V-shaped assembly of suction apertures

A technology of suction port and suction hole, applied in the fields of tobacco, food science, application, etc., can solve the problems of inappropriate humidity, wrong adjustment of rolling brake block, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

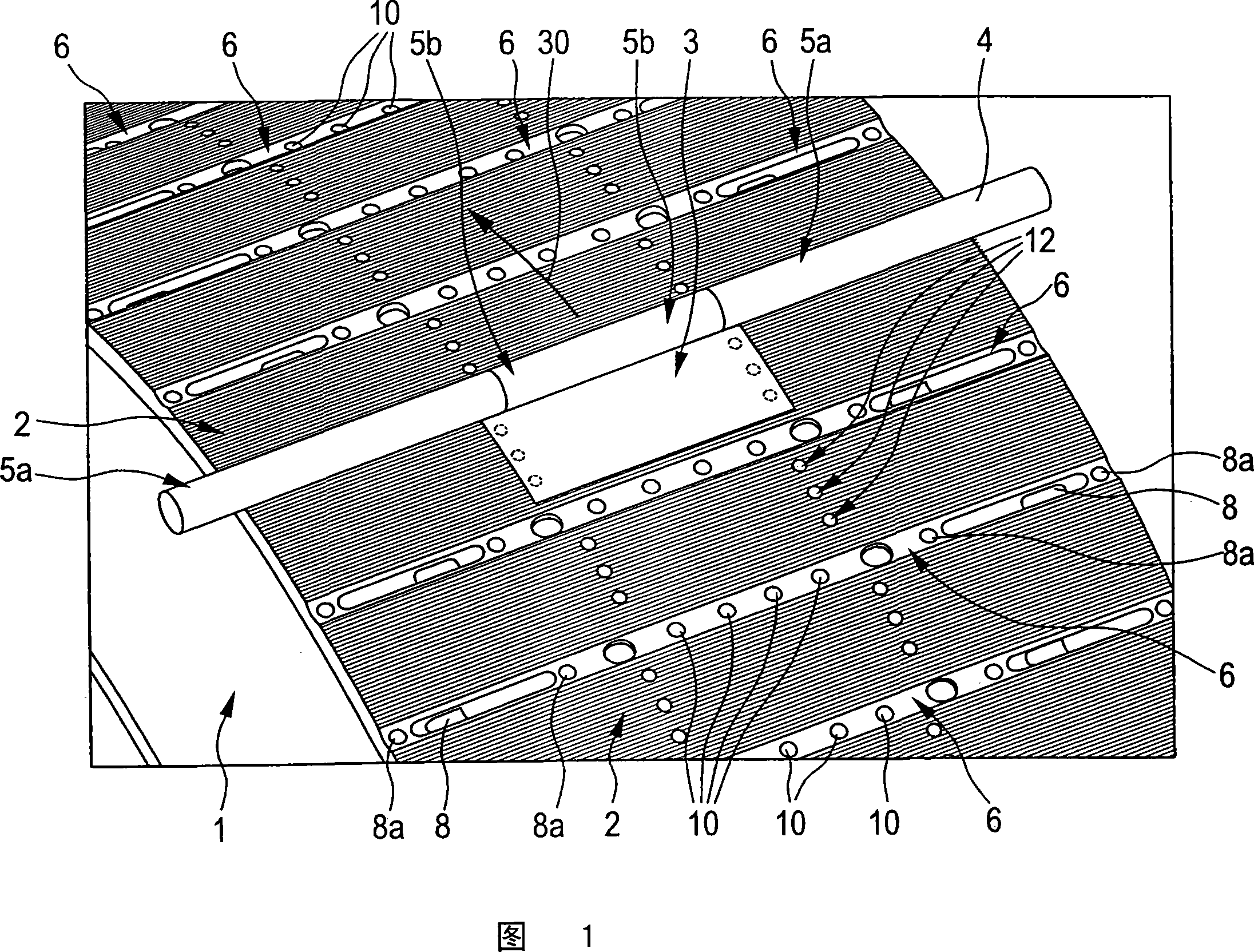

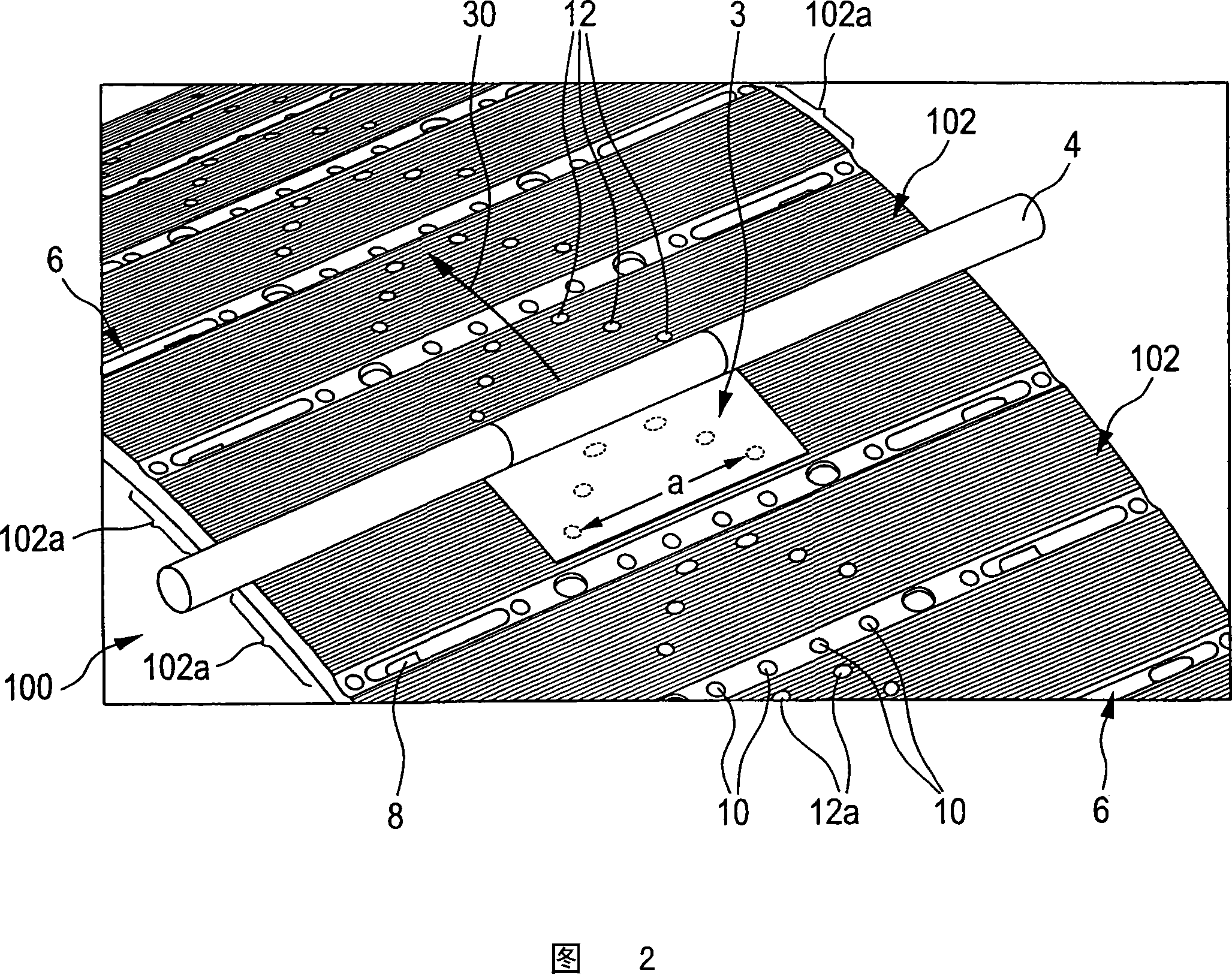

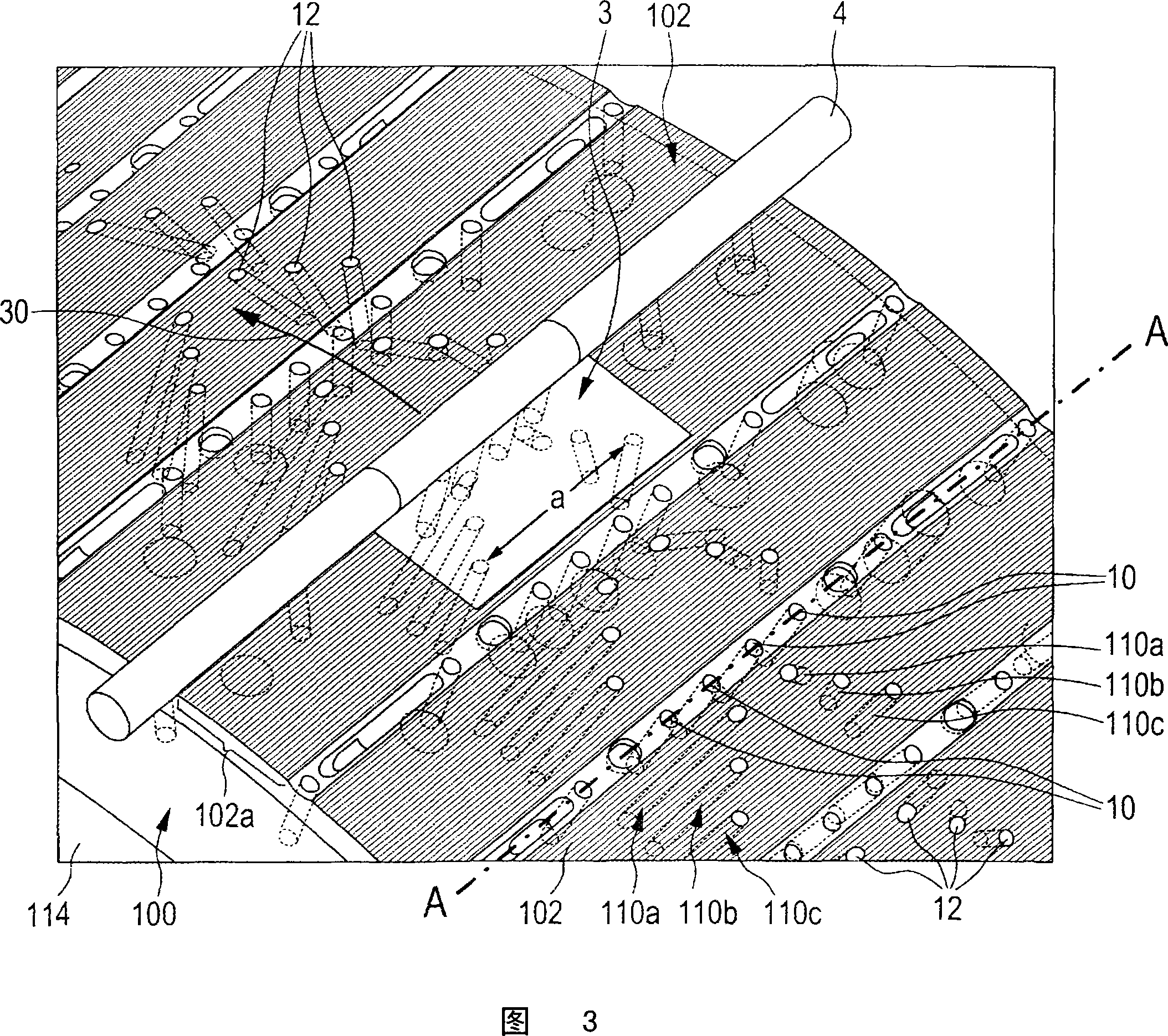

[0029] FIG. 1 shows a perspective view of a prior art winding drum 1 . The winding drum 1 has a peripheral surface 2 which serves as a conveying surface 2 for conveying a covering paper 3 of rod-shaped products from the tobacco processing industry along a conveying direction 30 . These are double filter cigarettes 4 among the rod-shaped products of the tobacco industry. The double filter cigarette 4 consists of two tobacco rods 5a located on the outside and a double filter rod 5b arranged in the middle. The double-filter cigarette 4 arrives on the conveying surface 2 from an unrepresented conveying drum in a state in which the tobacco rod 5a and the double-filter rod 5b are completely and only partly by means of a double-filter rod 5b and the tobacco rod 5a. The covering paper strips 3 are connected to each other overlappingly. Before the start of rolling, the covering paper web 3 is only in contact with the double filter cigarette 4 in the region where it is already glued t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com