body (43,420; 52, 520) having a through-hole (41, 51), for a rod (W) to be cut, and a cutting edge (46) delimiting at least a portion of said through-hole (41, 51), wherein said cutting edge (46) is formed by at least two cutting jaws (401, 402; 403, 404) positioned within and supported by said body (43, 420; 52, 520).

Owner:MORPHIC TECH

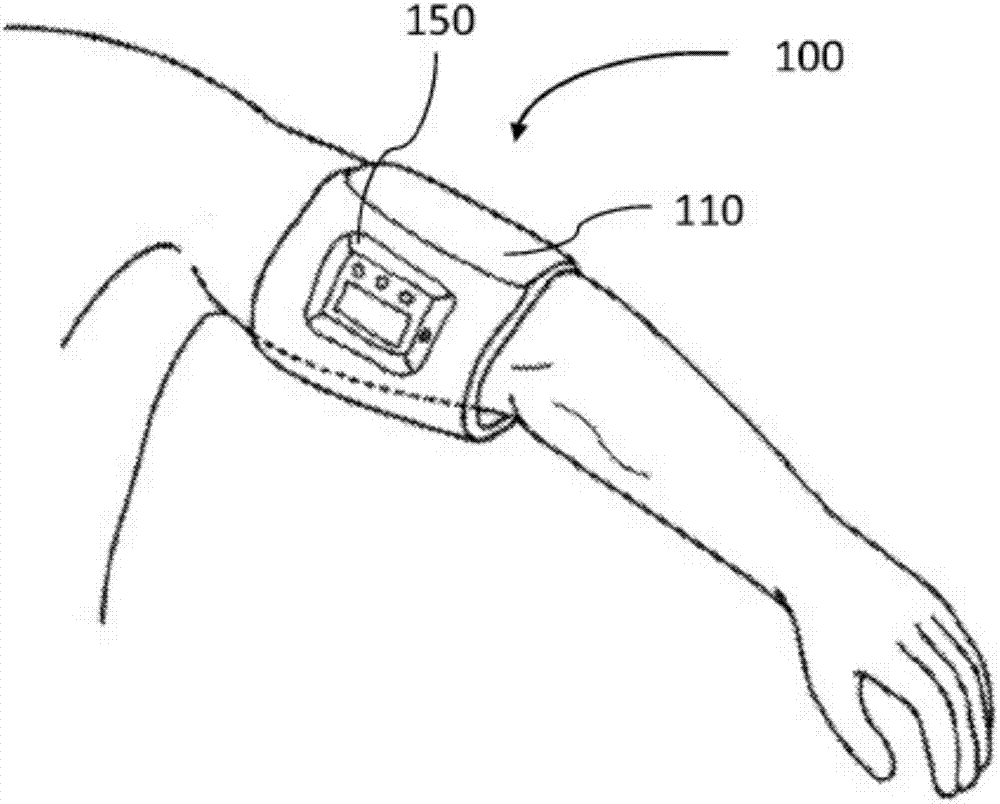

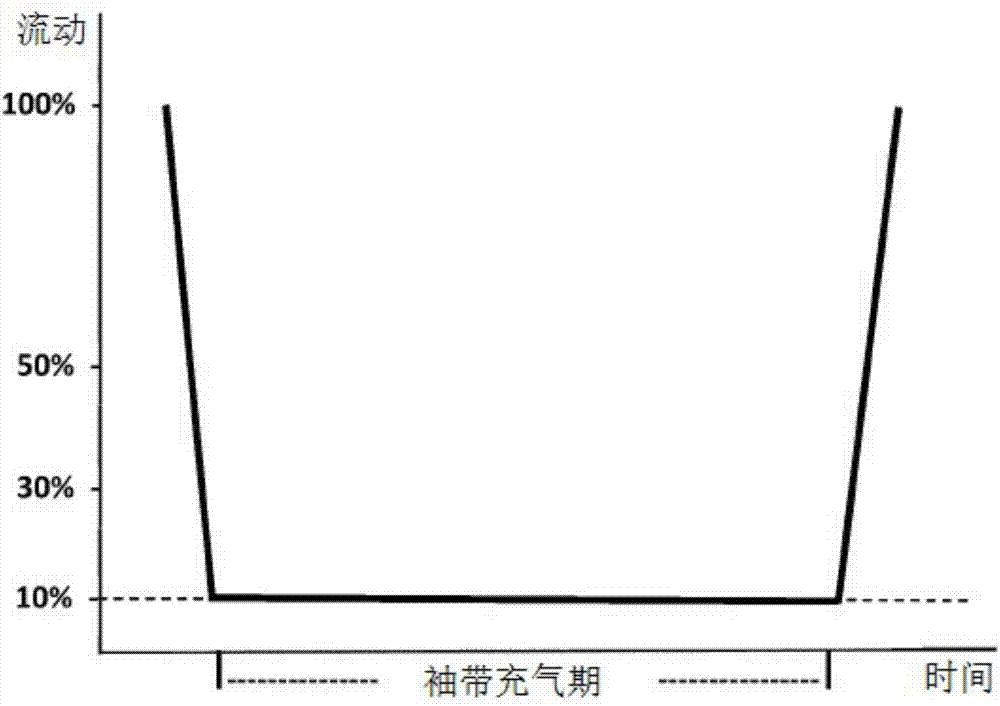

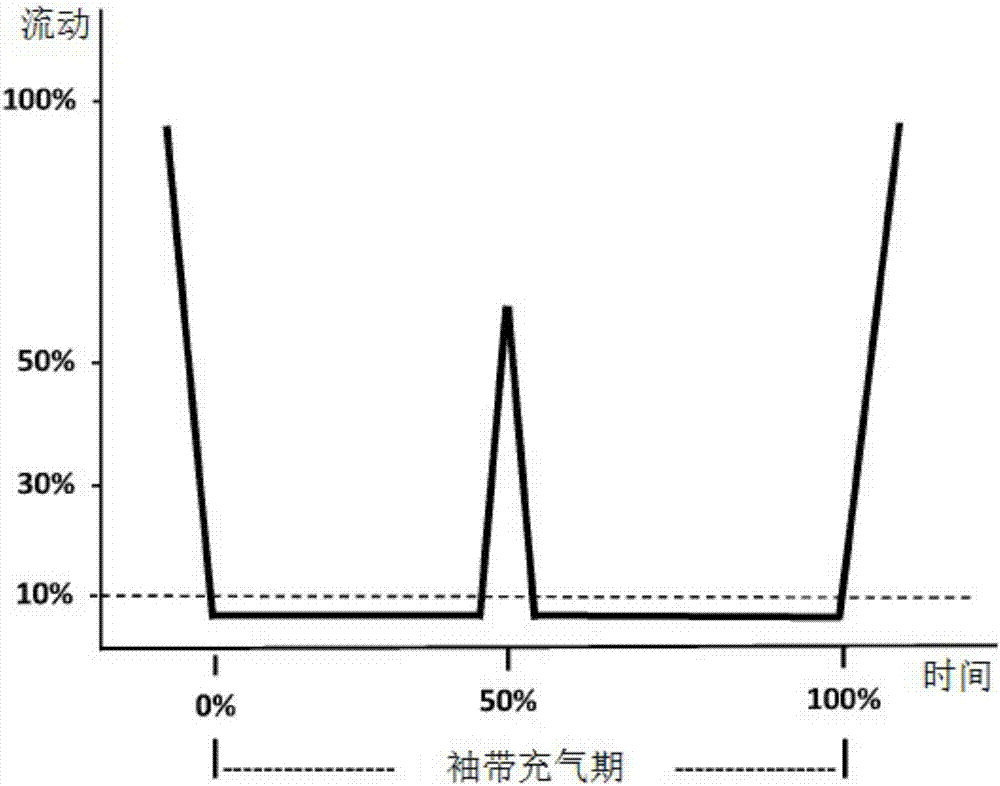

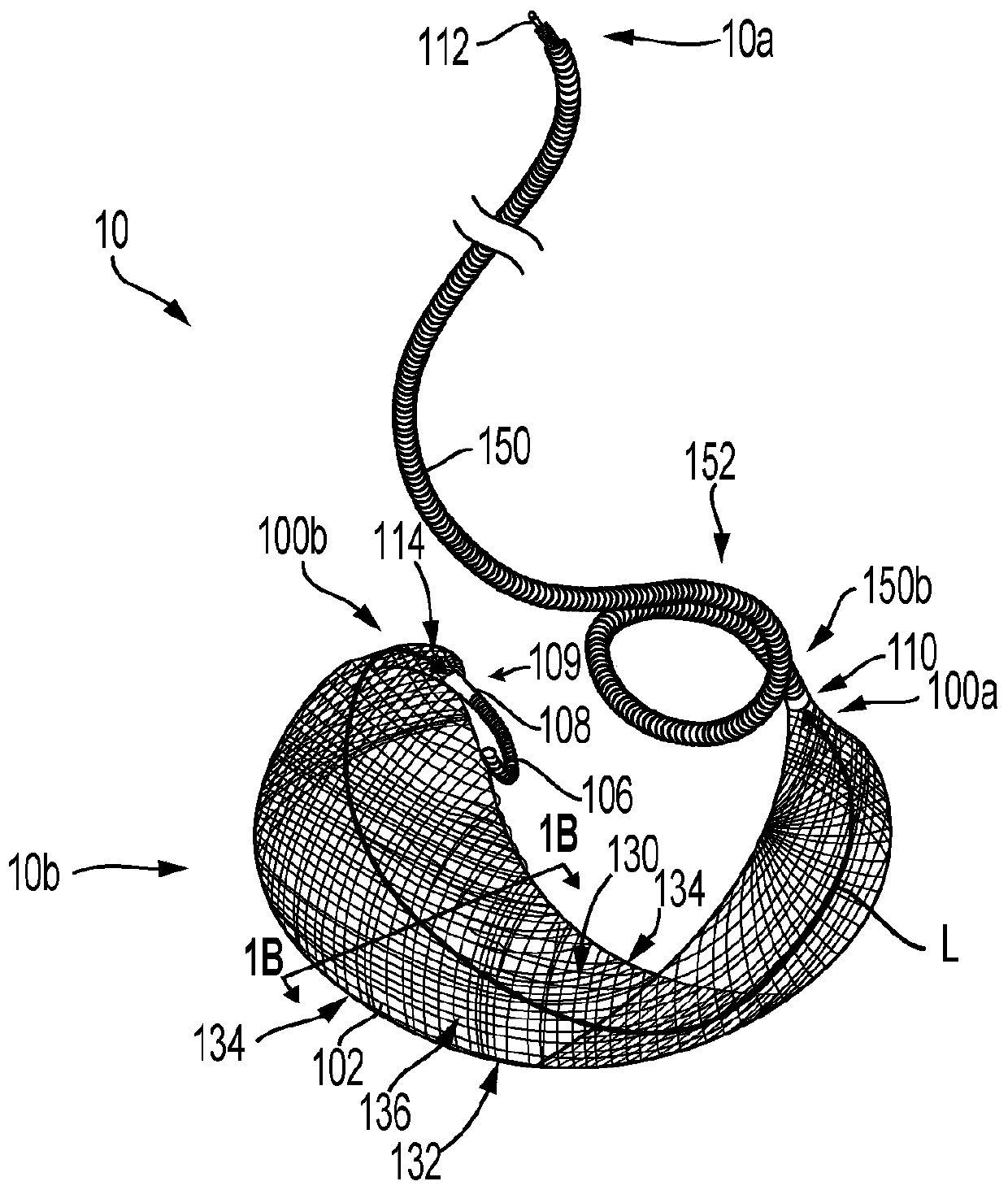

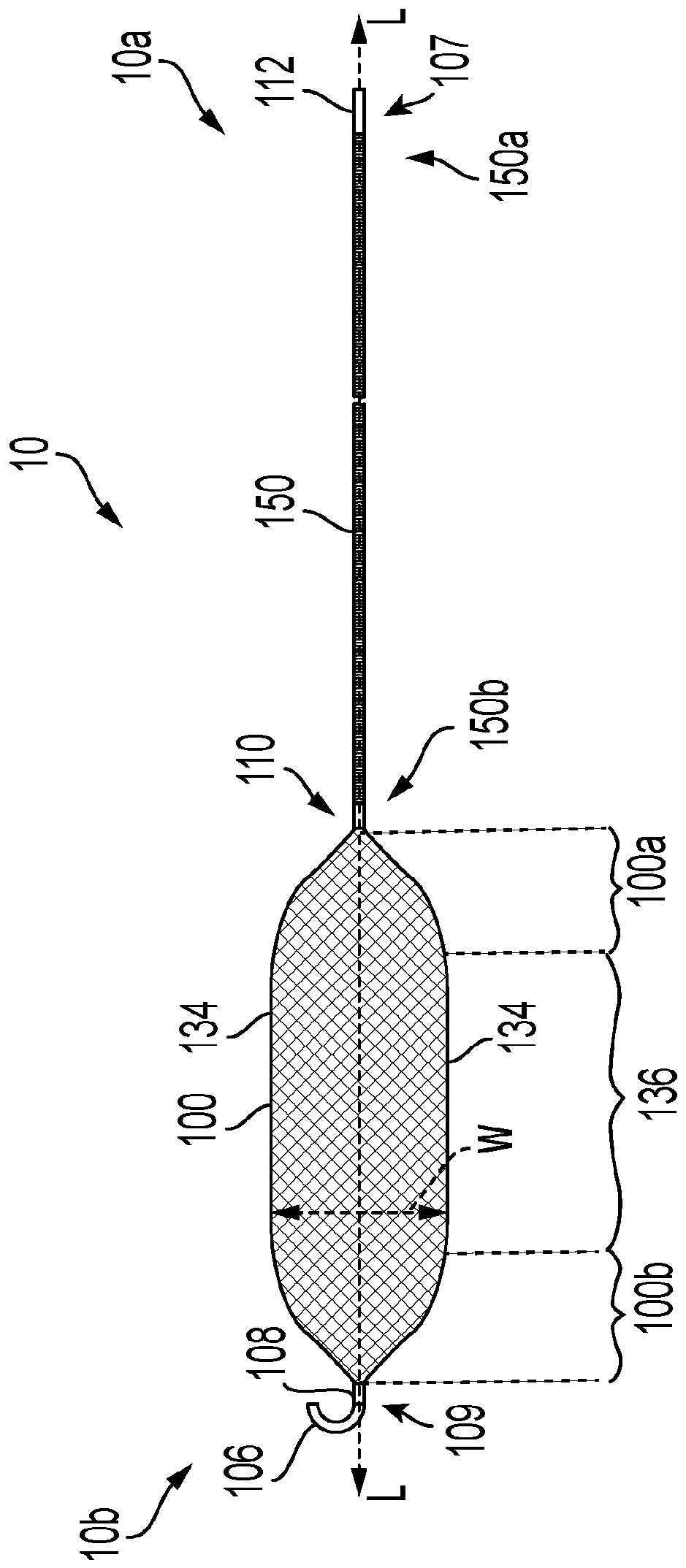

Methods and devices for remote ischemic conditioning via partial limb occlusion

Single- or dual-bladder devices (100) for automated delivery of remote ischemic conditioning treatment via partial limb occlusion involve various methods of operating the cuff (110) in which partial or full limb occlusion is achieved during the periods of cuff inflation. Achieving clinical benefits of remote ischemic conditioning without extended cessation of limb blood flow are advantageous due to lower required cuff pressure and reduced risk of clot formation in the limb vasculature.

Owner:LIFECUFF TECH

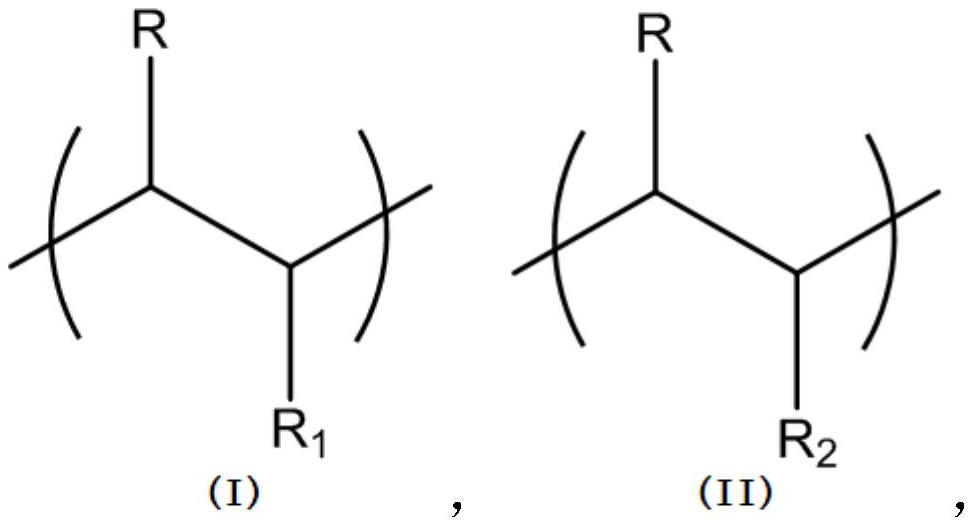

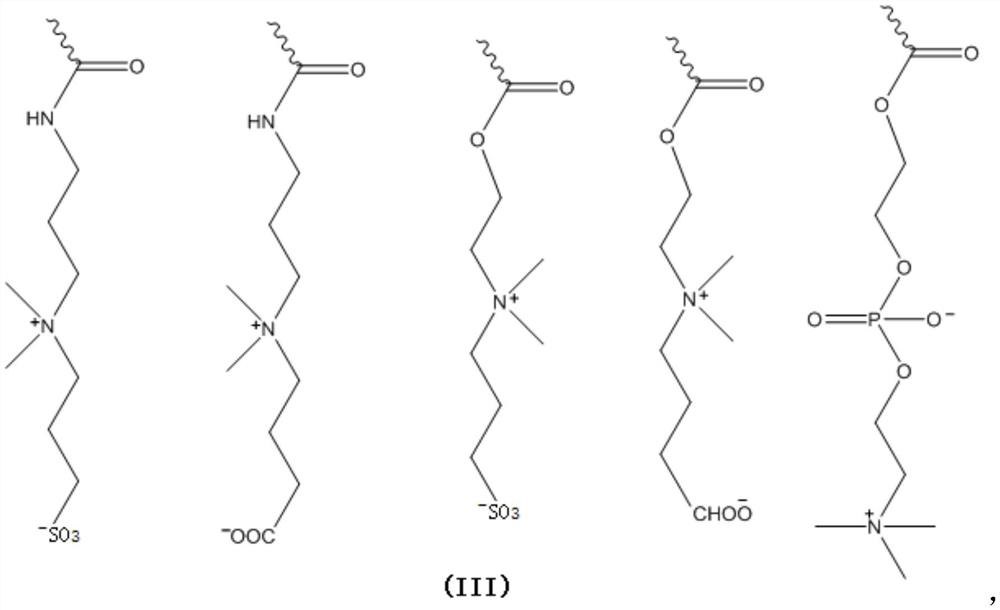

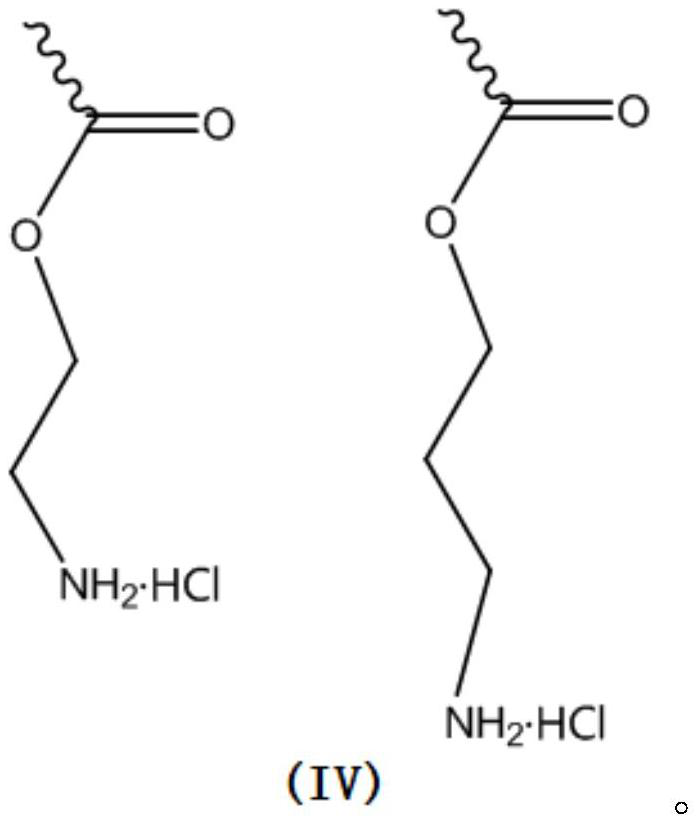

Valve with anti-thrombosis and anti-calcification functions, and preparation method and application of valve

ActiveCN111701077AGood biocompatibilityIncrease contentPharmaceutical containersMedical packagingThrombusAntiplatelet drug

The present invention discloses a valve with anti-thrombosis and anti-calcification functions, and a preparation method and an application of the valve. The valve comprises a valve base and a zwitterionic copolymer covalently connected to the valve base. During preparation, the valve base is firstly soaked in a glutaraldehyde solution to obtain a cross-linked valve; and then the cross-linked valveis soaked in a zwitterionic polymer solution with a concentration of 0.1-5 wt% for reaction for 2-4 days, and then reduction with a reducing agent is conducted to obtain the valve with the anti-thrombosis and anti-calcification functions. The valve material is subjected to anti-thrombosis and anti-calcification treatments, so that after the valve is implanted in patients, risks of valve leaflet thrombosis can be reduced, valve leaflet thickening and transvalvular differential pressure increase are prevented, a long-term hydrodynamic performance is improved, patients can avoid or reduce uses of anticoagulant and antiplatelet drugs, risks of patient bleeding are reduced, besides, aldehyde residues in the valve leaflet tissues are reduced, biocompatibility and anti-calcification ability areimproved, and ultimately complications of valve leaflet thrombosis are reduced and service life of the valve is extended.

Owner:JILIN VENUS HAOYUE MEDICAL LTD

Municipal sludge co-treatment method

ActiveCN112094013AReduce inhibitionReduce oil concentrationSolid waste disposalBiological sludge treatmentAnaerobic digestionAnaeromicrobium sediminis

The invention relates to a municipal sludge co-treatment method. Municipal sludge and one or more urban organic wastes are subjected to synergistic anaerobic digestion, and various benign complementation can be established between the municipal sludge and the organic wastes and between the organic wastes while the municipal sludge and one or more urban organic wastes are subjected to the synergistic anaerobic digestion; for example, the concentration of heavy metals in the sludge and the concentration of salt in the organic waste can be diluted through co-digestion of municipal sludge and municipal organic waste, the inhibiting effect of toxic substances on anaerobic microorganisms in the anaerobic digestion process is reduced, the concentration of oil in a digestion substrate is reduced,and the risk of oil particle formation is reduced; municipal organic waste and municipal sludge are co-digested, so that nutritional ingredients lacking in respective ingredients can be mutually supplemented, and the carbon-nitrogen ratio of a digestion substrate is adjusted to an appropriate range of anaerobic digestion; compared with single treatment, the urban organic waste and the municipal sludge are co-digested, so that the capital construction and operation cost can be reduced, and better economic benefits are achieved.

Owner:江苏泓润生物质能科技有限公司

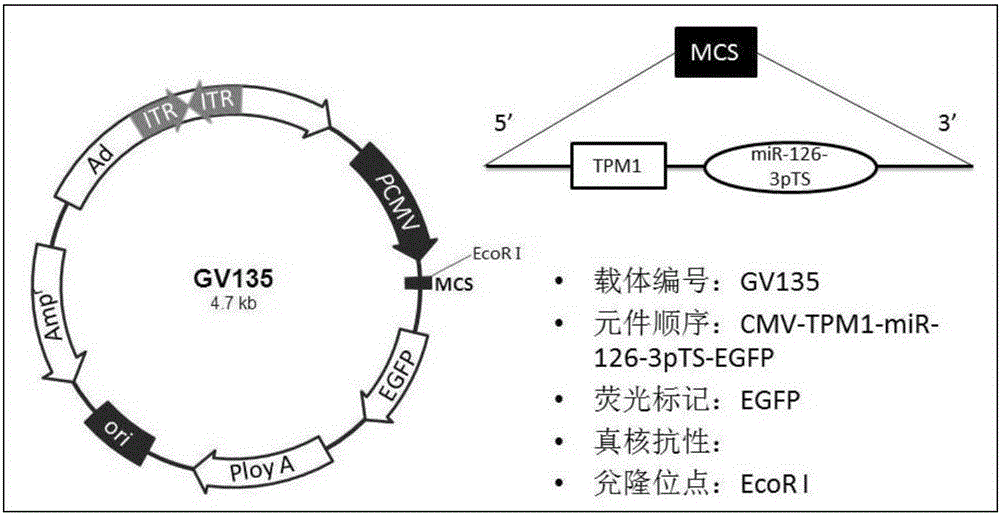

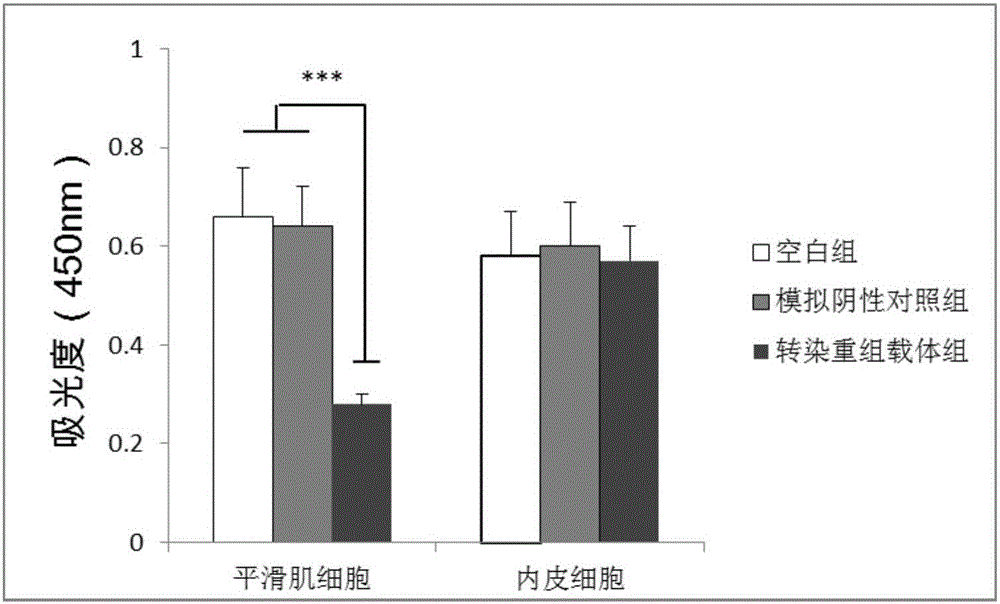

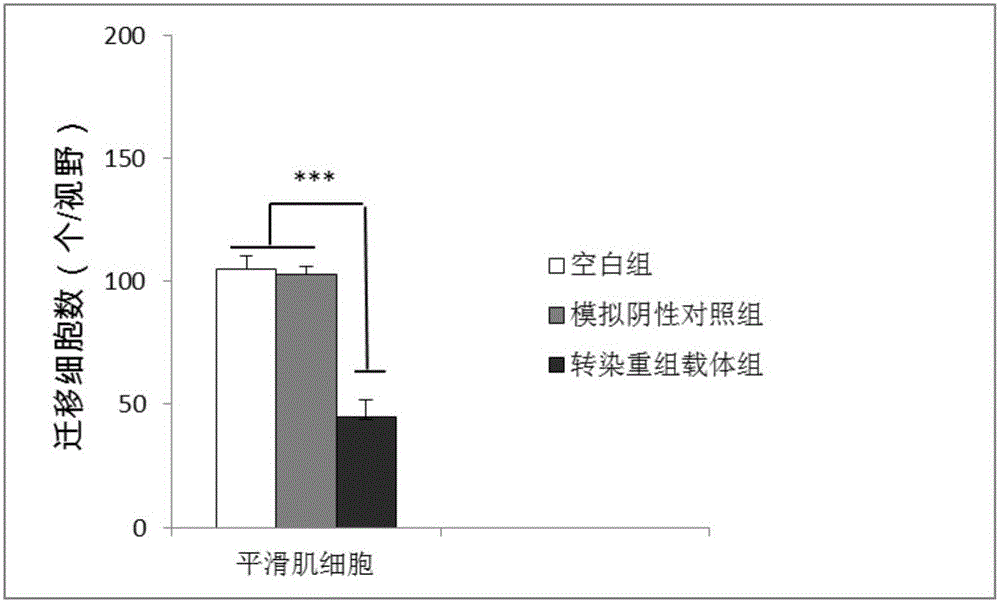

Adenovirus vector for specifically inhibiting proliferation and migration of smooth muscle cells and application of adenovirus vector

ActiveCN105950660APrevent proliferationInhibit migrationOrganic active ingredientsPeptide/protein ingredientsVascular endotheliumThrombus

The invention discloses an adenovirus vector for specifically inhibiting proliferation and migration of smooth muscle cells and application of the adenovirus vector. Target genes and miRNA regulatory sequences are inserted at multiple clone sites of the adenovirus vector. After atherosclerosis disease interventional therapy, a main principle of restenosis lies in that the smooth muscle cells migrate to an intima and perform pathological proliferation. The adenovirus vector disclosed by the invention is applied, so that the movement of the proliferation, the migration and the like of the smooth muscle cells can be well restrained, and restenosis can be avoided. The adenovirus vector is adjusted and controlled based on miRNA, so that the purpose of specifically inhibiting proliferation and the migration of vascular smooth muscle cells can be realized, and influence on vascular endothelial cells is little. Therefore, the repair of endothelium is not influenced, so that the risk of thrombosis is reduced, and the use of antiplatelets and bleeding can be reduced; the effect of interventional treatment of the atherosclerosis diseases can be improved.

Owner:姚陈 +4

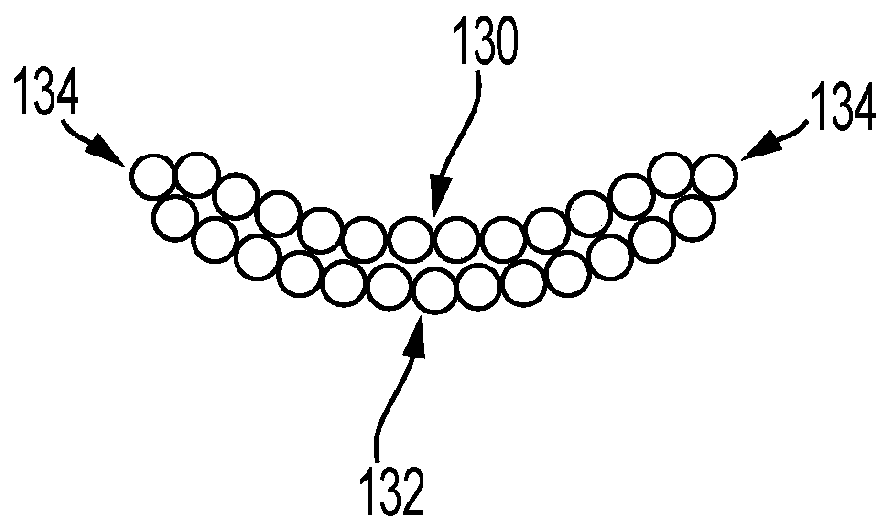

Occlusion device

InactiveCN111388045ALarge packing densitySmall package densityDiagnosticsOcculdersInternal iliac aneurysmBrain aneurysm

The invention discloses an occlusion device for treating intracranial aneurysm or cerebral aneurysm. The occlusion device comprises a mesh, the mesh has an expanded state and a low configuration statefor intravascular delivery to an aneurysm, the mesh includes a first end portion, a second end portion, and a length extending between the first and second end portions, and a first lateral edge, a second lateral edge, and a width extending between the first and second lateral edges. The mesh may have a predetermined shape in the deployed state, wherein (a) the mesh is curved along its width, (b)the mesh is curved along its length, and (c) the mesh has an undulating profile across at least a portion of one or both of its length or its width. The mesh is configured to be placed within the aneurysm in the deployed state such that the mesh extends over a neck of the aneurysm.

Owner:TYCO HEALTHCARE GRP LP

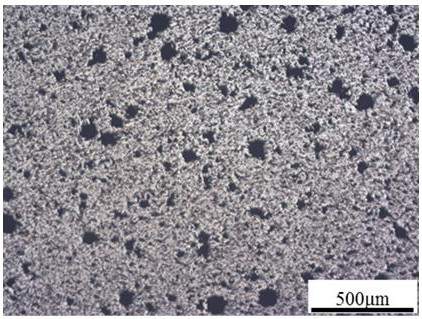

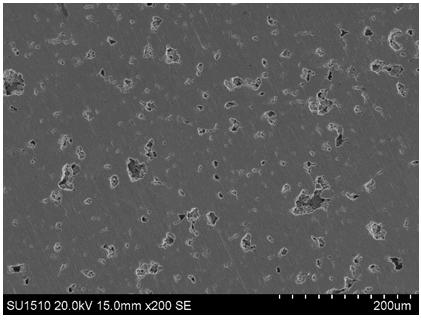

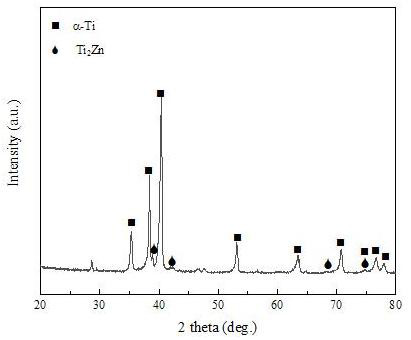

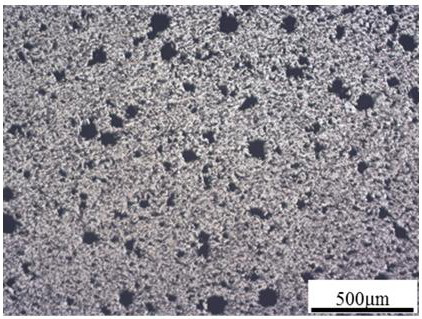

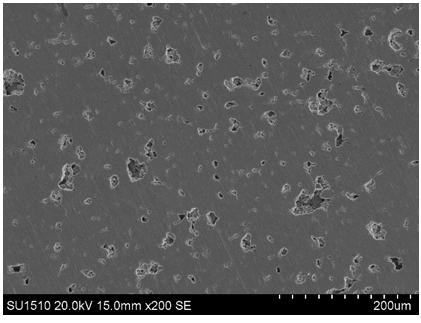

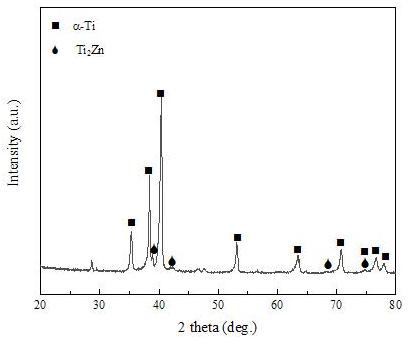

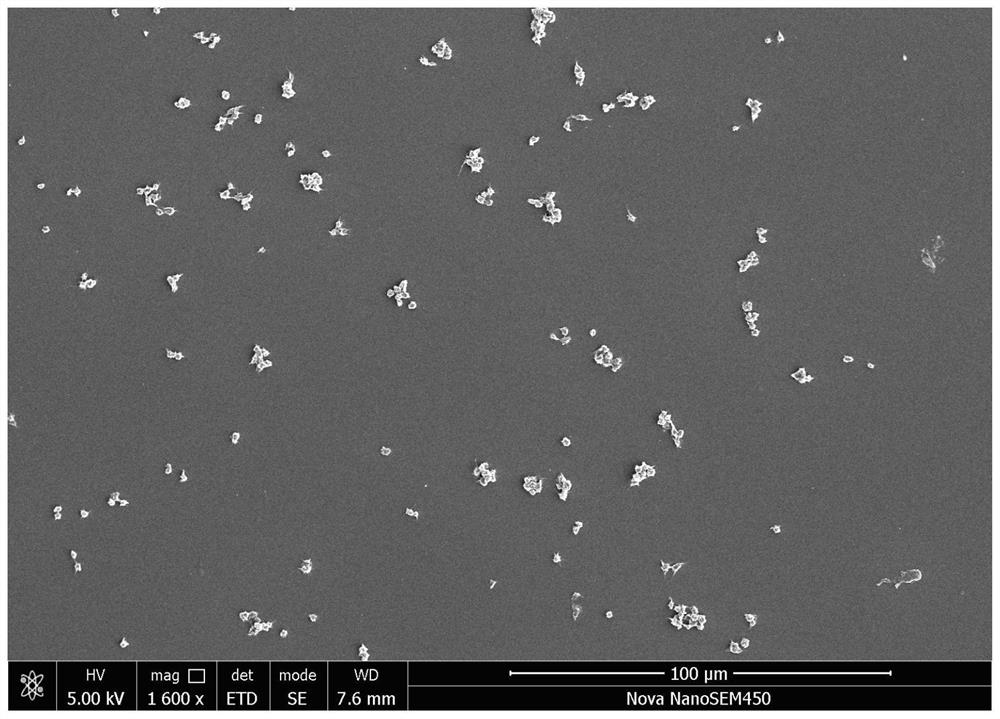

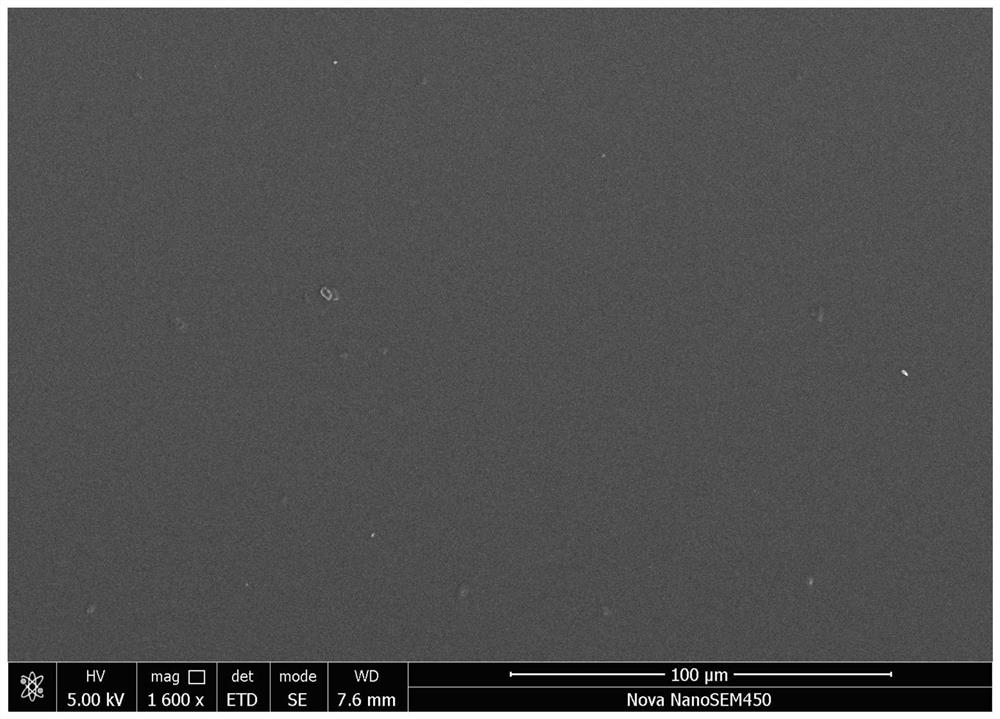

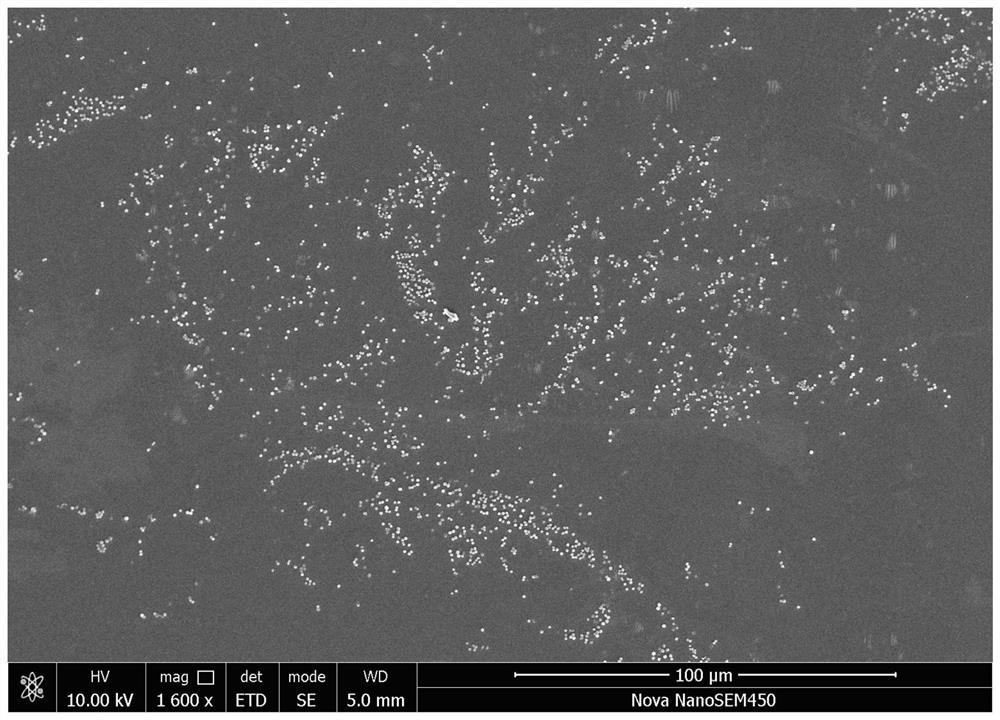

Biomedical porous Ti-Zn alloy and preparation method thereof

ActiveCN112708796AImprove mechanical propertiesImprove biological activityTissue regenerationProsthesisCarbide siliconFiber

The invention provides a biomedical porous Ti-Zn alloy and a preparation method thereof. The preparation method comprises the following steps that S1, titanium powder and zinc powder are mixed according to a certain proportion and then placed in a stainless steel ball milling tank to be subjected to dry mixing; S2, the dry-mixed powder is subjected to mold pressing under the pressure of 500-1000 Mpa to be manufactured into a pressed blank; S3, the pressed blank and the silicon carbide powder are put into a polycrystalline mullite fiber heat preservation barrel and then put into a microwave sintering furnace, argon with the purity being 99.999% is introduced after the vacuum degree in a furnace cavity is pumped to be lower than 0.1 Pa, the output power of the microwave sintering furnace is controlled, microwave sintering is conducted at a certain temperature rising speed, sintering temperature and sintering time, and the biomedical porous Ti-Zn alloy is obtained after furnace cooling. According to the biomedical porous Ti-Zn alloy and the preparation method thereof, the prepared porous Ti-Zn alloy is low in elasticity modulus, excellent in mechanical property and good in antibacterial effect and biological activity, and can be used as a hard tissue repairing and replacing material for bones, joints, artificial tooth roots and the like.

Owner:NANCHANG HANGKONG UNIVERSITY

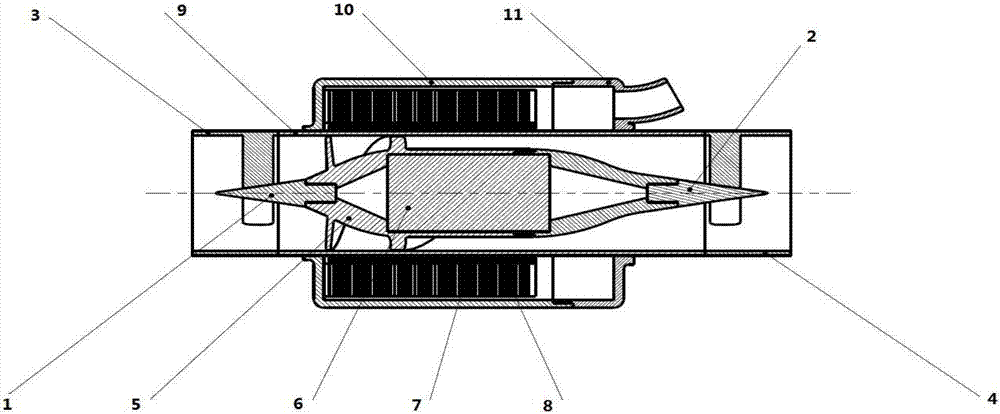

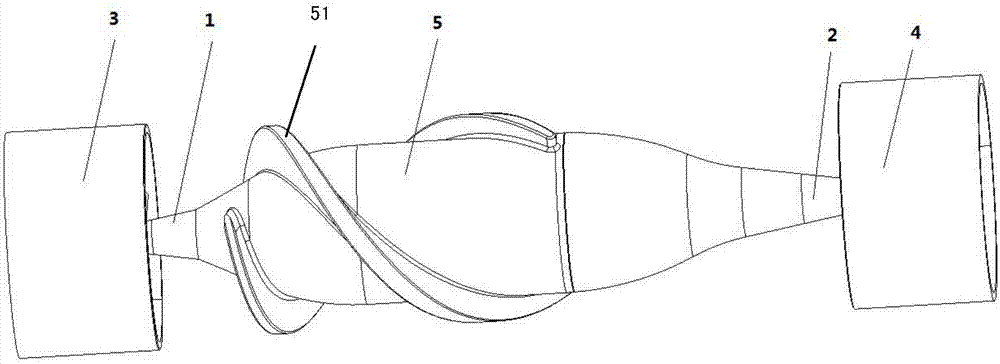

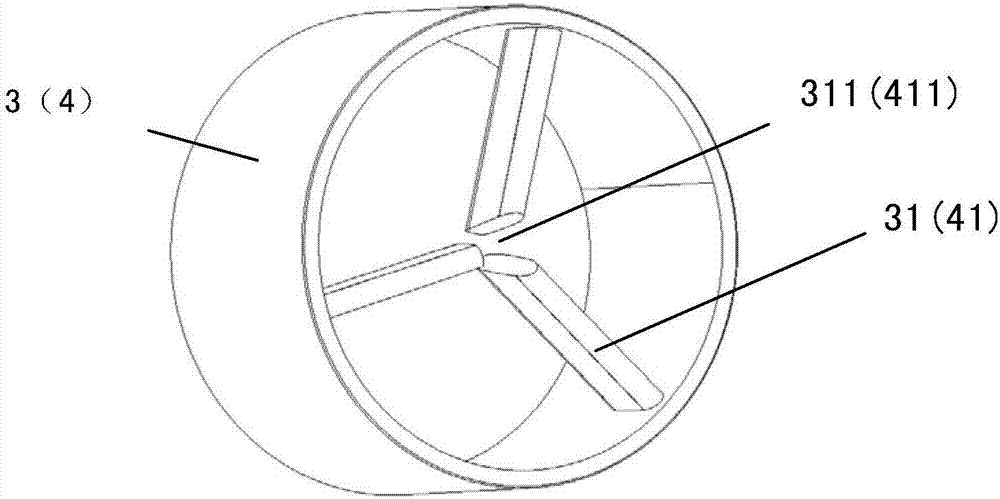

Axial flow blood pump adopting split through-hole bearing structure

PendingCN107158495AReduce risk of formationElimination of rotating and static interfacesBlood pumpsIntravenous devicesBlood pumpEngineering

The invention discloses an axial flow blood pump adopting a split through-hole bearing structure. The axial flow blood pump comprises a front cartridge, a rotor, a rotor cartridge and a rear cartridge; three straight blades are uniformly and integrally connected to the annular inner wall of the front cartridge, and the inner walls of the three straight blades are suspended, so that front axial holes are formed; three straight blades are uniformly and integrally connected to the annular inner wall of the rear cartridge, and the inner walls of the three straight blades are suspended, so that rear axial holes are formed; the rotor cartridge is integrally connected between the front cartridge and the rear cartridge; the rotor is arranged in the rotor cartridge; two rotating blades are arranged on the outer circumference of the rotor; and the two rotating blades, which are located between the rear half parts of the rotor, can promote obvious expansion of a runner. The axial flow blood pump provided by the invention has the beneficial effects that since the straight blades in the front cartridge and the rear cartridge, instead of bearings, can take a supporting effect, a rotary-static interface is eliminated; the split bearing structure is defined by the three independent blades; and blood can flow in gaps between front and rear jewel axles and the straight blades, so that a flowing dead zone is prevented and a risk of thrombosis at an axial end is effectively reduced.

Owner:FUWAI HOSPITAL CHINESE ACAD OF MEDICAL SCI & PEKING UNION MEDICAL COLLEGE

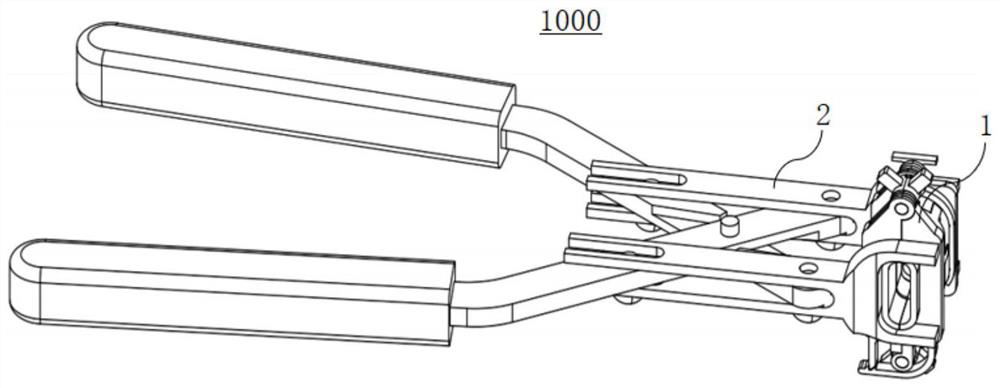

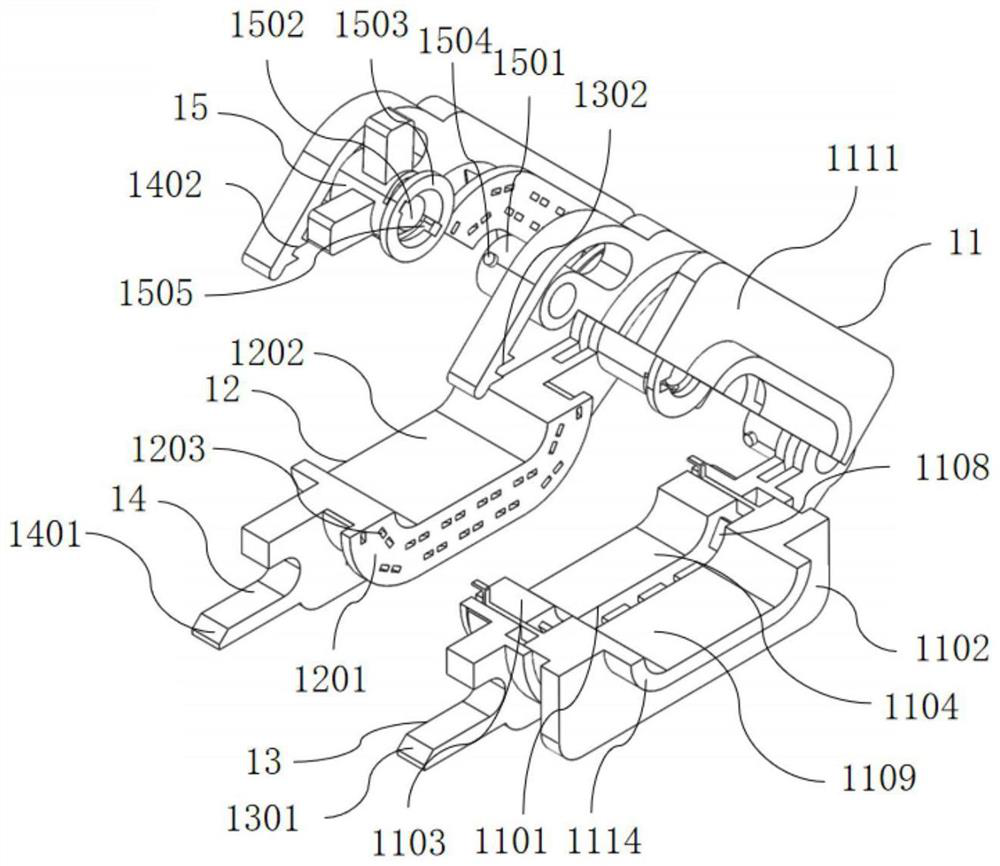

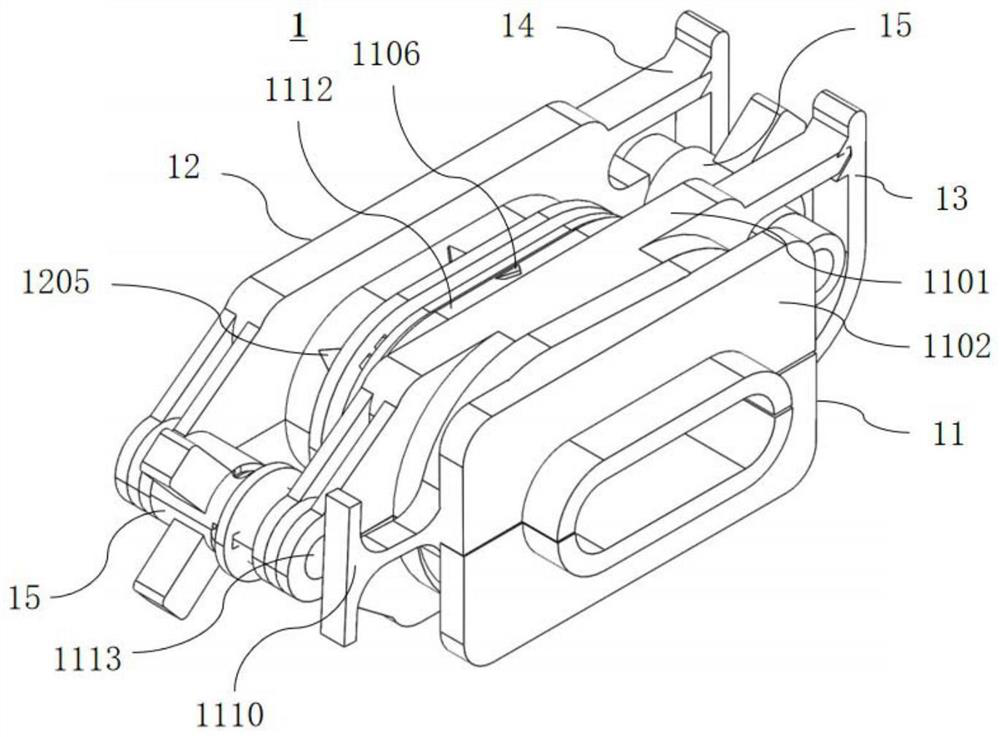

Rapid blood vessel anastomosis device

ActiveCN113892990ASimplify the anastomosis procedureFast matchingSurgeryOrgan transplantingBiomedical engineering

The invention discloses a rapid blood vessel anastomosis device. The rapid blood vessel anastomosis device comprises a first end sleeve, a second end sleeve, a nail hammer and a handheld suturing nail percussion assembly, wherein the first end sleeve and the second end sleeve are coaxially arranged in an end-to-end opening and closing mode. The first end sleeve comprises a nail bin and the nail hammer, the nail bin is provided with a plurality of nail bin holes which are through along the axial direction and used for containing suturing nails, and suturing nail pushing pieces at one end of the nail hammer are used for being inserted into the nail bin holes in a one-to-one correspondence and matched mode from one end of the nail hammer; the second end sleeve is provided with a plurality of nail anvils; and the handheld suturing nail percussion assembly is used for being connected with the nail hammer of the first end sleeve and the second end sleeve, and clamping force is applied by holding the handheld suturing nail percussion assembly by a hand, so that the suturing nails in the corresponding nail bin holes are pushed out by the suturing nail pushing pieces of the nail hammer, and blood vessel suturing is conducted under the cooperation of the nail anvils. The rapid blood vessel anastomosis device can be used for conveniently and rapidly connecting blood vessels in a narrow in-vivo space during organ transplantation, the blood vessel anastomosis quality is high, the activity of an organ after transplantation can be improved, and the risk of transplantation complications is lowered.

Owner:BEIJING TSINGHUA CHANGGUNG HOSPITAL

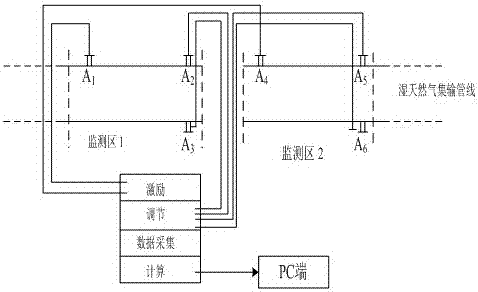

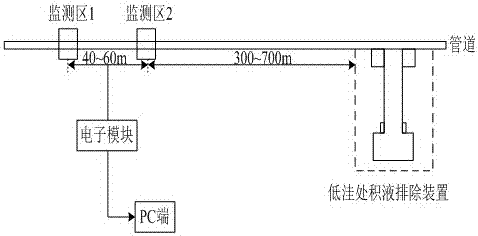

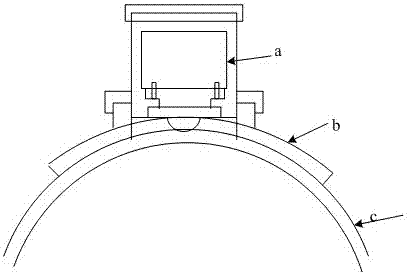

A device and method for removing liquid accumulation in low-lying parts of pipelines and on-line monitoring of corrosion inhibitor concentration

InactiveCN104950859BReasonable exclusionEfficient exclusionTotal factory controlProgramme total factory controlUltrasonic velocityEngineering

Owner:SOUTHWEST PETROLEUM UNIV

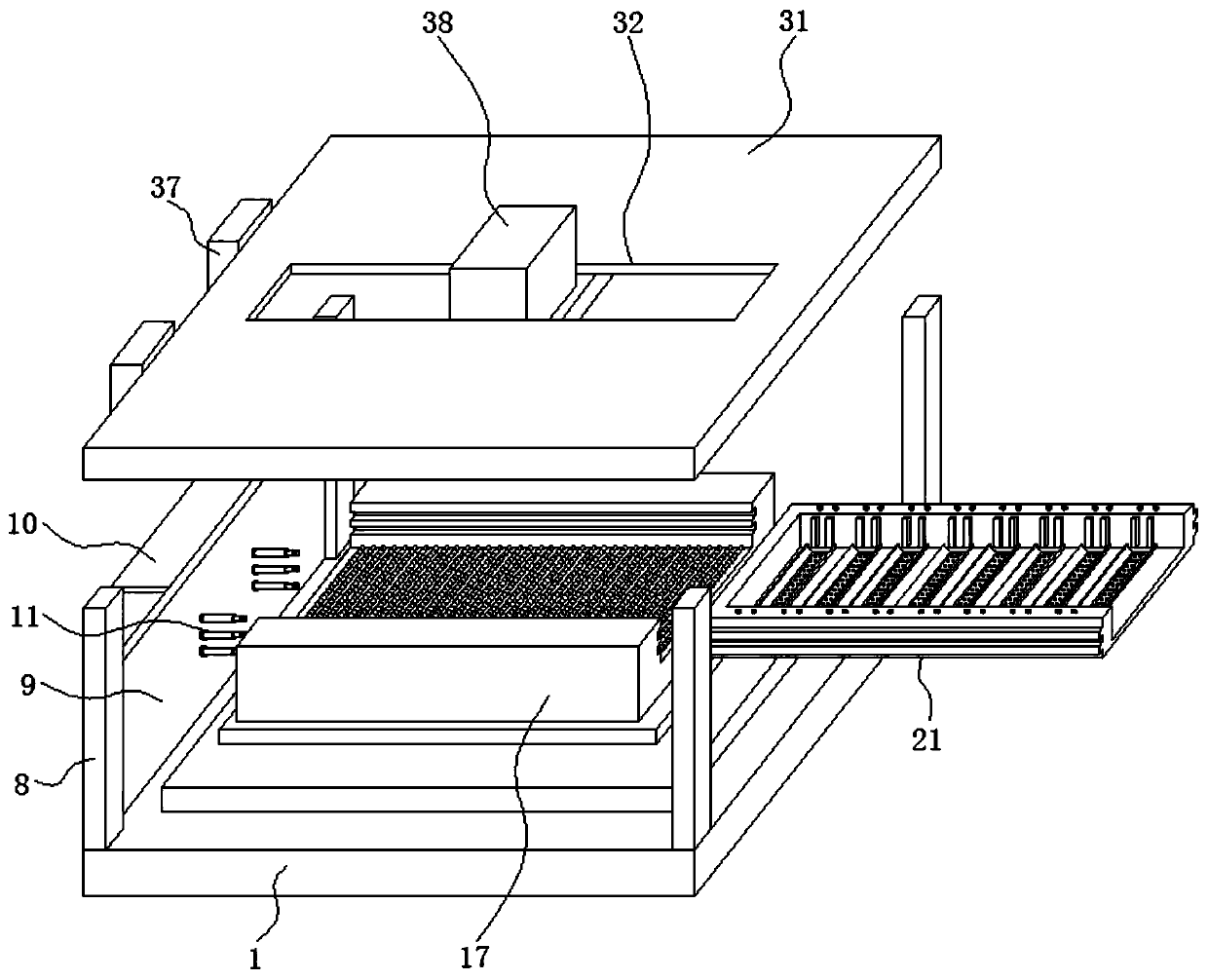

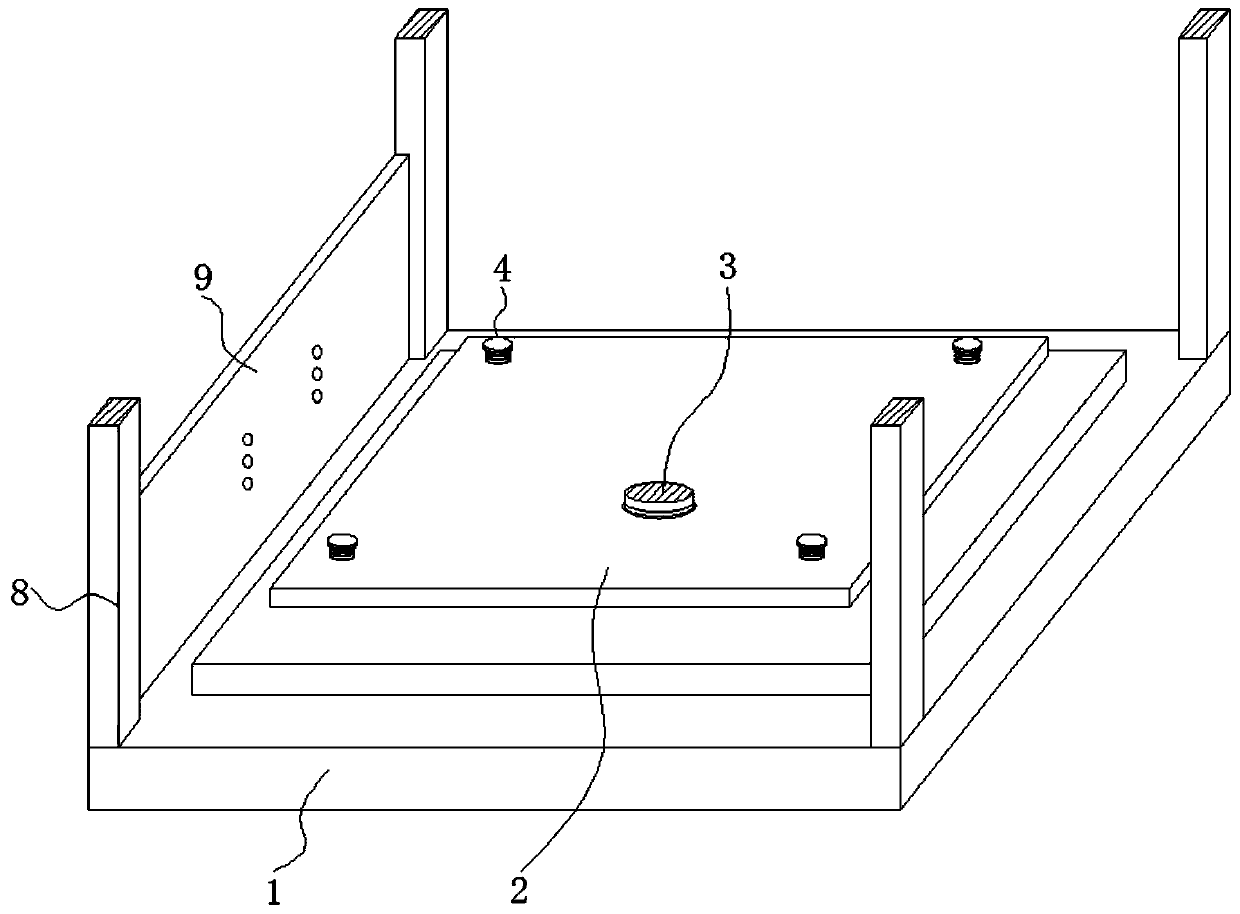

Chill grid line processing equipment and processing technology thereof

PendingCN111545729AEnables motorized press molding operationsReduce adhesionFoundry mouldsFoundry coresMaterial resourcesMolten steel

The invention discloses chill grid line processing equipment and a processing technology thereof and relates to the technical field of casting production. The chill grid line processing equipment specifically comprises a base, pressing easing mechanisms, a bracket, a film forming seat and a top plate; a lifting plate is fixed above the base; the pressing easing mechanisms are arranged at four corners of the upper surface of the lifting plate; an air cylinder case is mounted on the outer wall surface of a support plate; the bracket is arranged above the pressing easing mechanisms; the film forming seat is mounted in the middle above the bracket in a sliding manner; and the top plate is fixed at the top end of a support rod. The chill grid line processing equipment and the processing technology thereof can process grid line chill, can realize mechanization compression moulding operation of the grid line chill and save manpower and material resources; the grid line chill is prepared by adopting a grid line chill manufacturing die, that is, on the basis of smooth-surface chill, the grid line is cast on the surface of the chill, and through adding the grid line, the coating adhesive force is increased, and the surface tension of molten steel is reduced to reduce the risk of forming an air vent.

Owner:无锡市蠡湖铸业有限公司

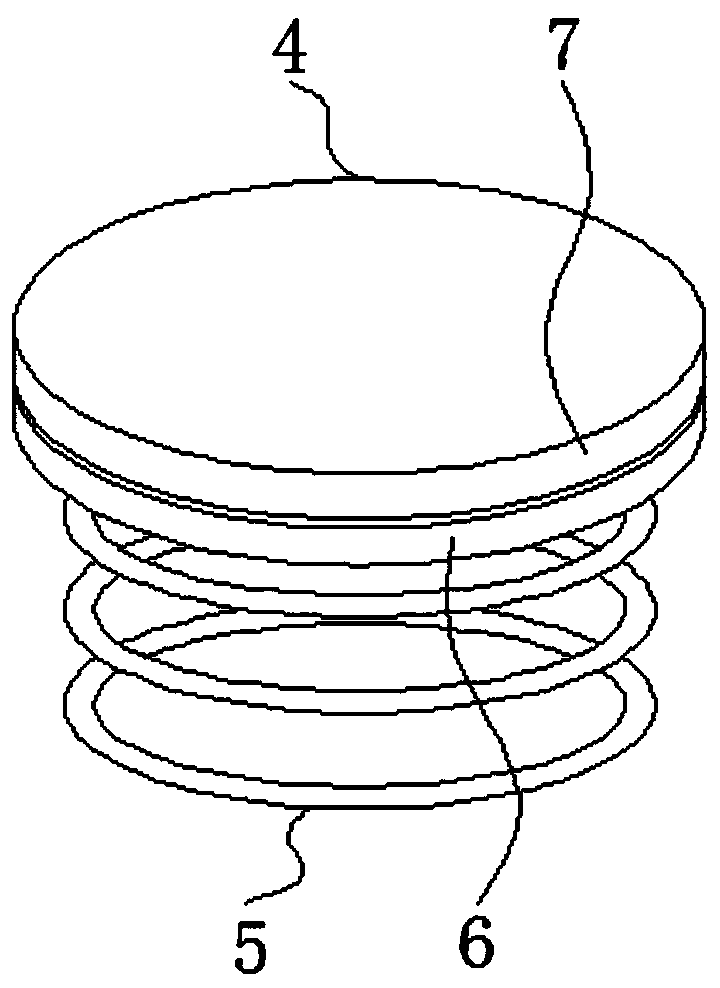

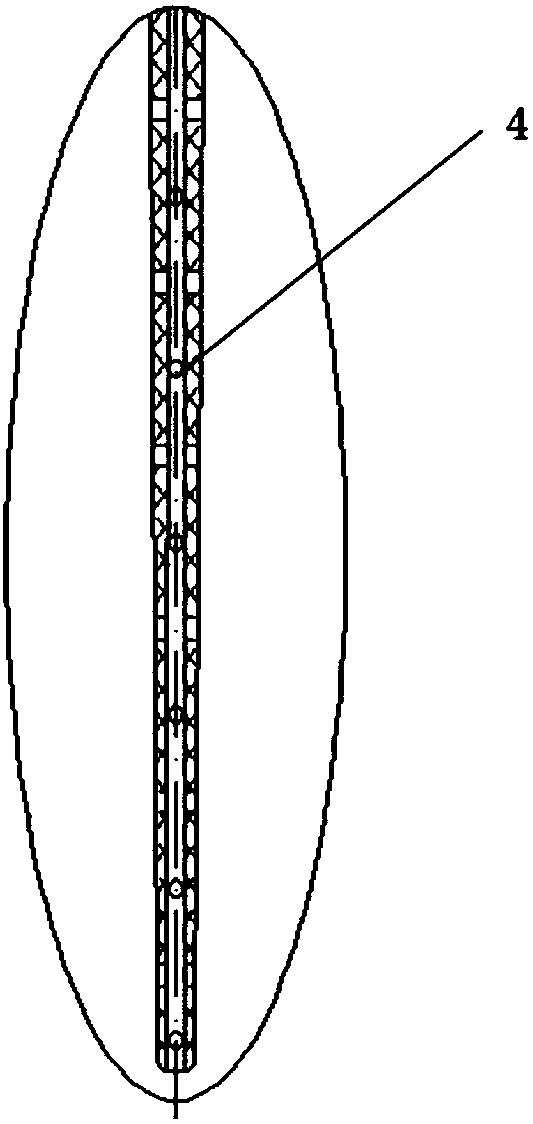

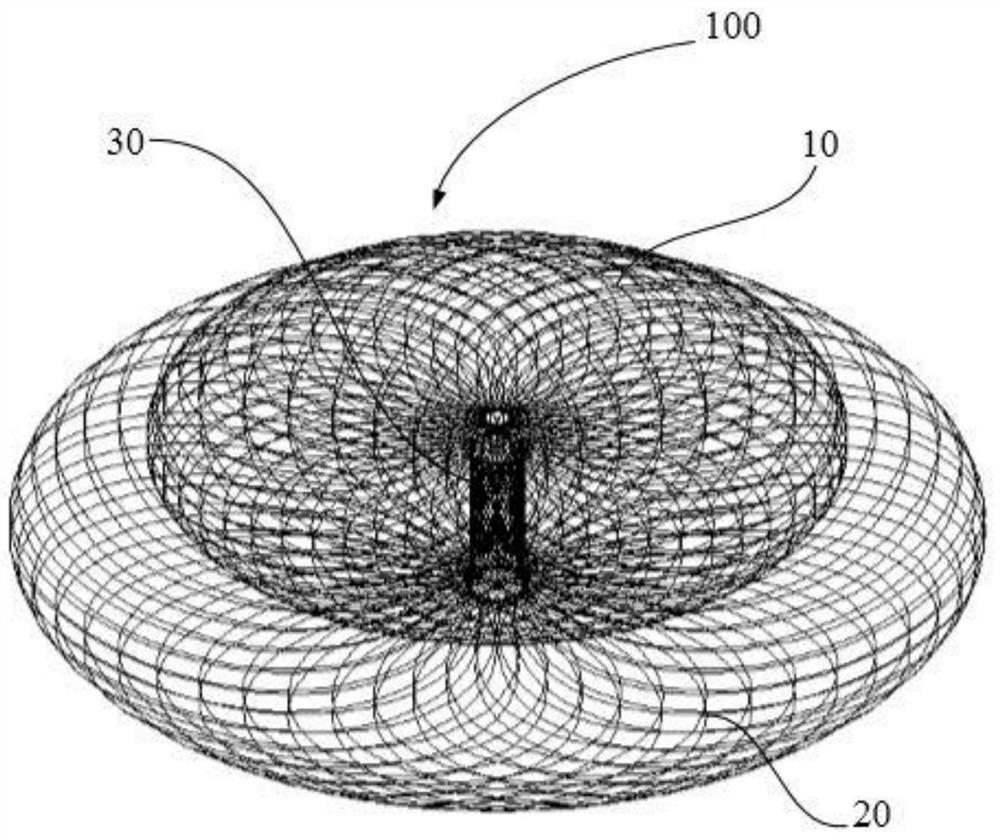

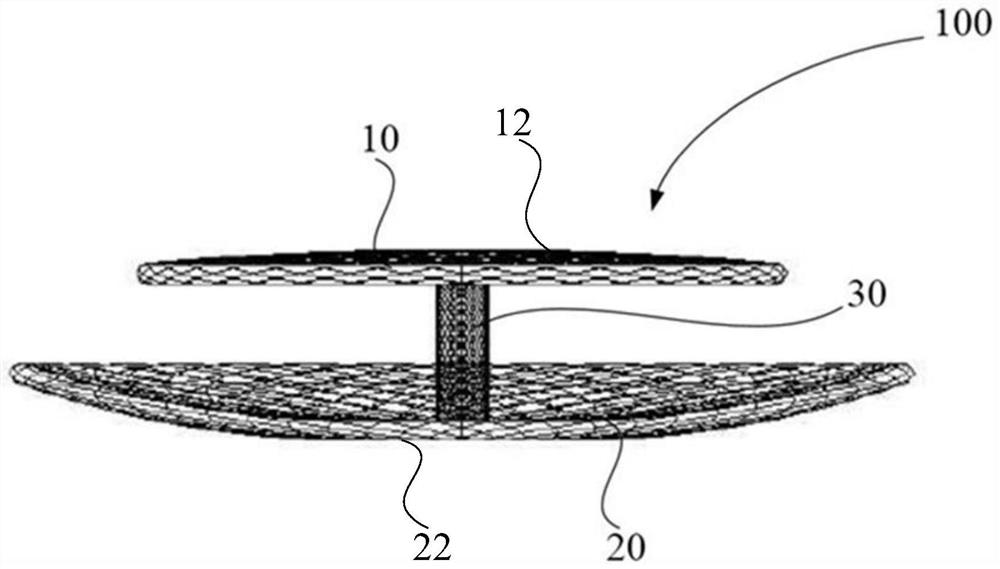

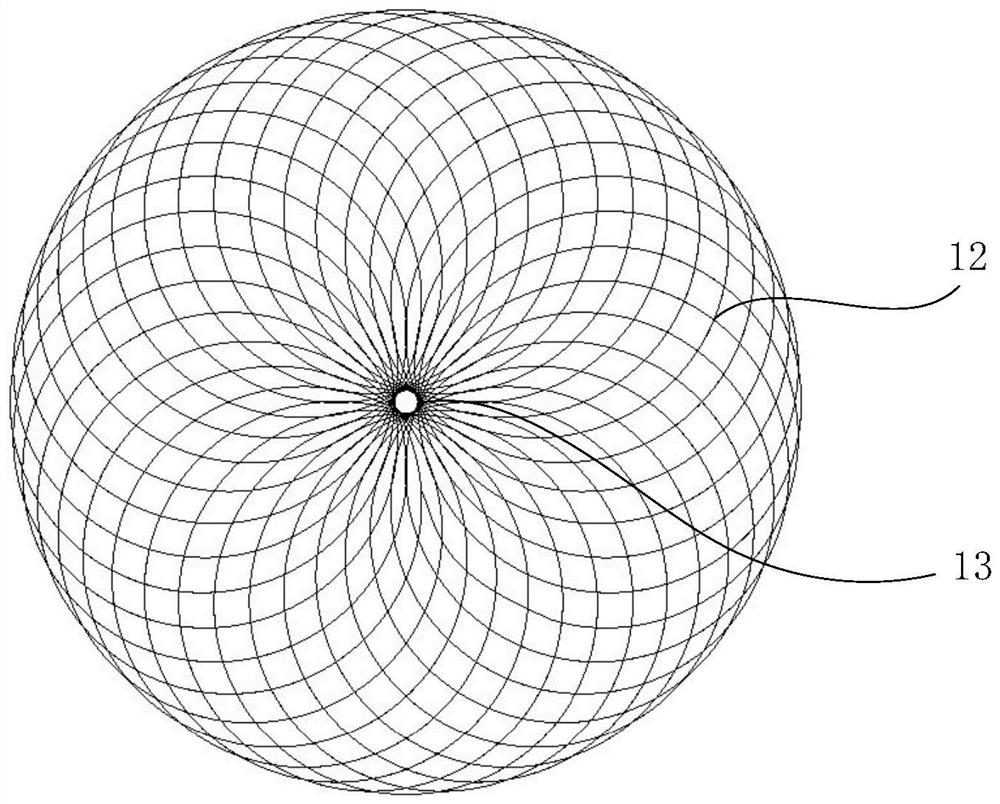

Patent foramen ovale plugging device with two flat end faces and manufacturing method thereof

The invention discloses a patent foramen ovale plugging device with two flat end faces and a manufacturing method thereof. The patent foramen ovale plugging device comprises a main body part, a flow blocking part and a suture line, wherein the main body part is of a net body structure and comprises a first disc-shaped part, a tubular part and a second disc-shaped part which are sequentially connected, and the two ends of the tubular part are connected to the center of the first disc-shaped part and the center of the second disc-shaped part respectively; the flow blocking part is at least two layers of degradable films or non-degradable films used for blocking blood flowing; after the opening is closed through a closing line, the outer net face of the first disc-shaped part and the outer net face of the second disc-shaped part are both continuous and flat net-shaped faces; the patent foramen ovale plugging device is made of a special mold; the special mold comprises a core mold; and the core mold comprises a first cover body, a center part, a second cover body and a center column body. Shaping is carried out through the special mold, and the patent foramen ovale plugging device is simple, fast and low in cost. The two flat end faces are beneficial to accelerating the endothelialization process of the surface of the plugging device, and the patent foramen ovale position can be repaired by the tissue of the patent foramen ovale position earlier.

Owner:MALLOW MEDICAL SHANGHAICO LTD

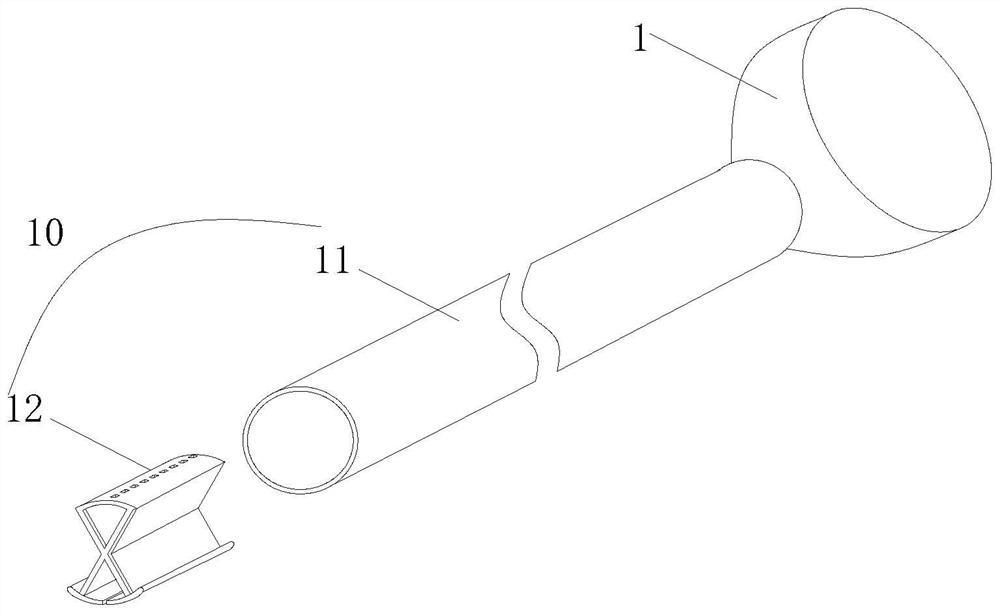

Anti-injury medical vessel dilator and simulation method of hemangiectasis

PendingCN108187215AEasy to makeReduce sizeSurgeryMedical devicesVascular dilationBlood vessel injury

The invention relates to an anti-injury medical vessel dilator and simulation method of hemangiectasis. The anti-injury medical vessel dilator comprises a flexible catheter, an injector connector arranged at the inlet end of the flexible catheter and a conical part at the outlet end of the flexible catheter; the injector connector, the flexible catheter and the conical part are connected orderly,the conical part is a hollow conical pipe; diameter of the conical part is gradually enlarged from the free end of the conical part to the joint of the flexible catheter; multiple guide flow holes arearranged on the side wall of the conical part. The invention solves the technical problems that the hemangiectasis section applied to the operation process of autologous internal arteriovenous fistula plasty at present is poor in dilating effect, easy to cause blood vessel injury, and low in operation success rate. The vessel dilator provided by the invention can rapidly dilate operation vessel and not damage blood vessels during the operation process.

Owner:THE FIRST AFFILIATED HOSPITAL OF MEDICAL COLLEGE OF XIAN JIAOTONG UNIV

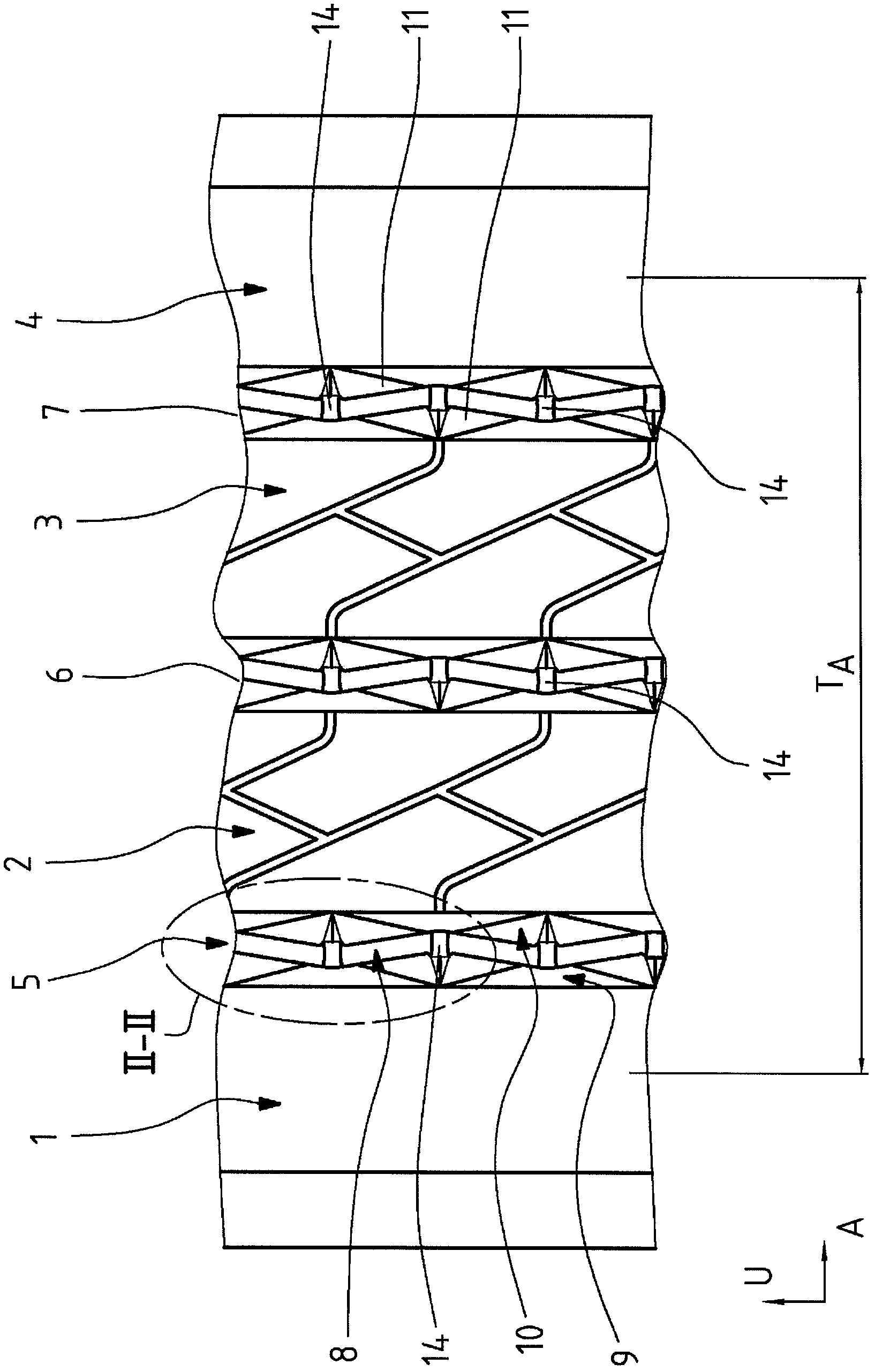

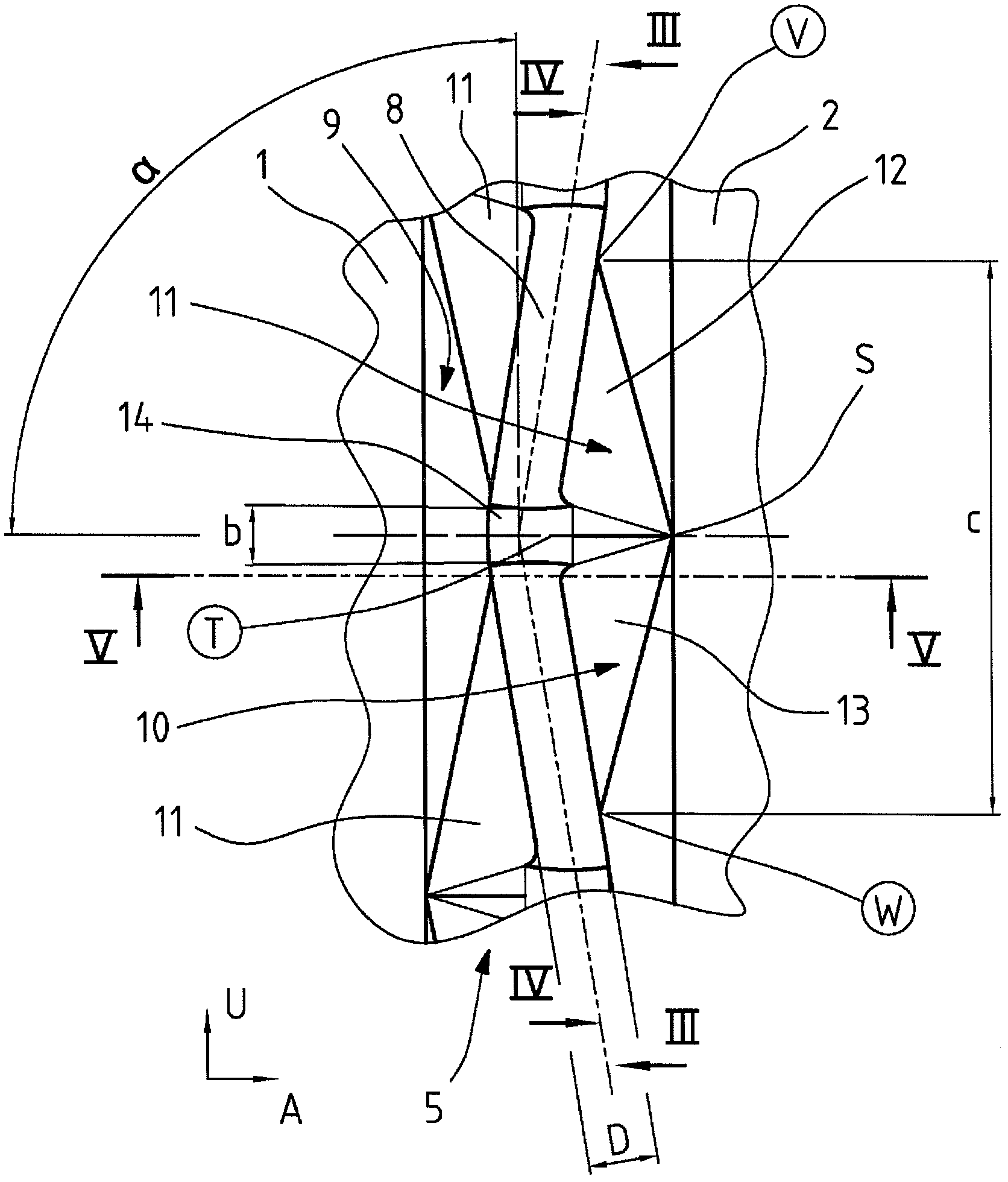

Tread profile of a vehicle tire

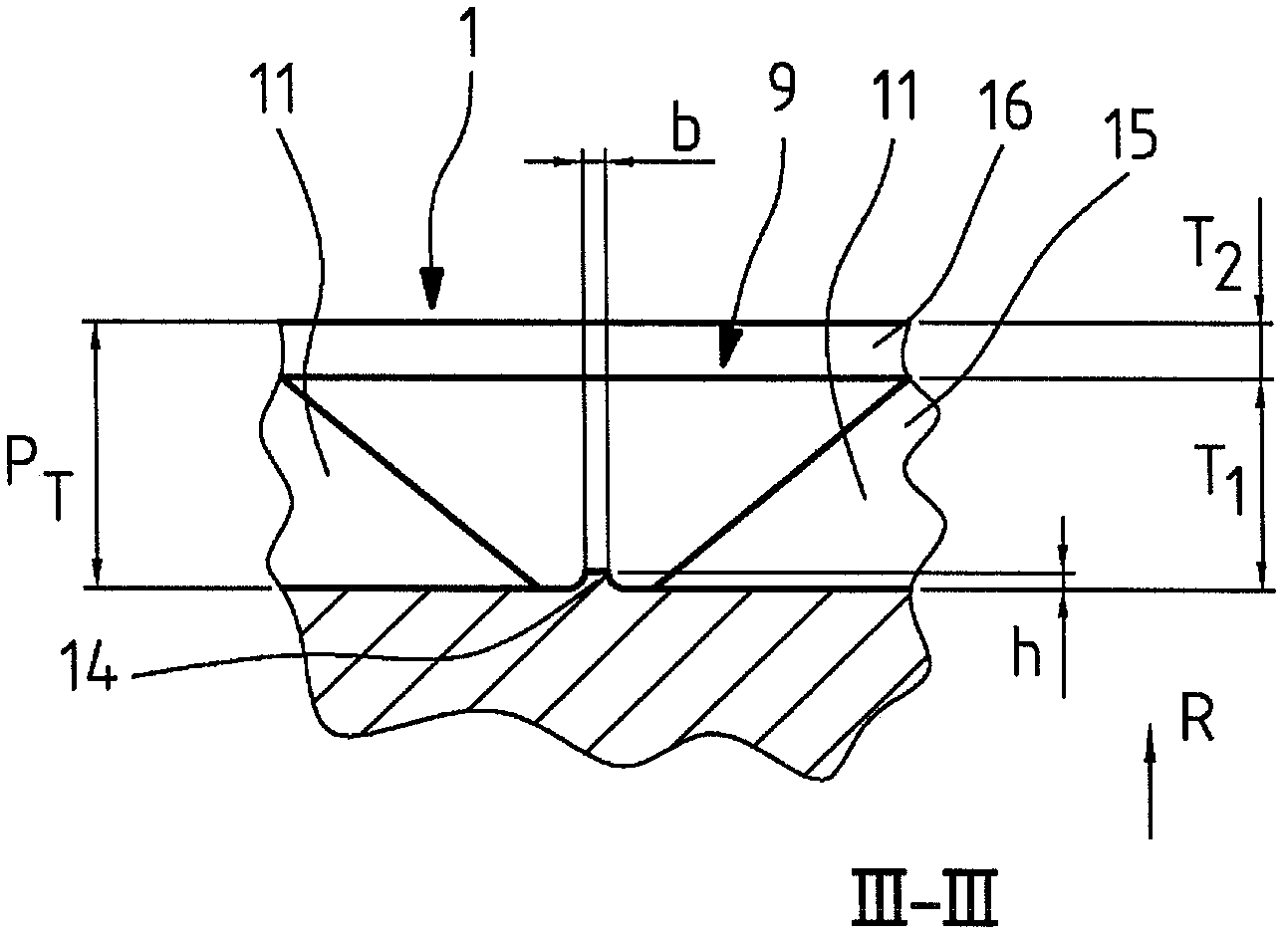

ActiveCN102548776BReduced risk of crackingIncreased durabilityTyre tread bands/patternsGround contactEngineering

The invention relates to a tread profile having radially raised profile elements (1, 2, 3, 4) separated from each other by grooves (5, 6, 7), wherein the grooves (5, 6, 7) are bounded on the inside in the radial direction R by the groove floor thereof (8) and on both sides of the groove floor (8) by one groove wall (9, 10) each extending in the radial direction from the groove floor (8) outward to the generated surface forming the ground contact surface, wherein at least one groove (5) extends over the circumference of the vehicle tire, wherein raised areas (11) of the groove wall (9, 10) each extending radially outward from the groove floor (8) and inward into the groove (5) in the direction perpendicular to the groove wall (9,10) are formed at least in one groove wall (9, 10) and distributed around the circumference at a distance from each other, wherein at least one web-shaped raised area (14) of the groove floor (8) is implemented in the groove floor (8), each starting from a raised area (11) of the one groove wall (10), extending transverse to the direction of extension of the groove floor (8) out to the other groove wall (9), and connecting the other groove wall (9)in the radially inner extension area of the groove (5) to the raised area (11) implemented in the one groove wall (10).

Owner:CONTINENTAL REIFEN DEUTSCHLAND GMBH

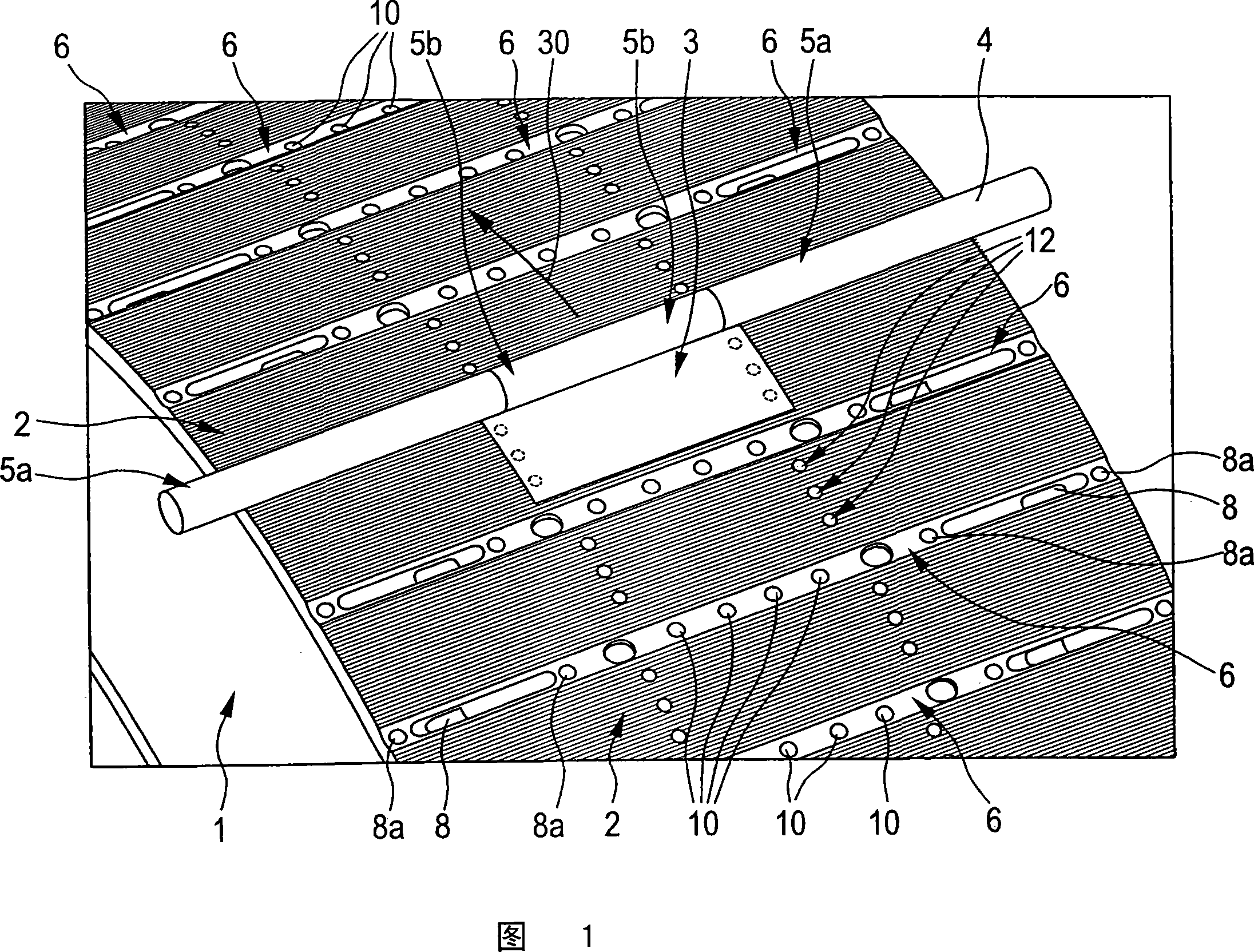

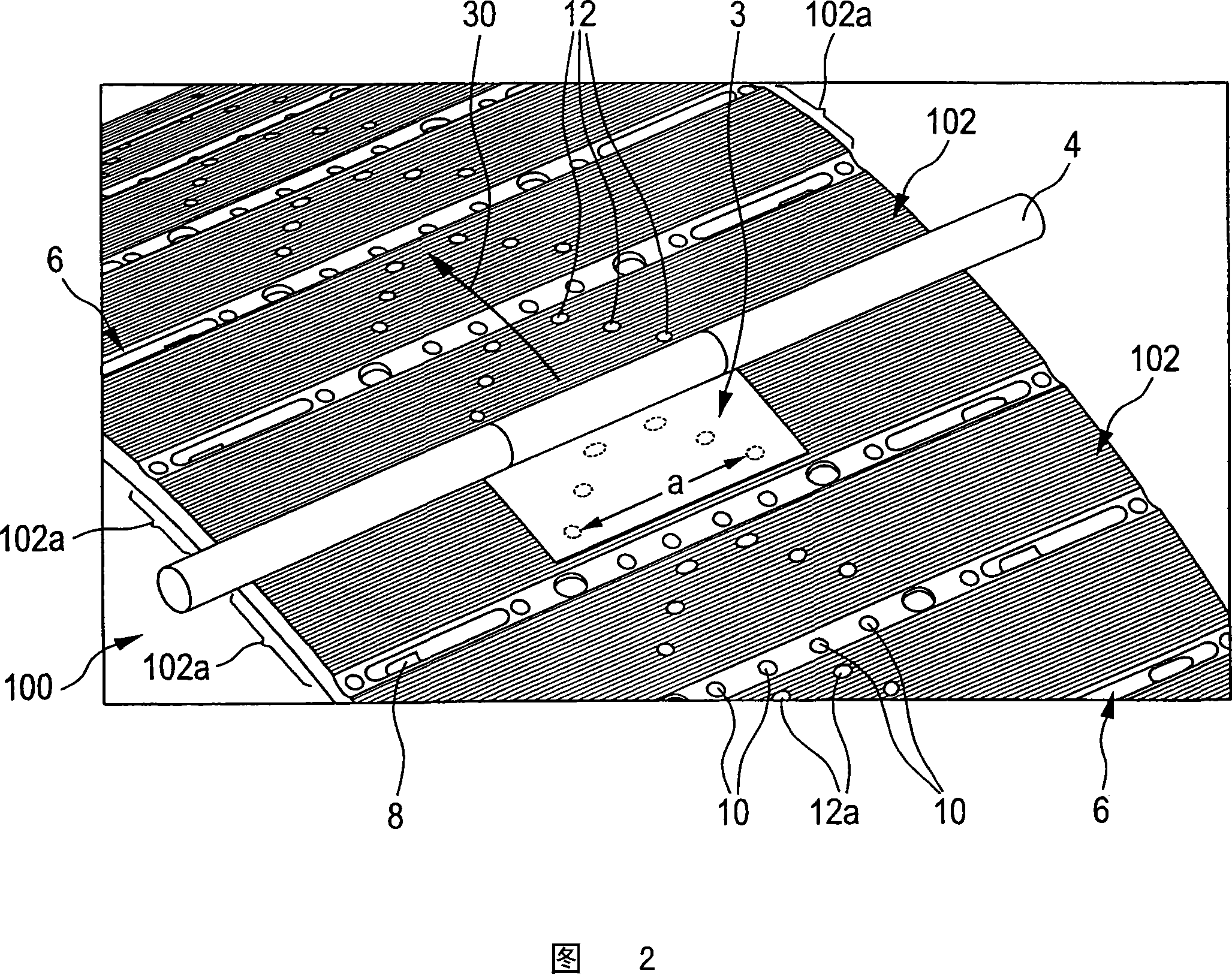

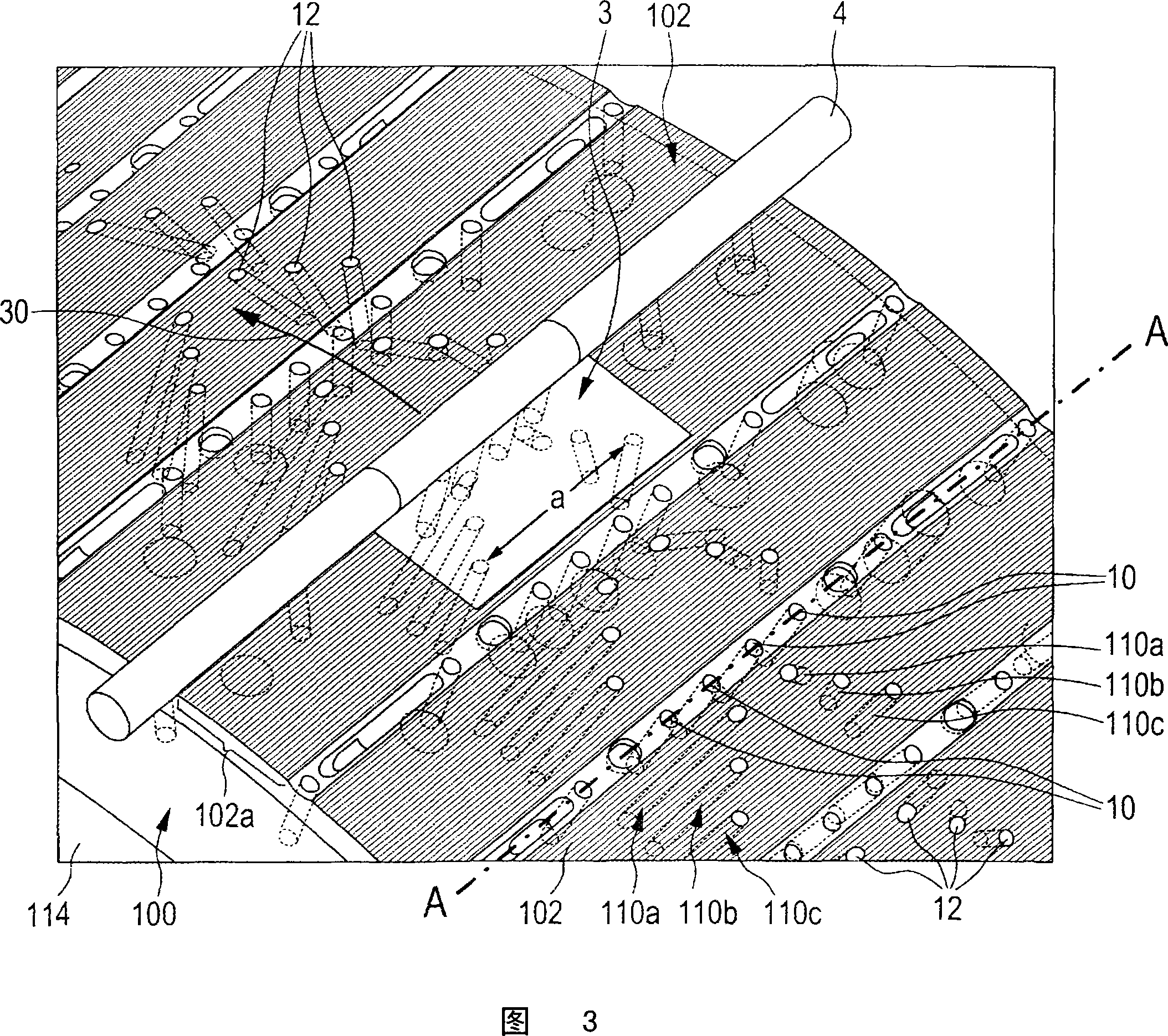

V-shaped assembly of suction apertures

ActiveCN101138434BPrevent smoothingReduce creasesCigarette manufactureTobacco smoke filtersClassical mechanicsEngineering

Owner:KOERBER TECH GMBH

Cardiac patent foramen ovale occluder with flat ends and manufacturing method thereof

The invention discloses a heart patent foramen ovale occluder with flat two-end surfaces and a manufacturing method thereof. The patent foramen ovale occluder includes: a main body part, a flow blocking part and a suture thread; the main part is a mesh structure and includes a first disc-shaped part, a tubular part and a second disc-shaped part connected in sequence, and the tubular part The two ends are respectively connected to the center of the first disc-shaped part and the second disc-shaped part; the flow blocking part is at least two layers of degradable or non-degradable films used to block blood flow; after being closed by the closing line, the second The outer mesh surfaces of the first disc-shaped part and the second disc-shaped part are continuous and flat mesh surfaces; the patent foramen ovale occluder is made of a special mold; the special mold includes a mandrel; the mandrel includes: the first A cover, a central part, a second cover, and a central column. The shaping is carried out through a special mold, which is simple, fast and low in cost. The smoothness of both ends is conducive to accelerating the endothelialization process of the surface of the occluder, so that the patent foramen ovale of the heart can be repaired by its own tissue earlier.

Owner:MALLOW MEDICAL SHANGHAICO LTD

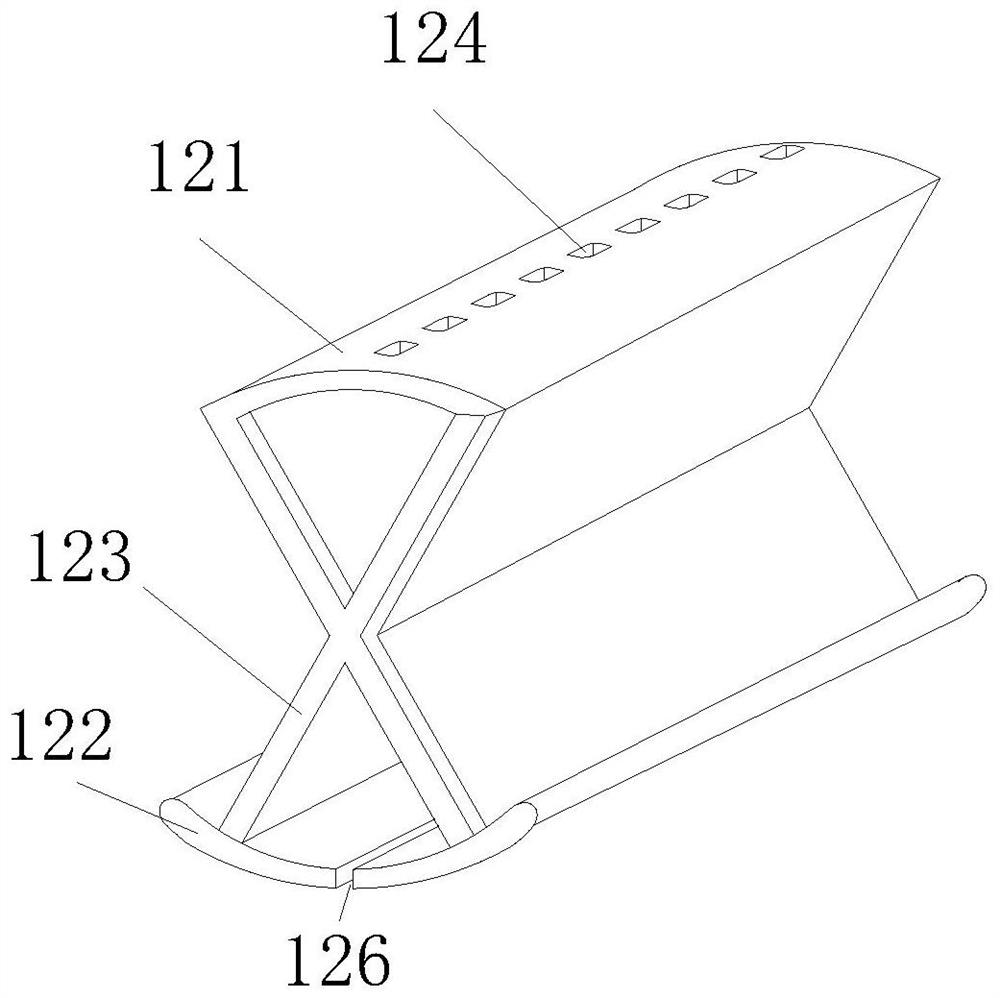

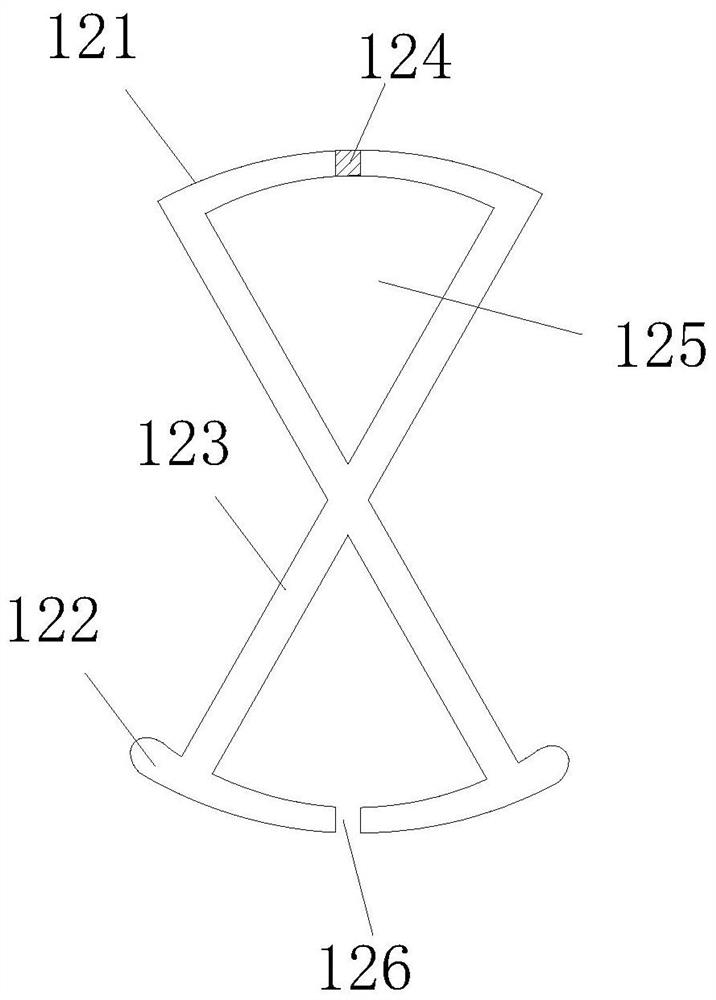

Drainage device for abdominal operation wound

The invention provides an abdominal operation wound drainage device which comprises a split drainage tube and a negative pressure ball, the split drainage tube is composed of a hose and a drainage apparatus, the drainage apparatus is inserted into one end of the hose, and the other end of the hose is connected with the negative pressure ball; the drainage device comprises an upper arc-shaped pressing piece, a lower arc-shaped pressing piece and an X-shaped supporting piece connected between the two arc-shaped pressing pieces, and two bottom feet on the upper side and the lower side of the X-shaped supporting piece are fixedly connected with the upper arc-shaped pressing piece and the lower arc-shaped pressing piece respectively. A row of drainage holes are distributed in the upper arc-shaped pressing piece in the length direction, and long-strip-shaped drainage grooves distributed in the length direction are formed in the lower arc-shaped pressing piece. The included angle alpha 1 of the two sides of the X-shaped supporting piece ranges from 50 degrees to 70 degrees, the two sides of the upper arc-shaped pressing piece are flush with bottom feet of the X-shaped supporting piece, and distances are reserved between the left side and the right side of the lower arc-shaped pressing piece and the bottom feet of the X-shaped supporting piece. The abdominal operation wound drainage tube can well conduct drainage on an abdominal operation wound, and compared with a traditional cross-shaped drainage tube, the abdominal operation wound drainage tube is beneficial to wound healing.

Owner:ZHONGSHAN HOSPITAL FUDAN UNIV

A kind of biomedical porous ti-zn alloy and preparation method thereof

ActiveCN112708796BImprove mechanical propertiesImprove biological activityTissue regenerationProsthesisFiberCarbide silicon

Owner:NANCHANG HANGKONG UNIVERSITY

A long-acting anticoagulant antibacterial coating for extracorporeal membrane oxygenation device (ecmo) and preparation method thereof

ActiveCN111298202BGood antifoulingGood sterilization functionSurgeryCoatingsFunctional monomerMedicine

The invention discloses a long-term anti-freezing antibacterial coating for extracorporeal membrane oxygenation (ECMO) device and a preparation method of the long-term anti-freezing antibacterial coating. The method comprises the following steps: (1) mixing an anti-freezing functional monomer, an antibacterial functional monomer and a film formation agent, and performing a reaction in a mode of free radical polymerization for 10-15 hours at 60-80 DEG C so as to obtain an anti-freezing antibacterial polymer; and (2) mixing the anti-freezing antibacterial polymer with a solvent, so as to obtainthe long-term anti-freezing antibacterial coating. The invention designs the coating with long-term anti-freezing and antibacterial functions simultaneously, and antifouling and sterilization functions can be well combined. With the combination of two functions, an effect of reducing risks of bacterium infection for a long time can be achieved. By reasonably selecting and controlling introductionof antibacterial functional components, the anti-freezing function of the coating can be well maintained.

Owner:SICHUAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com