Double-sleeve type drainage pipe easy to replace

A double-set, drainage tube technology, applied in the direction of wound drainage devices, catheters, etc., can solve the problems of difficult replacement of inner tubes, and achieve the effects of convenient replacement, enhanced use effect, and convenient filtration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

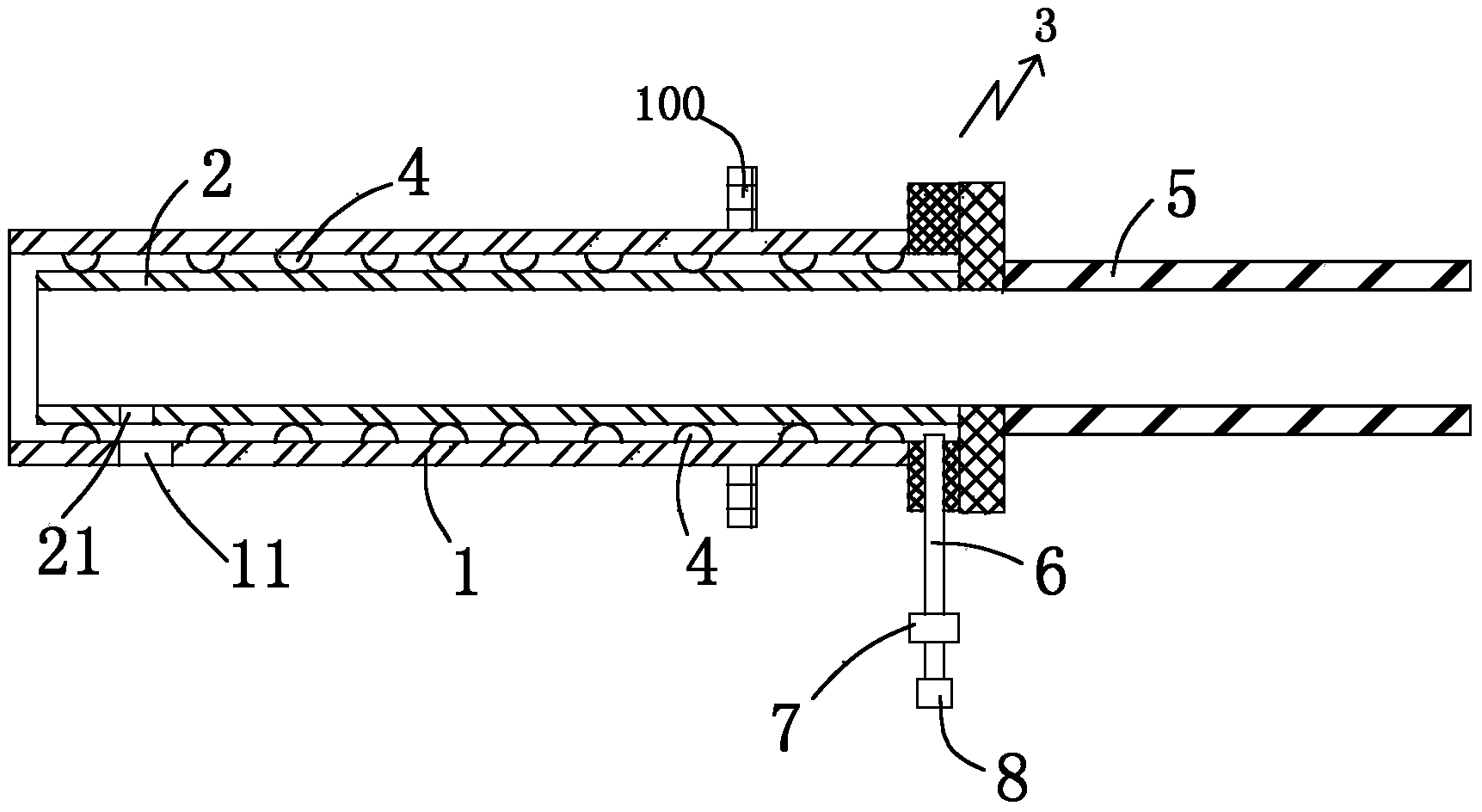

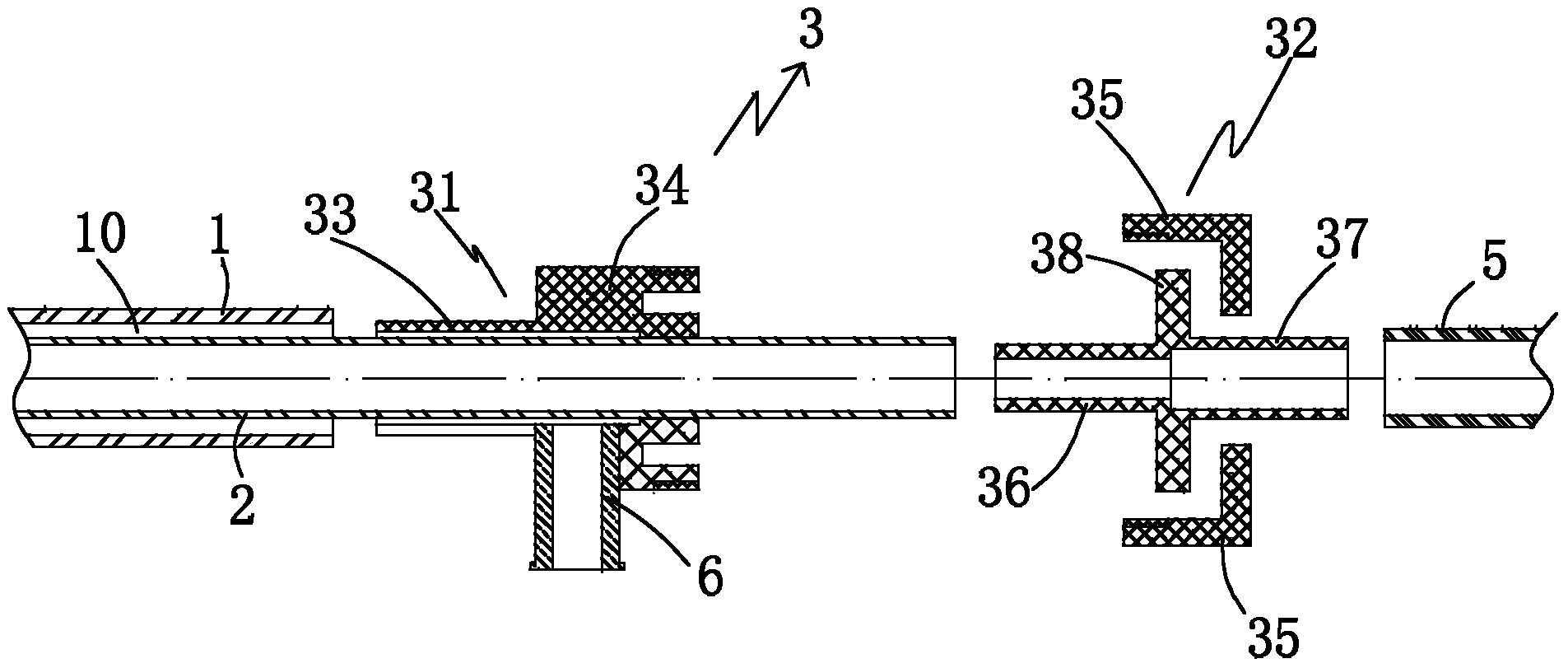

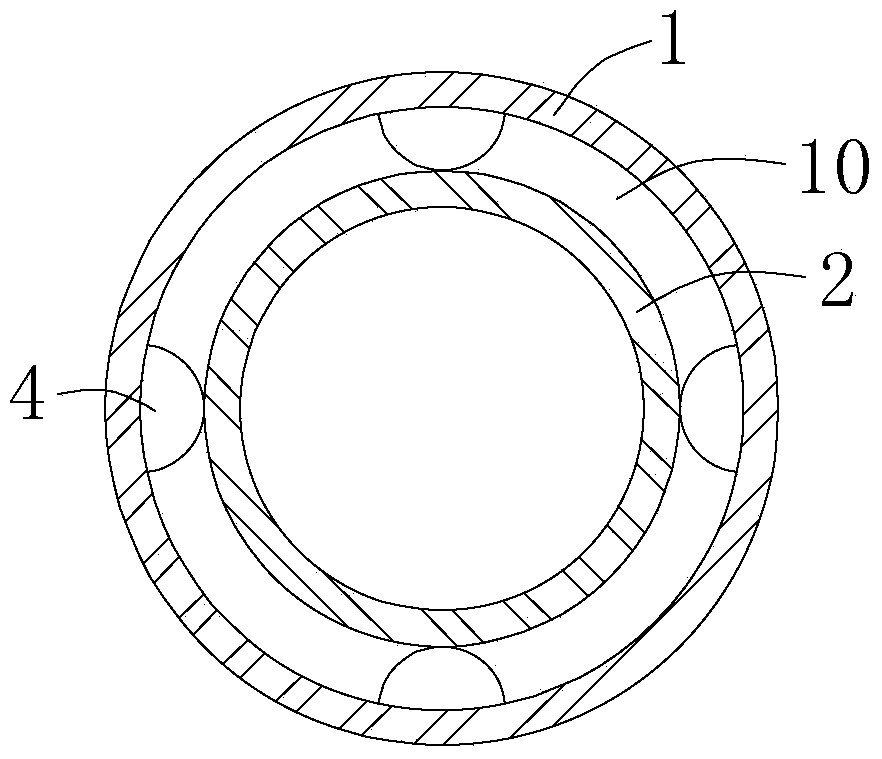

[0028] like Figure 1-7 As shown, the easily replaceable double-set drainage tube of this embodiment includes an outer tube 1 and an inner tube 2 sleeved in the outer tube 1, and is respectively arranged on the front end tube walls of the outer tube 1 and the inner tube 2. There are through outer drainage holes 11 and inner drainage holes 21. A connector 3 is provided at the end of the outer tube 1. The outer tube 1 and the inner tube 2 are detachably connected and airtight through the connector 3. The inner tube of the outer tube 1 Several protrusions 4 are equidistantly arranged on the wall, and the height and quantity of the protrusions 4 can support the outer pipe and the inner pipe, so that only these protrusions pass between the inner pipe wall of the outer pipe and the outer pipe wall of the inner pipe. Contact shall prevail. The outer surface of the protrusion 4 is a spherical surface, so that a point contact is formed between the protrusion 4 and the outer surface of...

Embodiment 2

[0033] like Figure 8As shown, the difference between this embodiment and Embodiment 1 is that several ribs 9 are arranged on the inner tube wall of the outer tube 1, the ribs 9 are arranged along the axial direction of the drainage tube, and the ribs 9 can be arranged along the outer tube The entire length direction of the wall is arranged at intervals, or only one section, and several sections of convex ribs are arranged alternately. The shape of the convex rib 9 can be a triangular prism, a semi-cylindrical column or other polygonal columns, and the height and quantity of the convex rib 9 can support the outer tube and the inner tube, so that there is a gap between the inner tube wall of the outer tube and the outer tube wall of the inner tube. Only contact through these ribs shall prevail. In this embodiment, the rib 9 is semi-cylindrical, so that a line contact is formed between the rib 9 and the outer surface of the inner tube 2 .

Embodiment 3

[0035] like Figure 9 As shown, the difference between this embodiment and Embodiment 1 is that: a ball groove 41 is provided on the protrusion 4, and a ball 42 is arranged in the ball groove 41, and the ball 42 is arranged on the inner wall of the outer tube and the inner tube. A rolling connection is formed between the outer pipe walls. During the processing, the ball groove 41 can be set to cover more than half of the ball 42, and there is a certain space between the ball groove 41 and the ball 42, which can be filled with aseptic lubricant, so that the ball 42 will not Comes out and is free to roll.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com