Patents

Literature

83 results about "Wound drainage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Wound drainage provides a way for unnecessary body fluids or air to flow out of the body from a wound. What is a wound drain? After surgery, some patients require wound drains such as the one pictured above. The wound drain is inserted while the patient is in the operating room receiving generalanesthesia.

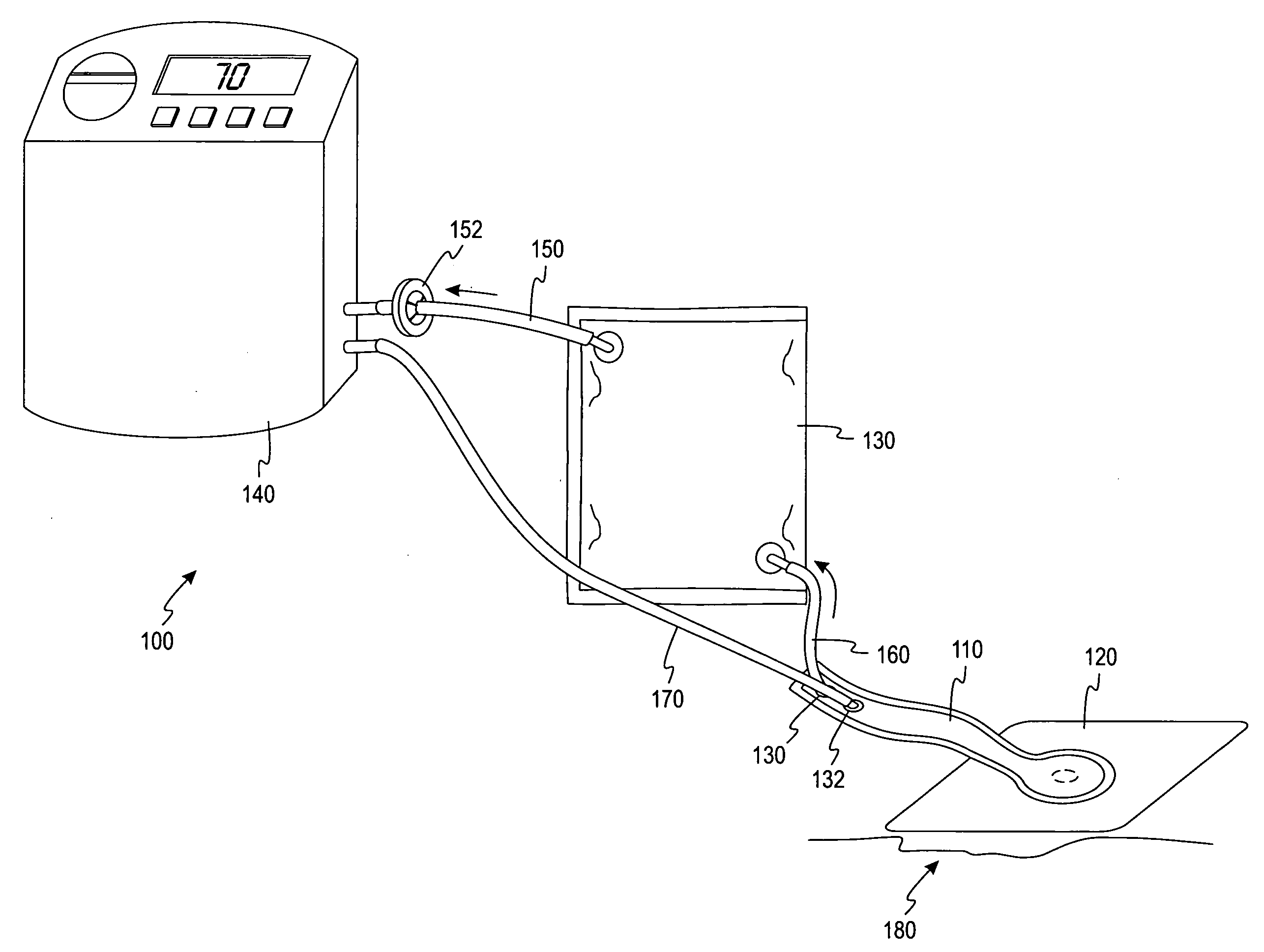

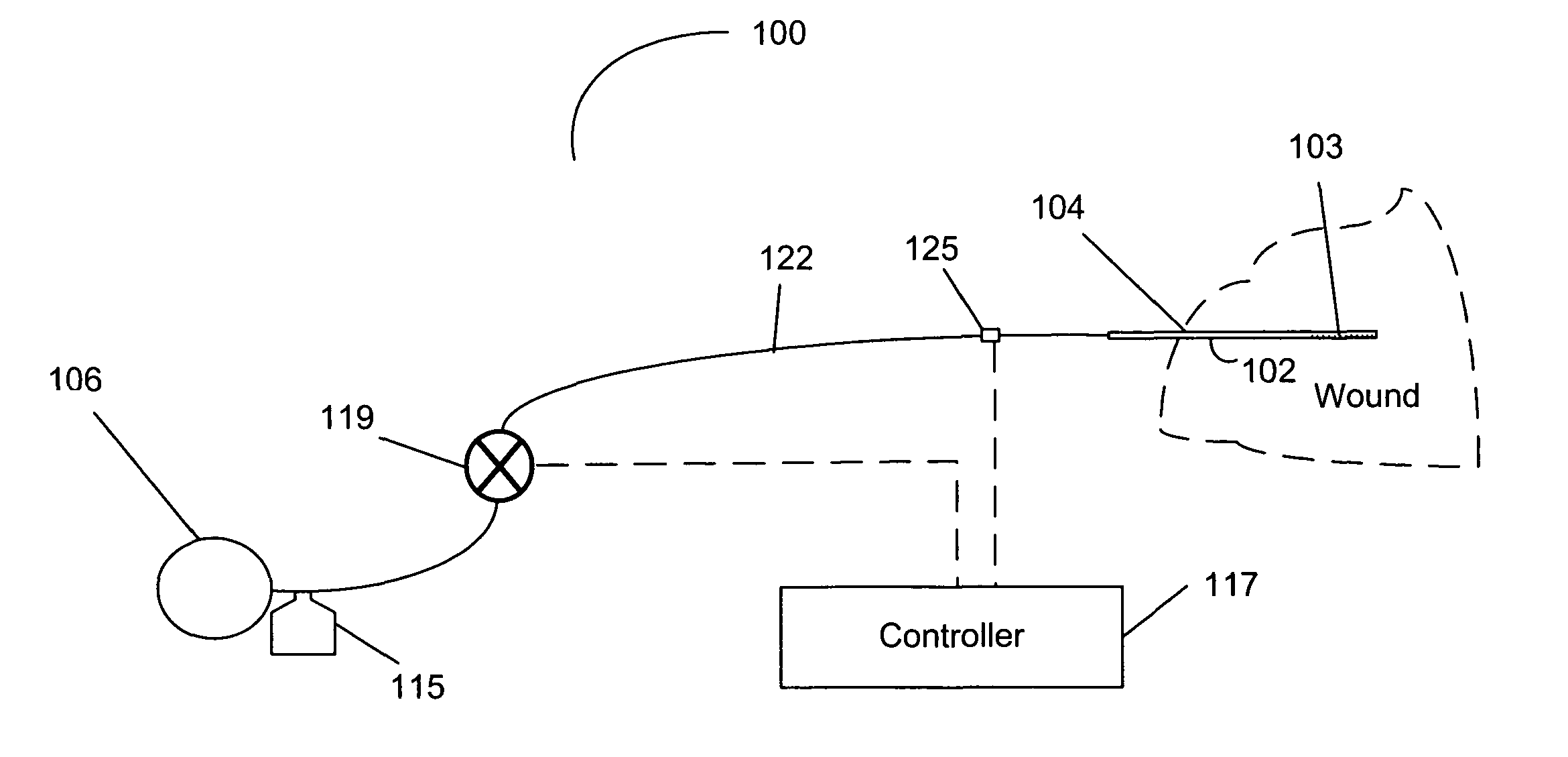

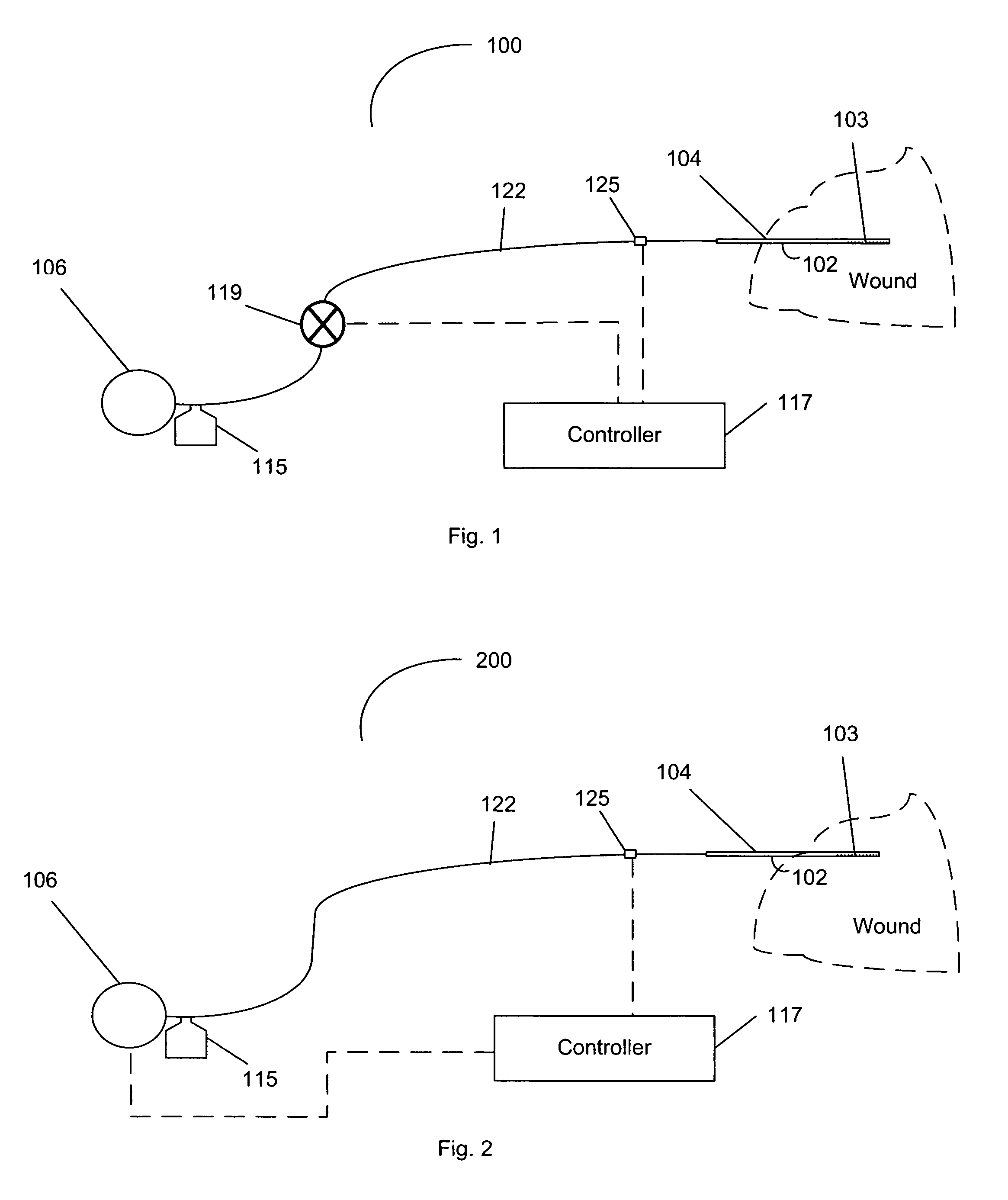

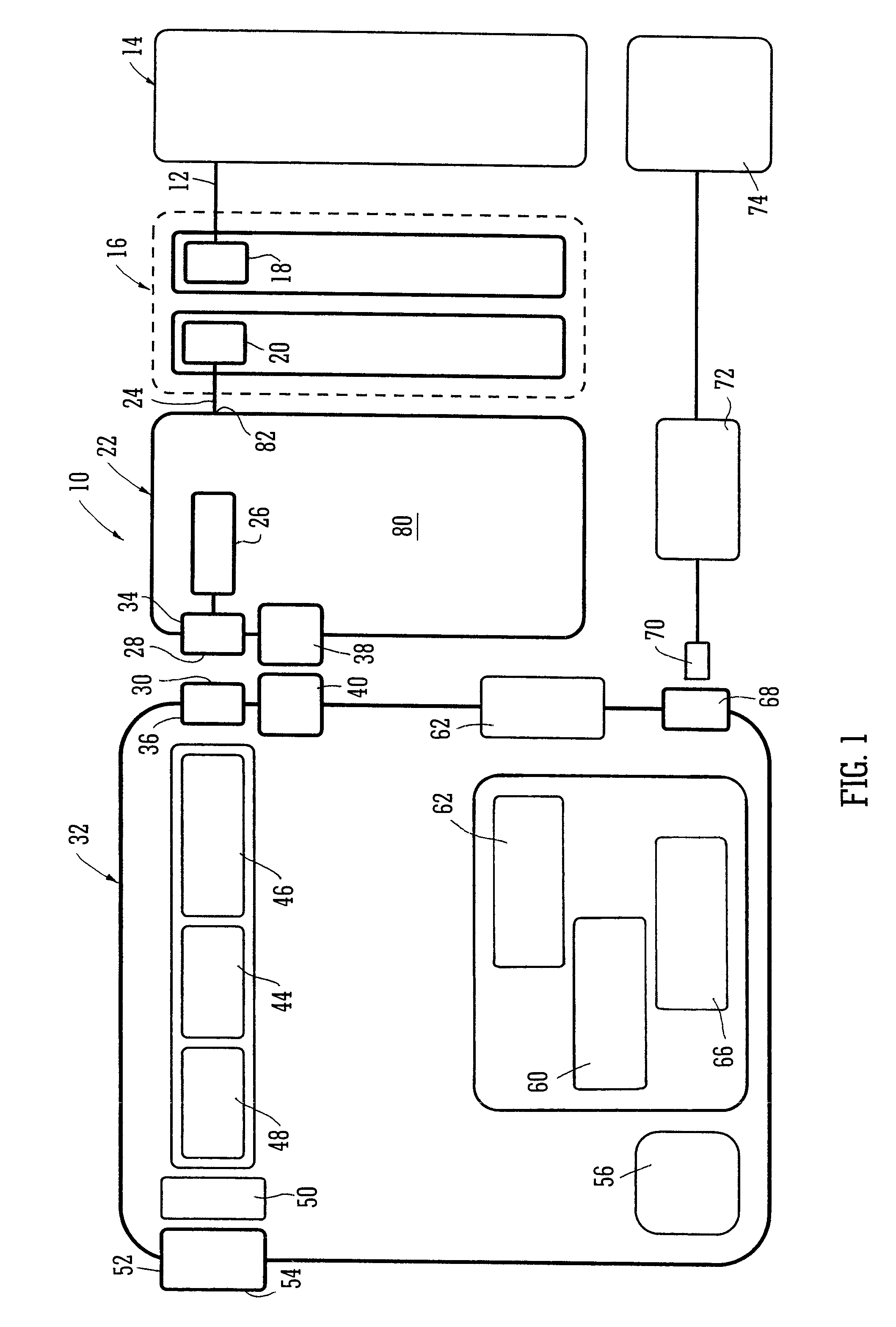

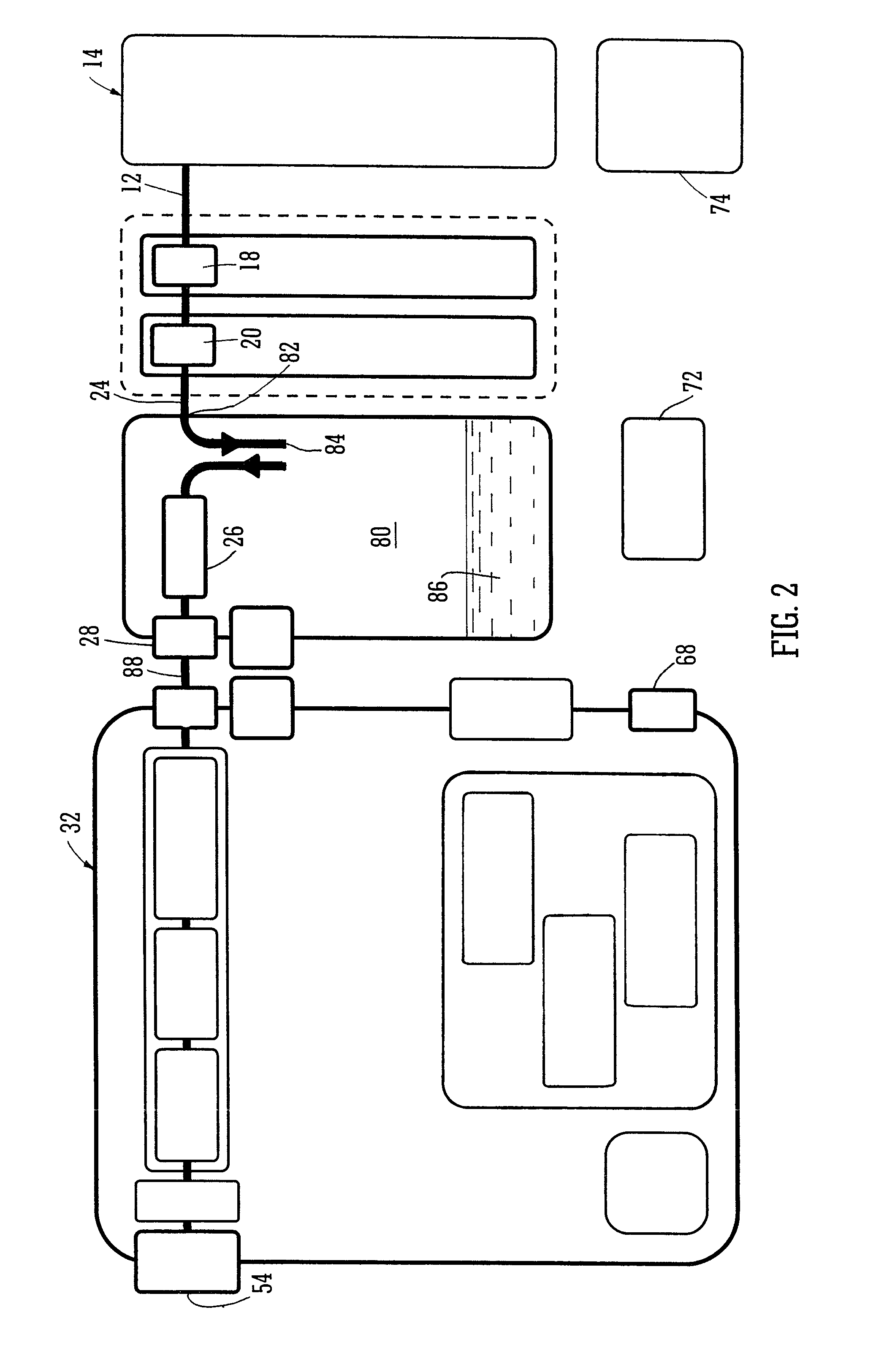

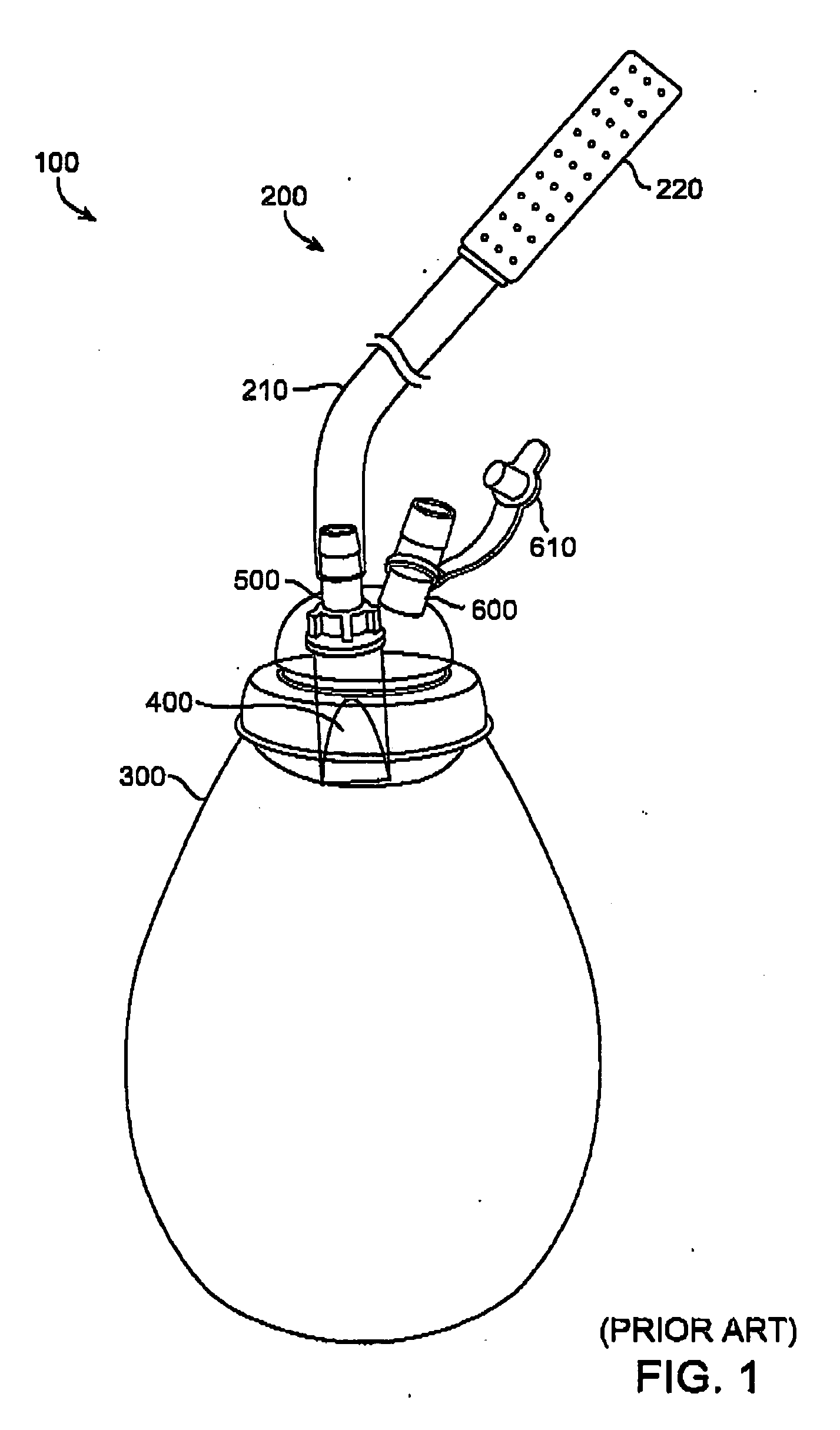

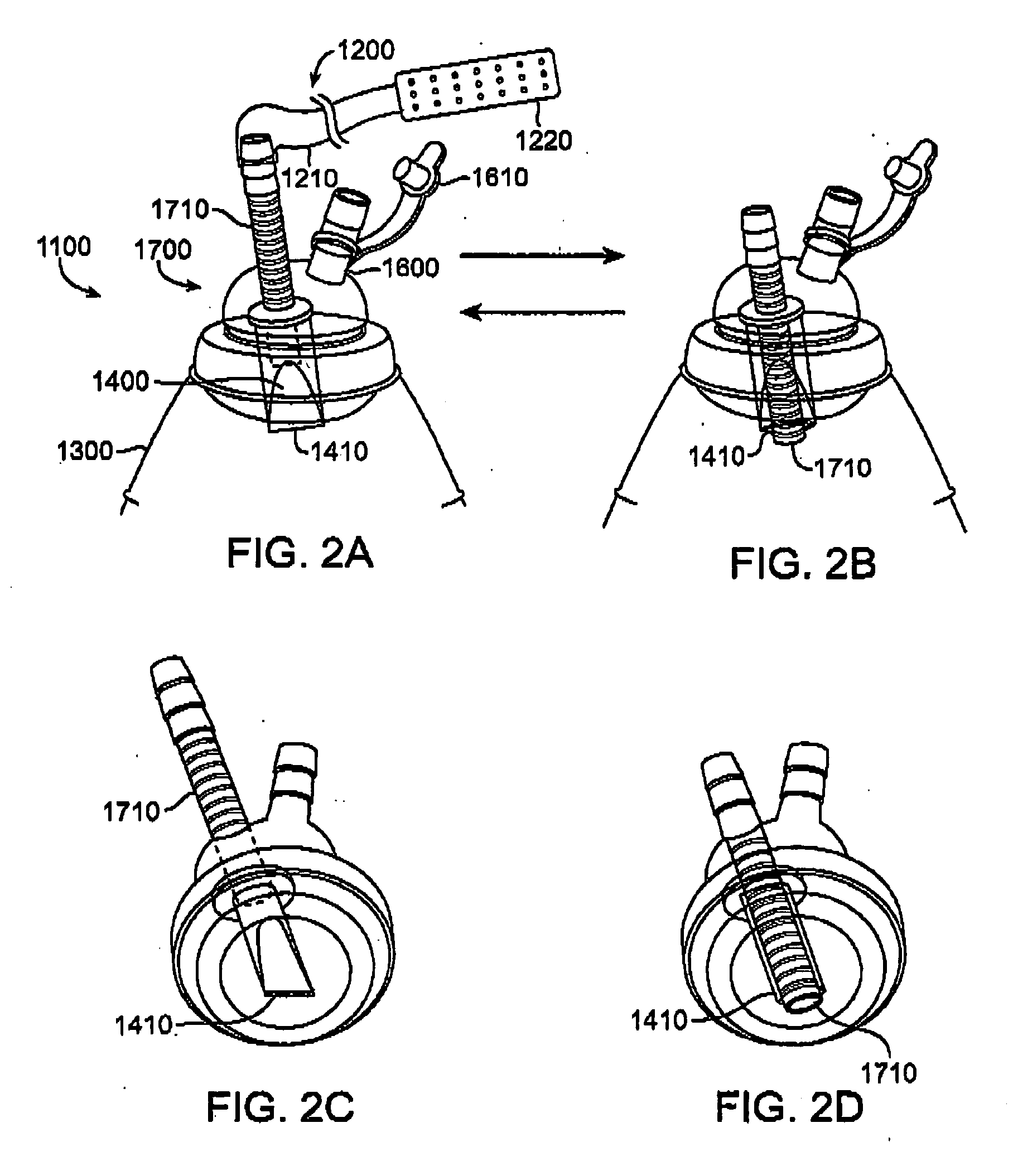

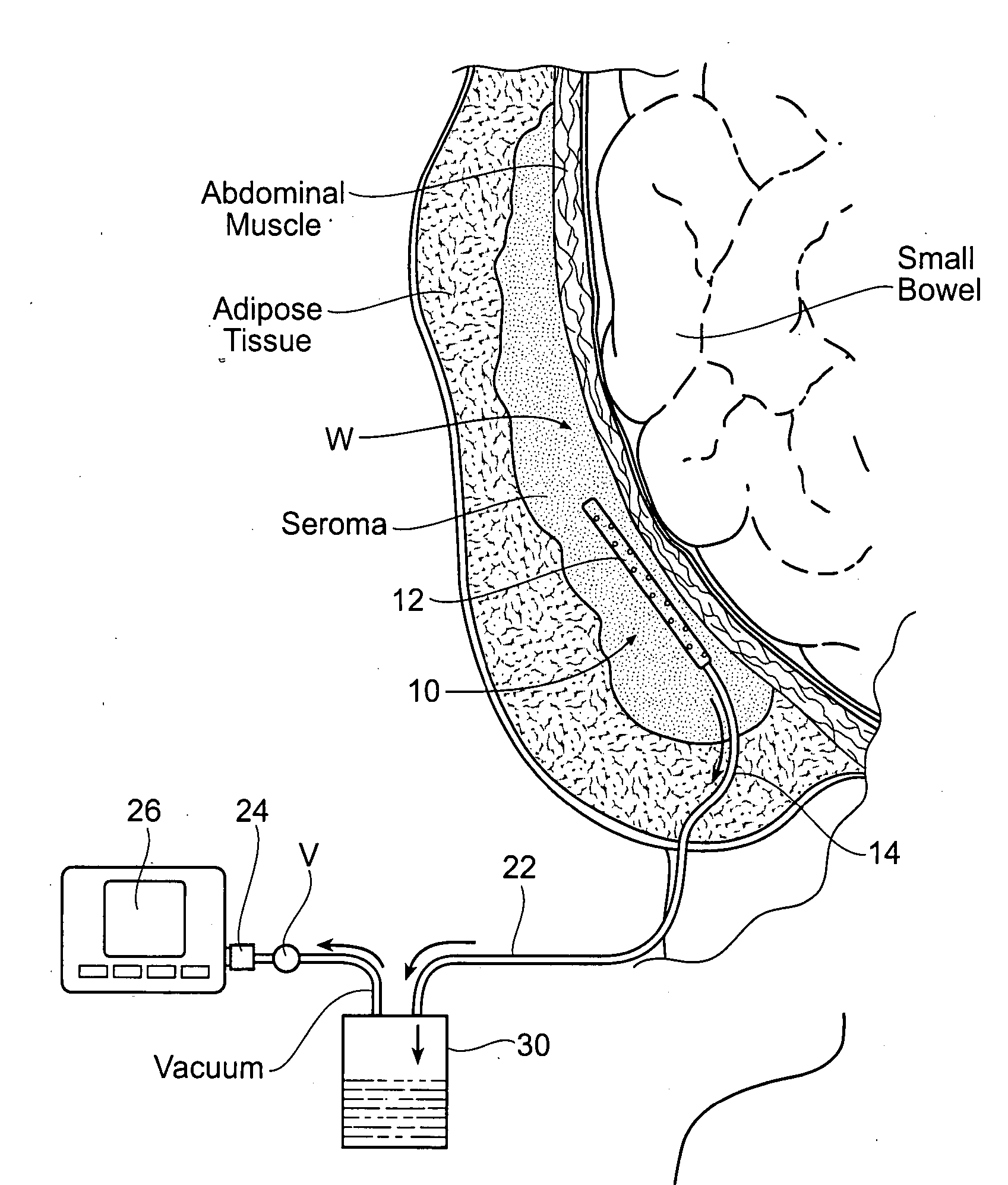

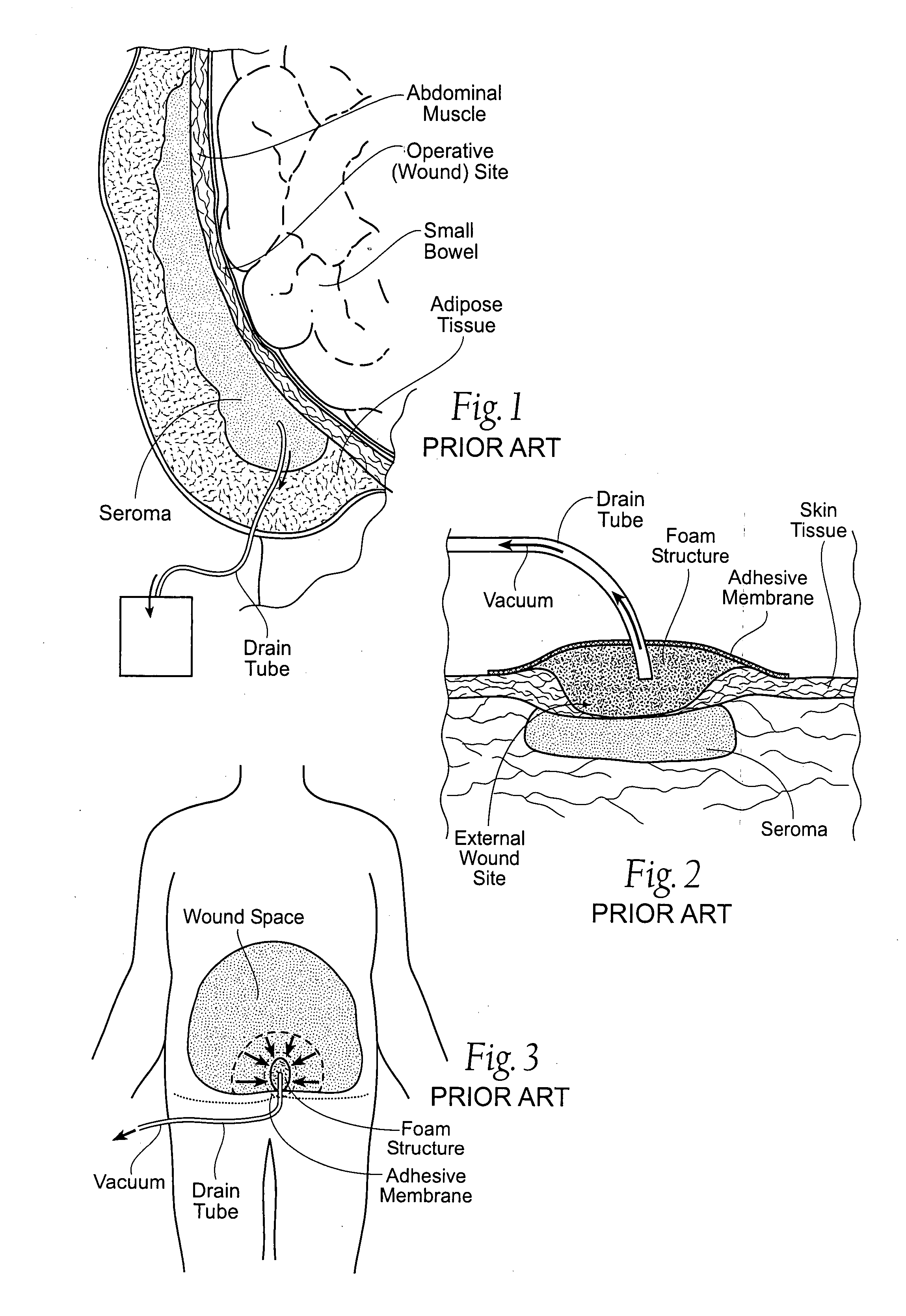

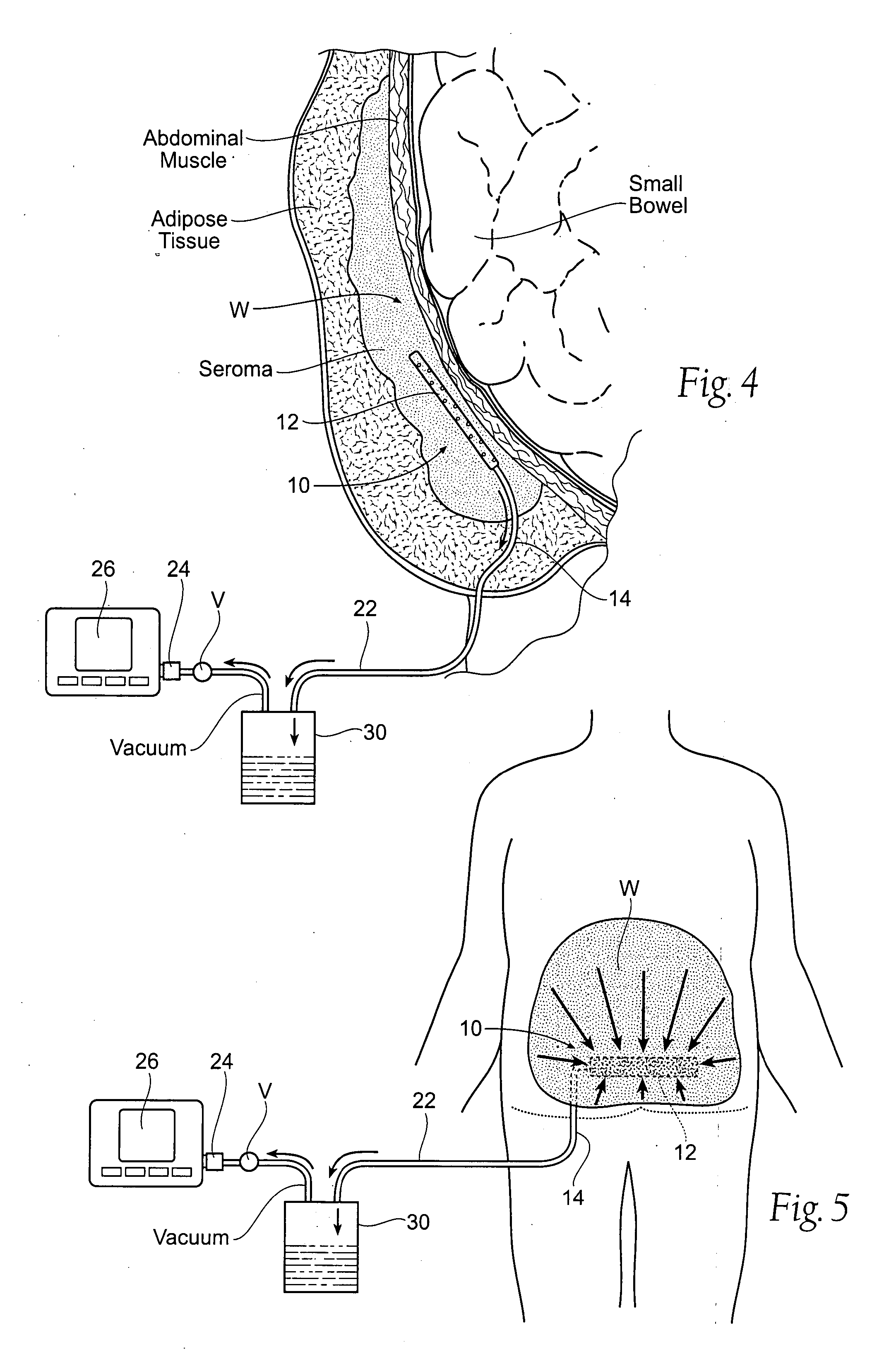

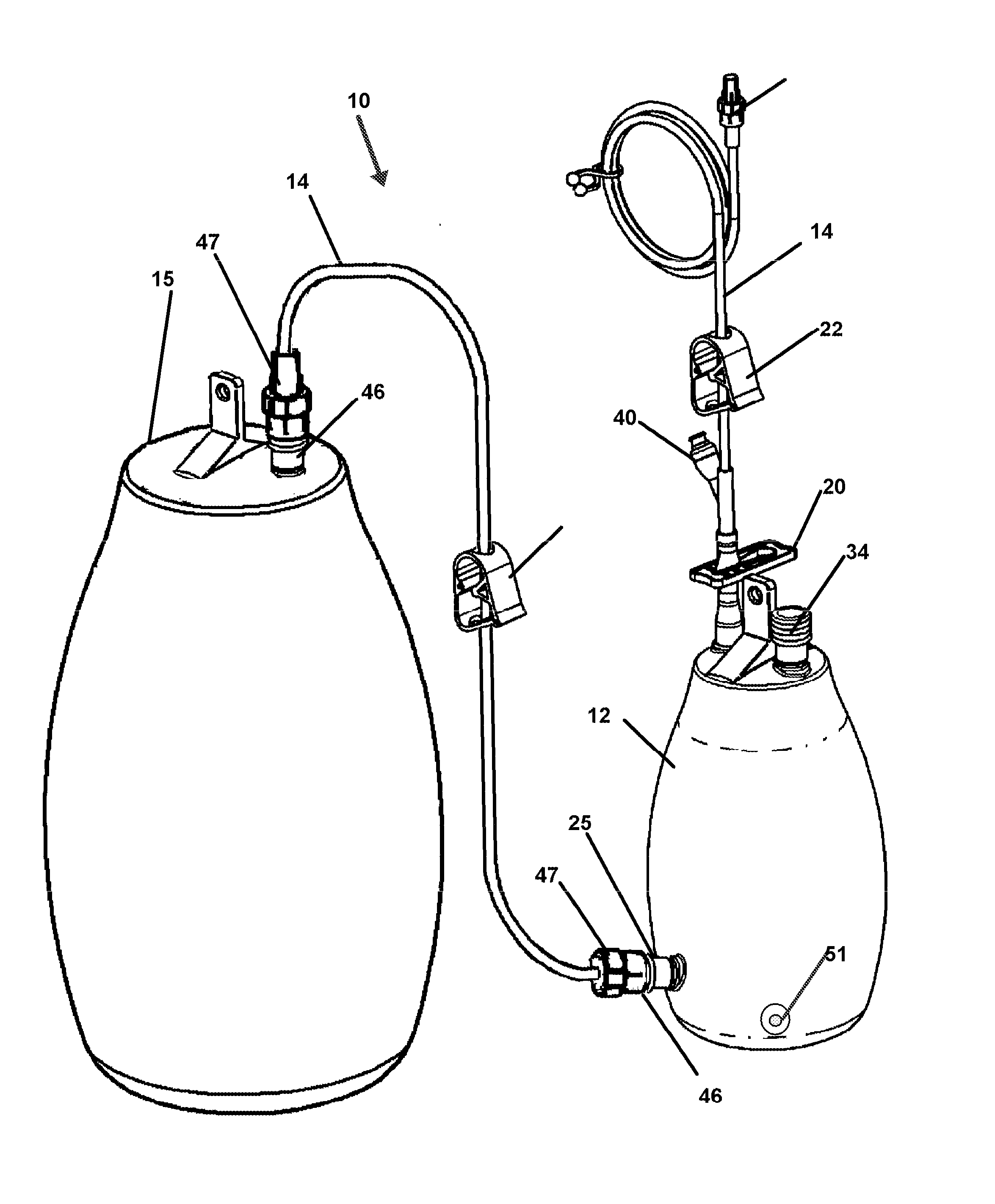

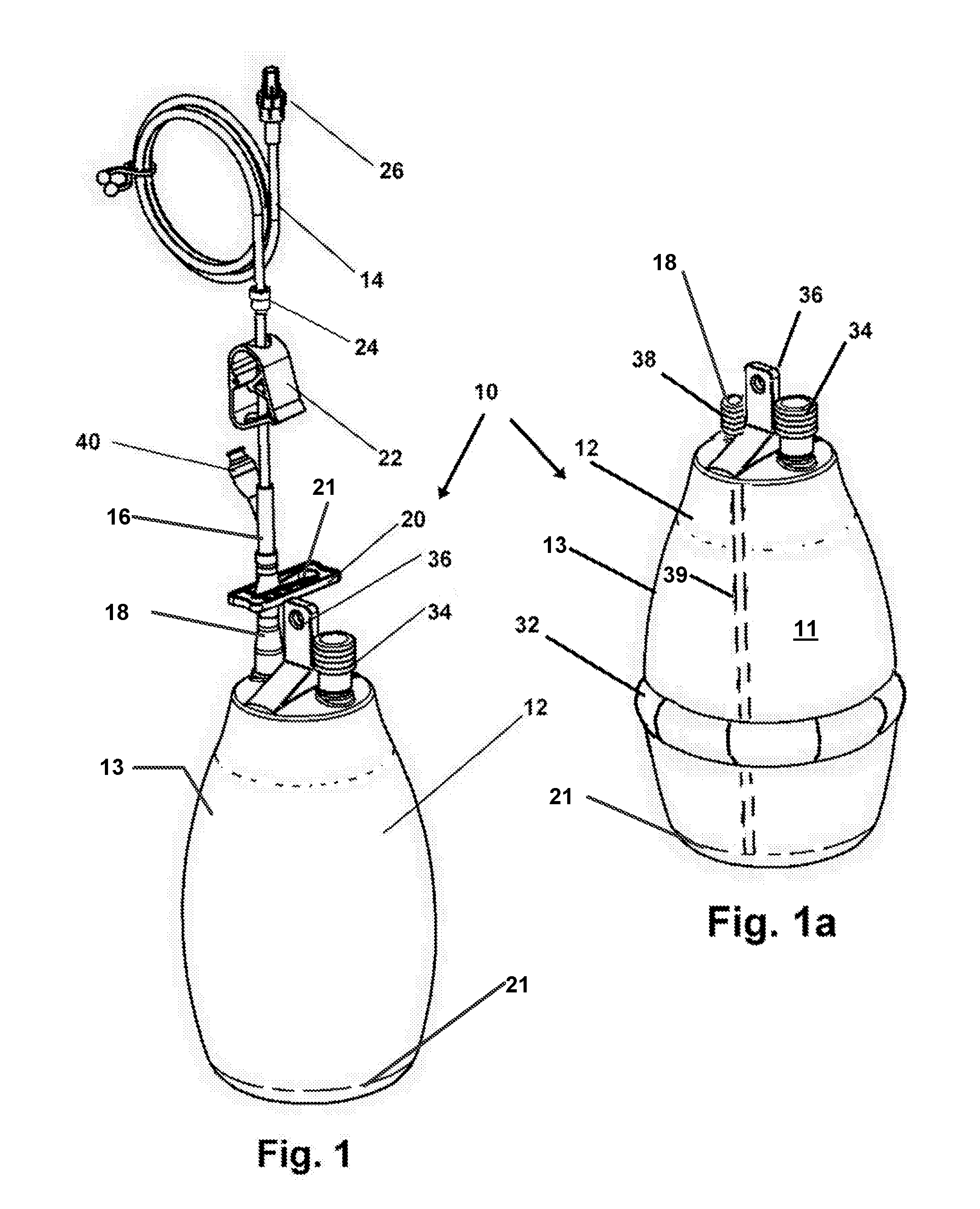

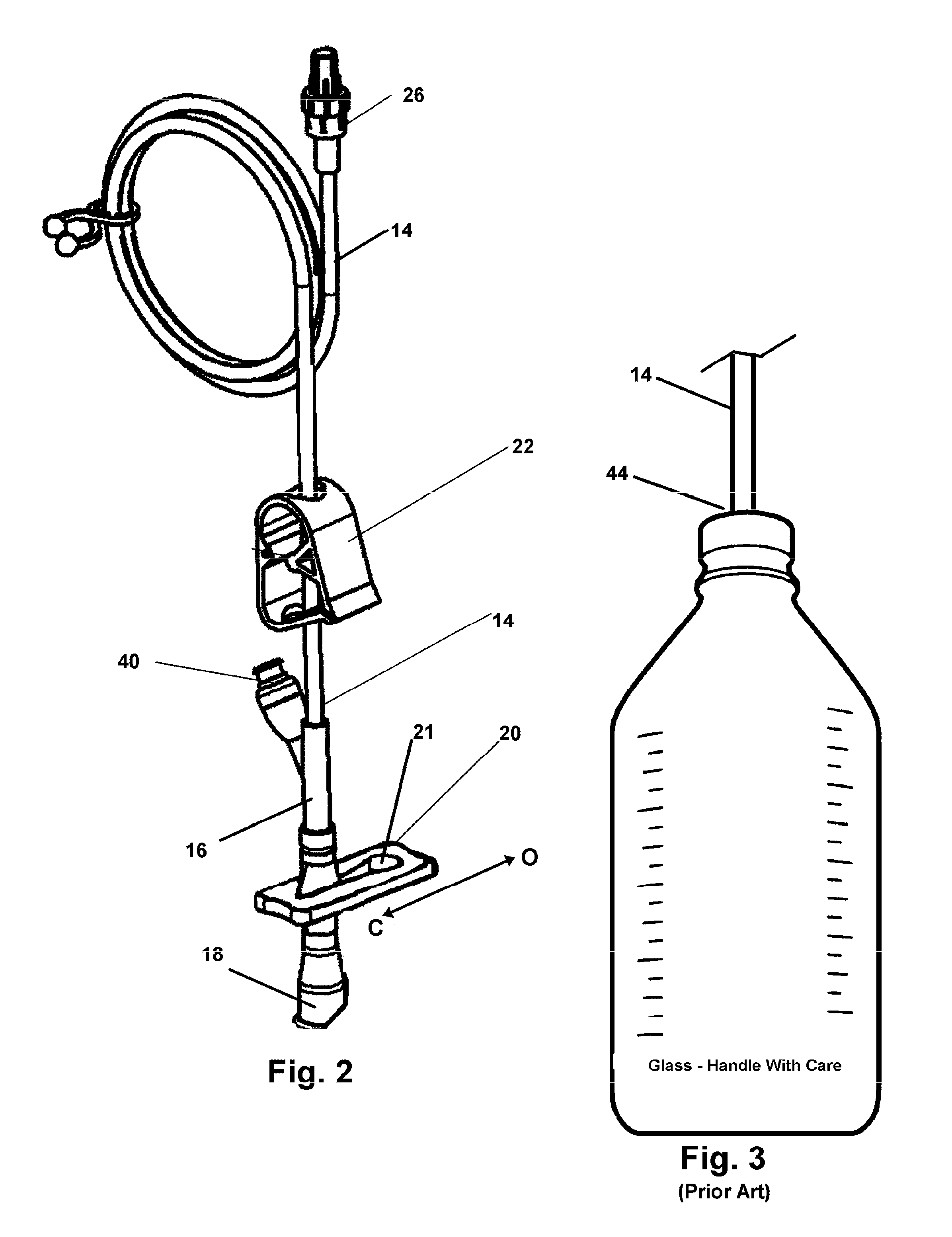

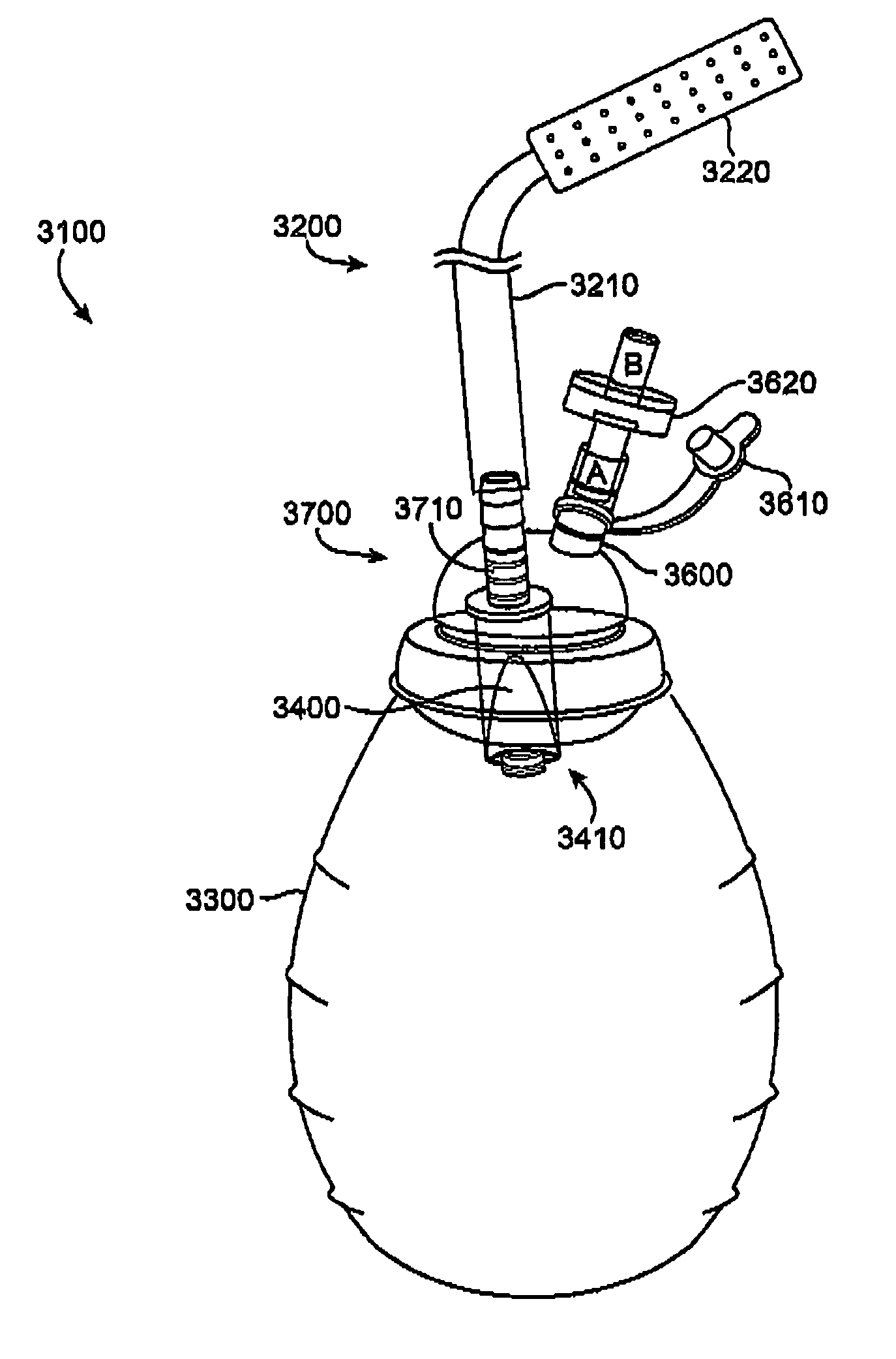

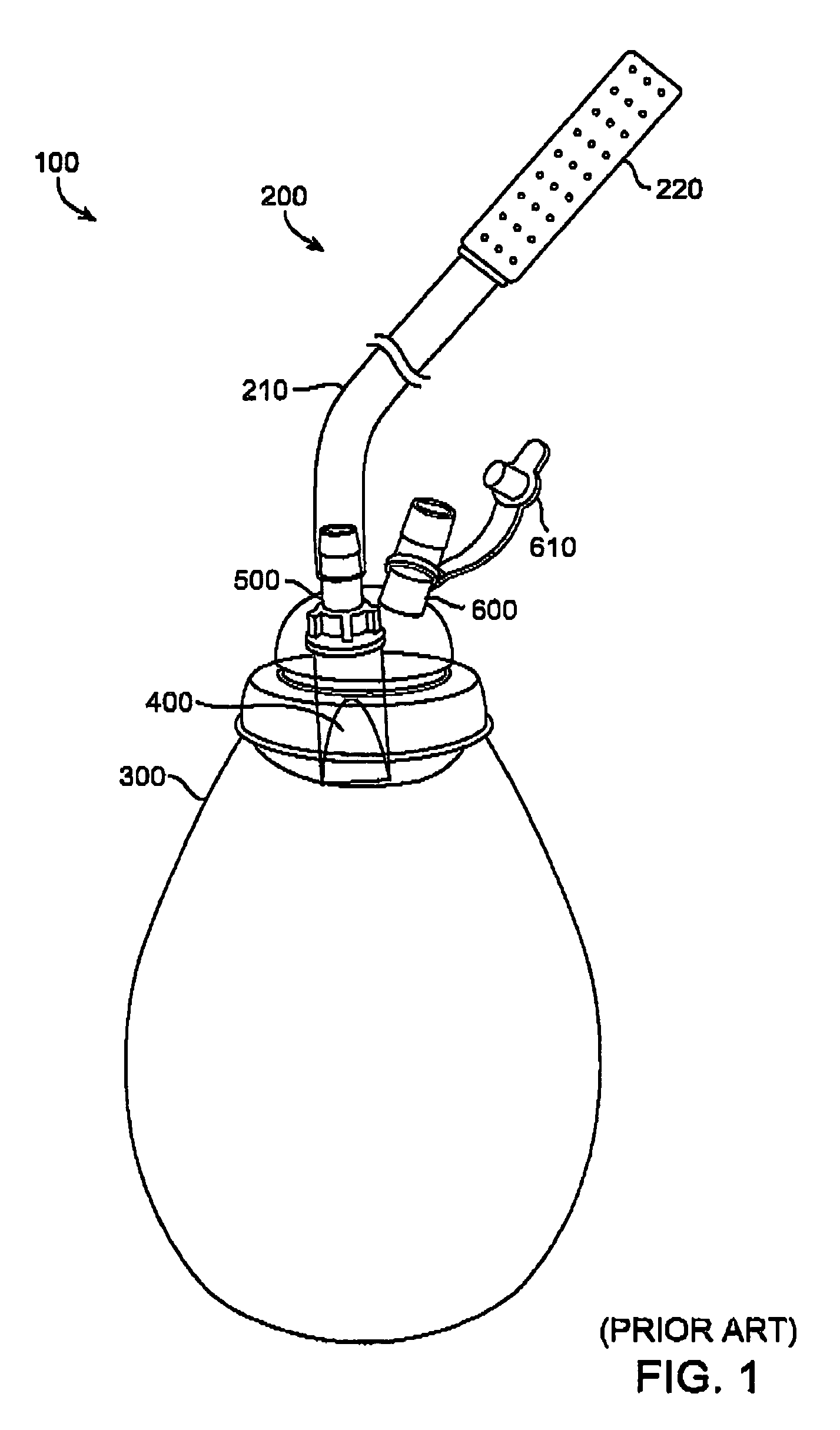

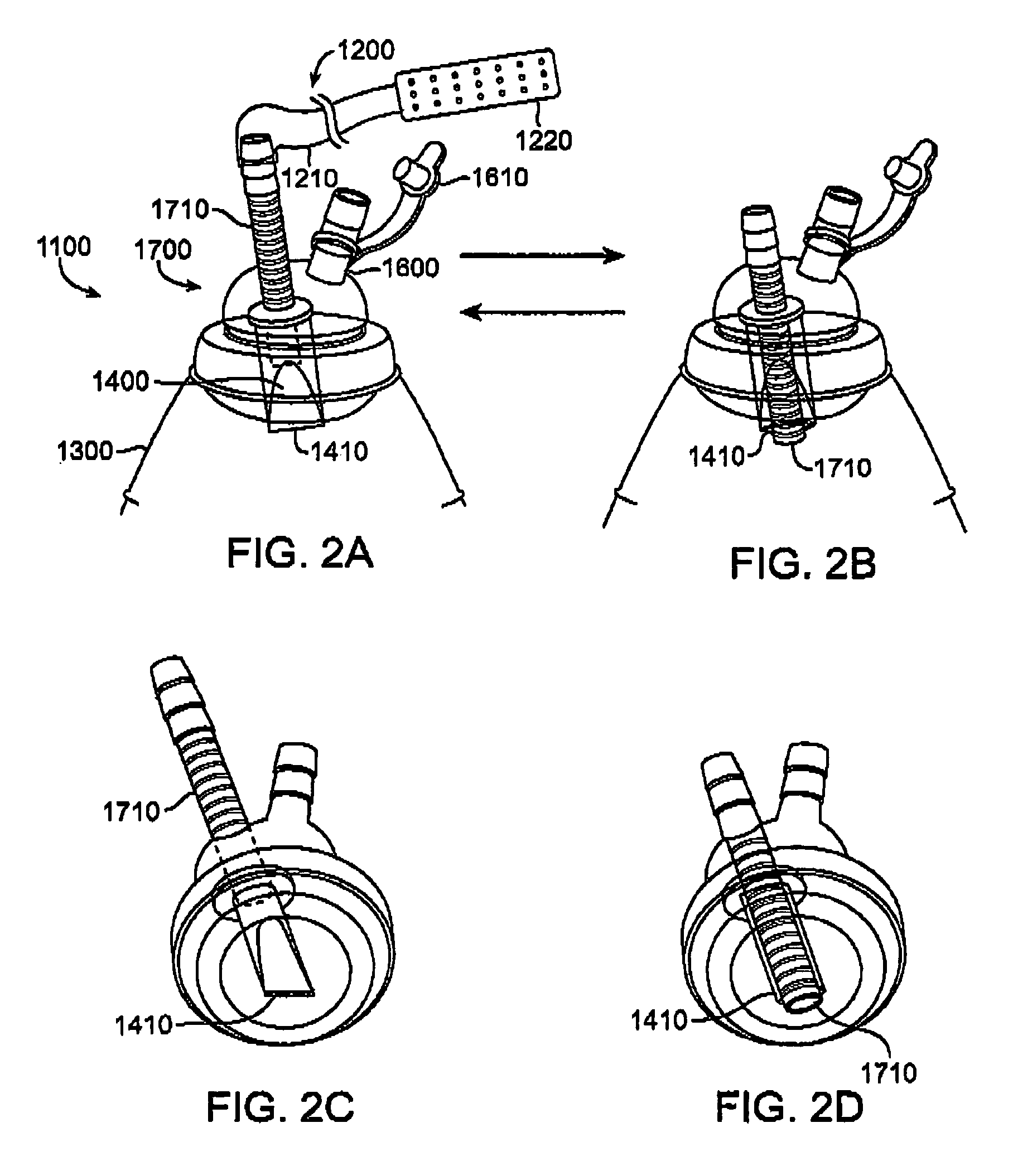

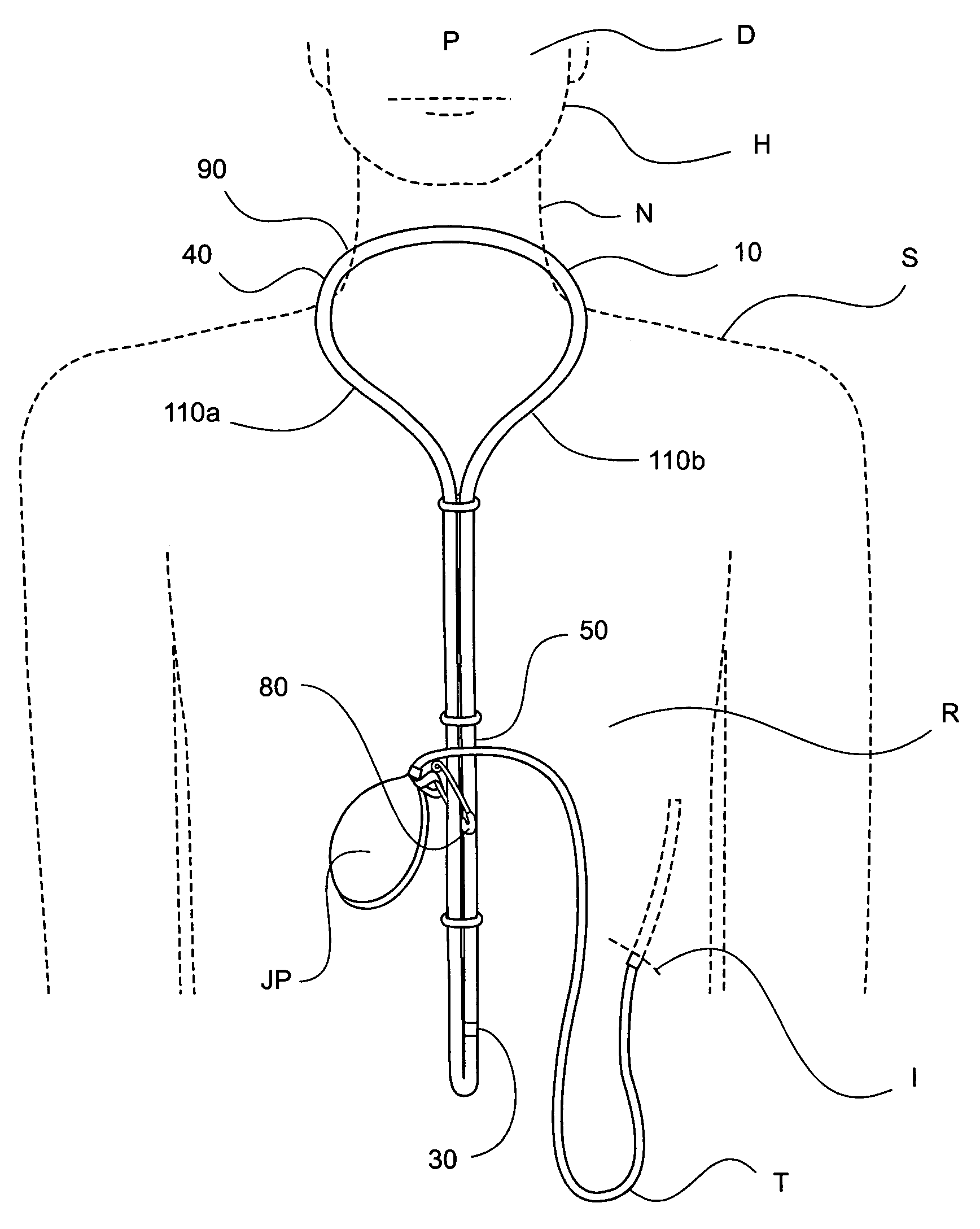

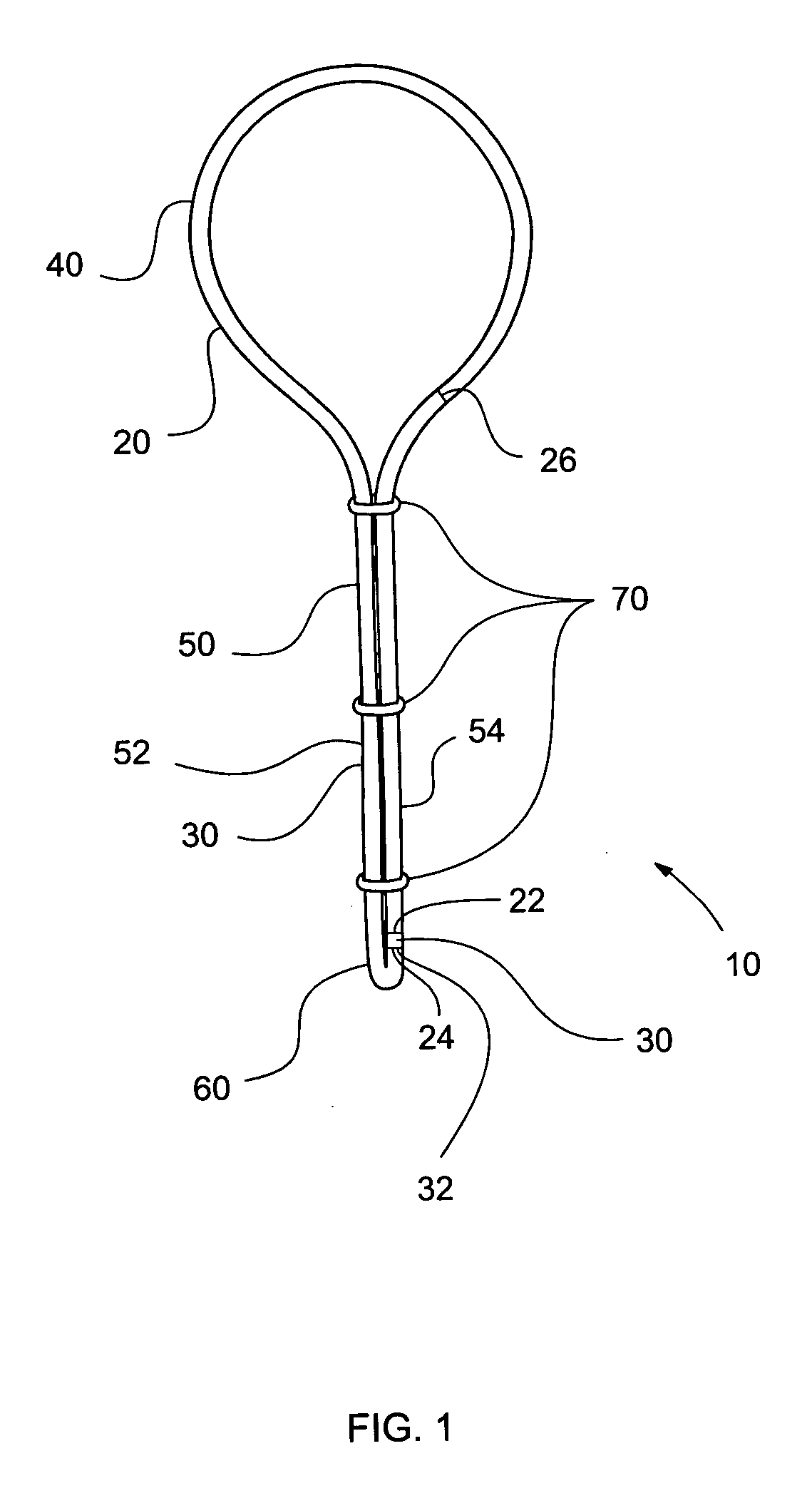

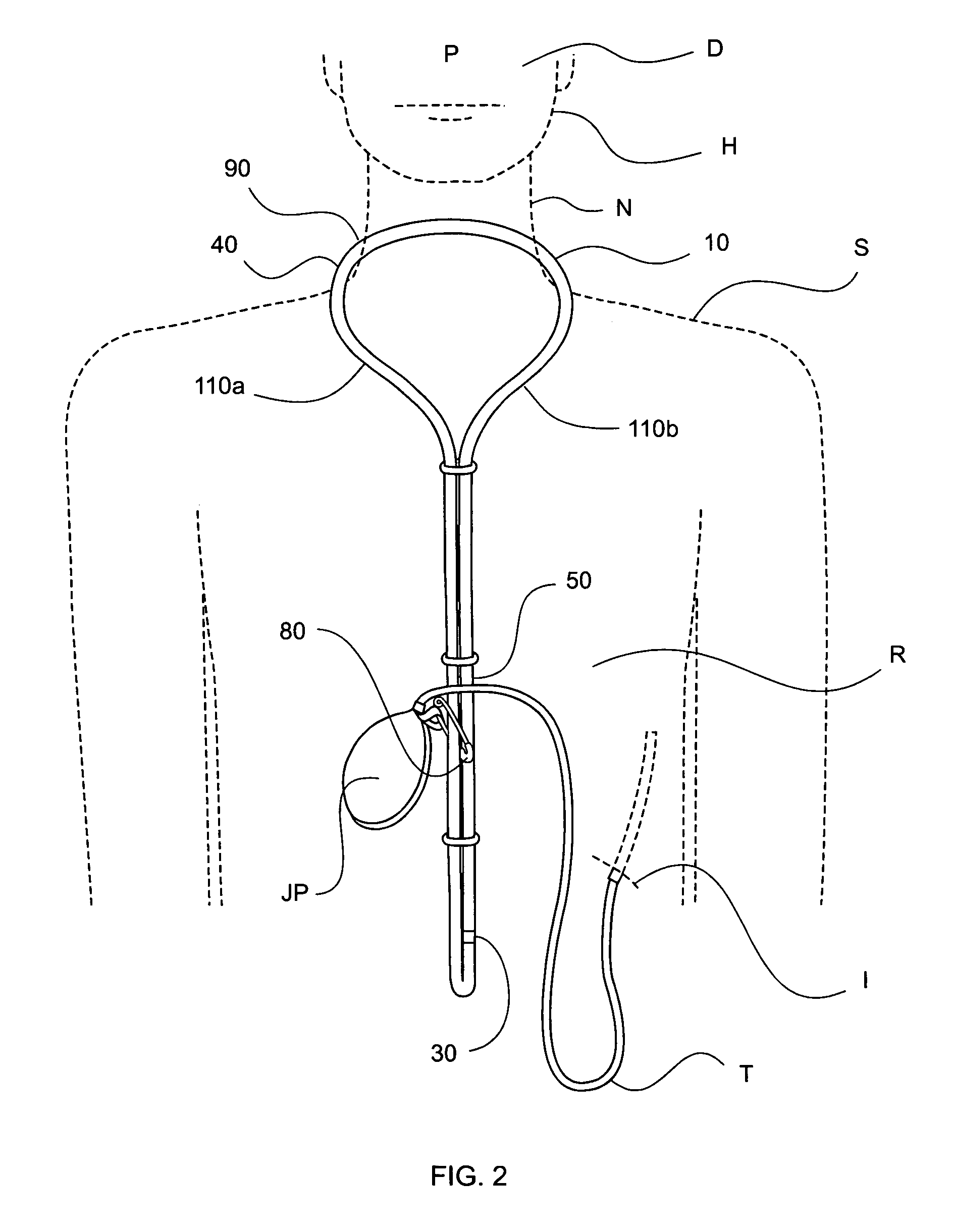

Assemblies, systems, and methods for vacuum assisted internal drainage during wound healing

ActiveUS20070282309A1Enhanced wound healing benefitDecreasing tissue edema of tissueWound drainsIntravenous devicesVacuum assistedMedicine

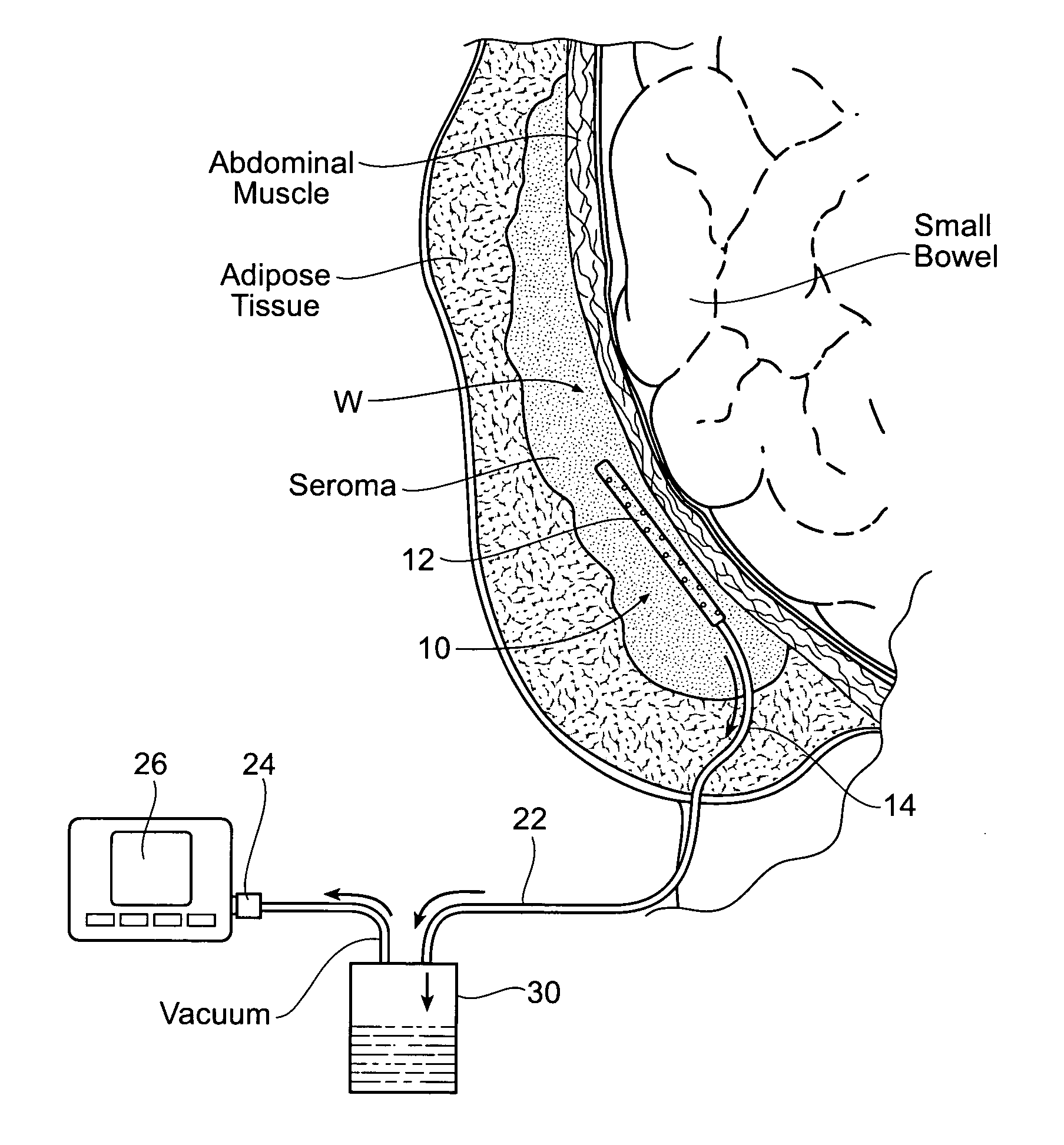

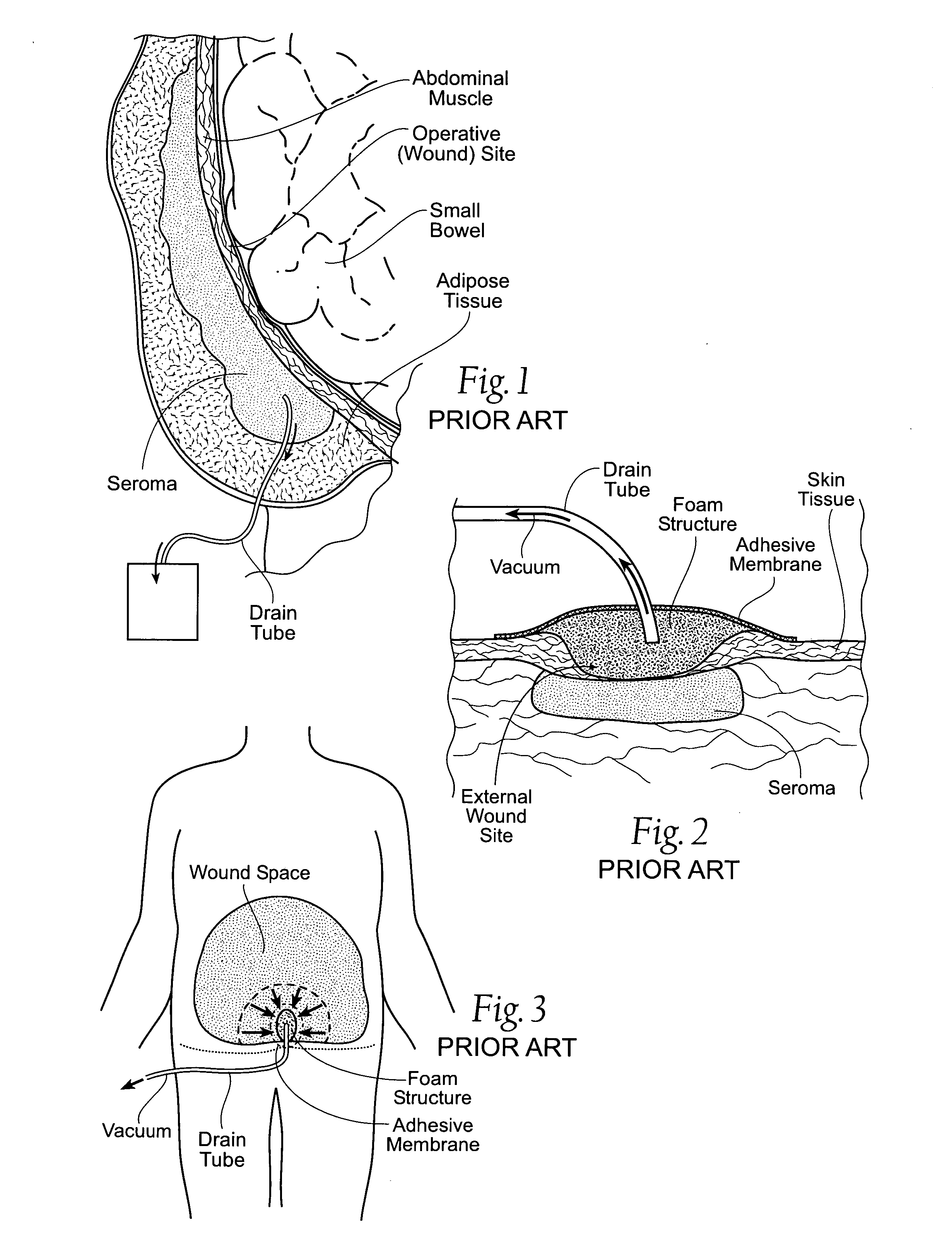

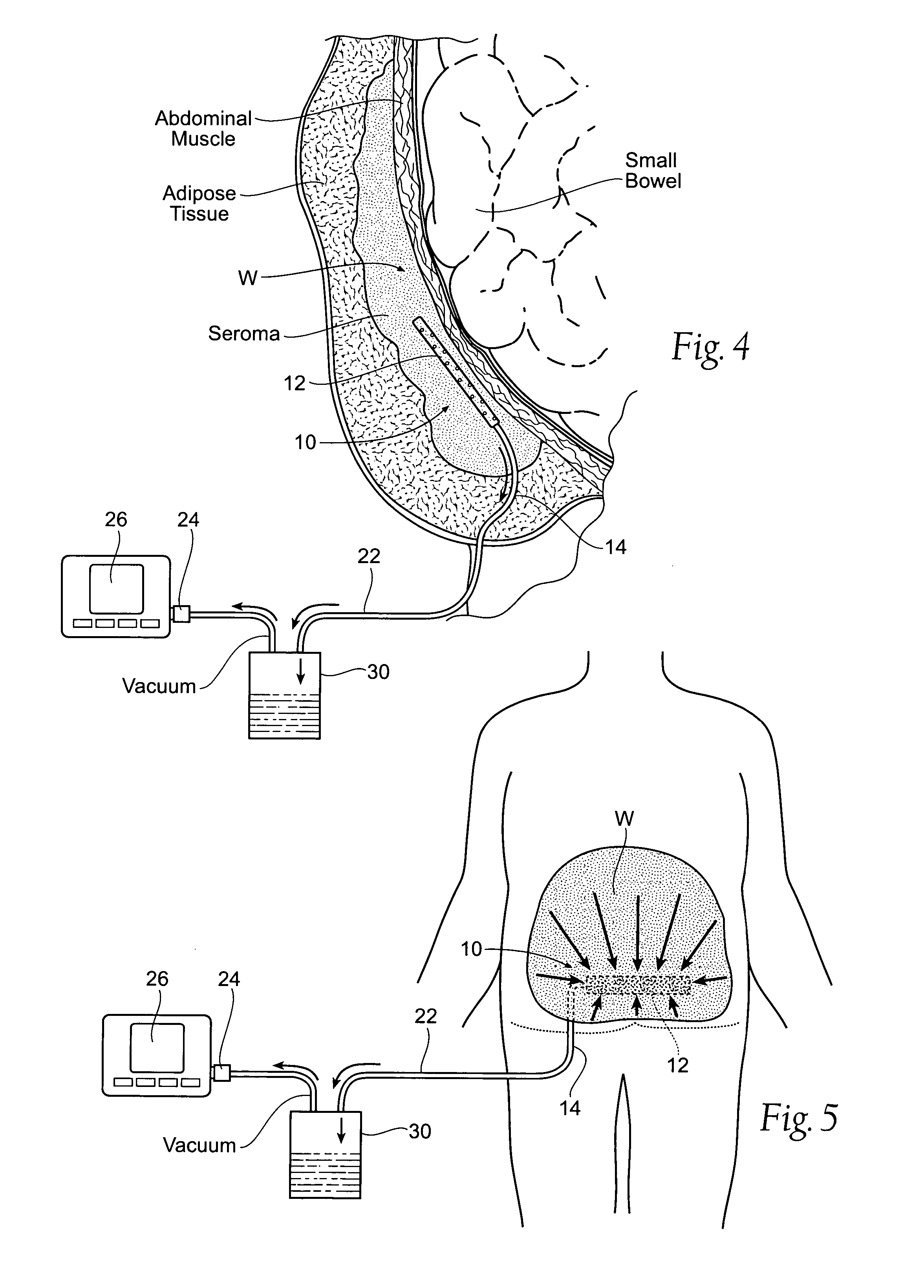

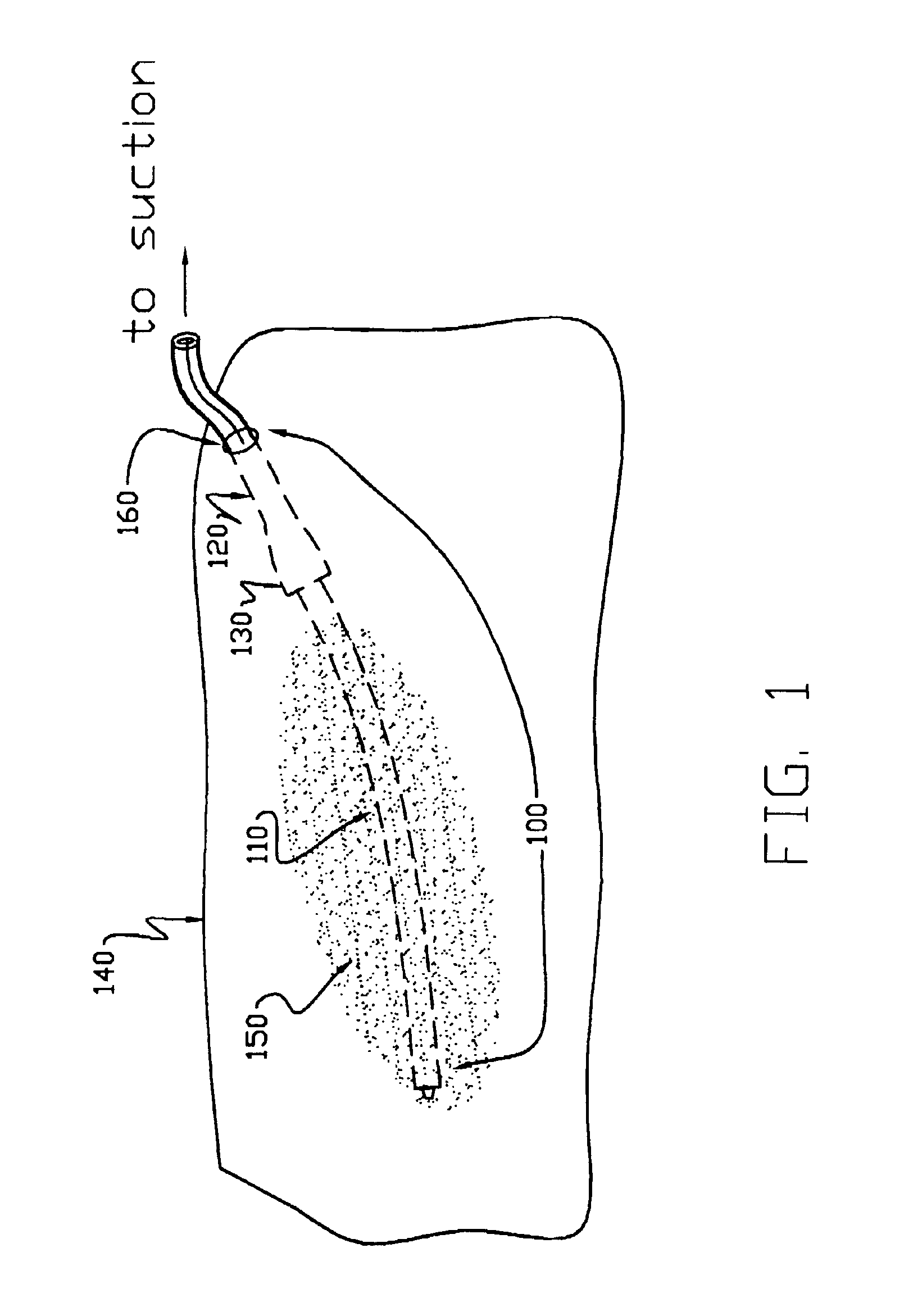

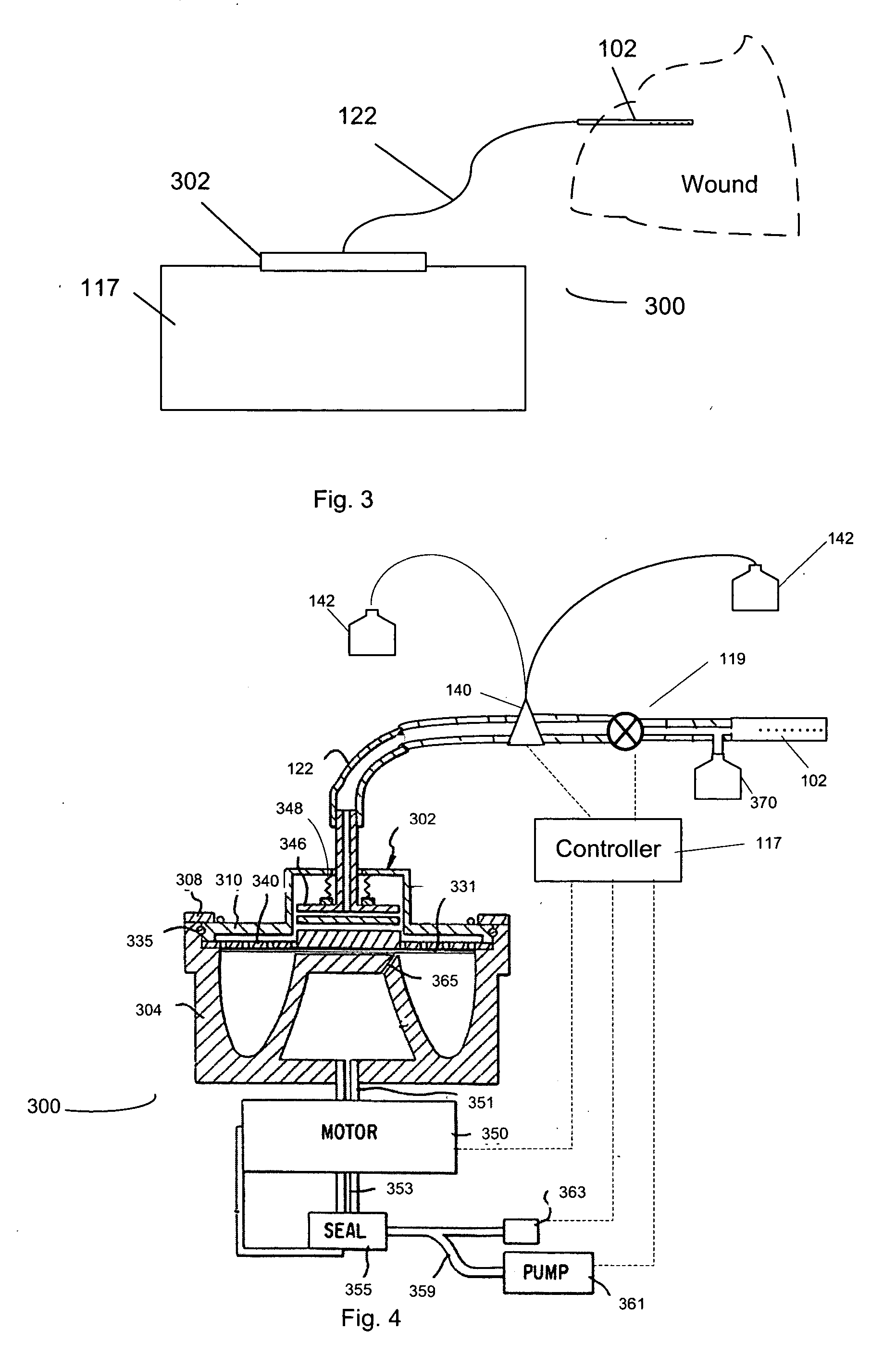

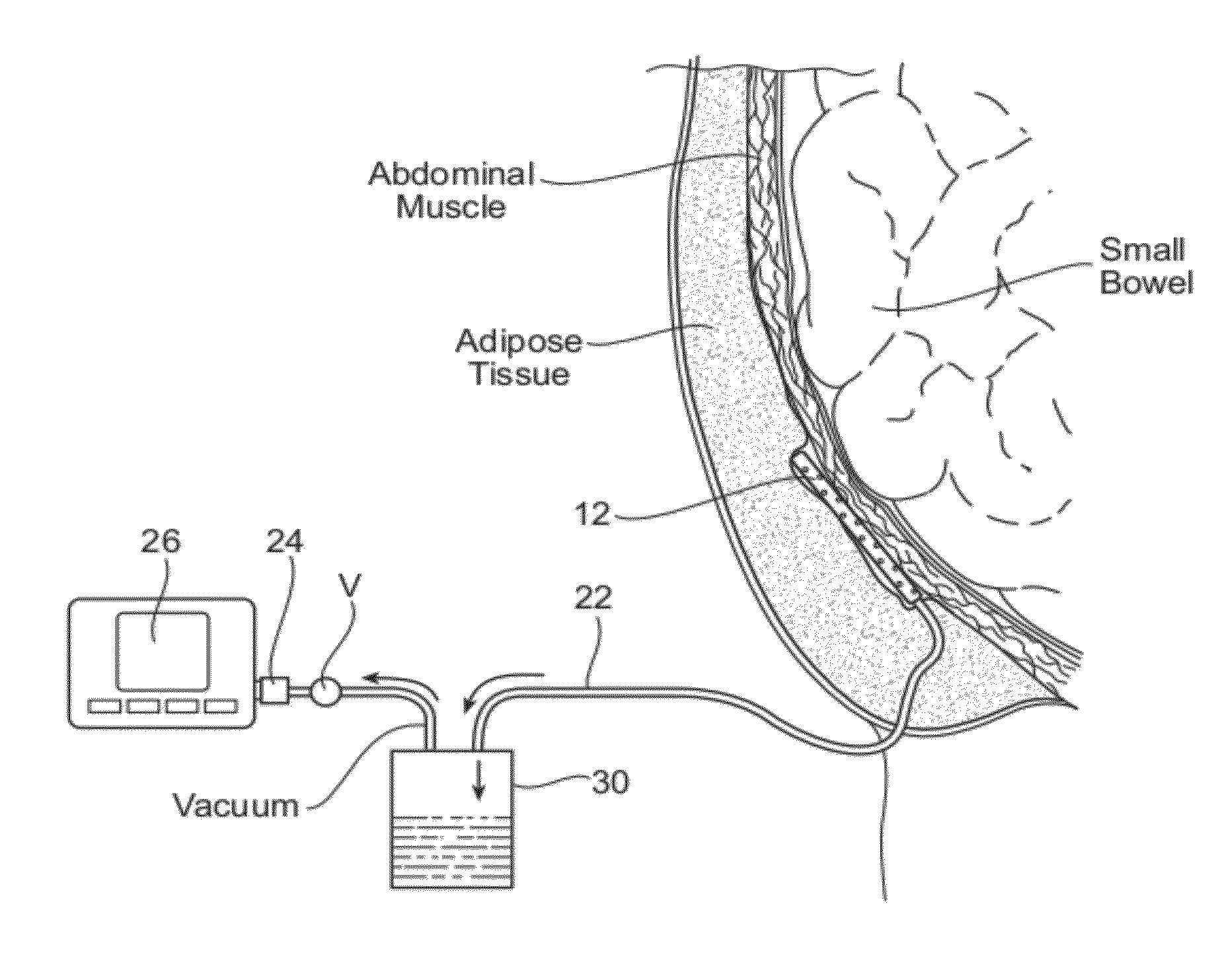

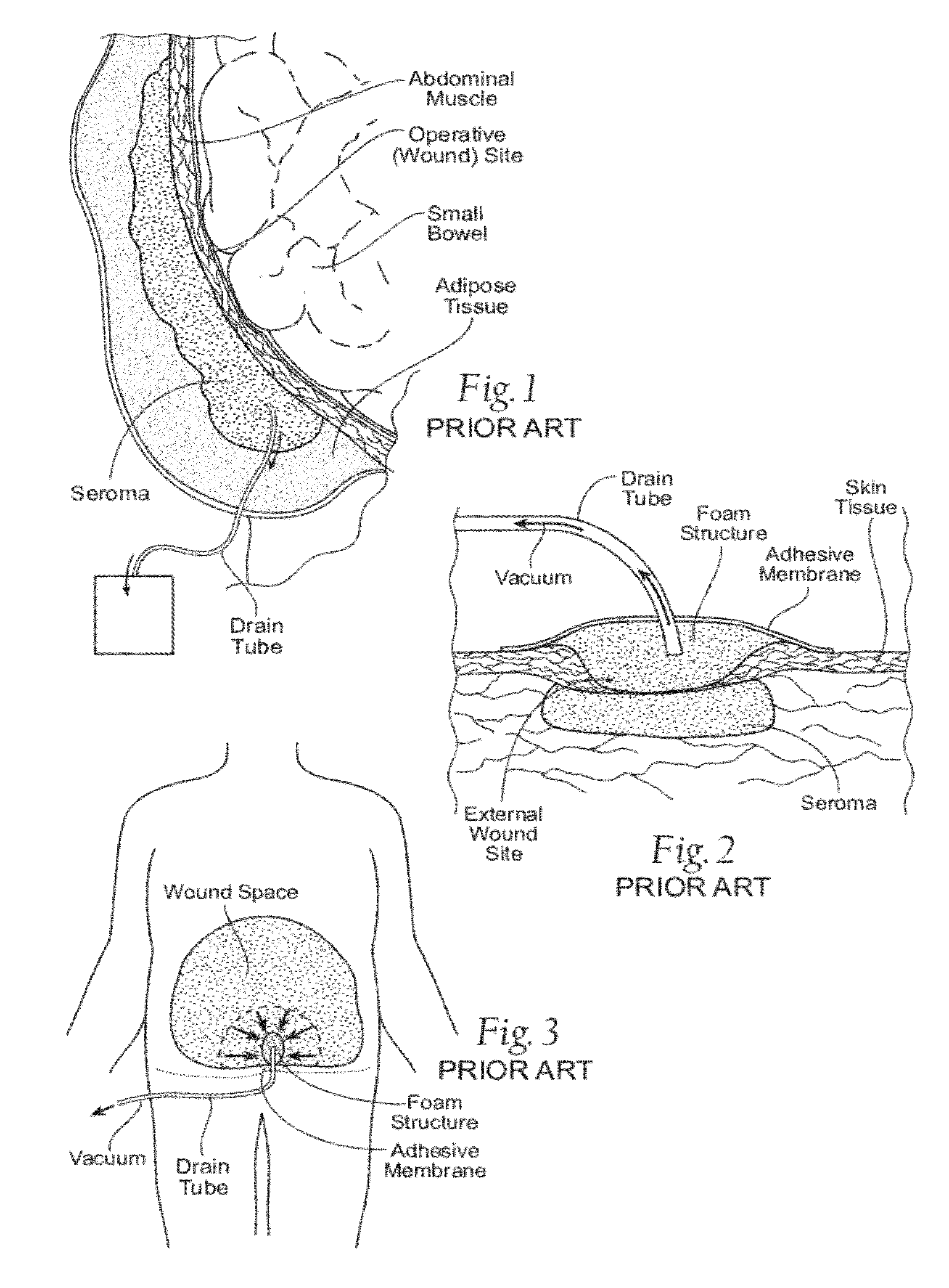

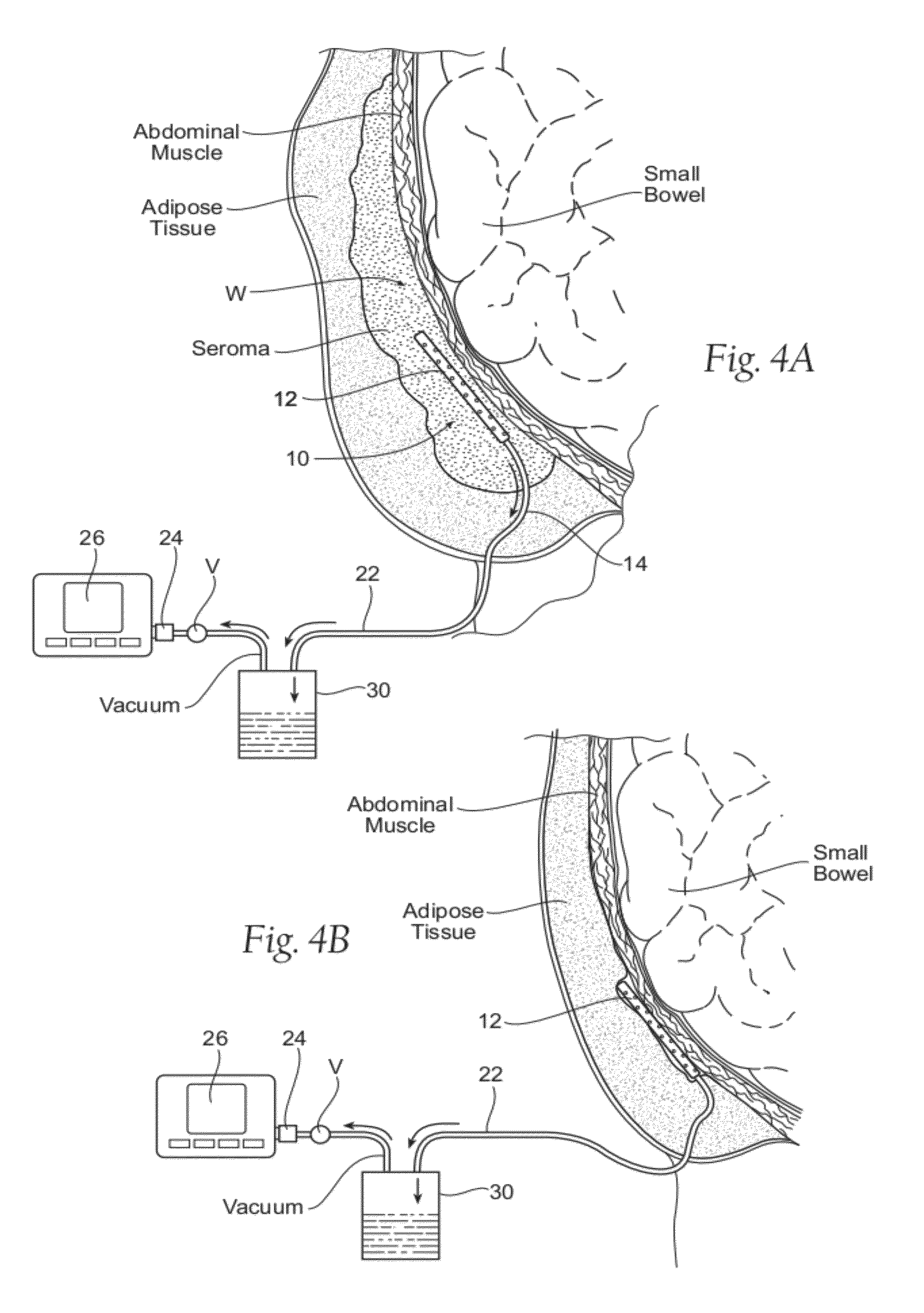

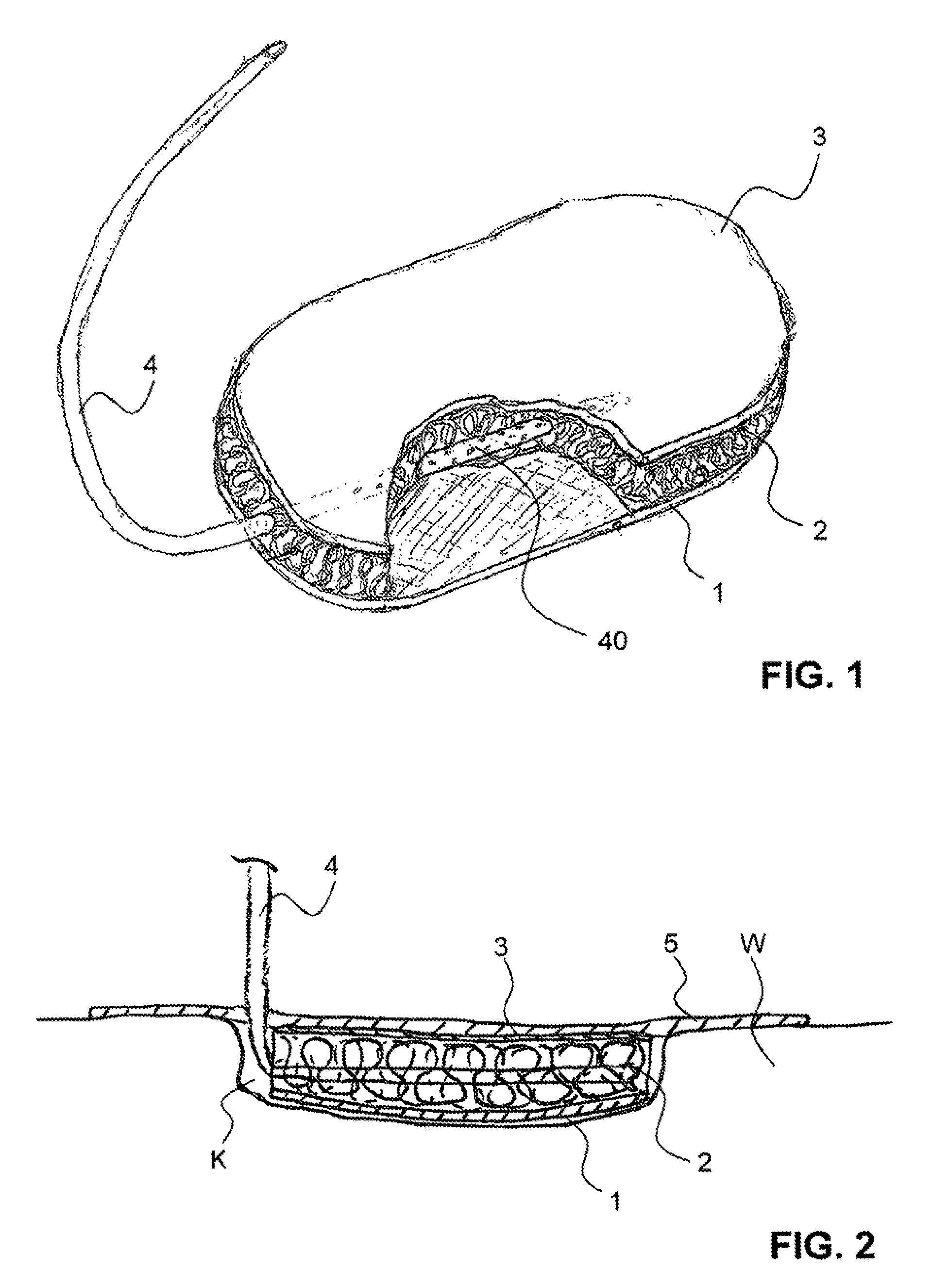

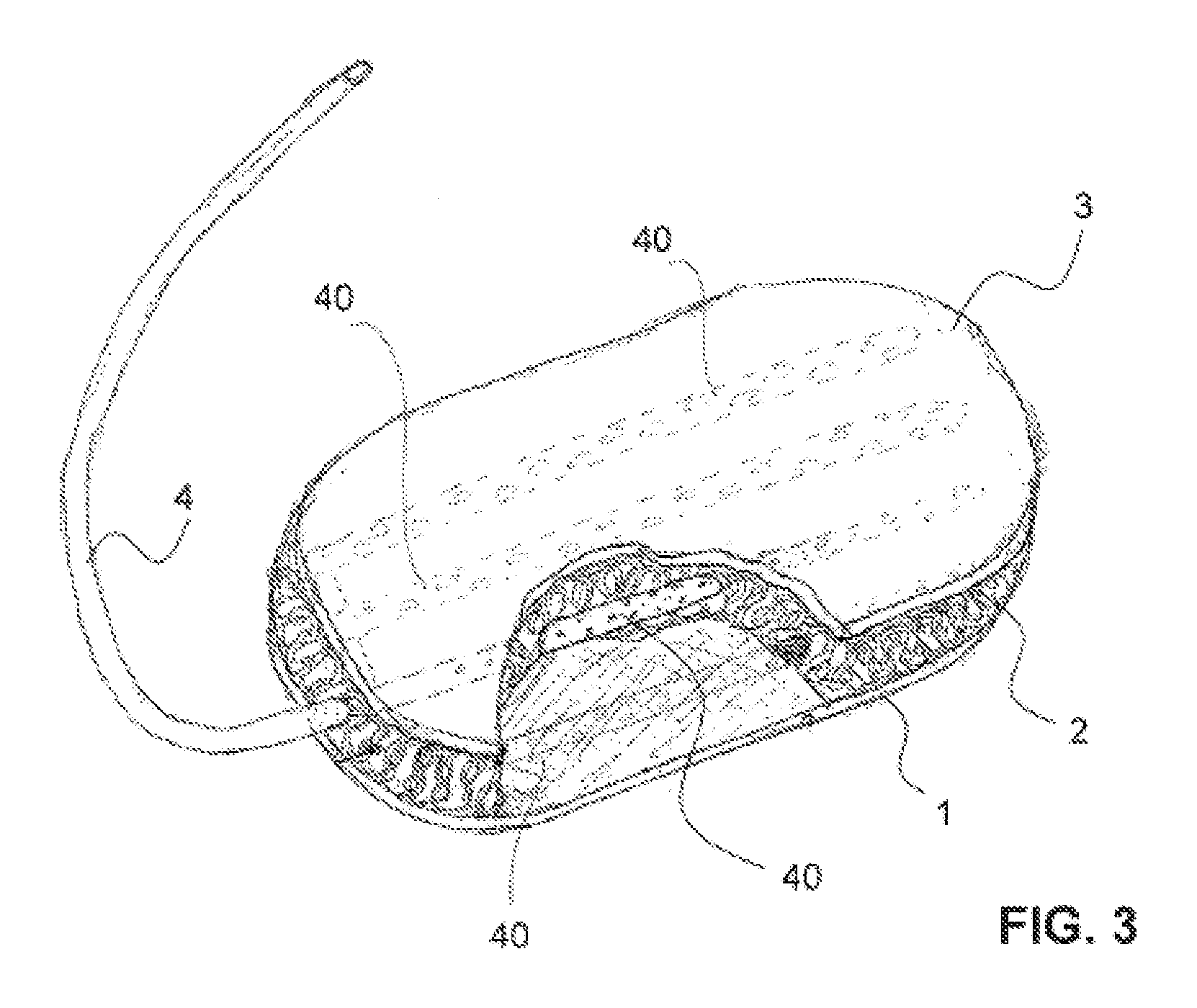

Assemblies, systems, and methods convey fluid from an internal wound site or body cavity by applying negative pressure from a source outside the internal wound site or body cavity through a wound drain assembly that is placed directly inside the internal wound site or body cavity.

Owner:IC SURGICAL INC

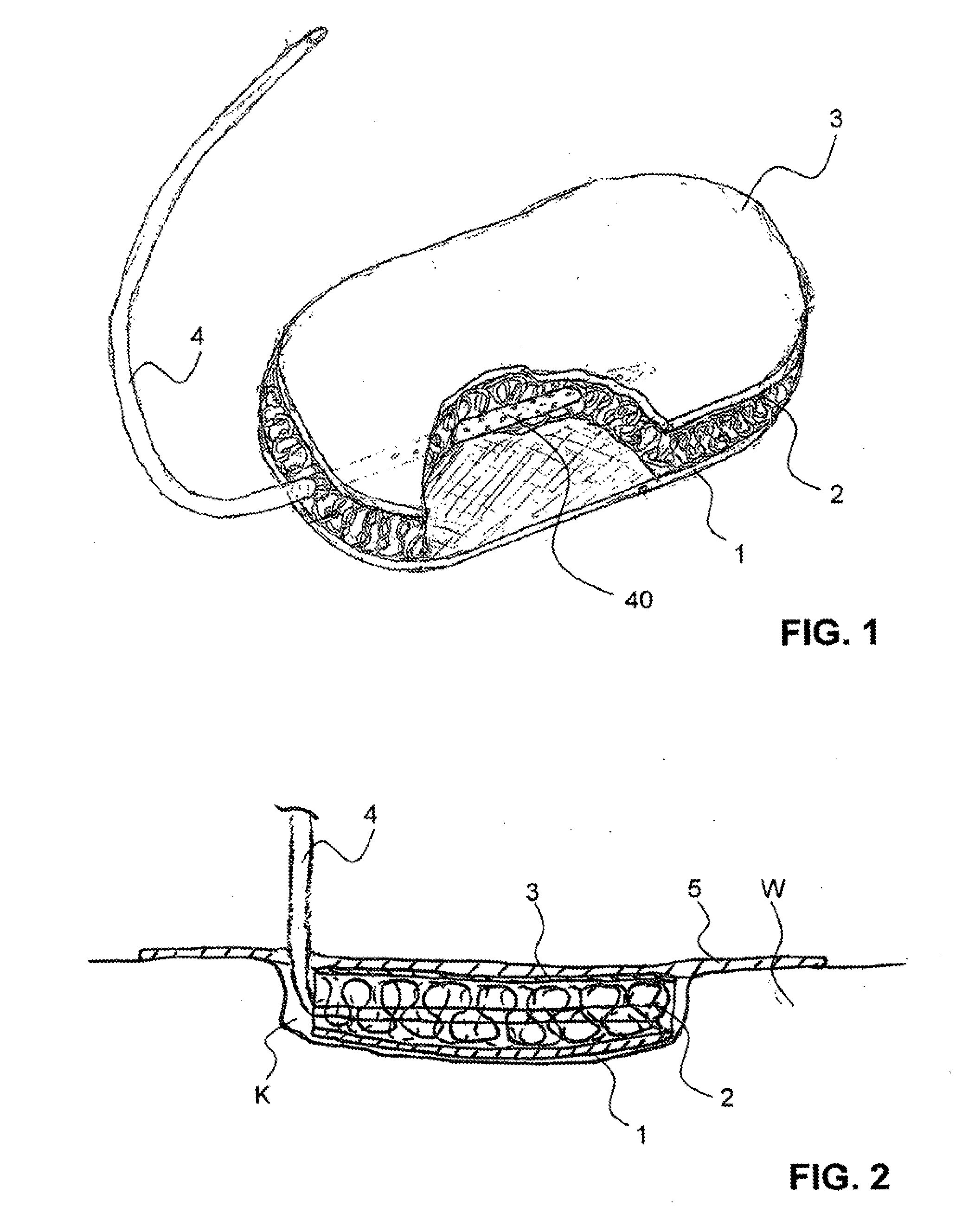

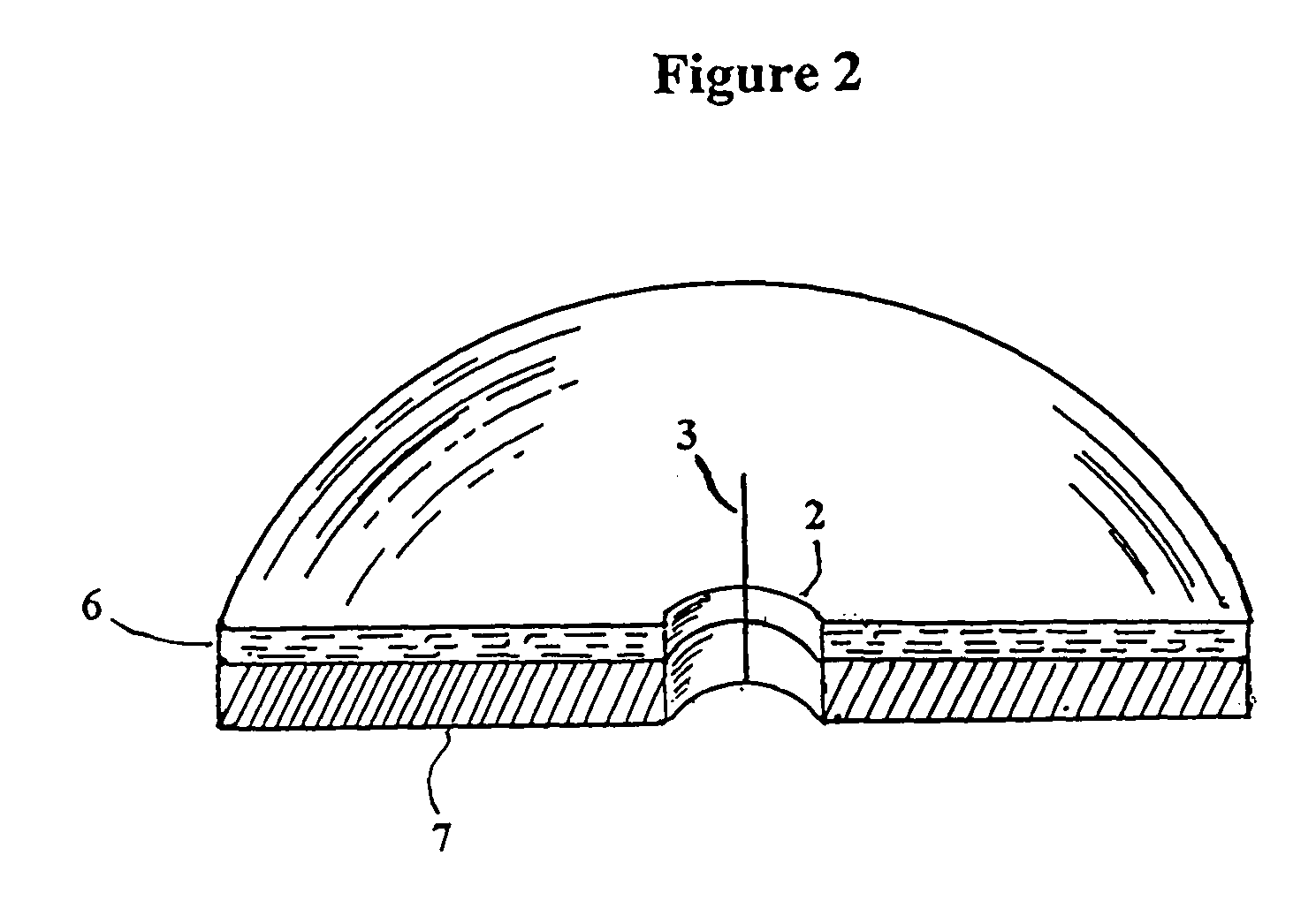

Wound drainage dressing

ActiveUS20100262091A1Easy constructionEasy to transportSurgical needlesPlastersSecretionBiomedical engineering

The invention relates to a wound drainage covering for covering, by means of low pressure, a wound that is to be treated. The covering comprises at least two layers that are superimposed. A first layer that is applied on the side of the wound is made of a functional textile material and second layer that is arranged thereon is dimensionally stable and permeable to liquid. The wound drainage covering has a simple design and due to the functional first layer, is effective and ensures, due to the dimensionally stable second layer, an optimal removal of wound secretion.

Owner:MEDELA HLDG AG

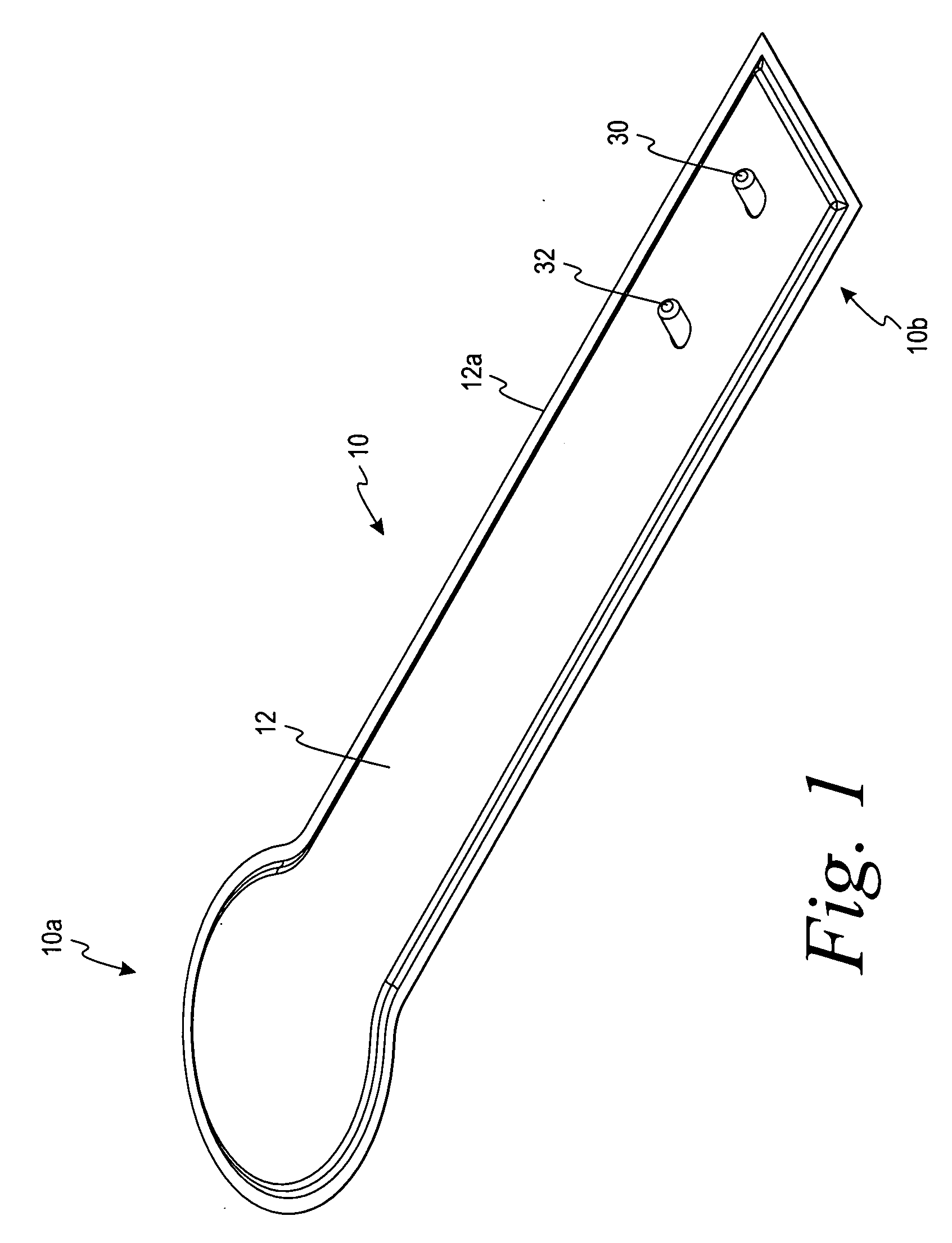

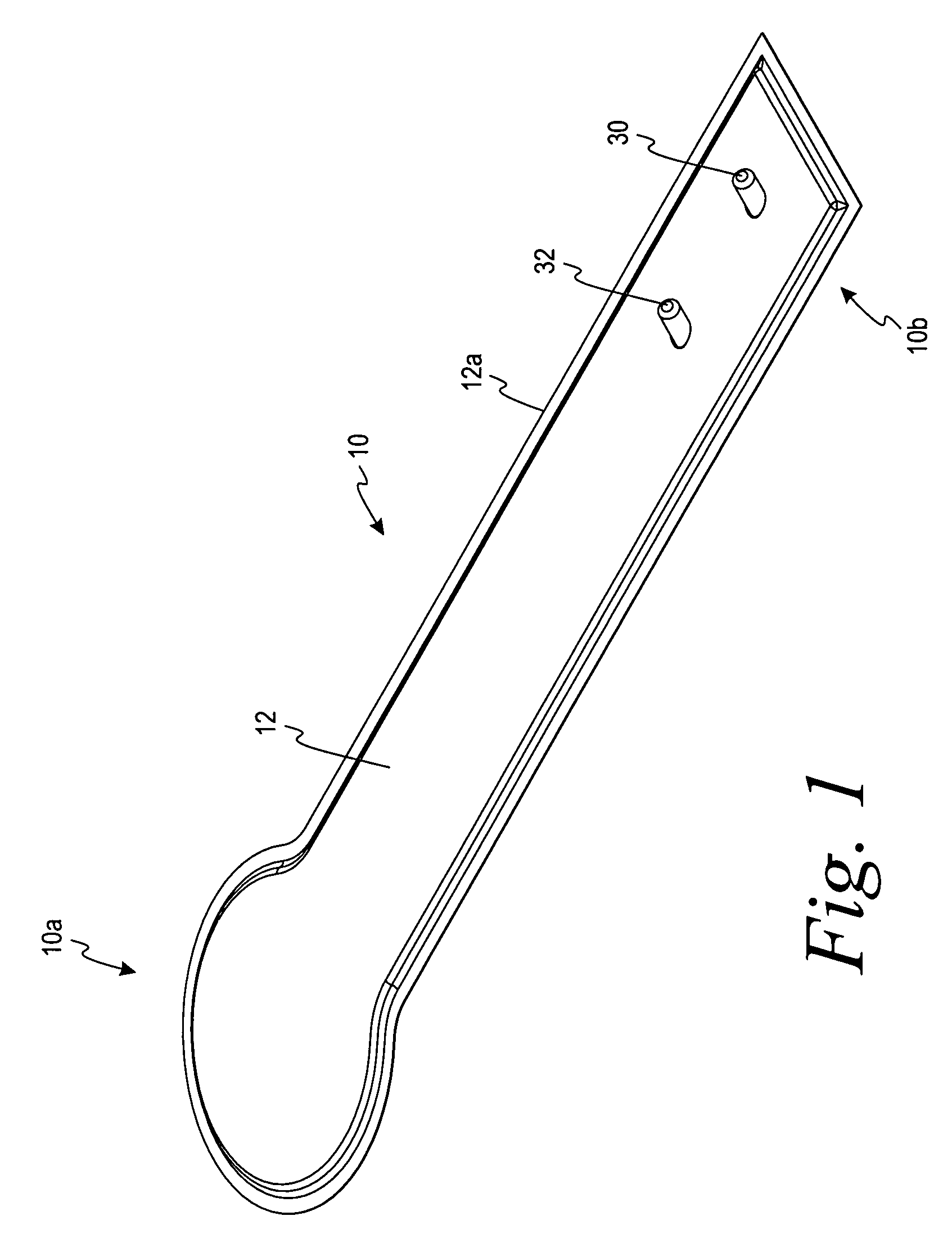

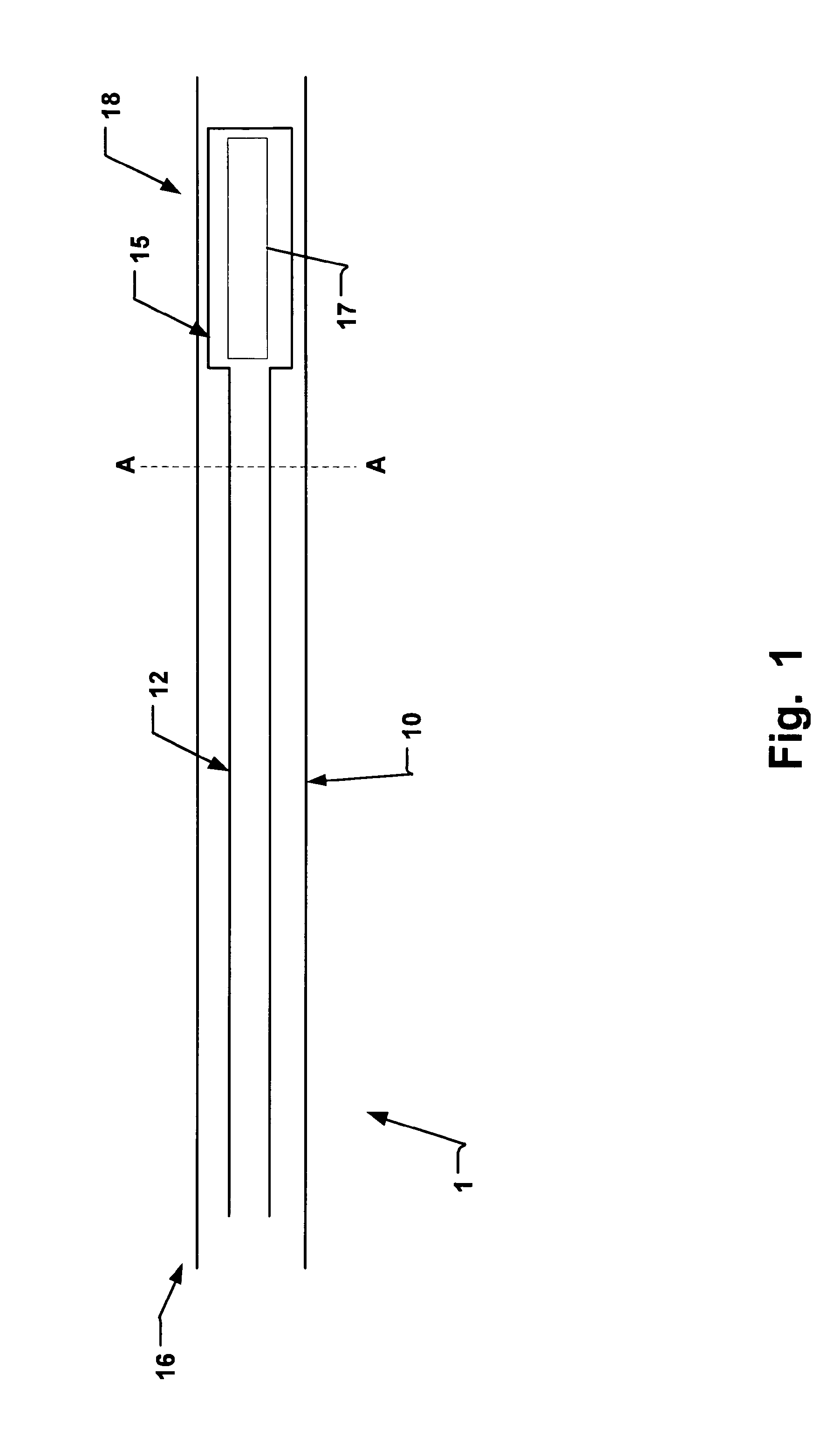

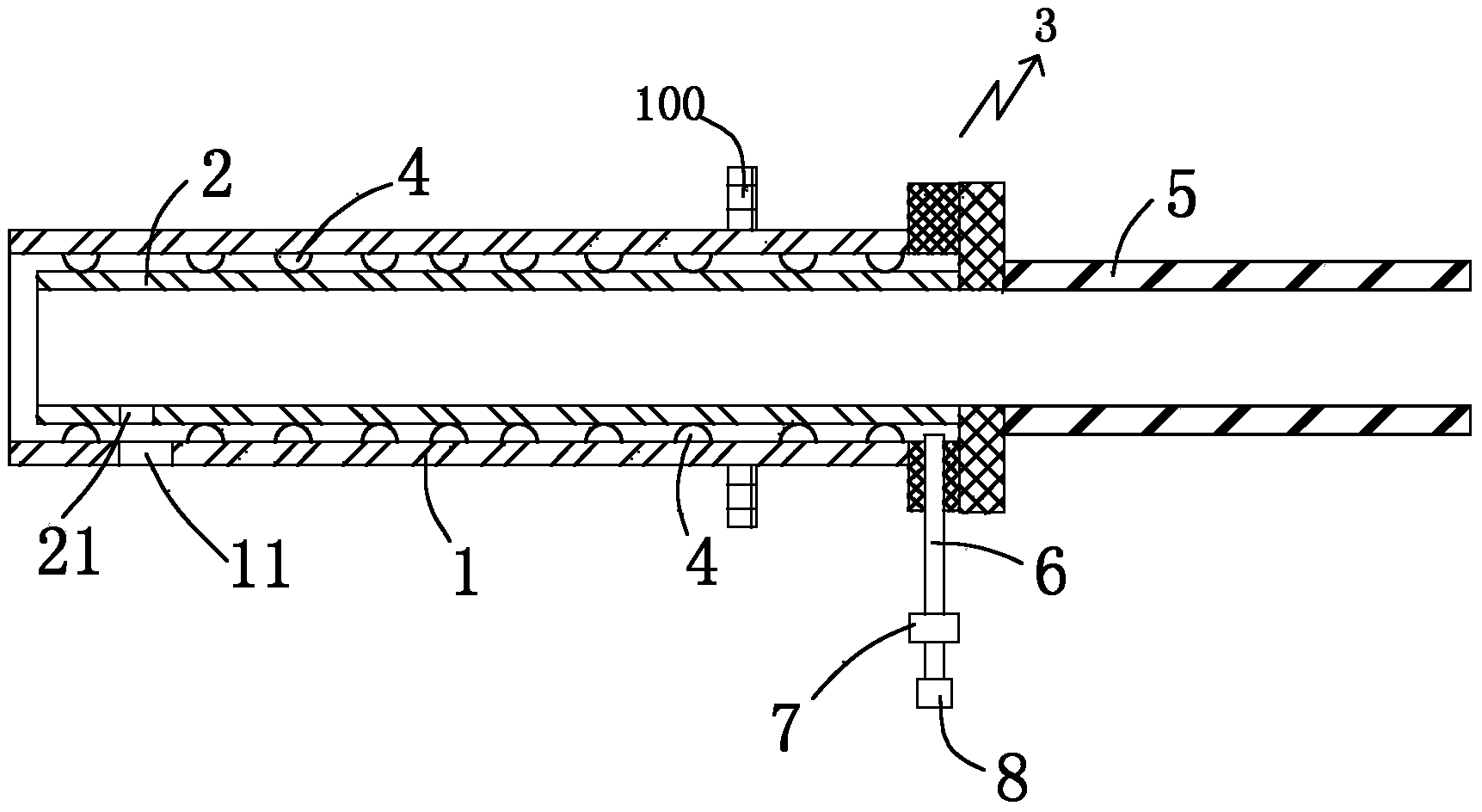

Flat-hose assembly for wound drainage system

A flat-hose assembly has a proximal end and a distal end adapted for use with a negative pressure wound drainage system. The flat-hose assembly comprises a top layer, a bottom layer, and a filter layer. The bottom layer forms an opening at the distal end of the flat-hose assembly to allow exudates of a wound to flow into the flat-hose assembly. The filter layer is disposed between the top layer and the bottom layer. The top and bottom layer form a seal area along a periphery of the top layer and the bottom layer to seal the filter layer therebetween.

Owner:CONVATEC LTD

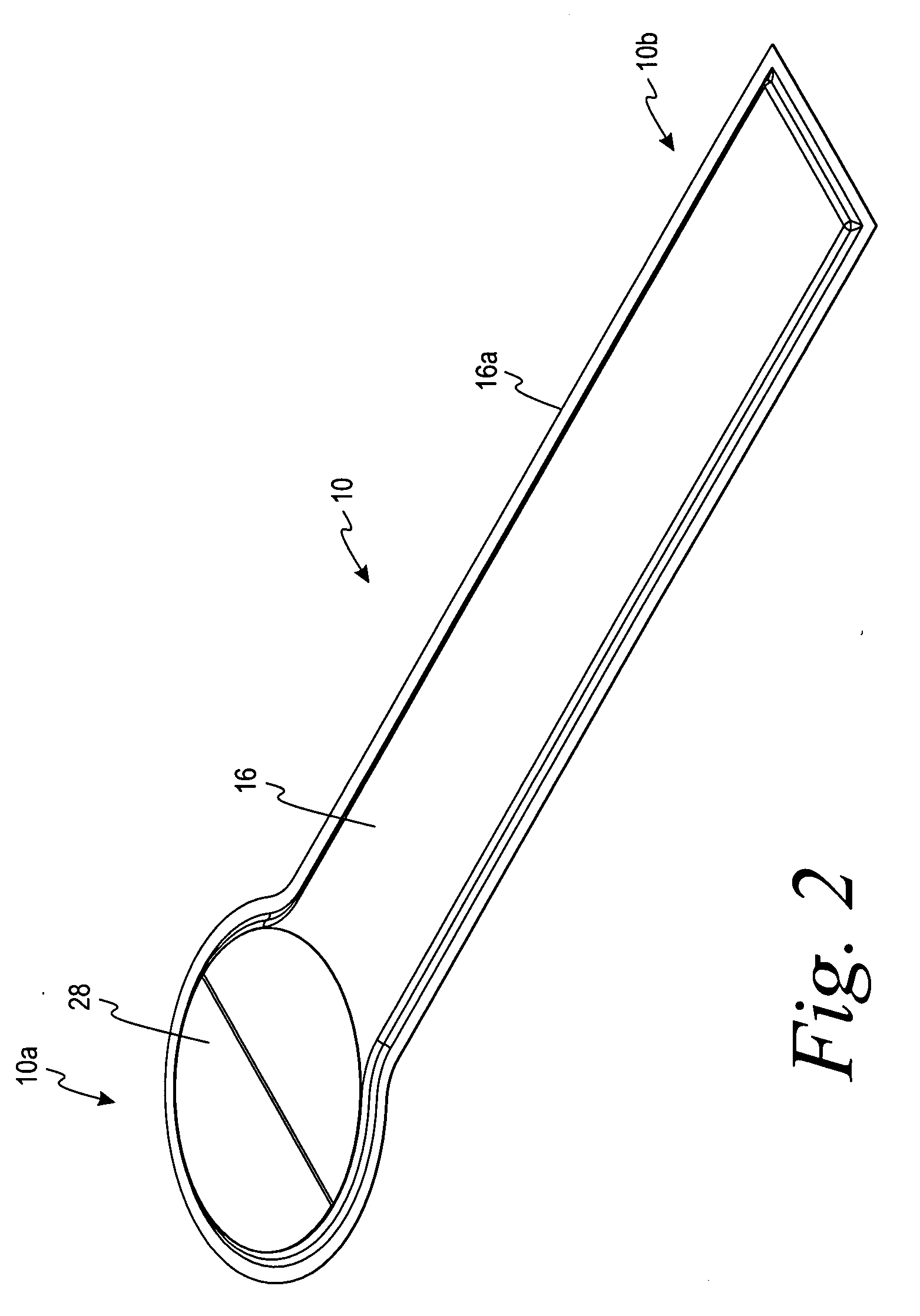

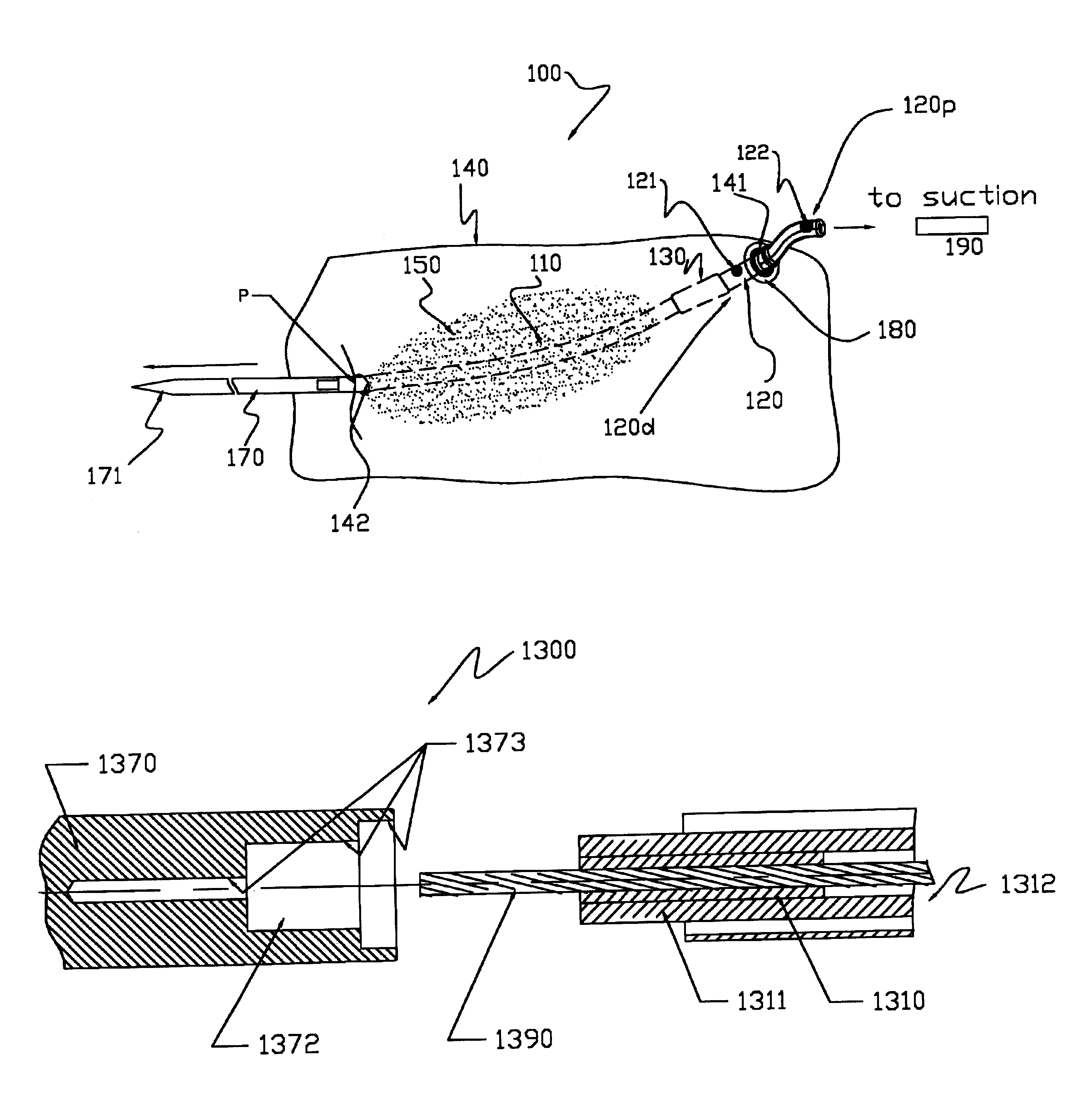

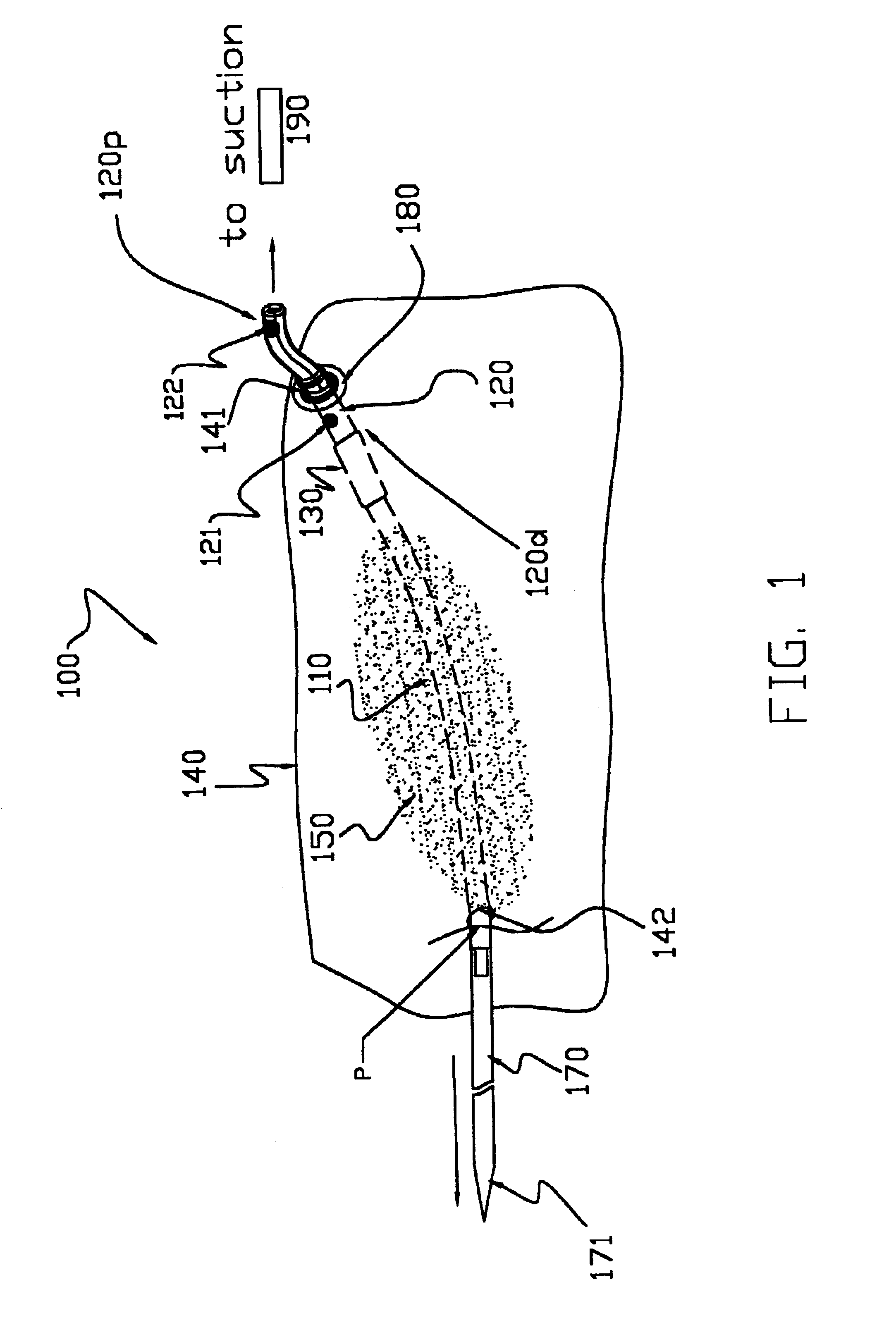

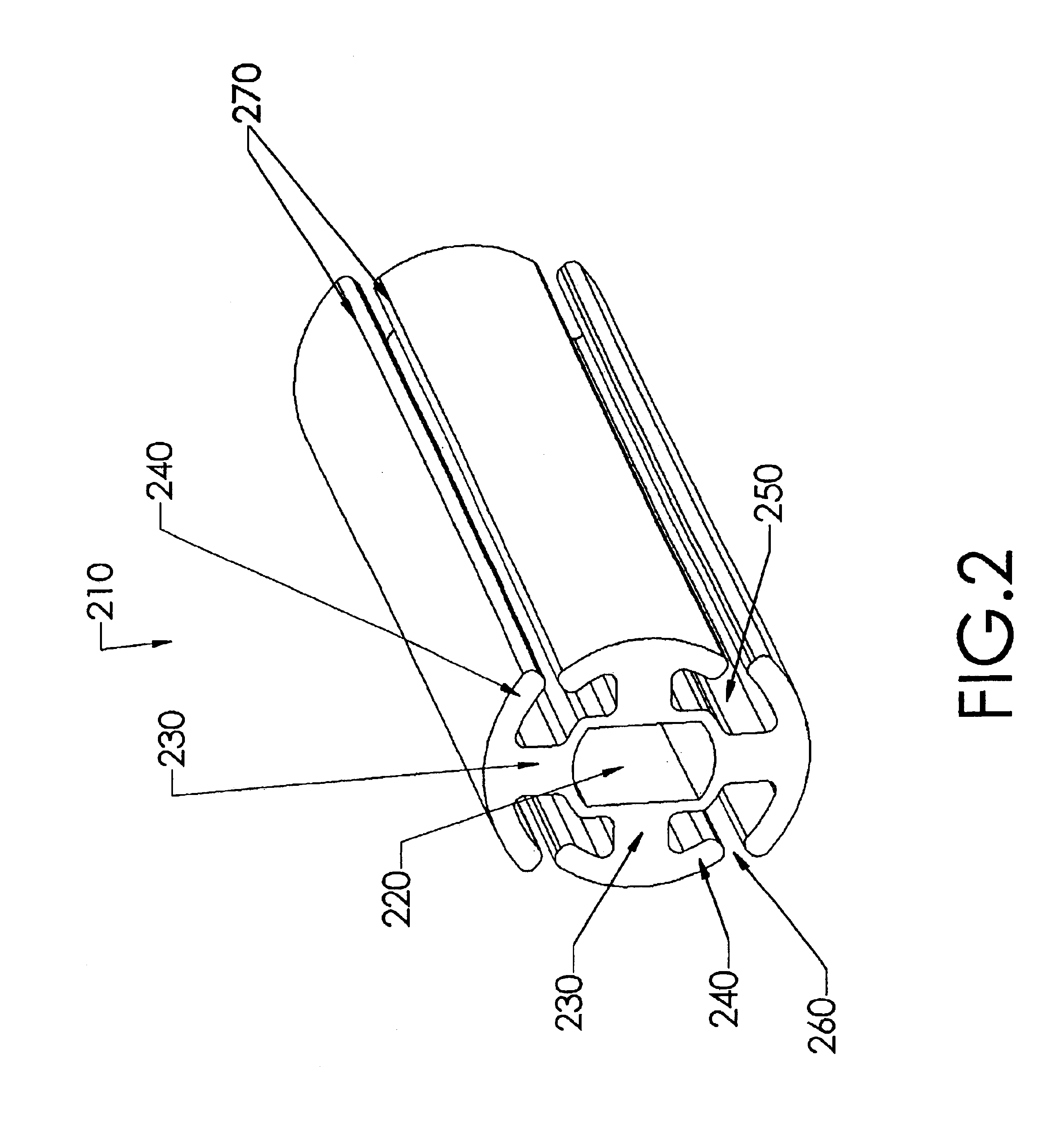

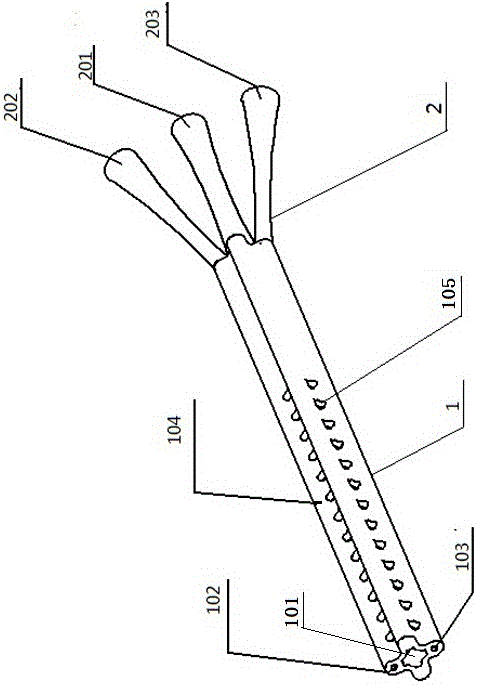

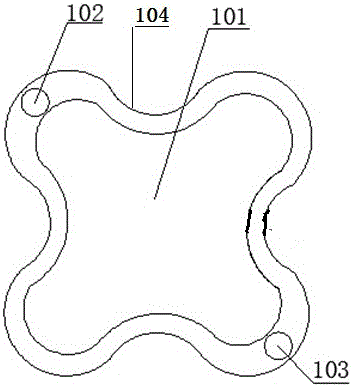

Drain catheters

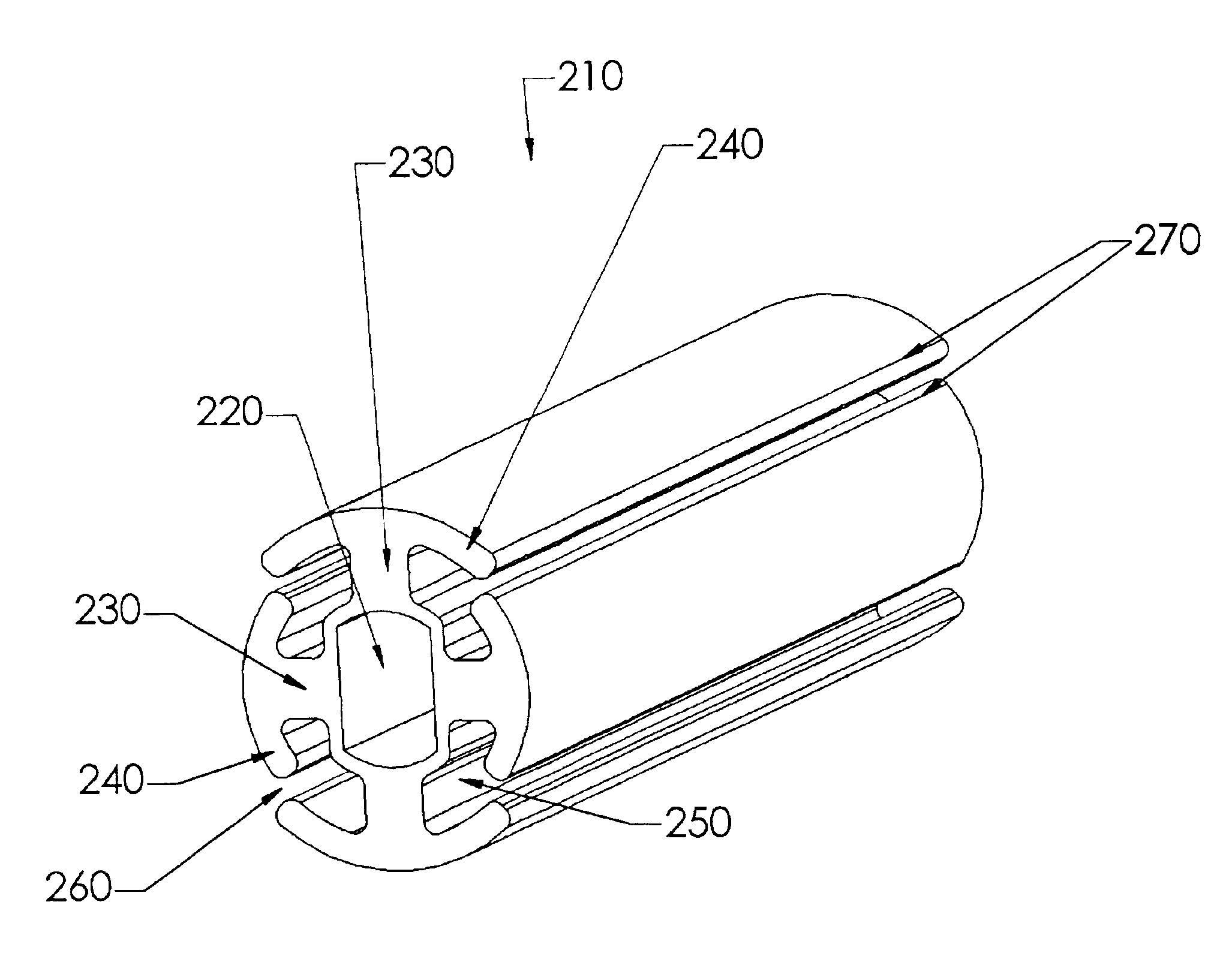

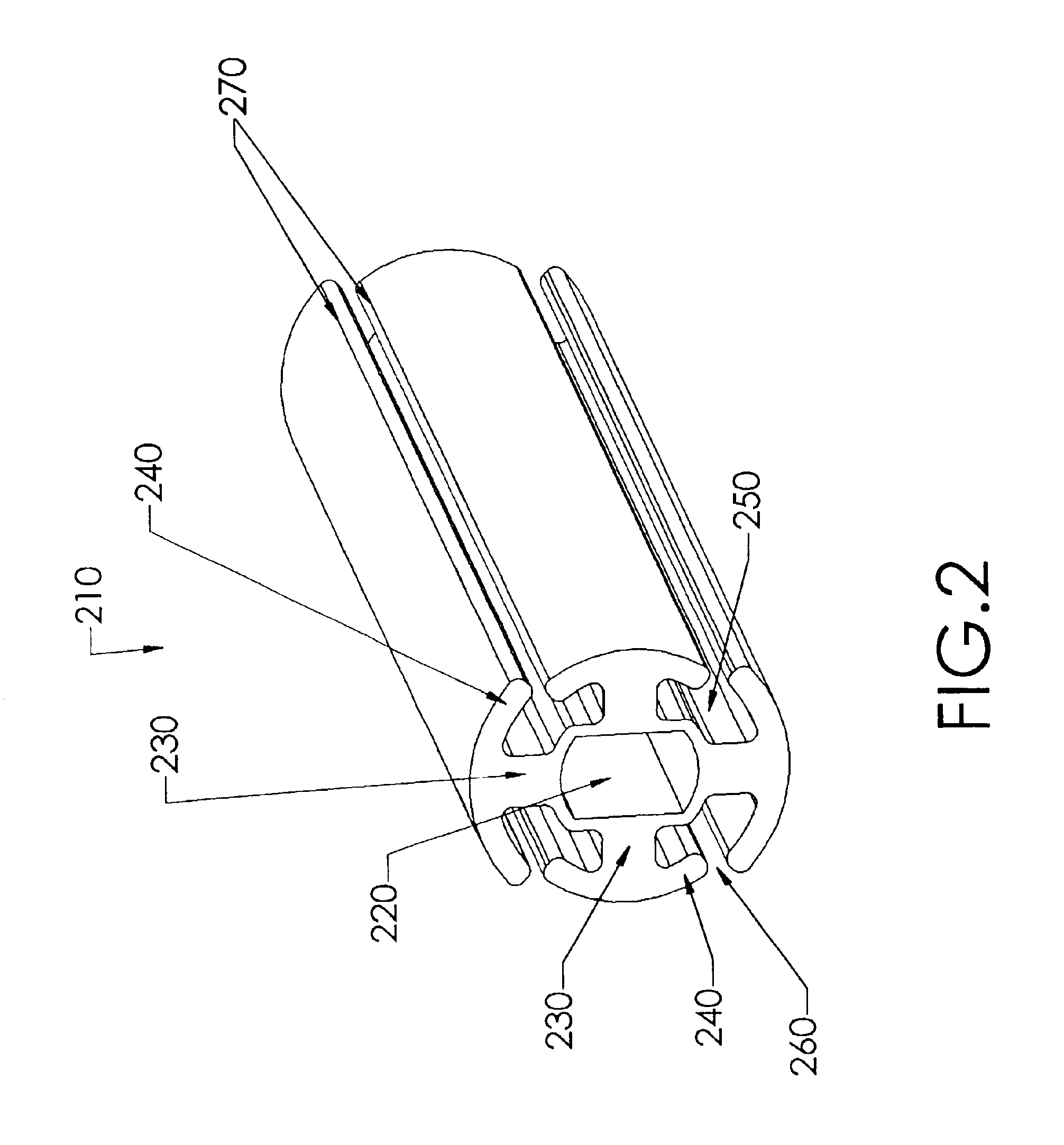

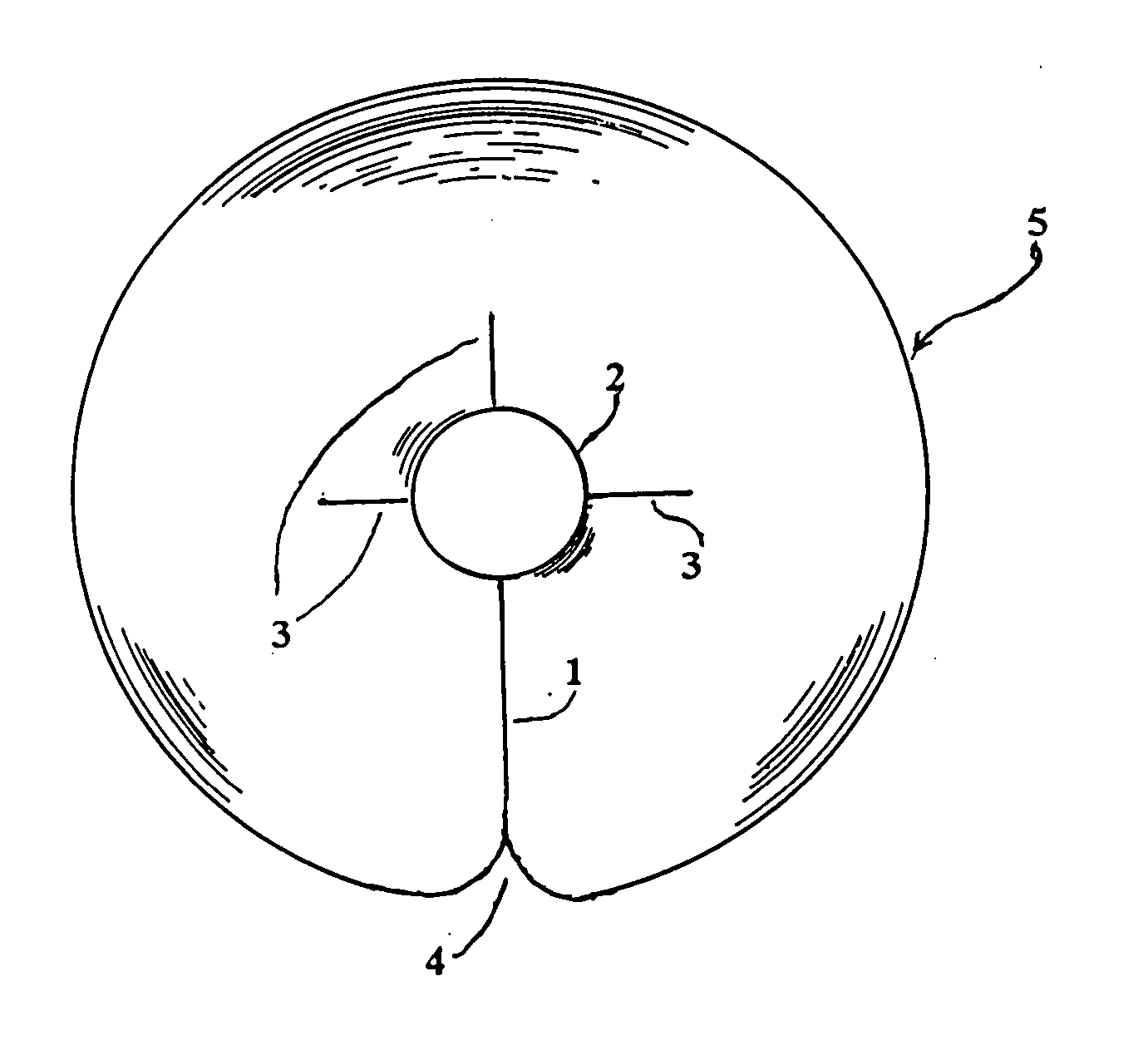

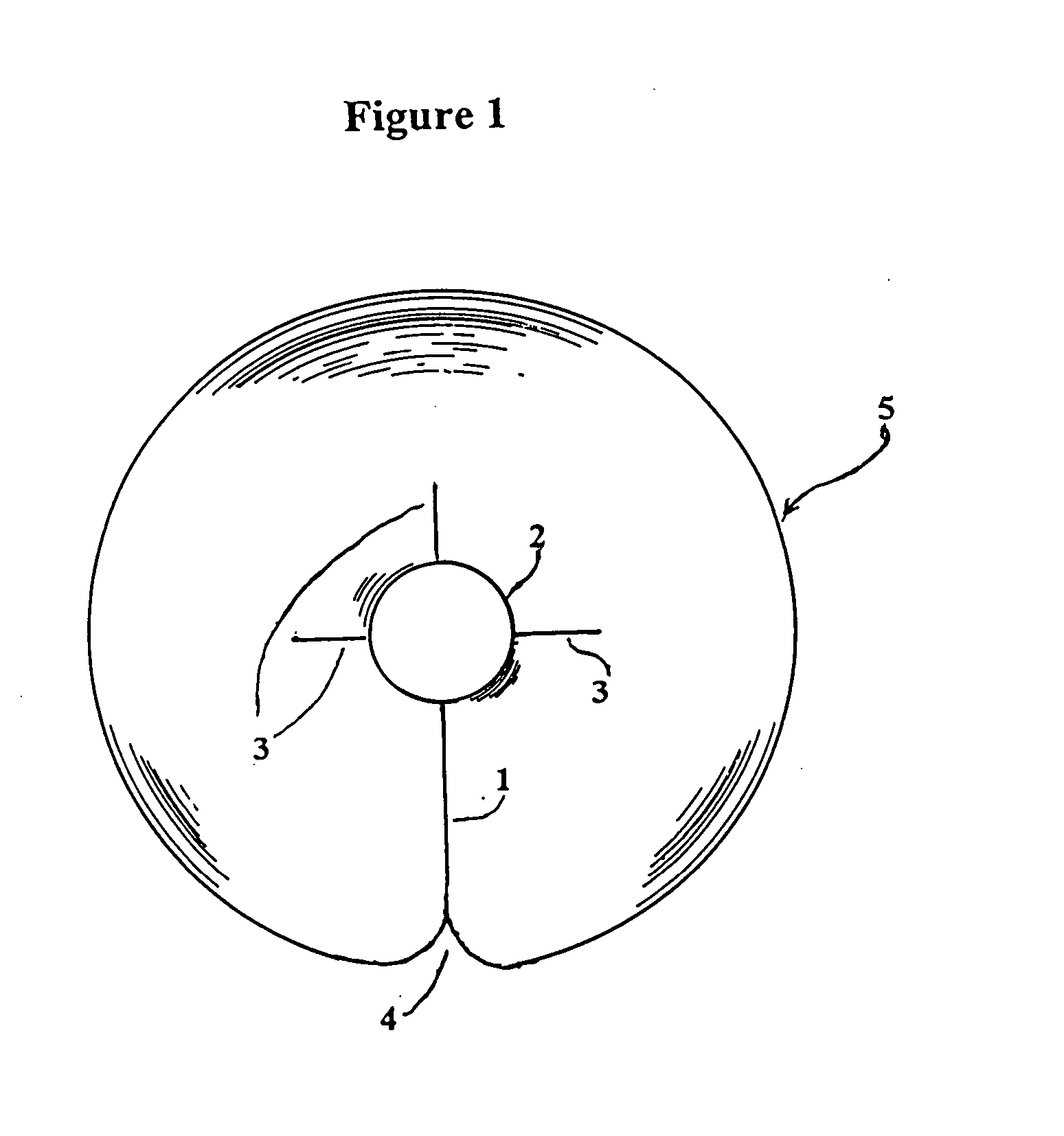

The present invention is directed to a wound drain catheter for draining fluid from, or supplying medication to, a wound in a patient. The wound drain catheter comprises a drain, a flexible outflow tube, and means for connecting the drain to the flexible outflow tube. The drain comprises a hollow core having a longitudinal axis; plural struts extending outwardly from the hollow core and being closed to the hollow core; and plural overhangs connected to the outward ends of the struts, respectively, the overhangs cooperating with the struts to form plural longitudinal lumens, the overhangs cooperating with each other to form, on the outer surface of the drain, segments of a segmented, closed curve with gaps between the segments providing plural longitudinal grooves for fluid communication between the wound and a respective lumen, the grooves sized to inhibit tissue from growing therein and debris from passing therethrough. The present invention also includes a method for draining fluid from, or supplying medication to, a wound in a patient.

Owner:SHCHERVINSKY SEMYON

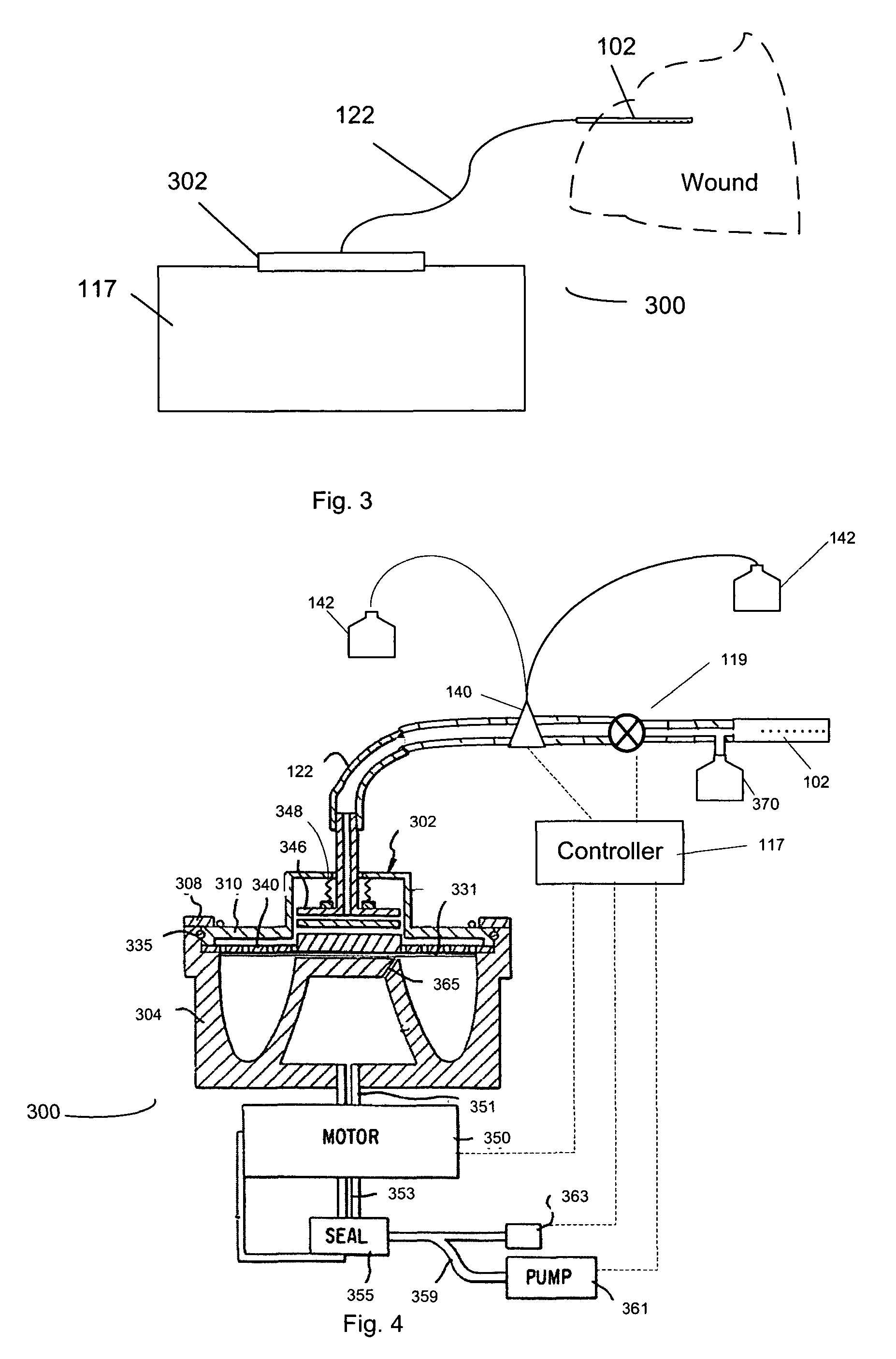

Wound drainage suction relief

InactiveUS20050192548A1Avoid obstructionReduce suctionElectrotherapyOther blood circulation devicesDrainage cathetersWound drainage

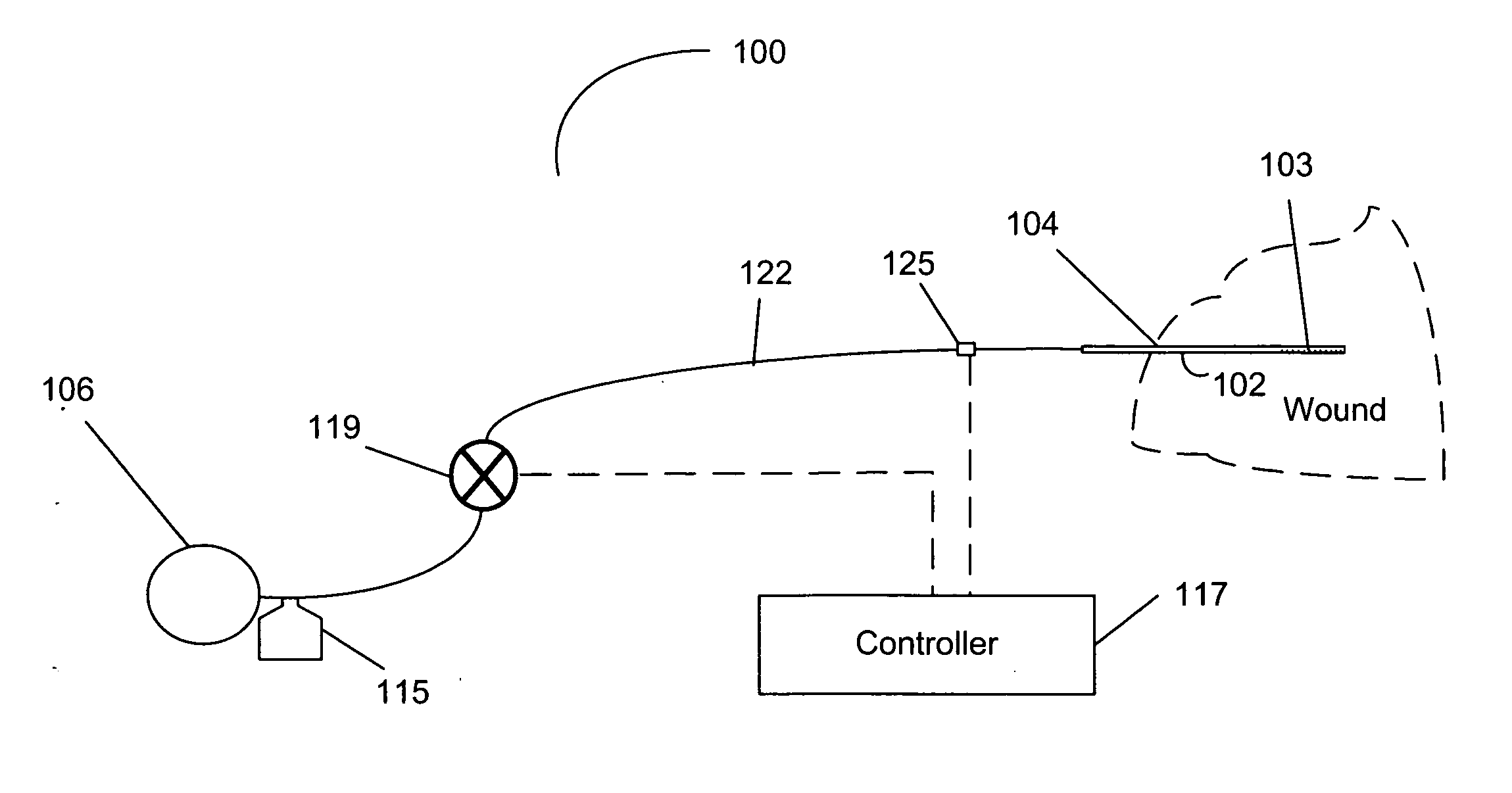

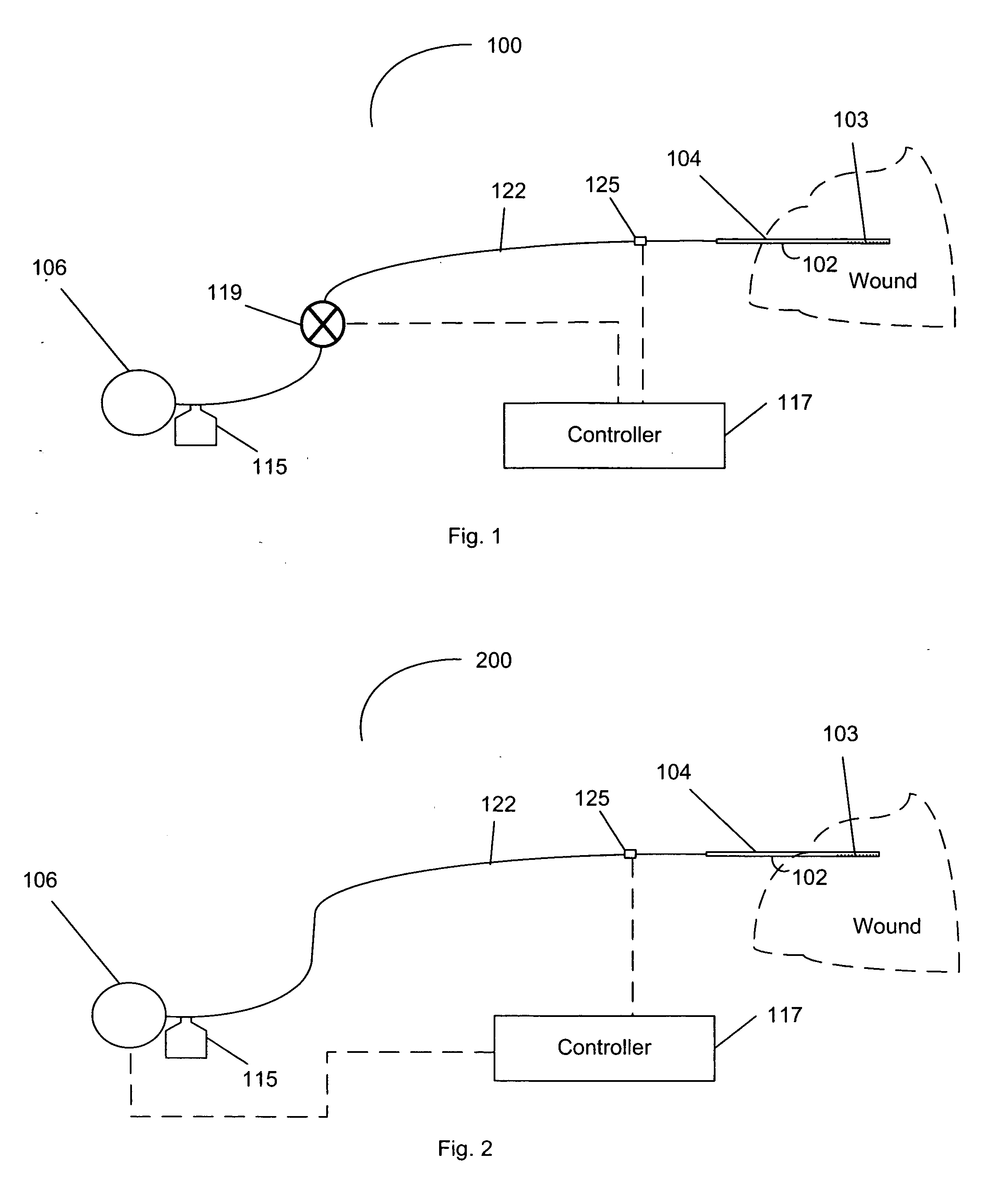

In accordance with one embodiment of the invention, there is provided a wound drainage system for draining fluid from a wound of a patient. The system includes a drain catheter. A suction means applies suction at the drain catheter such that fluid is drawn from the wound. While drawing fluid from the wound, a controller periodically increases and decreases the application of suction at the drain catheter. This allows the tissue surrounding the wound drain to relax, thus preventing obstruction of the drain catheter.

Owner:HAEMONETICS

Flat-hose assembly for wound drainage system

A flat-hose assembly has a proximal end and a distal end adapted for use with a negative pressure wound drainage system. The flat-hose assembly comprises a top layer, a bottom layer, and a filter layer. The bottom layer forms an opening at the distal end of the flat-hose assembly to allow exudates of a wound to flow into the flat-hose assembly. The filter layer is disposed between the top layer and the bottom layer. The top and bottom layer form a seal area along a periphery of the top layer and the bottom layer to seal the filter layer therebetween.

Owner:CONVATEC LTD

Assemblies, systems, and methods for vacuum assisted internal drainage during wound healing

ActiveUS20120071841A1Enhanced wound healing benefitImprove natureWound drainsMedical devicesVacuum assistedInternal wounds

Assemblies, systems, and methods convey fluid from an internal wound site or body cavity by applying negative pressure from a source outside the internal wound site or body cavity through a wound drain assembly that is placed directly inside the internal wound site or body cavity.

Owner:IC SURGICAL INC

Wound drainage suction relief

InactiveUS8157792B2Avoid obstructionReduce suctionElectrotherapyOther blood circulation devicesWound drainage bagCatheter

In accordance with one embodiment of the invention, there is provided a wound drainage system for draining fluid from a wound of a patient. The system includes a drain catheter. A suction means applies suction at the drain catheter such that fluid is drawn from the wound. While drawing fluid from the wound, a controller periodically increases and decreases the application of suction at the drain catheter. This allows the tissue surrounding the wound drain to relax, thus preventing obstruction of the drain catheter.

Owner:HAEMONETICS

Silencer for vacuum system of a wound drainage apparatus

ActiveUS8845603B2Reduce decreaseLess noisyWound drainsMedical devicesSilencing ElementsBiomedical engineering

Apparatus (10, 200) for the provision of TNP therapy to a wound is described, the apparatus (10, 200) including: a waste canister (22, 204) into which fluid is aspirated from a wound by aspiration pump means (44, 248) and a fluid flow path (420, 422) for at least a part of said aspirated fluid on an outlet side of said aspiration pump means (44) wherein said fluid flow path (420, 422) on the outlet side comprises a silencing system (400) having a plurality of silencing elements (402, 404, 406) therein.

Owner:SMITH & NEPHEW INC

Drain catheters

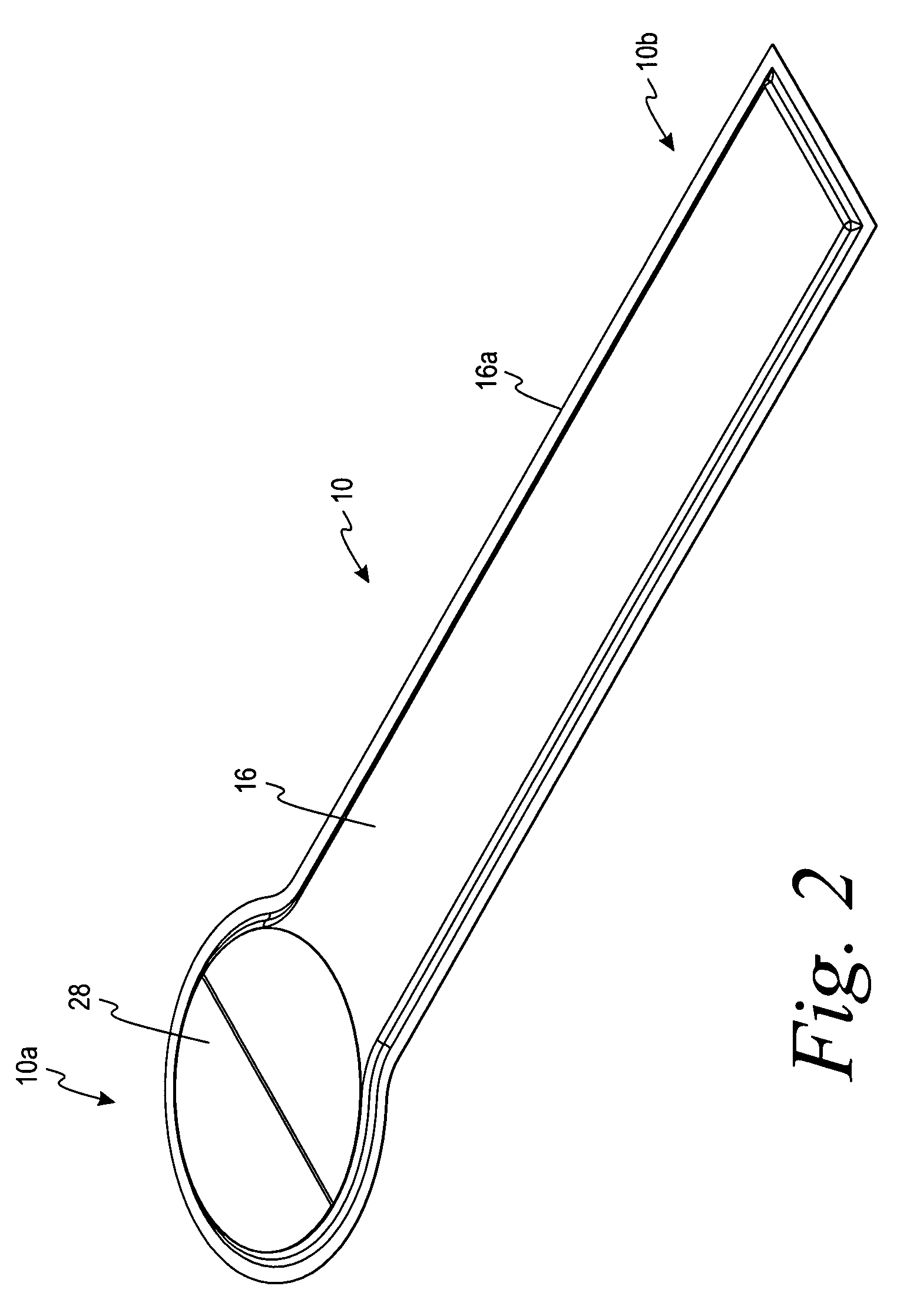

The present invention is directed to a wound drain catheter system for draining fluid from, or supplying medication to, a wound in a patient. The system comprises (A) a trocar having (a) a blade portion on a distal end; and (b) a connector portion on a proximal end, the connector portion being a hollow core lying on a longitudinal axis; (B) a drain having (a) a first connector portion on a distal end, the first connector portion being a protrude lying on a longitudinal axis; and (b) a second connector portion on a proximal end; (C) a flexible outflow tube having (a) a proximal end and a distal end; and (b) a smooth exterior for sealing to surface tissue at the point of exit from the body of a patient; and (D) means for connecting the second connector portion of the drain to the distal end of the flexible outflow tube. The protrude of the first connector portion of the drain engages the interior of the hollow core of the connector portion of the trocar. The wound drain catheter system may also include a bioabsorbable transitional part.

Owner:SHCHERVINSKY SEMYON

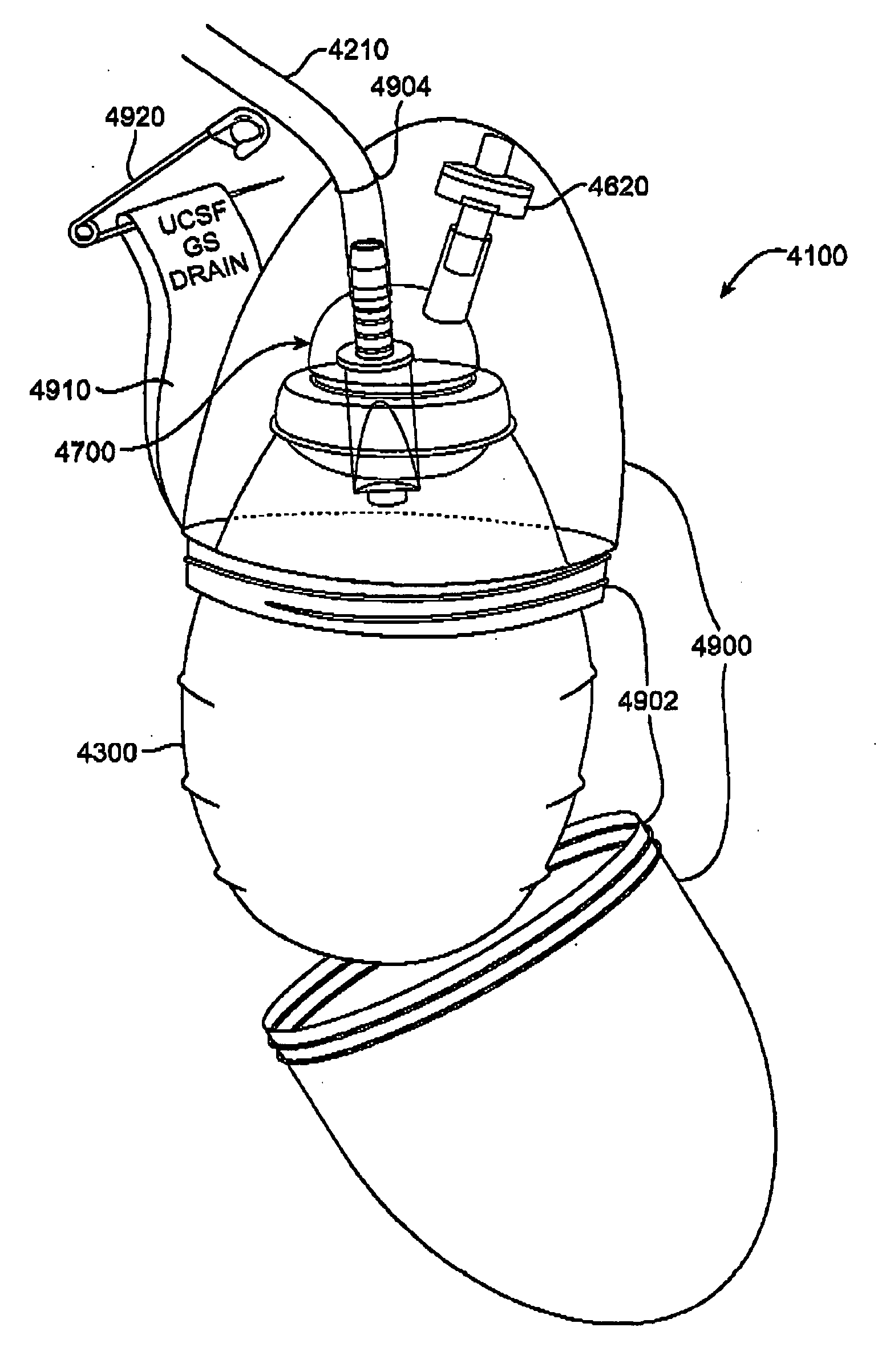

Drainage devices and methods

InactiveUS20070027433A1Efficient releaseSafe and effective and usefulWound drainsMedical devicesBiomedical engineeringVALVE PORT

Active and passive wound drainage systems and method are provided. A drainage device includes an input passage for receiving the fluid from a site on or within the patient's body, a container for holding the fluid, and a reversible valve disposed between the input passage and the container. The reversible valve in an original configuration provides unidirectional fluid flow from the input passage toward the container, and in a reversed configuration provides fluid flow from the container toward the input passage.

Owner:RGT UNIV OF CALIFORNIA

Assemblies, systems, and methods for vacuum assisted internal drainage during wound healing

ActiveUS20070282310A1Enhanced wound healing benefitDecreasing tissue edema of tissueWound drainsIntravenous devicesVacuum assistedInternal wounds

Assemblies, systems, and methods convey fluid from an internal wound site or body cavity by applying negative pressure from a source outside the internal wound site or body cavity through a wound drain assembly that is placed directly inside the internal wound site or body cavity.

Owner:IC SURGICAL INC

Wound drainage dressing

ActiveUS9408755B2Easy constructionEasy to transportInfusion syringesSurgical needlesSecretionBiomedical engineering

The invention relates to a wound drainage covering for covering, by means of low pressure, a wound that is to be treated. The covering comprises at least two layers that are superimposed. A first layer that is applied on the side of the wound is made of a functional textile material and second layer that is arranged thereon is dimensionally stable and permeable to liquid. The wound drainage covering has a simple design and due to the functional first layer, is effective and ensures, due to the dimensionally stable second layer, an optimal removal of wound secretion.

Owner:MEDELA HLDG AG

Catheter patch

ActiveUS20070225652A1Significant level of absorptionCatheterInfusion needlesGuide tubeWound drainage

The present invention relates to a patch, which can be used to secure catheters, wound drainage devices, and / or drug delivery devices, when said catheter and related devices are inserted into the body. The invention also can deliver antimicrobial substances to the site of insertion of a catheter and related devices into a body as well as other medicinal factors, such as wound and tissue healing factors that may be desired to be delivered to the site of insertion.

Owner:B BRAUN HOSPICARE LIMITED IRELAND

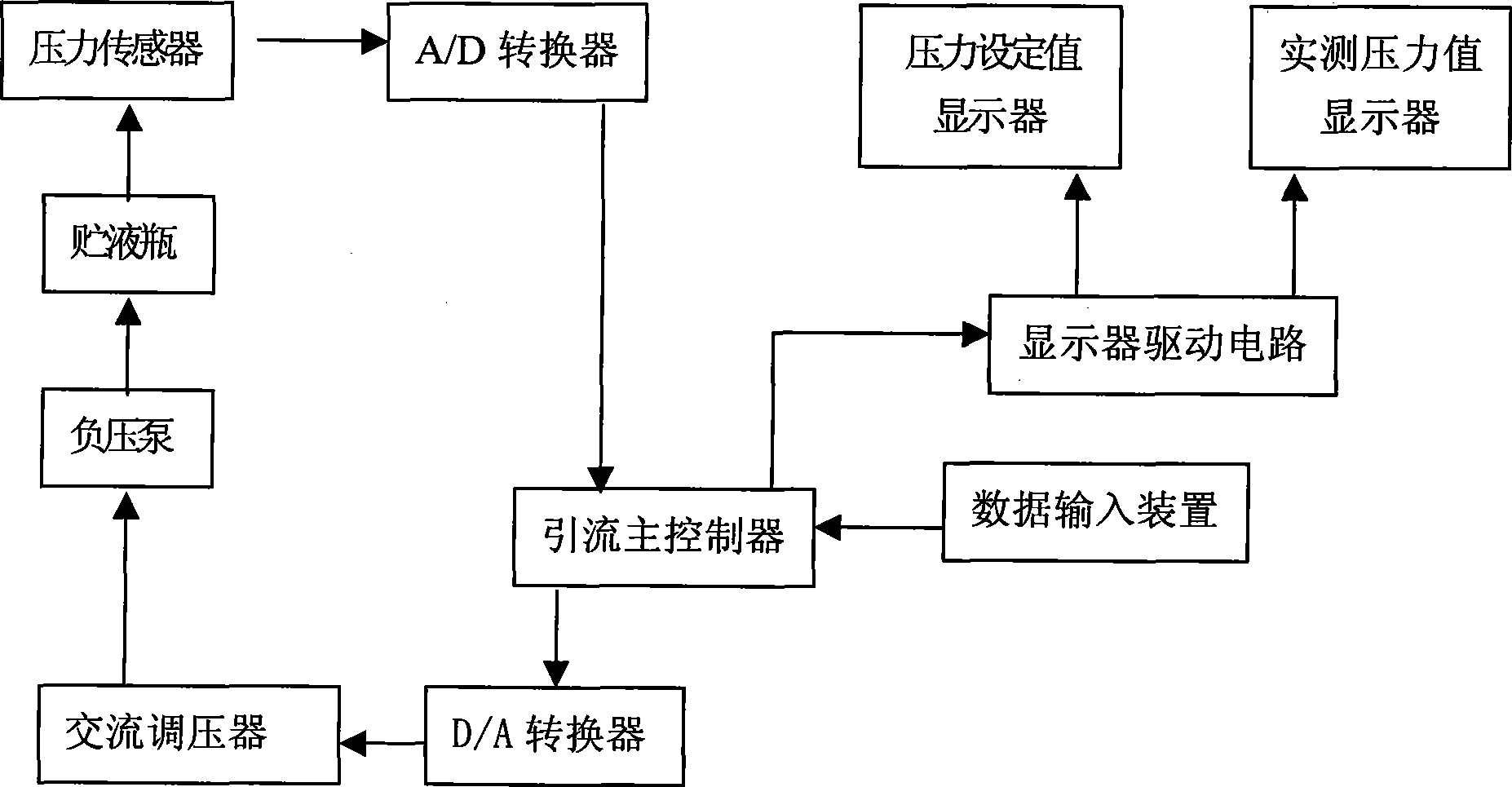

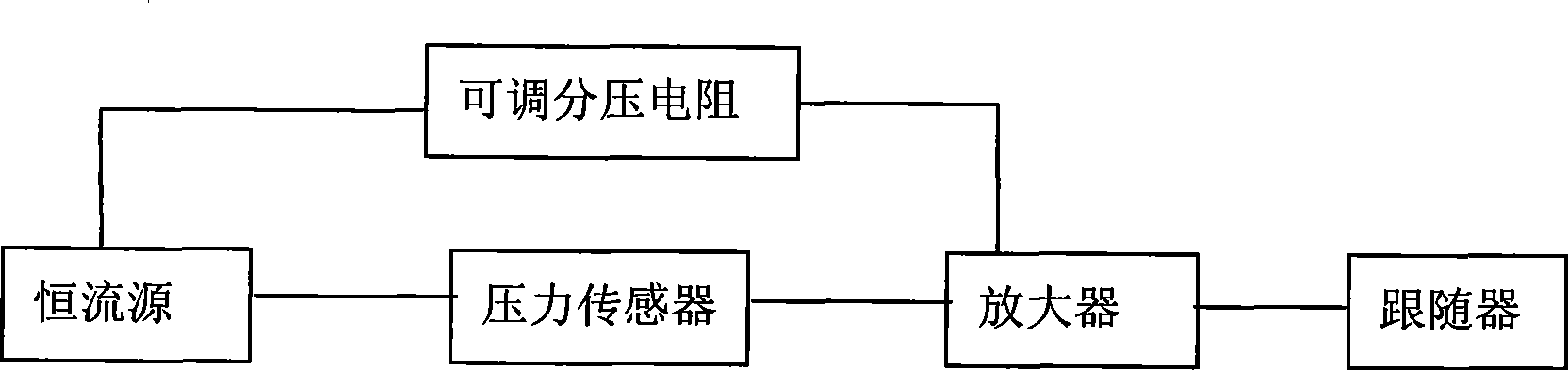

Intelligent low constant pressure wound drainage system

InactiveCN101385887AReduce labor intensityAchieve pressureWound drainsControl signalVoltage regulation

The invention discloses a smart low constant-pressure wound drainage system, which aims at providing a wound drainage system which can detect the actual negative pressure value and control a negative pressure pump to adjust the pressure during the drainage, so as to realize a scientific drainage treatment and reduce the labor intensity of the nursing staff. A pressure sensor is connected with a liquid tank; the pressure sensor is also connected with a control signal input terminal of a main drainage controller by an A / D converter; the control signal output terminal of the main drainage controller is connected with that of an AC voltage regulator by a D / A converter; the control signal output terminal of the AC voltage regulator is connected with a negative pressure pump which is connected with the liquid tank, and the main drainage controller is connected with a data inputting device. The smart low constant-pressure wound drainage system can detect the actual negative pressure value in the liquid tank and control the negative pressure pump to adjust the pressure during the drainage, thus realizing pressure monitoring and precise control; furthermore, the system has excellent performance of voltage regulation and simple operation and reduces the labor intensity of the nursing staff.

Owner:高敏

External-applied medicinal preparation for treating burns and its preparation method

InactiveCN101167856AReduce water evaporationAvoid pollutionHydroxy compound active ingredientsInorganic active ingredientsMyrrhSide effect

The invention discloses an external used medicine and process for preparation, which comprises the components as following, raw rheubarb, coptis chinesis, honeysuckle, polygonum ciliinerve, raw gardenburnet, phellodendron bark, radix notoginseng, polygonum cuspidate, astragalus, lithospermum, safflower, myrrh, olibamum, margarita, camphol, zine oxide, and sesame oil, and is processed in steps. The invention sinks gauze dressing in the form of oil solution, and then is stuck on wound, thereby reducing the water evaporation of wound, preventing wound infection, and avoiding wound incrustation,and the effusion of wound can easily mix with the finish oil gauze, which is beneficial for wound drainage, and largely relieves sufferings of burn patients. The invention is an externally used medicine for treating burn wound, which has short course of treatment, fast effect, strong safety, excellent repair virtue for wound, few scars after curing, and no side effect.

Owner:郭光华 +1

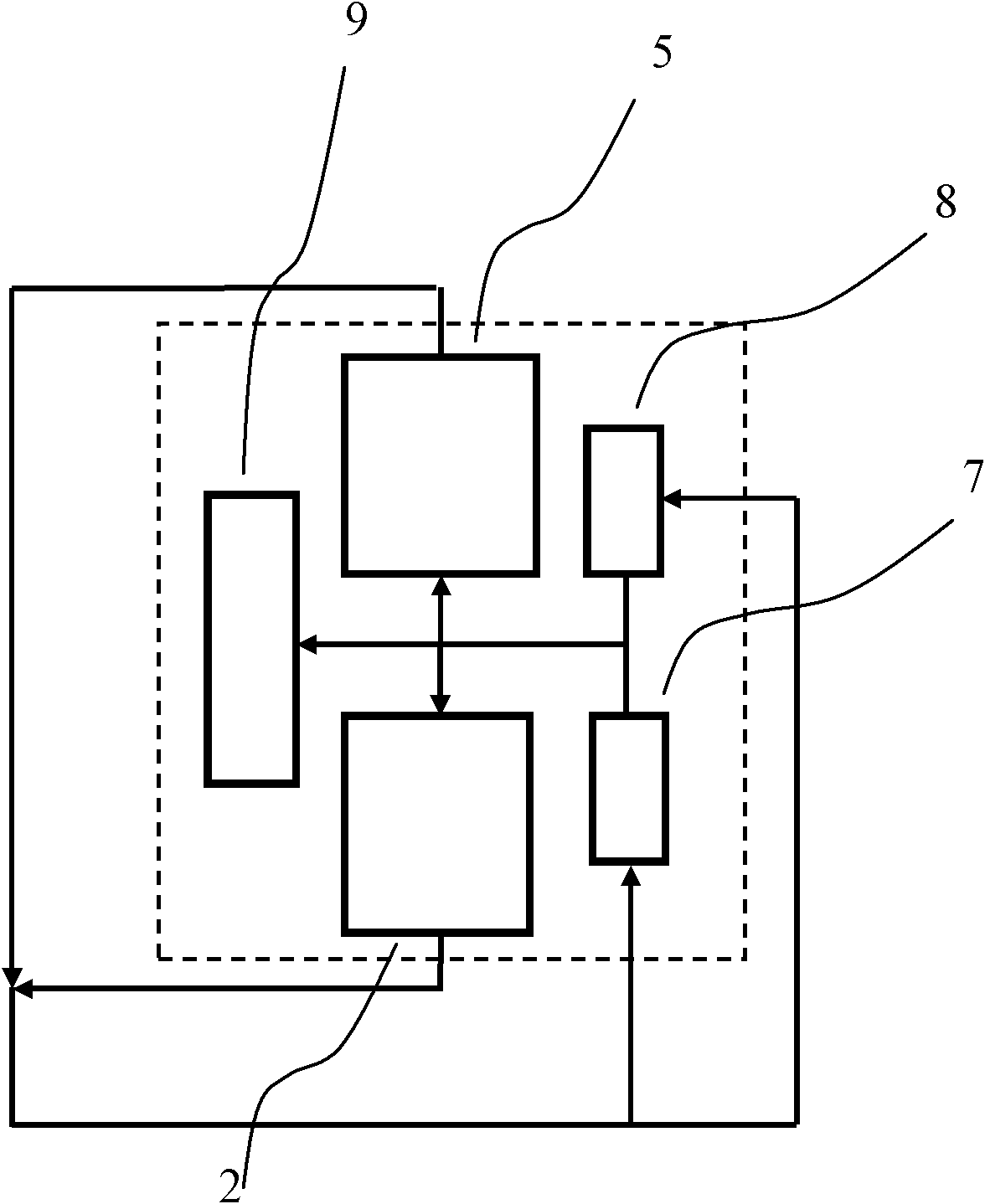

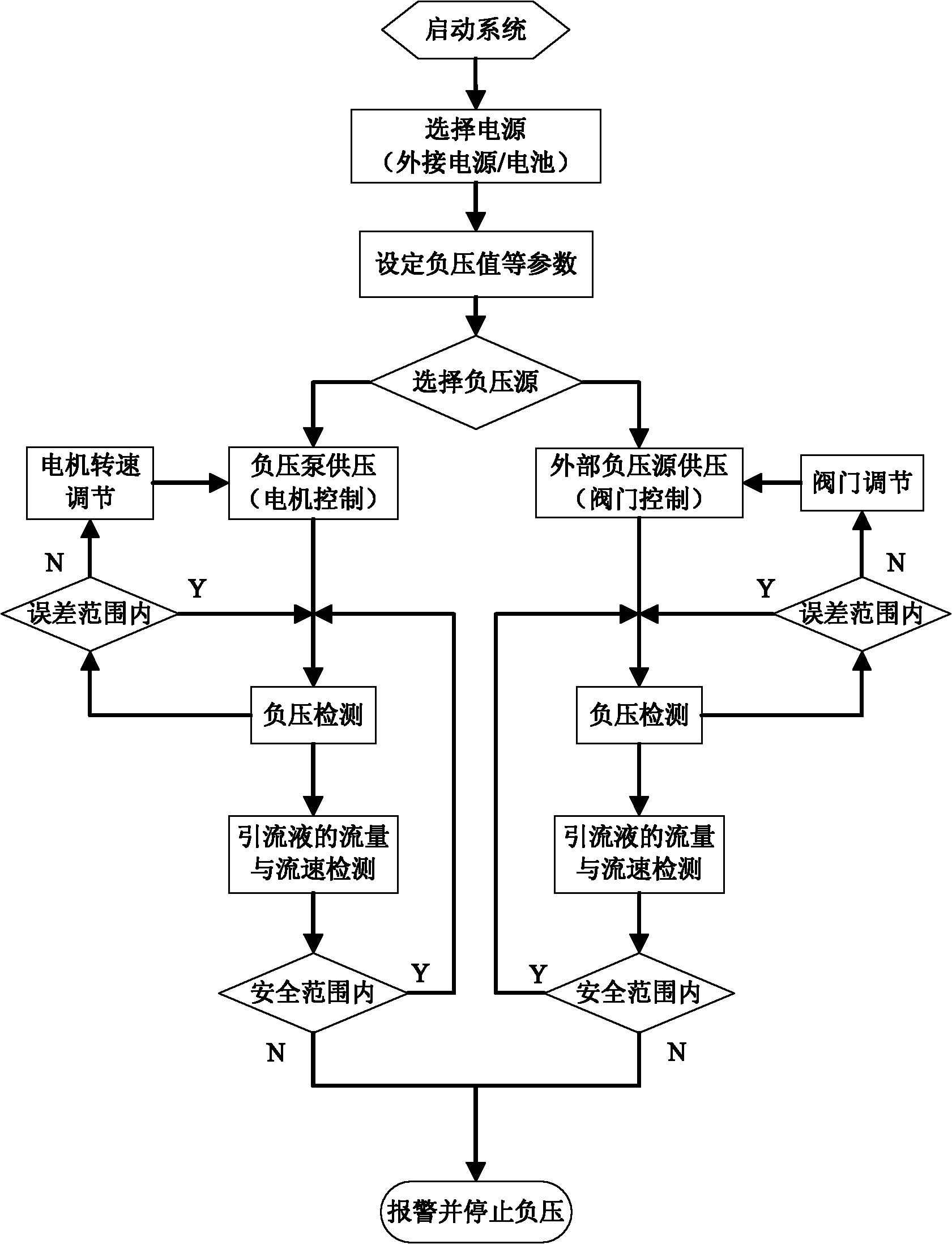

Dual negative pressure adjustable wound negative pressure therapy device based on microprocessor core

Owner:BEIHANG UNIV

Catheter patch

The present invention relates to a patch, which can be used to secure catheters, wound drainage devices, and / or drug delivery devices, when said catheter and related devices are inserted into the body. The invention also can deliver antimicrobial substances to the site of insertion of a catheter and related devices into a body as well as other medicinal factors, such as wound and tissue healing factors that may be desired to be delivered to the site of insertion.

Owner:B BRAUN HOSPICARE LIMITED IRELAND

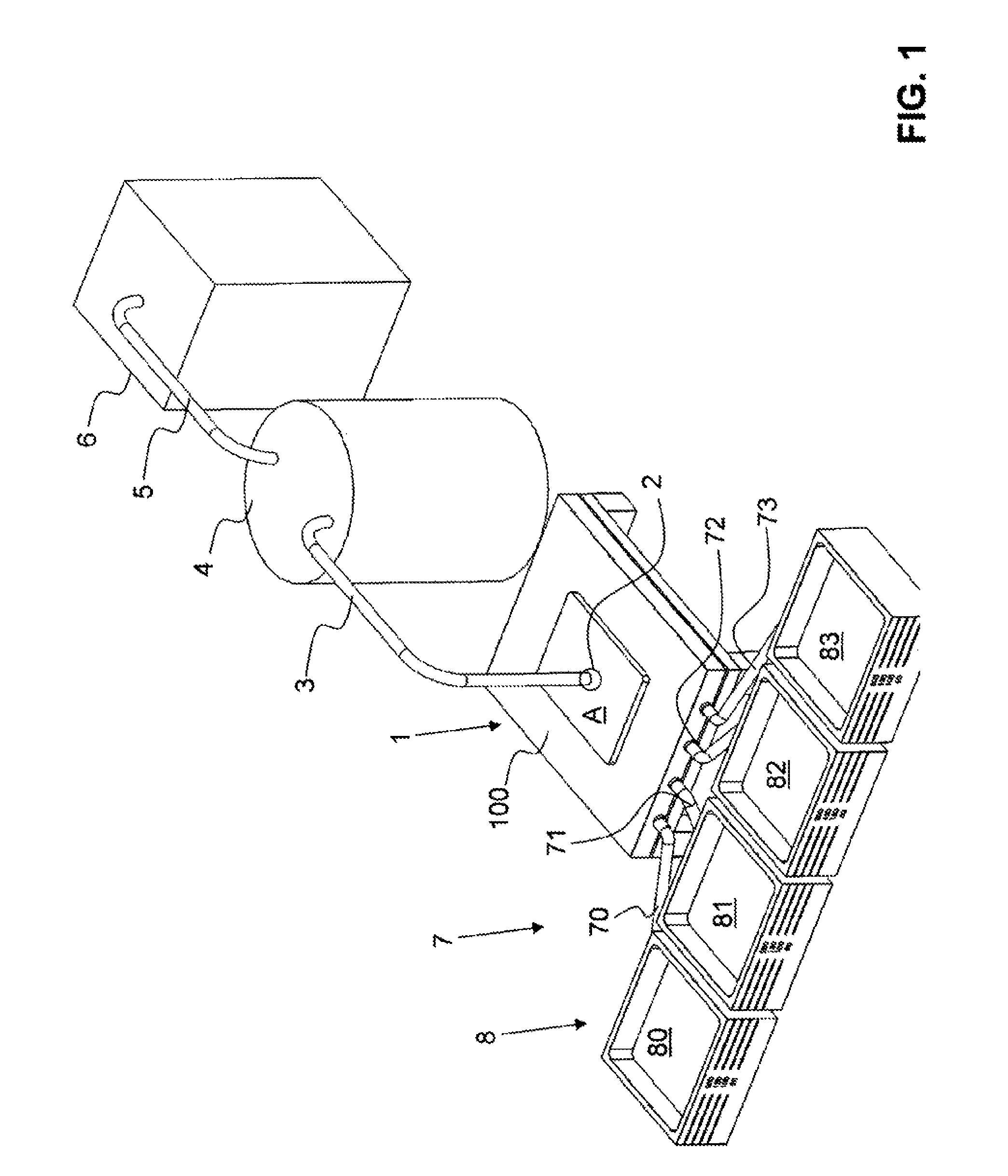

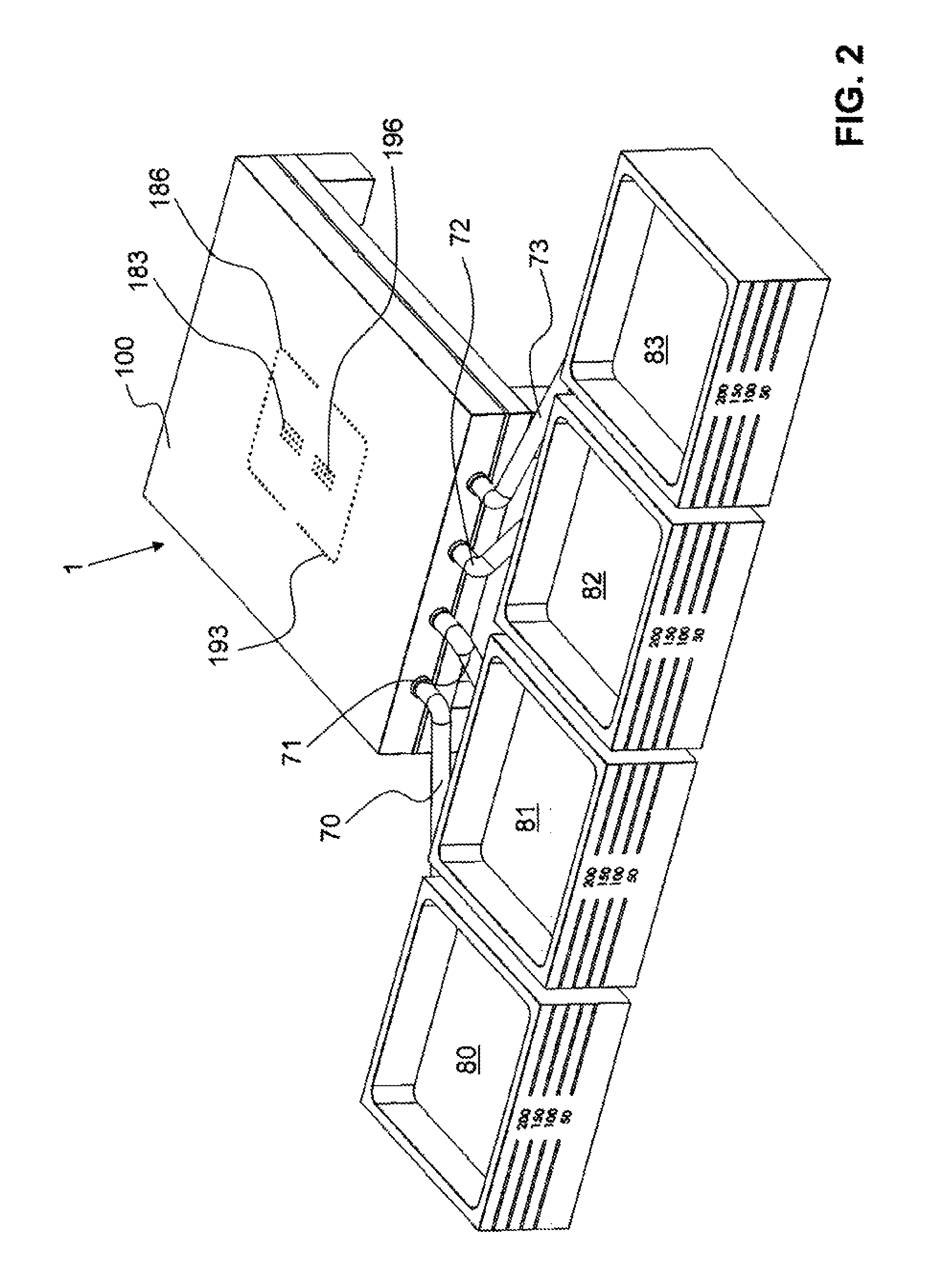

Test unit for wound drainage dressings

ActiveUS8647327B2Easy to useQuick and easy applicationWound drainsSurgeryBiomedical engineeringSupport surface

The invention relates to a test unit for wound drainage coverings comprising: a base body with at least one cavity; at least one supply line that runs through the base body and which connects an outer side of the base body to the cavity; a surface of the base body that is embodied as a support surface for supporting wound coverings and the wound drainage coverings thereof and several channels that run through the base body, the channels connecting the cavities to the support surface. Low pressure can be produced in the cavity and the channels when the support surface is covered in an air-tight manner. As a result, wound drainage applications are tested in different ways using simple and economical means.

Owner:MEDELA HLDG AG

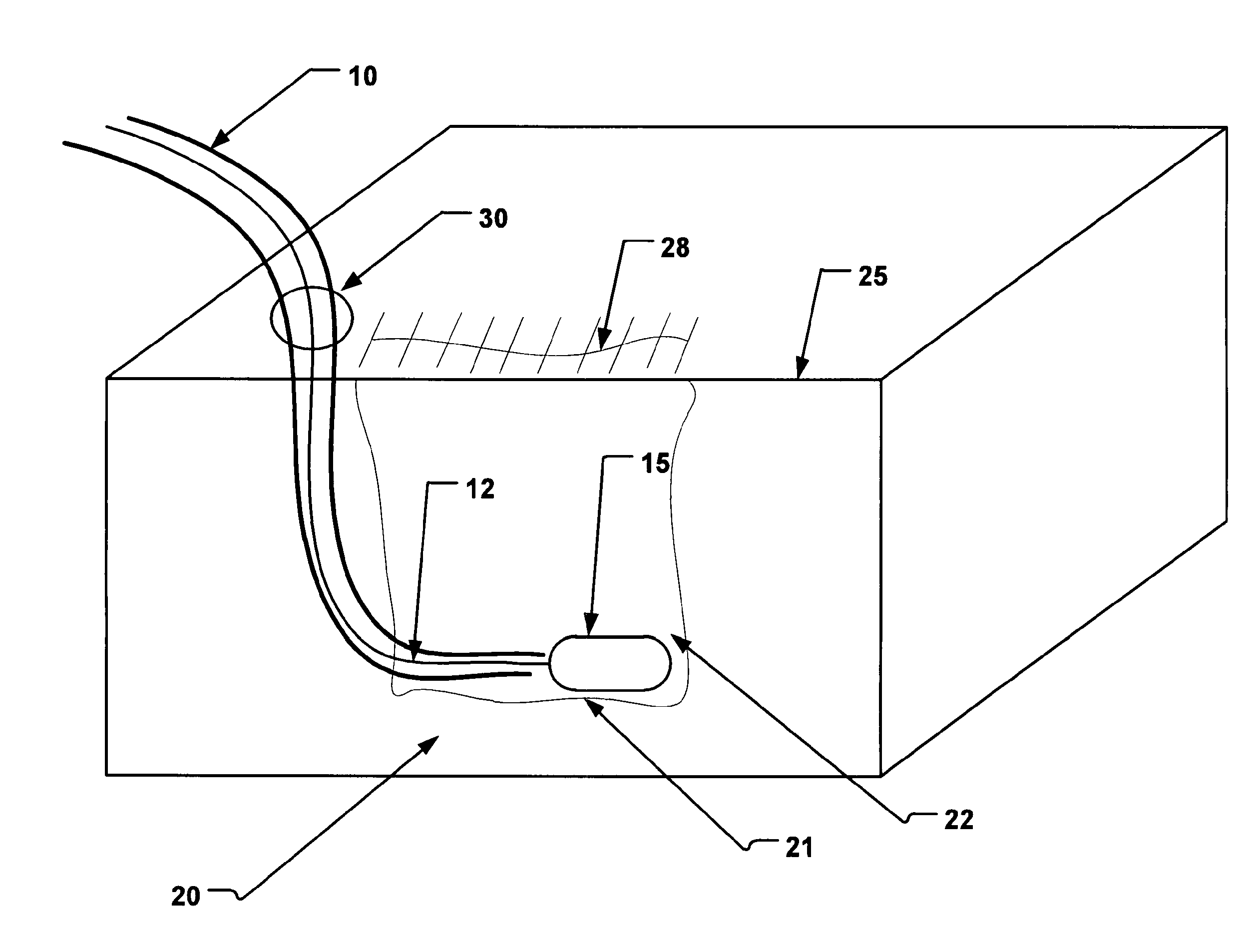

Drainage System for Wounds

ActiveUS20140243707A1Prevent accidental leakagePrevent drainageSurgeryVaccination/ovulation diagnosticsDrainage tubesBiomedical engineering

A fluid drainage system is provided which is configured to engage with a drainage tube engaged with a drainage site with a patient. The container has an internal cavity with negative pressure to impart suction to the drainage tube and can be engaged to the drainage tube without loss of negative pressure during the process. Secondary containers may be engaged to restore negative pressure to the first container and remove fluid therefrom. Walls of the first container may be shaped to resist deflection due to high internal negative pressure.

Owner:PFM MEDICAL

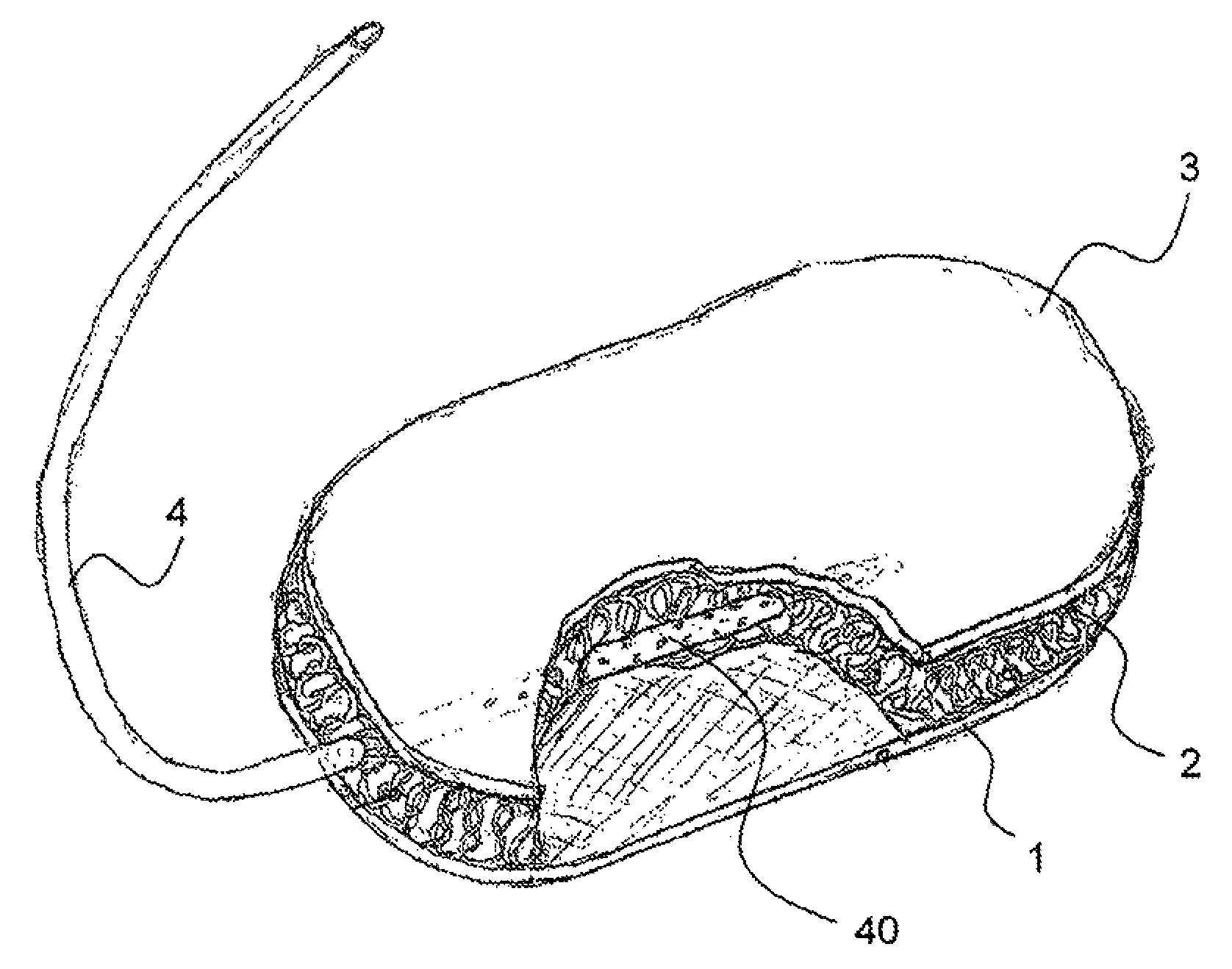

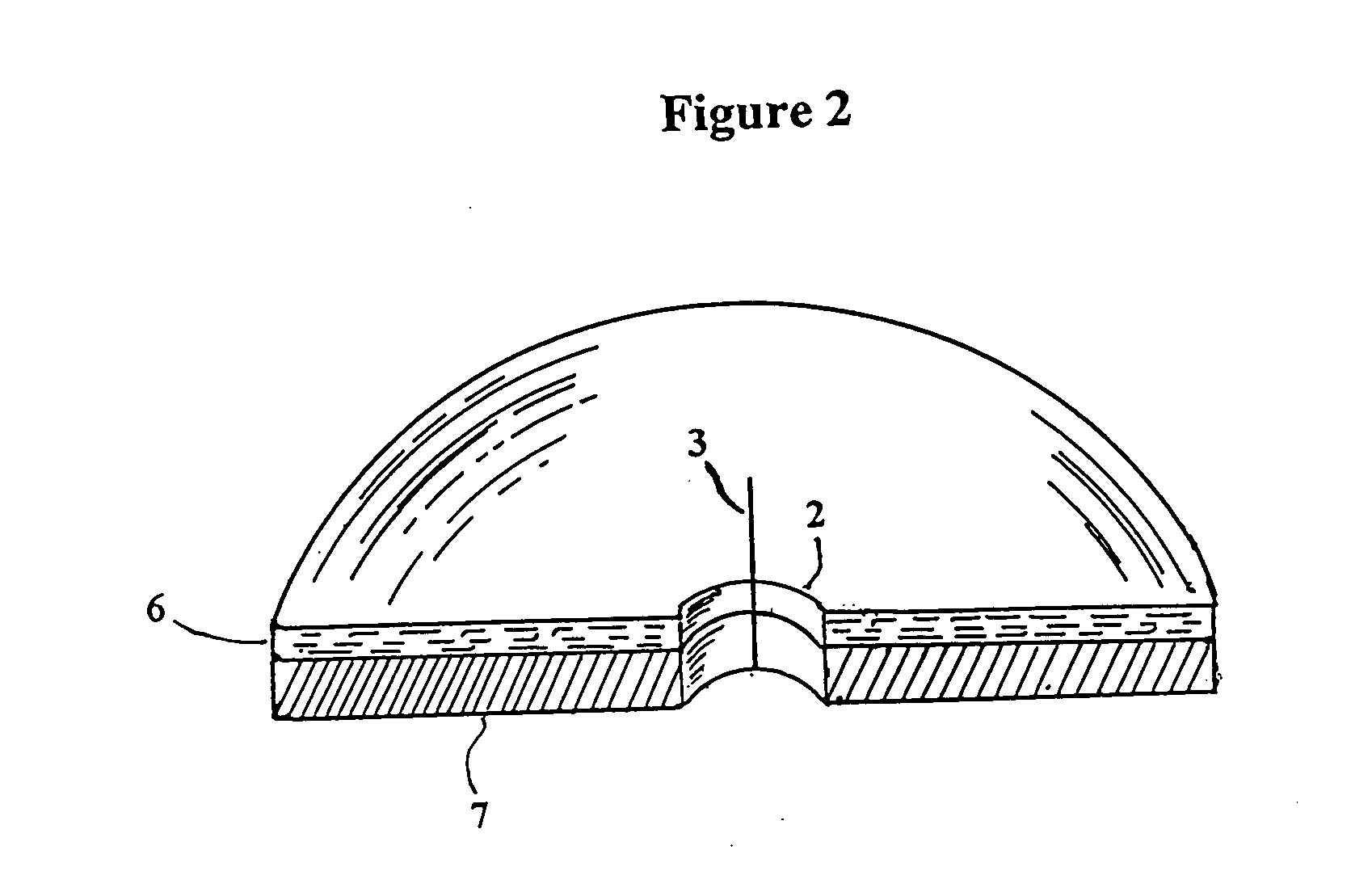

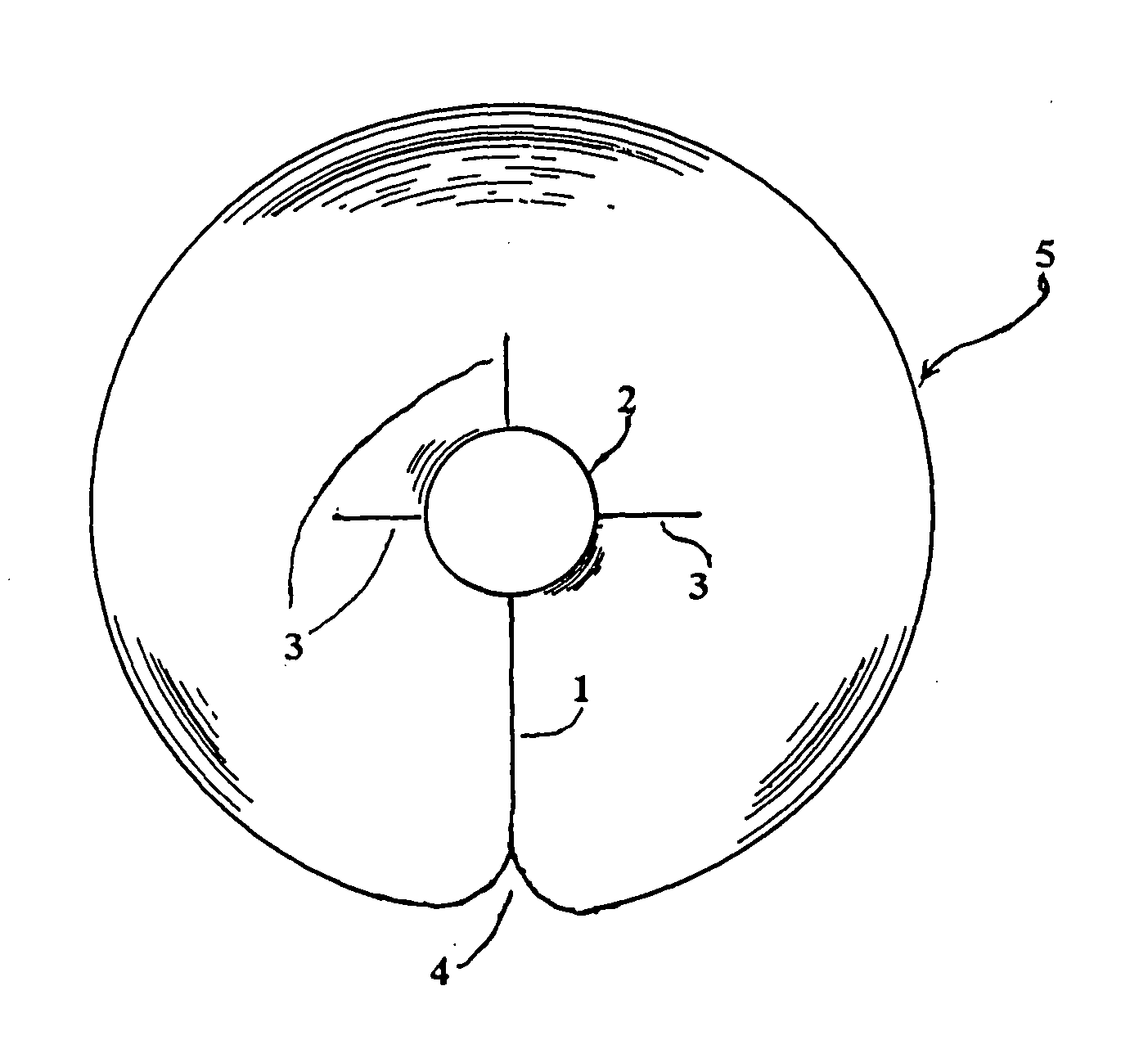

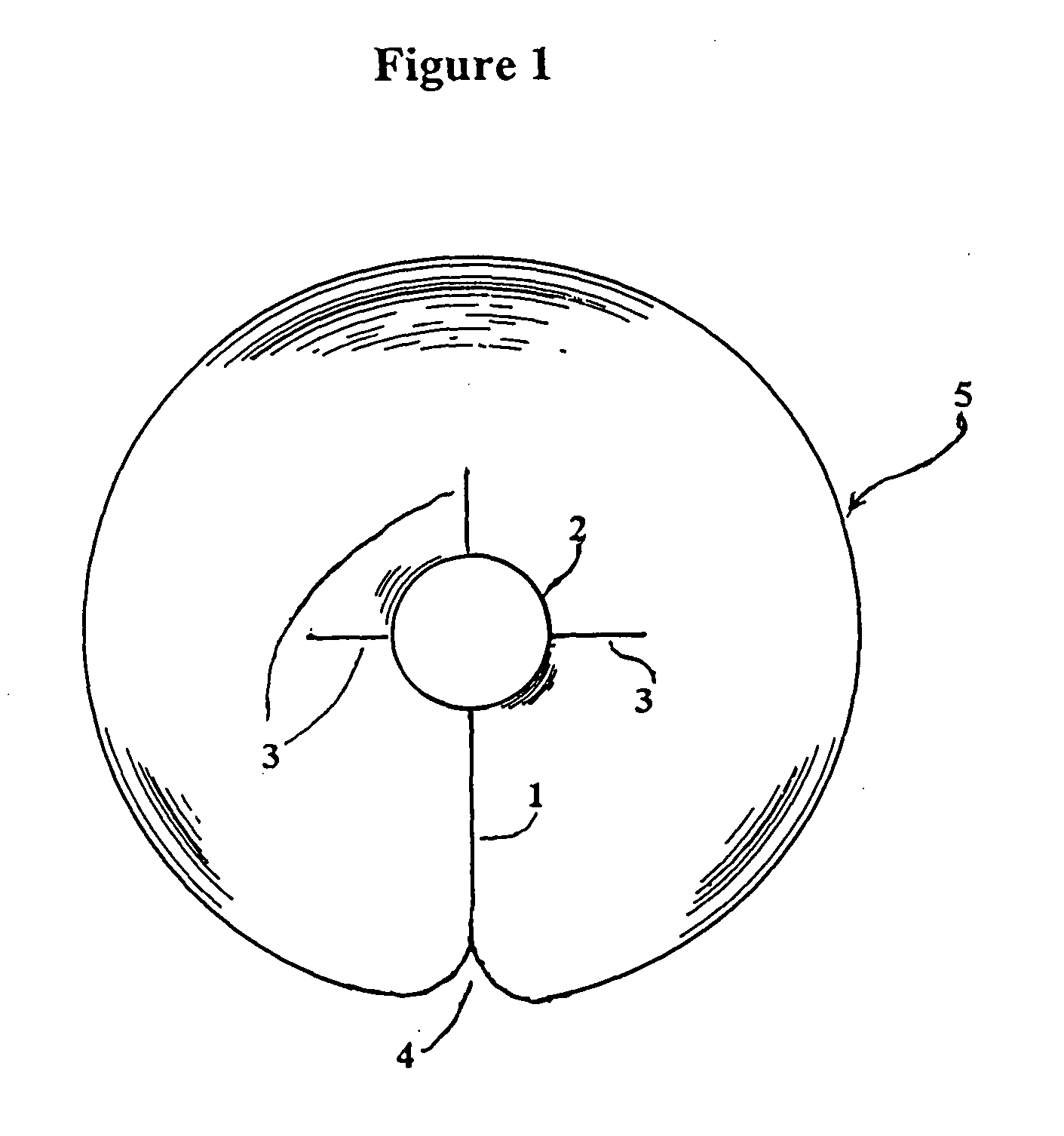

Post Operative Wound Support Device

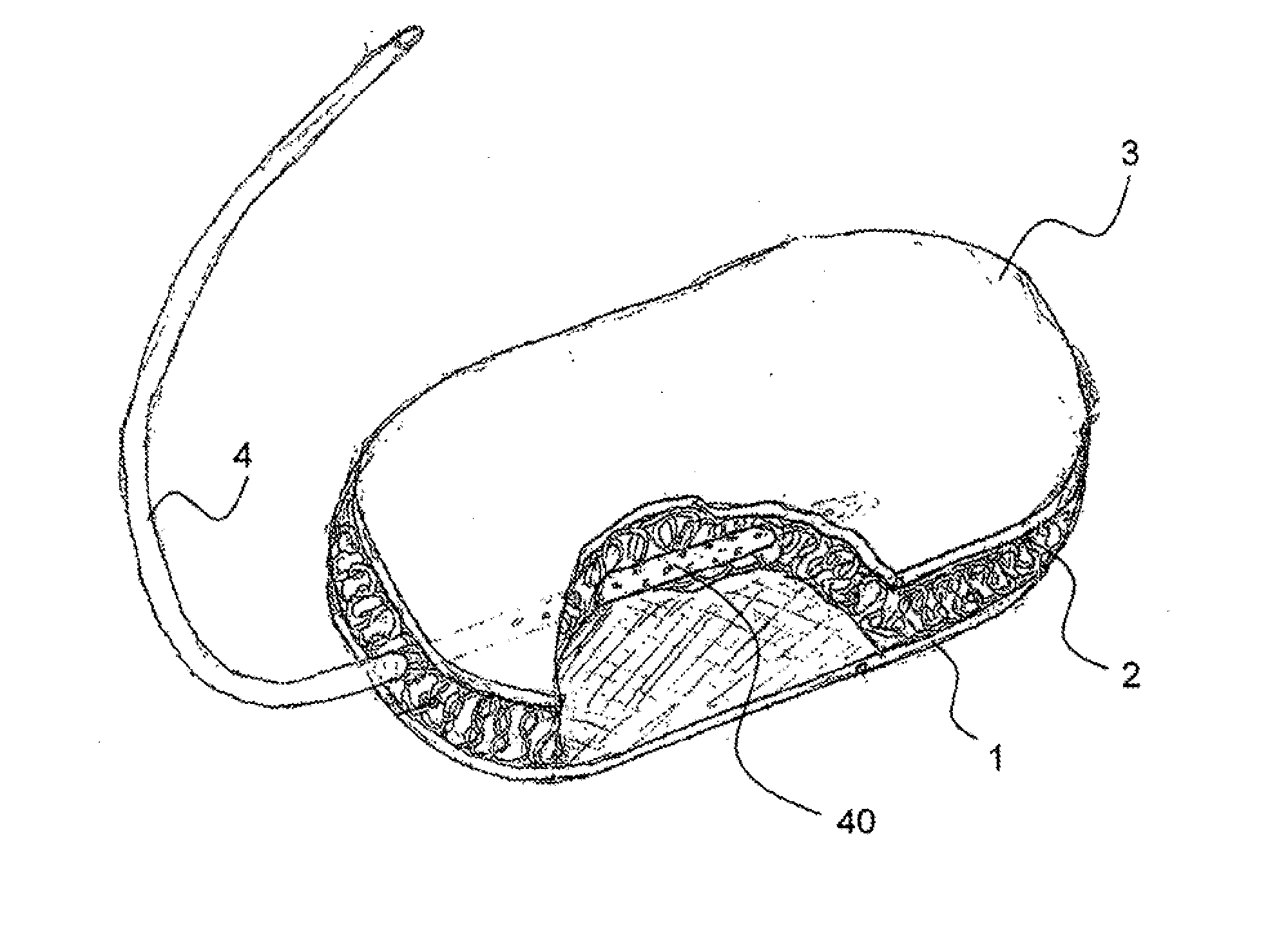

InactiveUS20120316491A1Easy to take backQuality improvementStentsBalloon catheterWound.exudatePost operative

A wound drainage and hemostasis promoting medical device (1) are disclosed. A balloon (15) is temporary inflated and arranged outside a sheath (10), in contact with tissue surrounding a wound cavity for hemostasis promotion. The drainage device comprises a fluid communication channel for wound exudate from wound. The balloon is deflated and retracted into said sheath for removal from said wound cavity. Thus the medical device is percutaneously retractable from said confined wound.

Owner:AEEG

Drainage devices and methods

InactiveUS7766886B2Efficient releaseSafe and effective and usefulWound drainsMedical devicesBiomedical engineeringVALVE PORT

Active and passive wound drainage systems and method are provided. A drainage device includes an input passage for receiving the fluid from a site on or within the patient's body, a container for holding the fluid, and a reversible valve disposed between the input passage and the container. The reversible valve in an original configuration provides unidirectional fluid flow from the input passage toward the container, and in a reversed configuration provides fluid flow from the container toward the input passage.

Owner:RGT UNIV OF CALIFORNIA

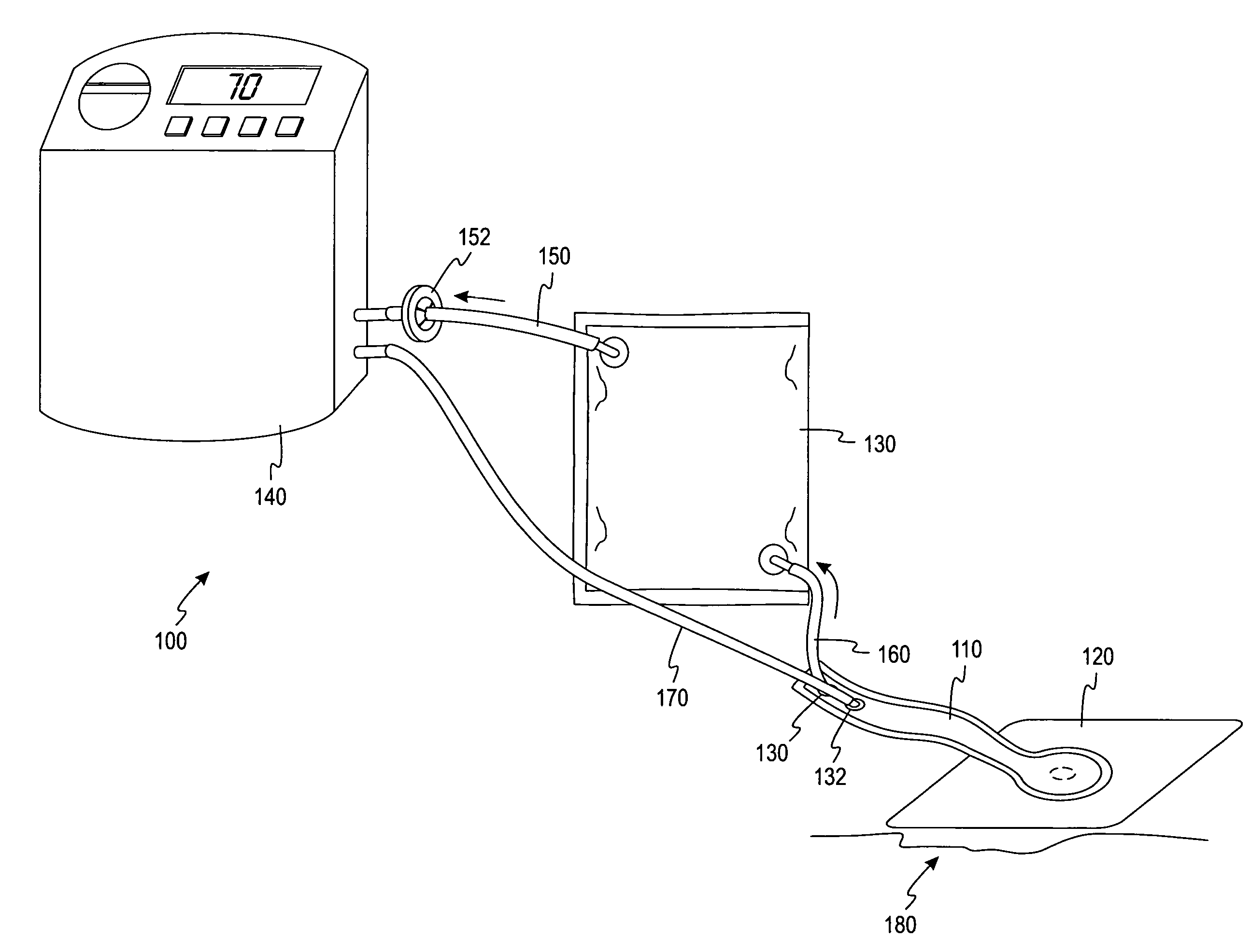

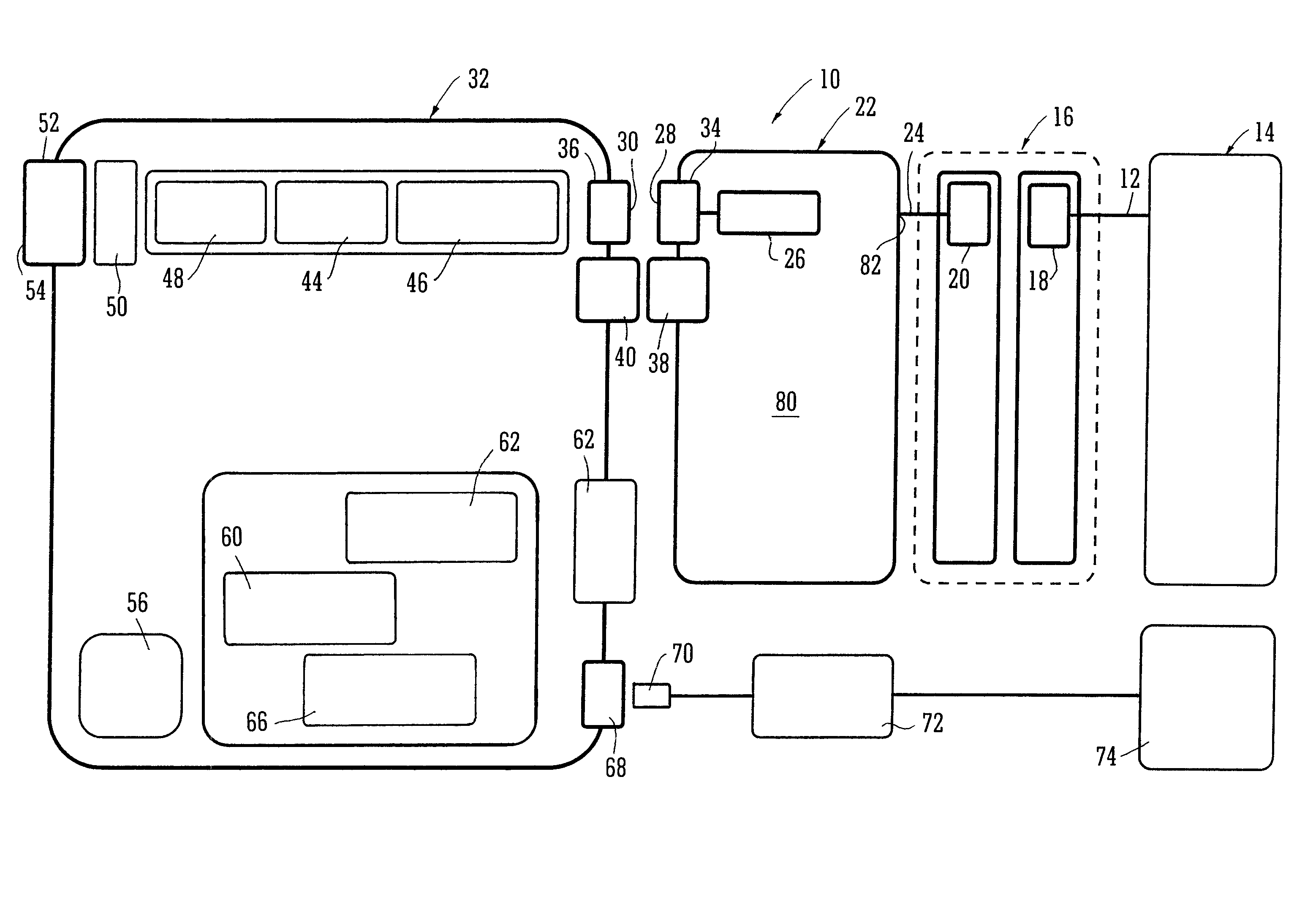

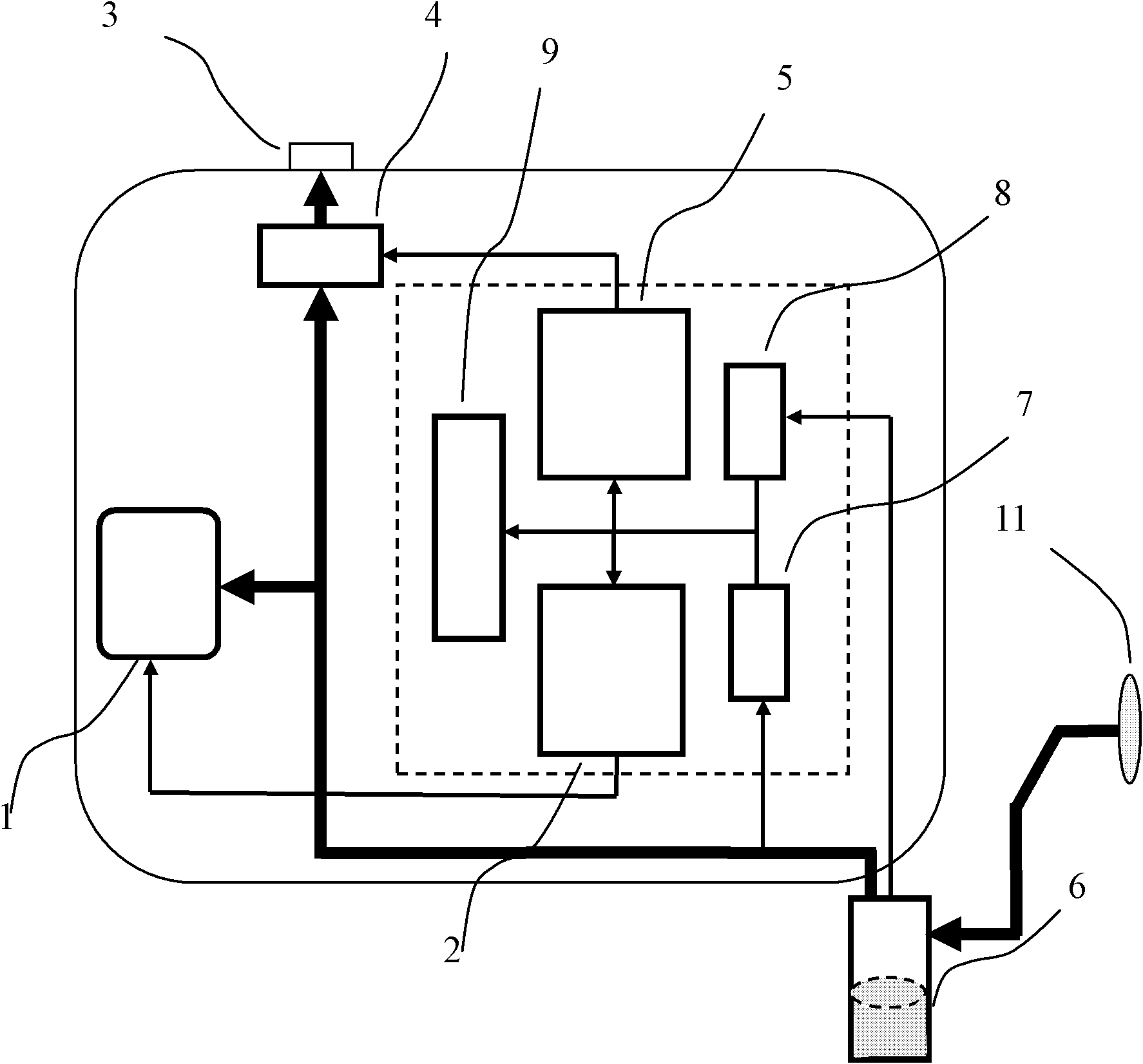

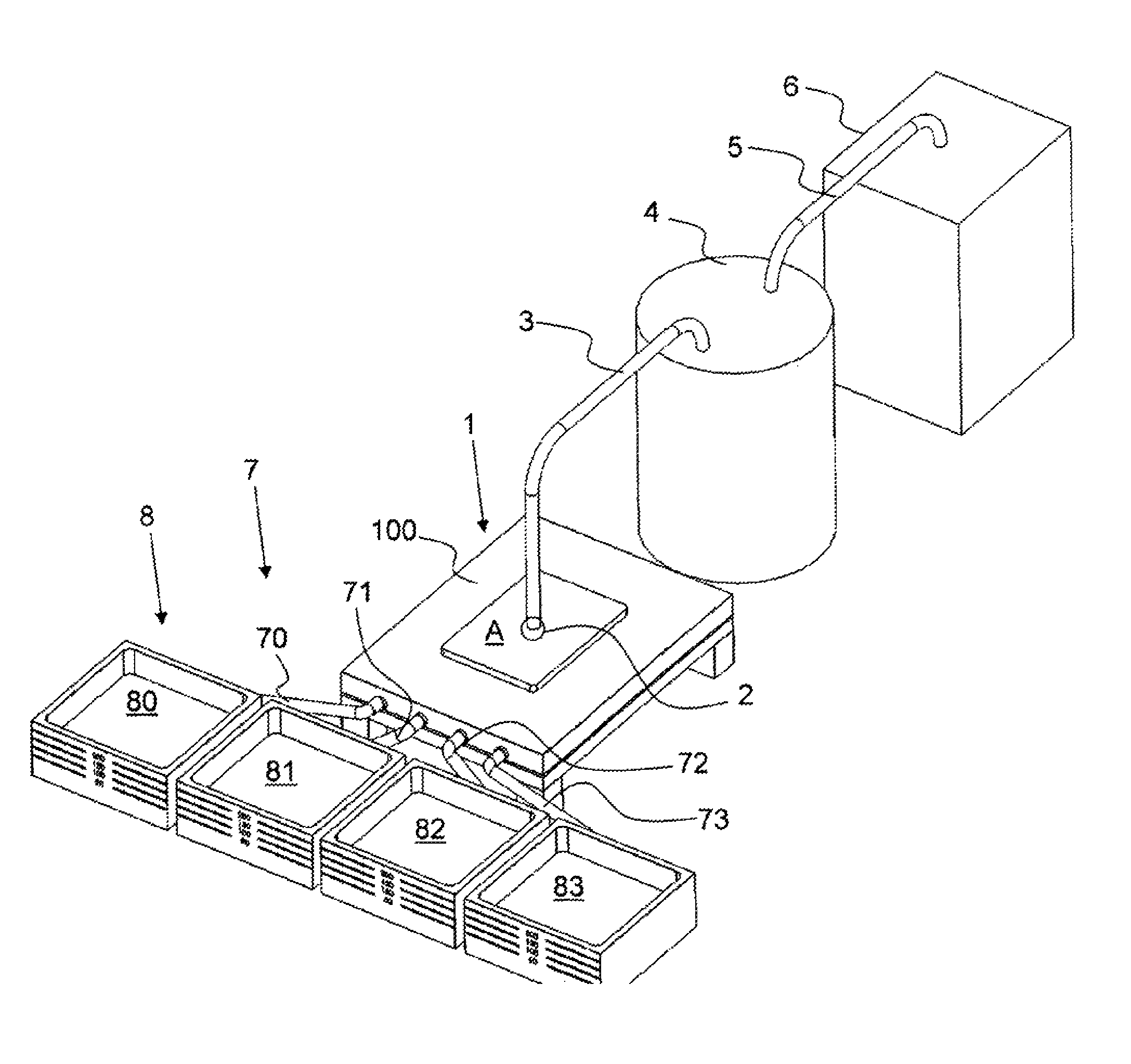

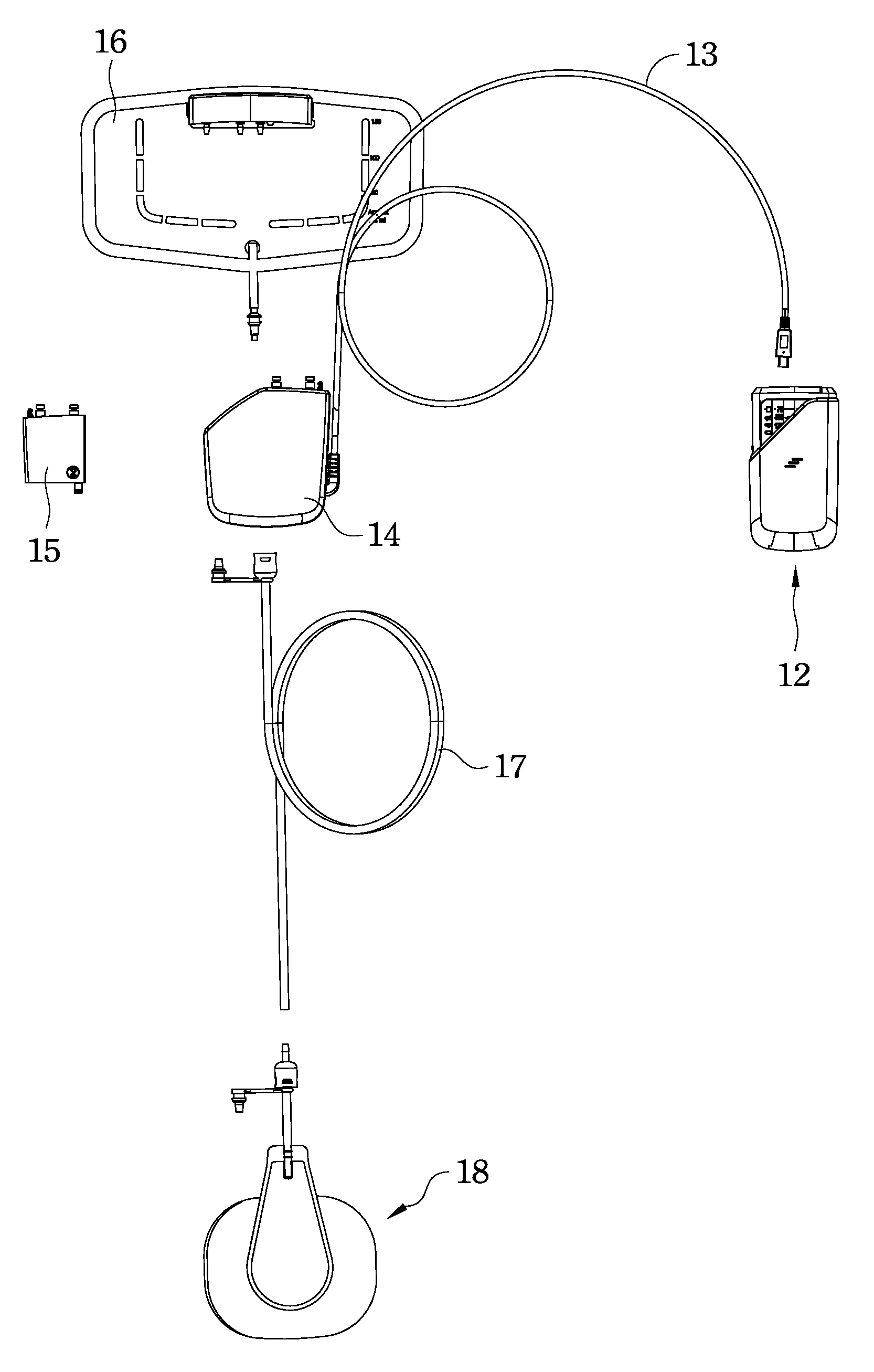

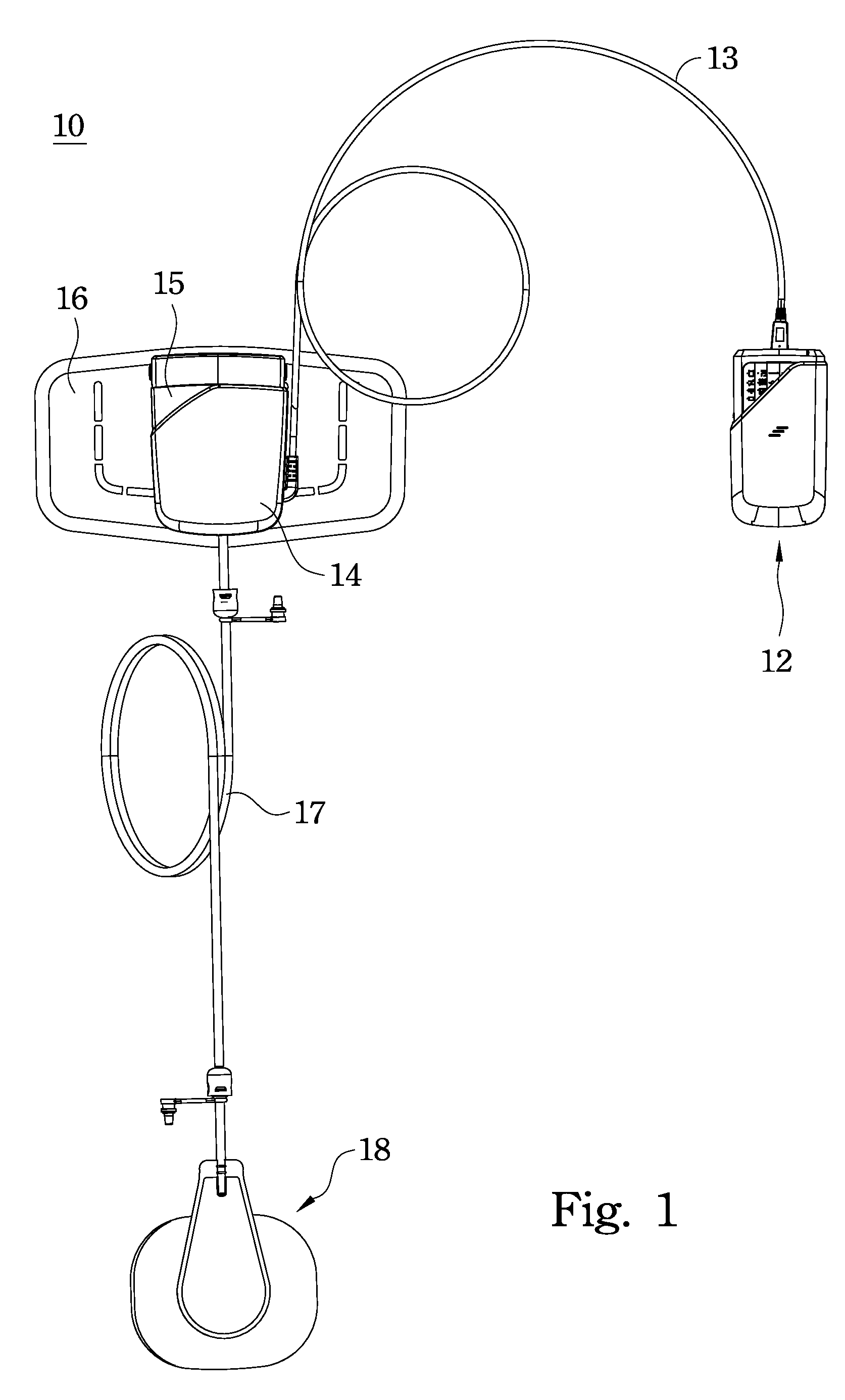

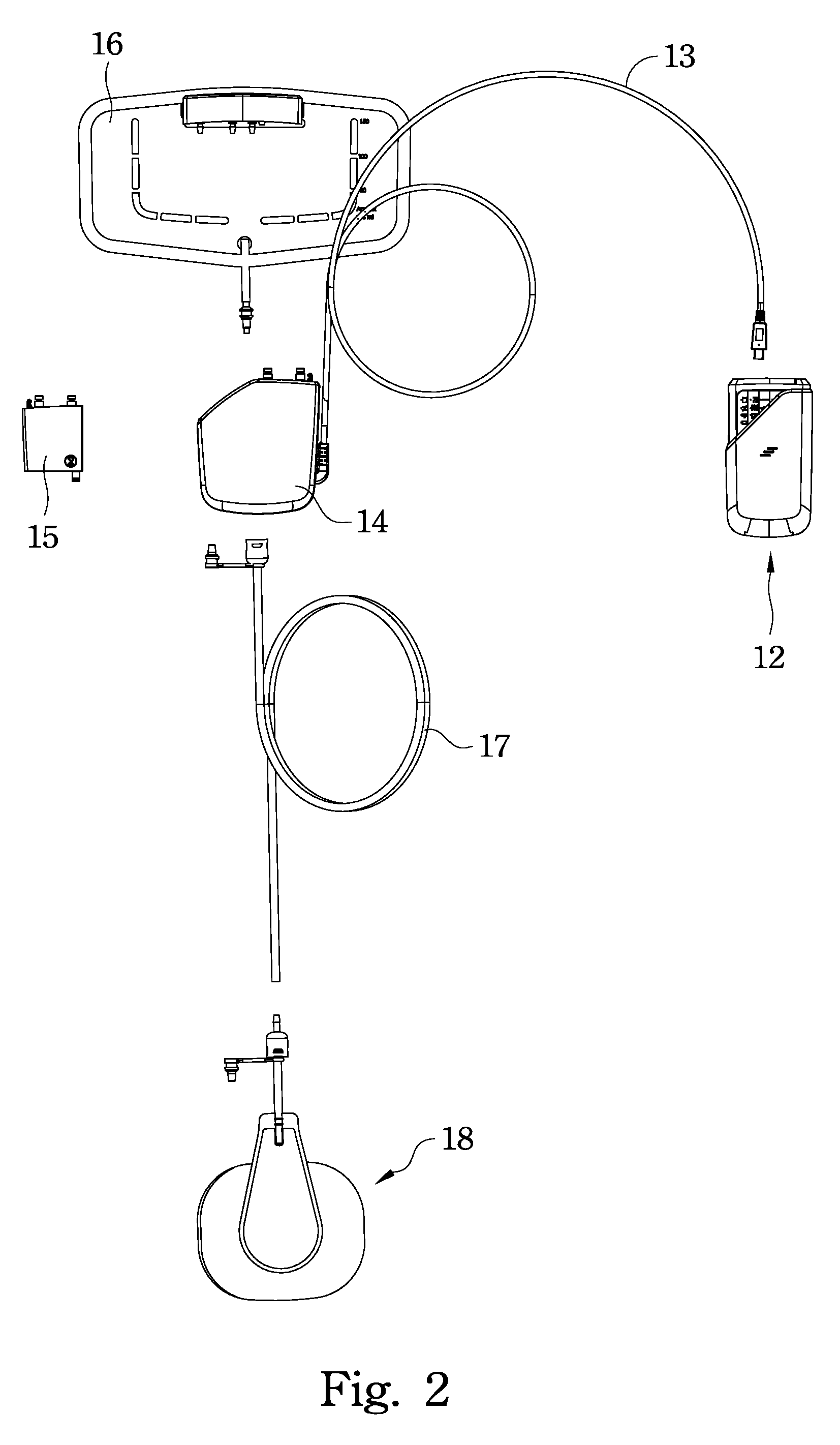

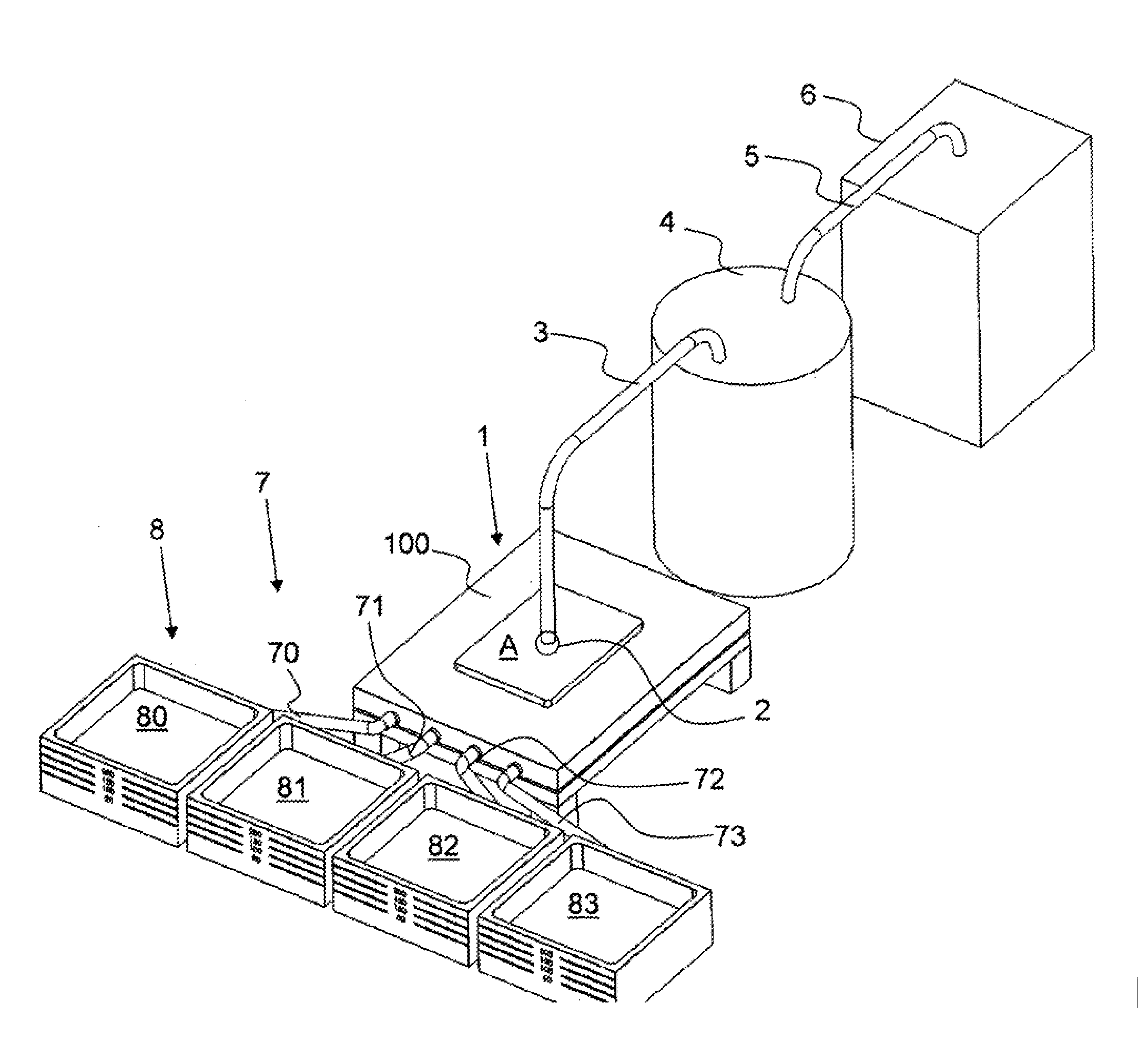

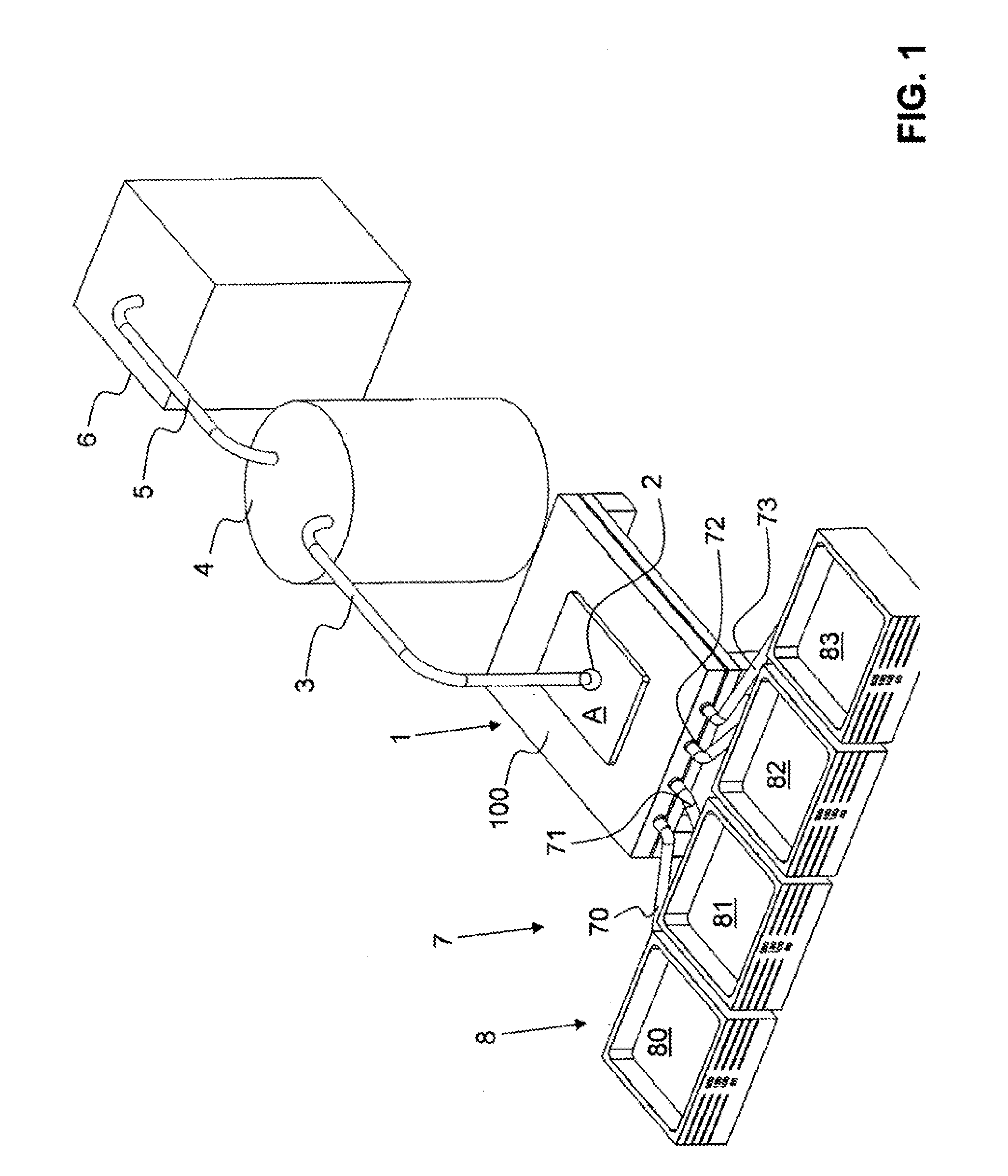

Wound drainage therapy system

ActiveUS9199010B2Easy to disassembleEven more portableIntravenous devicesSuction drainage systemsPositive pressureComputer module

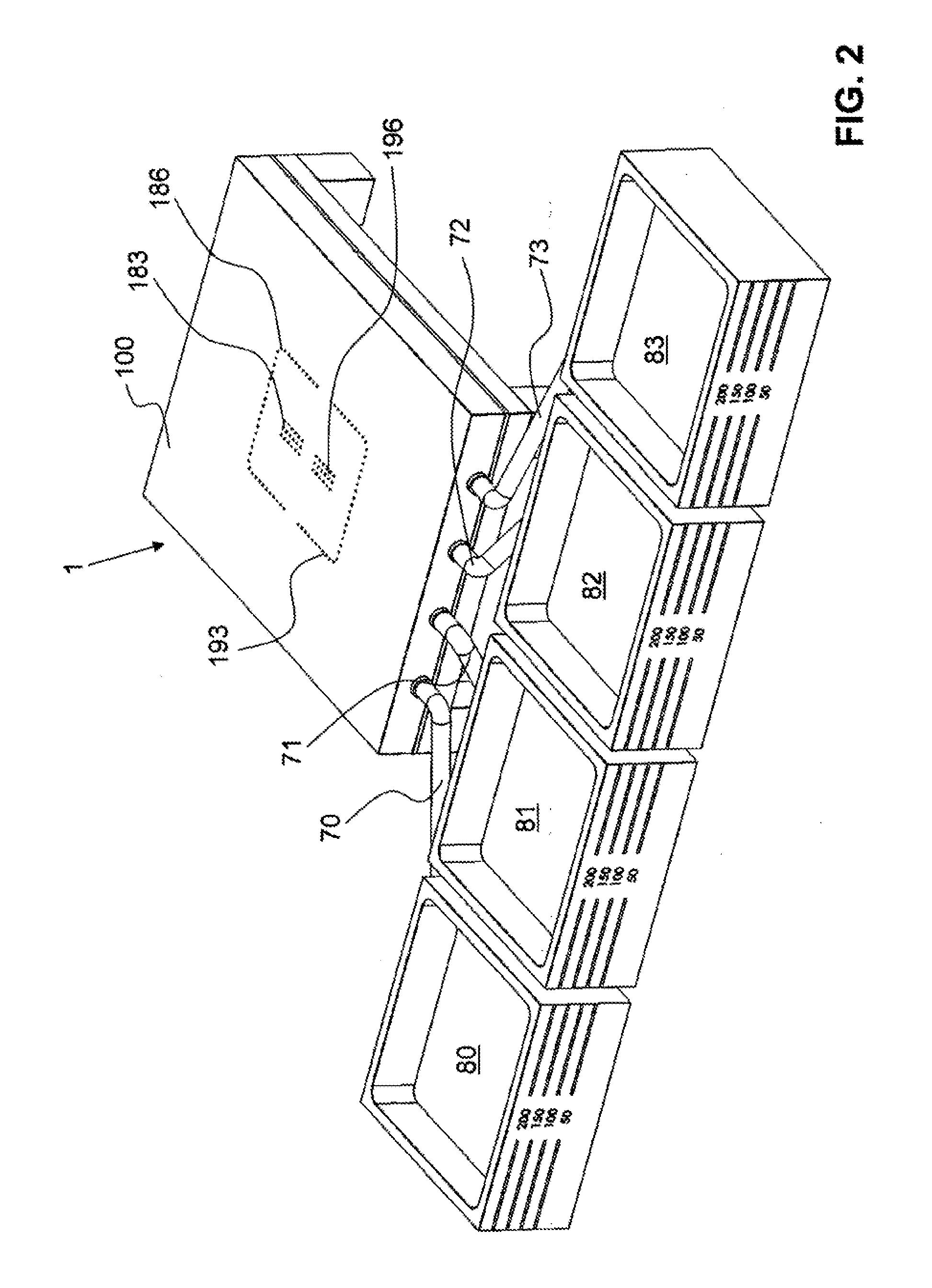

A wound drainage therapy system includes a wound seal unit, a fluid collector unit, a vacuum driving unit and an actuator. The fluid collector unit is detachably connected with the wound seal unit, and the fluid collector unit has a multiple-pipe integration module and a collection bag. The multiple-pipe integration module has a first row connection port group and a second row connection port group. The vacuum driving unit has a vacuum generator. The actuator has a motor, a negative pressure detector and a positive pressure detector, wherein the motor is used to drive the vacuum generator to operate and the motor is detachably connected with the vacuum generator. A connection port of the negative pressure detector and a connection port of the positive pressure detector are detachably connected with another two connection ports of the second row connection port group respectively.

Owner:APEX MEDICAL CORPORATION

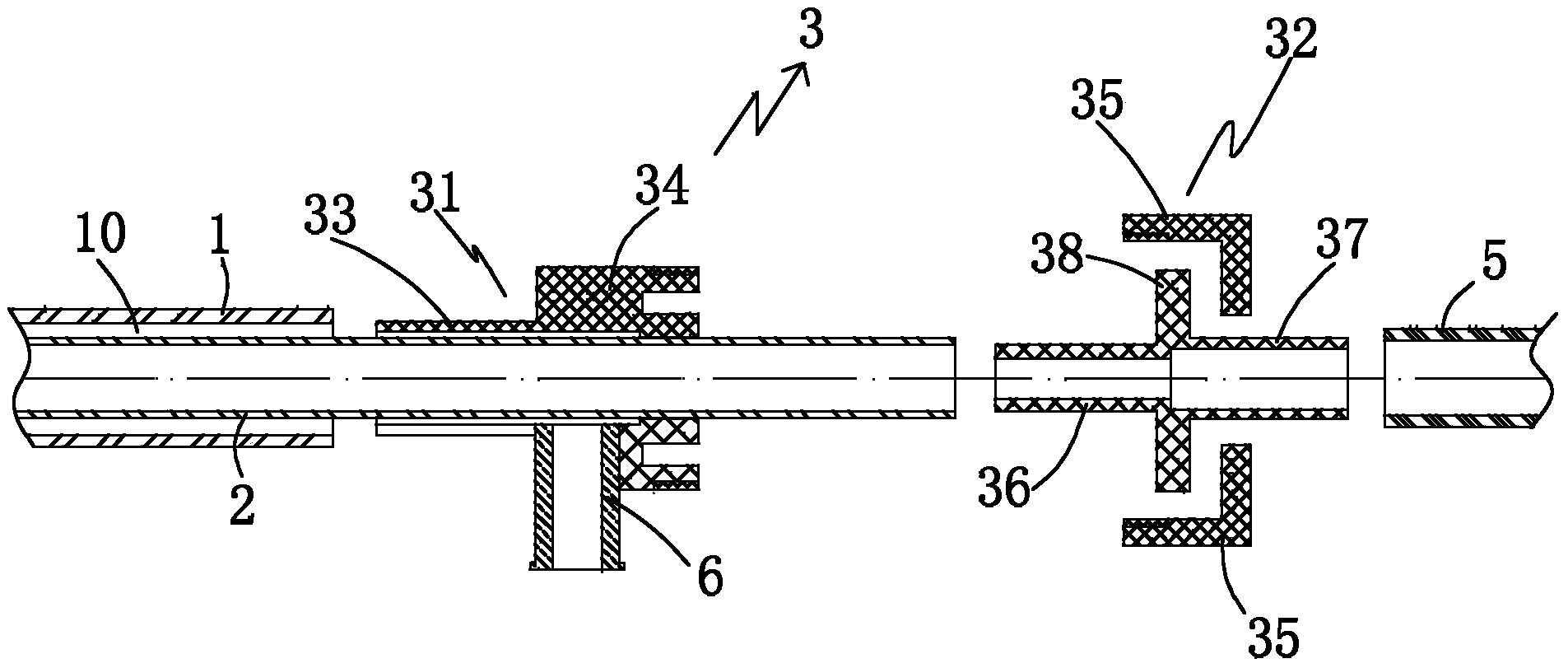

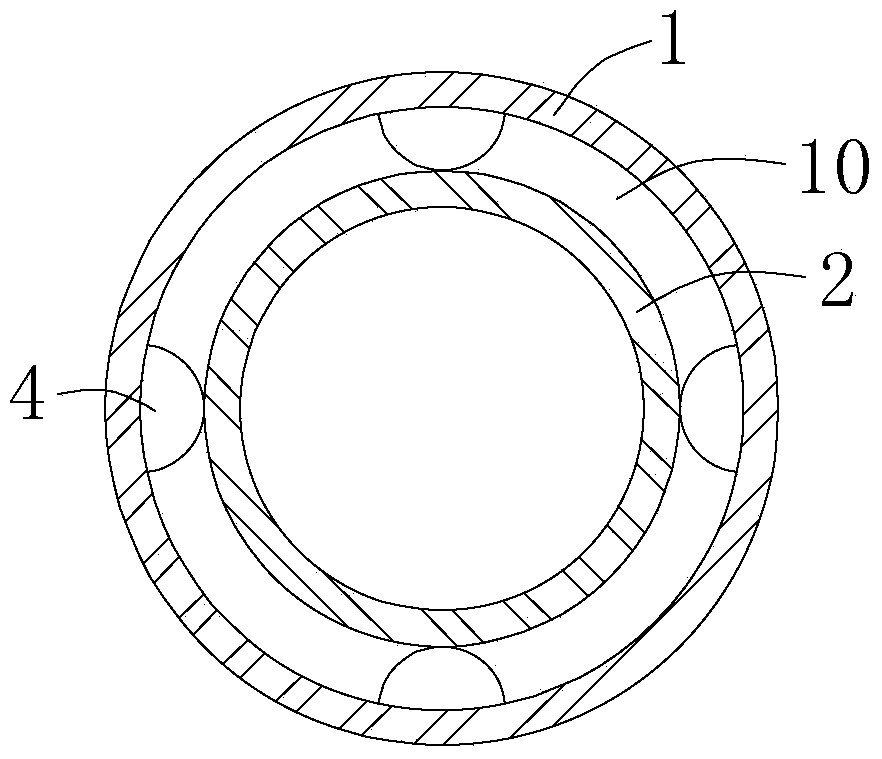

Three-cavity negative-pressure wound irrigation and drainage tube

ActiveCN104941015AHigh hardnessImplanted smoothlyMulti-lumen catheterIntravenous devicesGynecologyDrainage tubes

The invention relates to medical human body wound drainage consumables and provides a three-cavity negative-pressure wound irrigation and drainage tube. The negative-pressure wound irrigation and drainage tube comprises an in-vivo drainage tube and an in-vitro connection tube, wherein the in-vivo drainage tube adopts an integral structure and is provided with a main drainage tube, an irrigation tube and a guide wire implanting tube which are parallelly arranged lengthways; the main drainage tube is arranged in the geometric center of the in-vivo drainage tube, and the irrigation tube and the guide wire implanting tube are located at the periphery of the main drainage tube; a lower groove is formed in the outer wall of the in-vivo drainage tube, and a plurality of drainage openings are formed in the lower groove and communicated with the main drainage tube; the in-vitro connection tube comprises an in-vitro drainage tube, an in-vitro irrigation tube and an in-vitro guide wire implanting tube which are mutually independent; the in-vitro drainage tube, the in-vitro irrigation tube and the in-vitro guide wire implanting tube are respectively communicated with the main drainage tube, the irrigation tube and the guide wire implanting tube which are arranged at the outer end of the in-vivo drainage tube. The three-cavity negative-pressure wound irrigation and drainage tube mainly adopts a three-cavity structure, is used for drainage of wounds deep in a human body and has the effects of being accurate in implanting, favorable in drainage and irrigation, resistant to blockage, and the like.

Owner:LANZHOU UNIVERSITY

Test unit for wound drainage dressings

ActiveUS20100268197A1Easy to useQuick and easy applicationWound drainsMedical devicesBiomedical engineeringSupport surface

The invention relates to a test unit for wound drainage coverings comprising: a base body with at least one cavity; at least one supply line that runs through the base body and which connects an outer side of the base body to the cavity; a surface of the base body that is embodied as a support surface for supporting wound coverings and the wound drainage coverings thereof and several channels that run through the base body, the channels connecting the cavities to the support surface. Low pressure can be produced in the cavity and the channels when the support surface is covered in an air-tight manner. As a result, wound drainage applications are tested in different ways using simple and economical means.

Owner:MEDELA HLDG AG

Wound drainage equipment, conduit, connector and wound cover

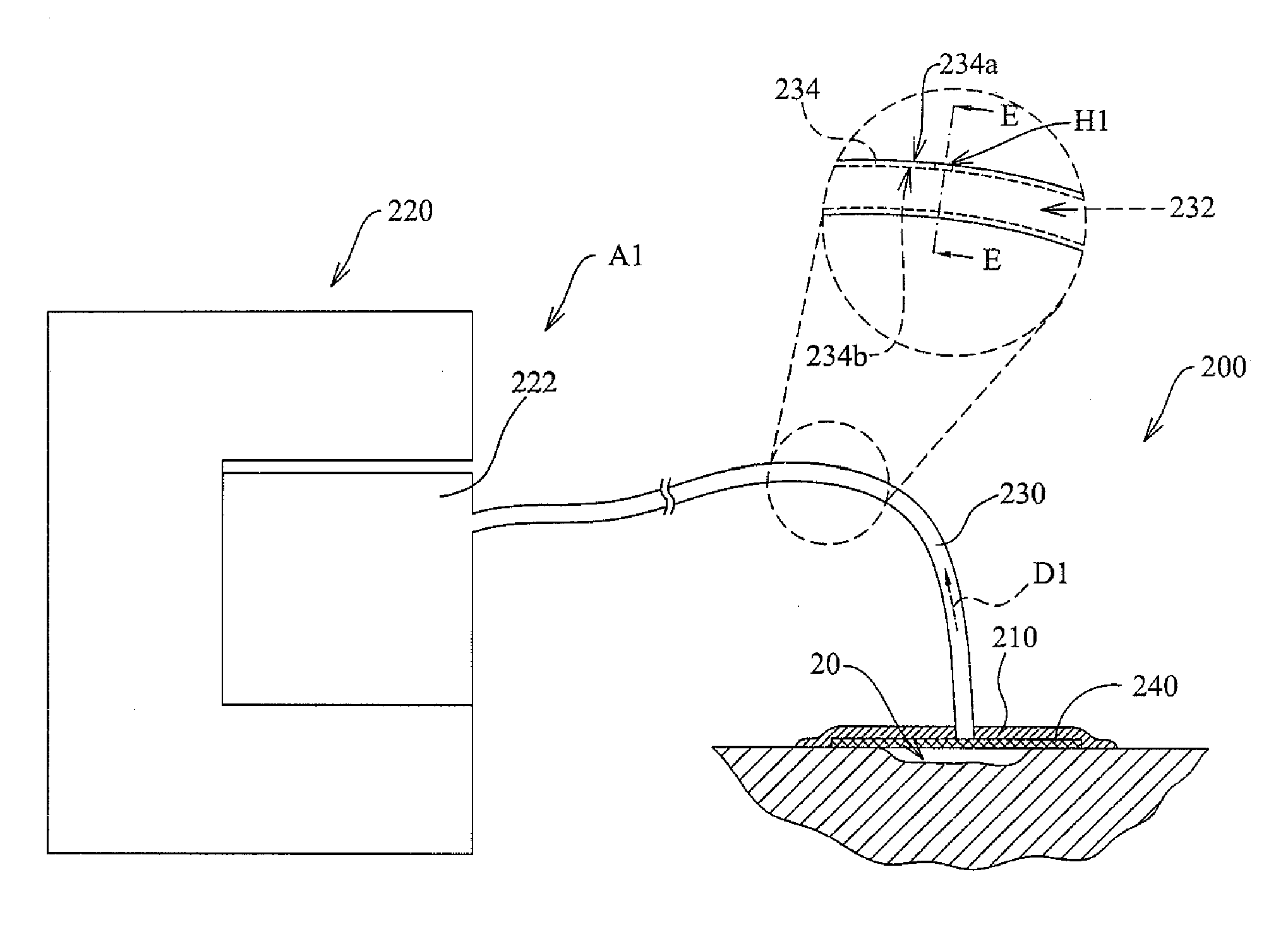

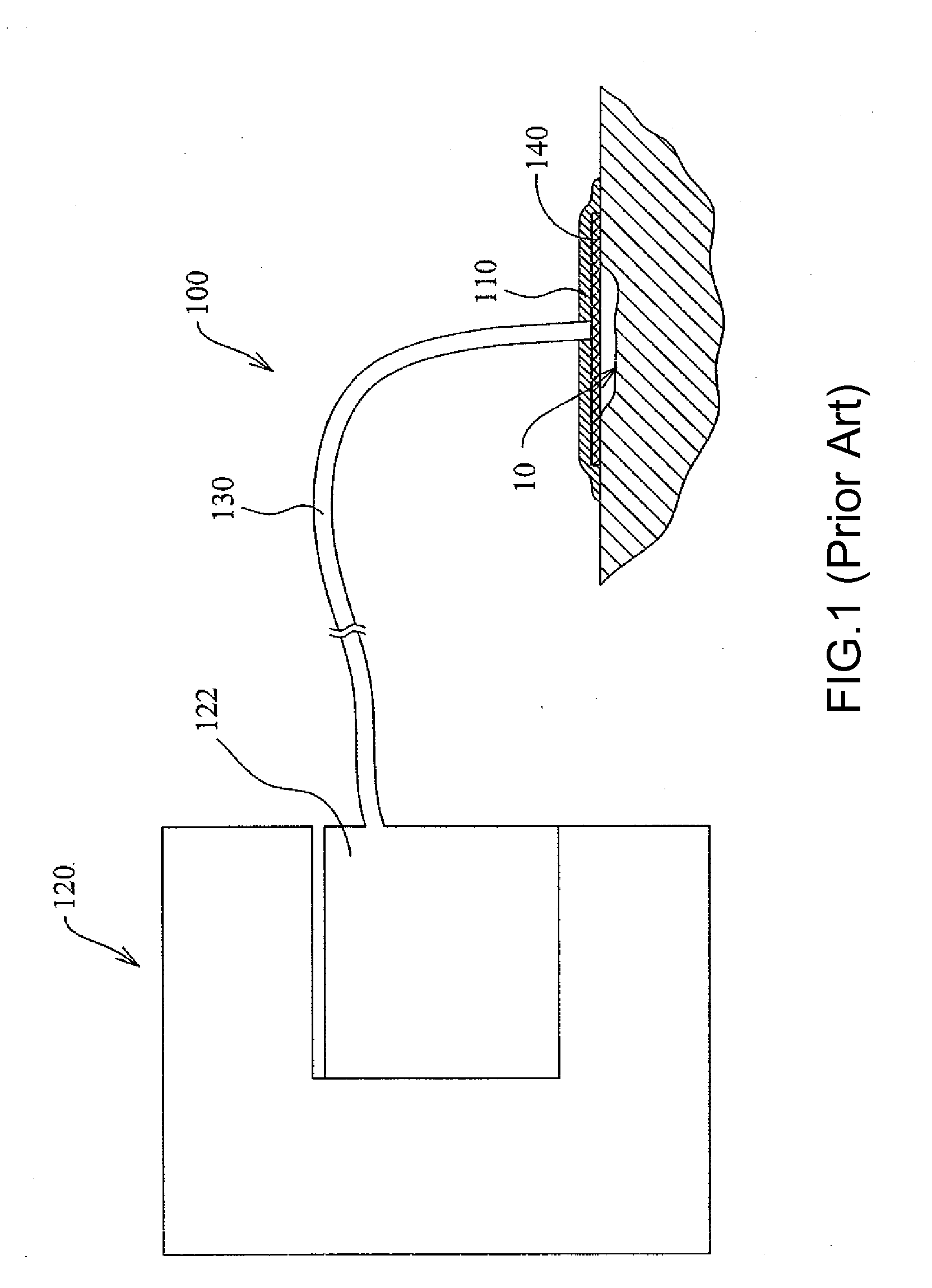

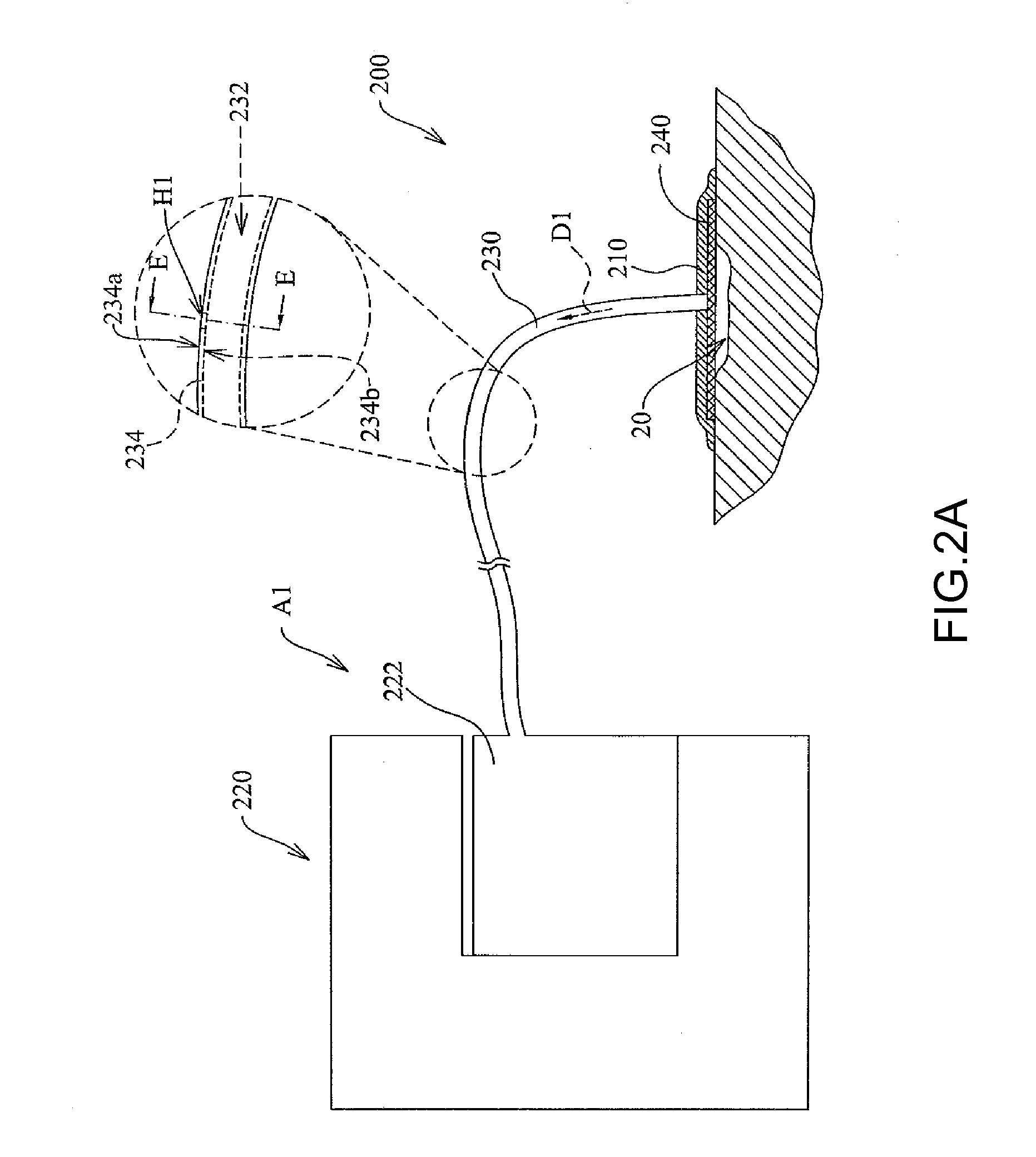

InactiveUS20120310189A1Sucks exudates in a wound more efficientlySucks the exudates in the wound more efficientlyMedical devicesIntravenous devicesCatheterBiomedical engineering

A wound drainage equipment adapted for sucking exudates in a wound is provided. The wound drainage equipment includes a wound drainage assembly and at least one aeration hole. The wound drainage assembly includes a wound cover and a conduit. The wound cover is adapted for being disposed at the wound. The conduit has a lumen adapted for communicating with the wound. The exudates in the wound are adapted for being sucked through the lumen. The aeration hole is disposed at the conduit. The aeration hole communicates with the lumen and an external environment. The efficiency of sucking the exudates in the wound according to the wound drainage equipment of an embodiment of the present invention is relatively high.

Owner:SUZRIC ENTERPRISE

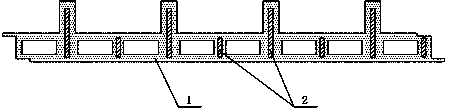

Double-sleeve type drainage pipe easy to replace

ActiveCN104014068AReduce contact areaReduce frictional resistanceWound drainsCatheterEngineeringMedical device

The invention relates to a wound drainage device or an analogue, in particular to a double-sleeve type drainage pipe easy to replace and belongs to the technical field of medical devices. The double-sleeve type drainage pipe solves the technical problem that a double-sleeve drainage pipe in the prior art is difficult to replace. The double-sleeve type drainage pipe comprises an outer pipe and an inner pipe sleeved with the outer pipe. The pipe wall at the front end of the outer pipe and the pipe wall at the front end of the inner pipe are provided with an outer drainage hole and an inner drainage hole respectively, wherein the outer drainage hole and the inner drainage hole are communicated. A connector is arranged at the tail end of the outer pipe, and the outer pipe and the inner pipe are detachably connected through the connector and are in air-tight seal. The double-sleeve type drainage pipe is characterized in that the inner pipe wall of the outer wall or the outer pipe wall of the inner pipe is provided with a plurality of protrusions and / or a plurality of flanges which are arranged in the axial direction of the drainage pipe, and the inner pipe wall of the outer wall and the outer pipe wall of the inner pipe form contact through the protrusions and / or the flanges. The double-sleeve type drainage pipe has the advantages that the inner pipe is convenient to replace, and the drainage effect is good.

Owner:杭州康源随喜医疗科技有限公司

Hollow wall plastic steel wound drainage pipe material and manufacturing method thereof

ActiveCN103511765AImprove mechanical propertiesImprove wear resistanceCoatingsRigid pipesEngineeringPipe

The invention relates to a hollow wall plastic steel wound drainage pipe material and a manufacturing method thereof. The hollow wall plastic steel wound drainage pipe material comprises blending materials and high-strength steel belts, wherein the peripheries of the high-strength steel belts are wrapped by the blending materials. The manufacturing method includes the steps that the blending materials are manufactured, and corresponding high-strength steel belts are selected to be installed in a belt hanging machine and opened, enter a steel belt straightener and are heated through a high-frequency heater; the steel belts enter a cladding mold, the blending materials are added, and then the steel belts are placed in a high-speed mixer to be stirred; after stirring is completed, the steel belts are placed in an extruder to extrude the clad steel belts, the steel belts are pulled and cooled, and vacuum sizing is carried out on the steel belts; under the action of a belt sending machine, the steel belts are fed into a winding cage to be wound; rotational traction is added, the steel belts at cutting positions are picked off, cutting finishing is conducted, and the steel belts are examined and put in storage after completing. The plastic steel composite pipe material manufactured through the method has an excellent mechanical property, abrasion resistance and ageing resistance, and is good in toughness, high in ring stiffness, resistant to high and low temperatures, long in service life, good in basis adaptability and sealing performance and suitable for production and market promotion on a large scale.

Owner:JIANGSU BAIANJU PLASTIC PIPE IND CO LTD

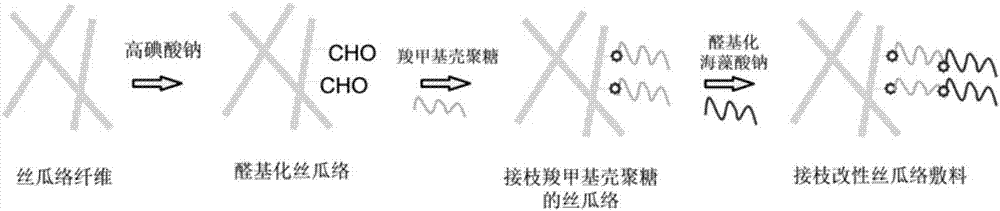

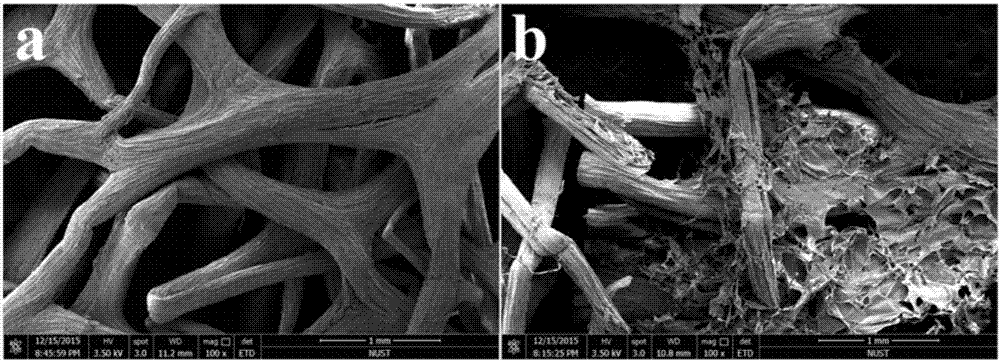

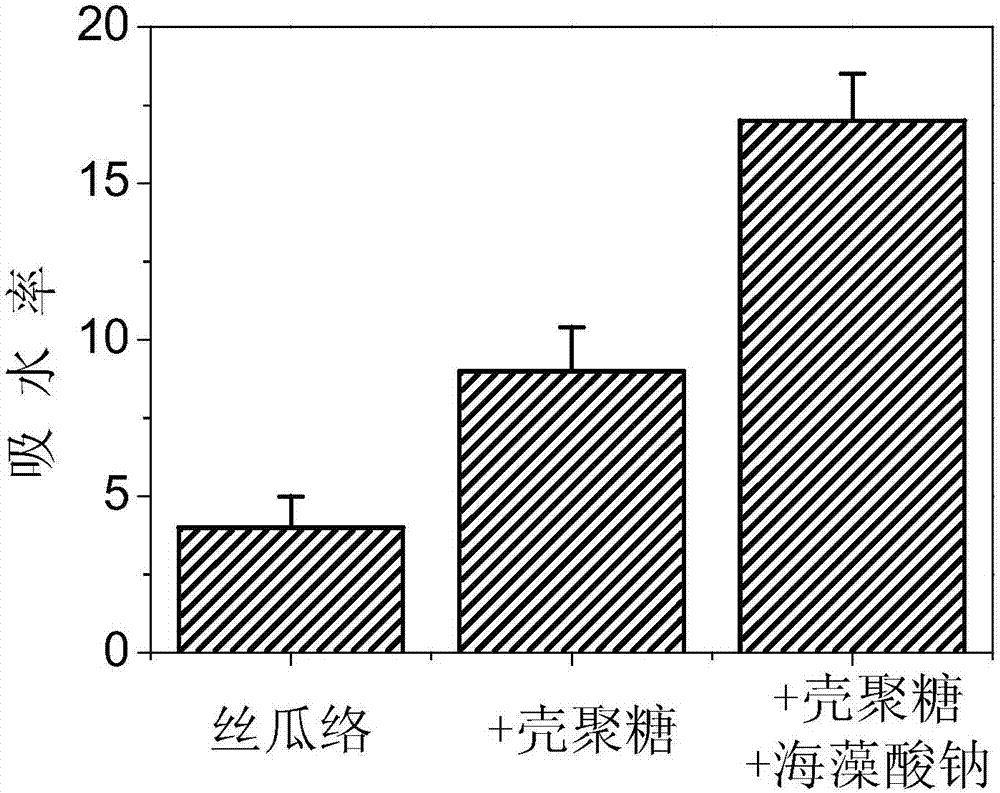

Preparation method of loofah sponge anti-adhesion dressing for wound surface

ActiveCN107137752AImprove hydrophilic abilityGood anti-adhesionAbsorbent padsBandagesFiberBiocompatibility Testing

The invention discloses a preparation method of loofah sponge anti-adhesion dressing for the wound surface. According to the preparation method, loofah plant fibers are adopted as the base material, polysaccharide molecules are grafted through conjugation reaction, so that the tissue anti-adhesion property of the natural plant fiber dressing for the wound surface is improved, and the effective protection for the wound of the skin is realized. The loofah sponge anti-adhesion dressing for the wound surface can be directly applied to the wound surface, has the extremely excellent absorption effect, and is particularly suitable for treating the skin diseases including burns, pus, wound drainage, anabrosis and the like. The hydrophilic performance and tissue-adhesion-resisting property of the natural plant fiber dressing for the wound surface are obviously improved, and meanwhile, the toxic chemical crosslinking agent is not used, so that the biocompatibility and the safety of the dressing are improved. The process is simple, the cost is low, the modifying temperature is low, the grafting speed is high, and the method is suitable for large-scale industrial production.

Owner:NANJING UNIV OF SCI & TECH

Device and method for supporting wound drainage systems

InactiveUS20050072820A1Secure retentionLow costTravelling sacksTravelling carriersEngineeringMedical treatment

A support and retention device for use in holding medical appliances, particularly wound drainage systems. The present invention comprises a soft, flexible material formed into a circle, spliced in a fashion that does not increase the diameter of the splice. An upper portion of the rope is placed around the wearer's neck, wherein a lower portion of the rope is gathered together to form a doubled length, and held together by a clasping means. A medical appliance may then be secured to the doubled length section of rope by a fastener, thereby securely supporting the medical appliance thereon.

Owner:HARDISON PAMELA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com