Axial flow blood pump adopting split through-hole bearing structure

A split-type, bearing technology, applied in the field of medical devices, can solve the problems of high risk of thrombus formation, flow stagnation area, large contact area between static and rotational, and achieve the effect of reducing the risk of thrombus formation at the shaft end

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

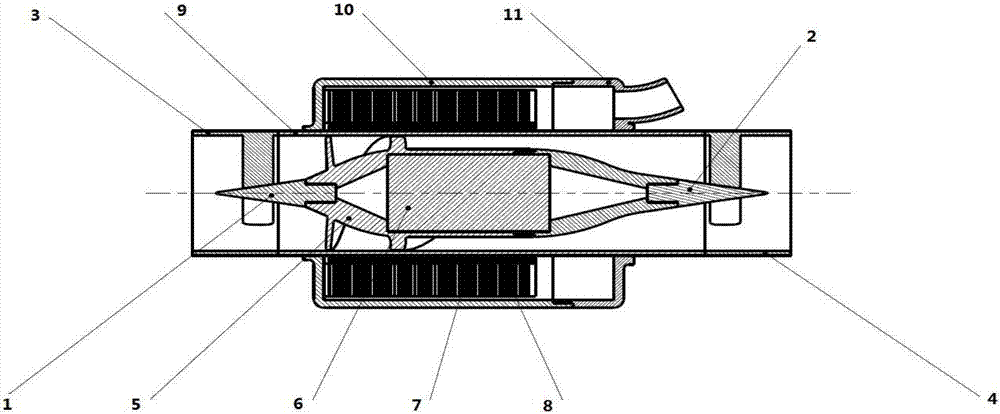

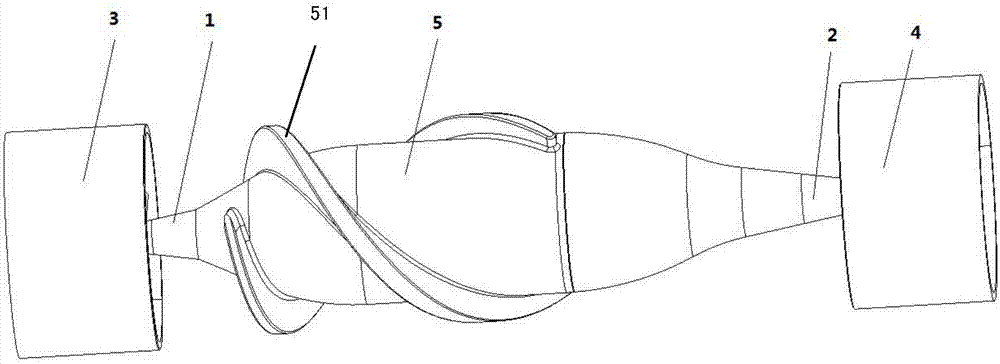

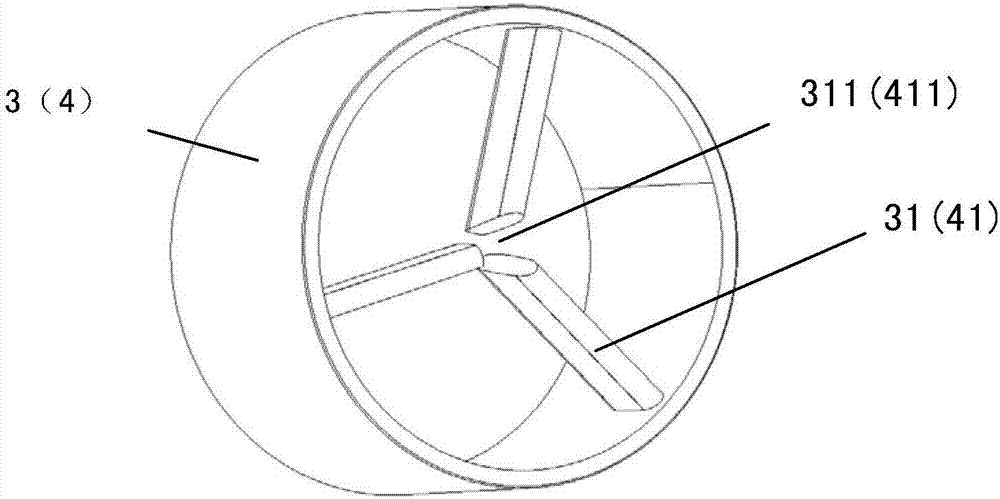

[0018] see figure 1 , figure 2 , image 3 , Figure 4 Shown: an axial flow blood pump adopting a split-type through-hole bearing structure, which includes a front casing 3, a rotor 6, a rotor casing 9 and a rear casing 4, the front casing 3 is circular, and the The circular inner wall of the front casing is uniformly connected with 3 straight blades 31, and the inner ends of the 3 straight blades are suspended to form the front axle hole 311. The rear casing 4 is circular, and the circular inner wall of the rear casing is uniform. There are three straight blades 41 integrally connected, and the inner ends of the three straight blades are suspended to form a rear shaft hole 411. Between the front casing 3 and the rear casing 4, a rotor casing 9 is integrally connected. The rotor casing 9 is a cylinder. shape, the inner diameter of the rotor casing 9 is the same as the inner diameter of the front casing 3 and the rear casing 4, and a rotor 6 is arranged in the rotor casing 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com