A device and method for removing liquid accumulation in low-lying parts of pipelines and on-line monitoring of corrosion inhibitor concentration

A technology for monitoring devices and corrosion inhibitors, which is applied in the field of liquid removal in low-lying areas of pipelines and on-line monitoring devices for corrosion inhibitor concentration, which can solve problems such as hydrate slug flow corrosion and unsafety, so as to slow down corrosion and reduce the risk of formation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

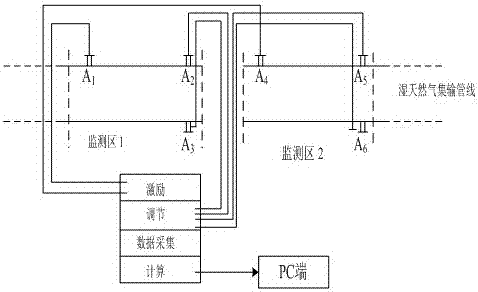

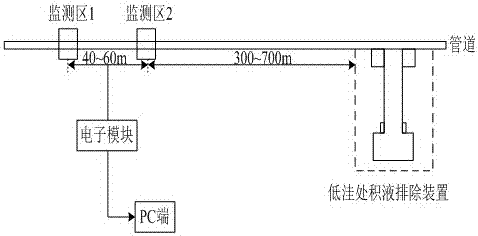

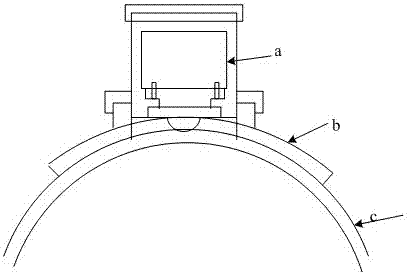

[0039] In this embodiment, the online monitoring of upstream slug flow is a non-invasive safety monitoring means. When the flow pattern of the fluid in the pipeline is slug flow, due to the high density of the liquid slug and the large mass per unit volume, the corresponding natural frequency f of the pipeline structure is lower than that of other flow patterns when the fluid passes through the pipeline. When the liquid slug passes through the monitoring area, the fluid density in the monitoring area increases rapidly, and the liquid slug density can be obtained by calculating the natural frequency of the pipeline structure. The natural frequency f of the pipeline structure is calculated by formula 1. From the above formula, it can be concluded that the natural frequency is the result of the action of mass. m is the quality of the pipeline structure, k is the stiffness coefficient, and the quality m of the pipeline structure refers to the sum of the quality of the pipeline mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com