Preparation method of loofah sponge anti-adhesion dressing for wound surface

A technology of loofah and anti-adhesion, which is applied in the preparation of loofah anti-adhesion wound dressing and the preparation of natural plant fiber anti-adhesion wound dressing, which can solve the problems of wound granulation tissue adhesion and secondary trauma, and achieve anti-adhesion performance Good, ensure safety, avoid tissue adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

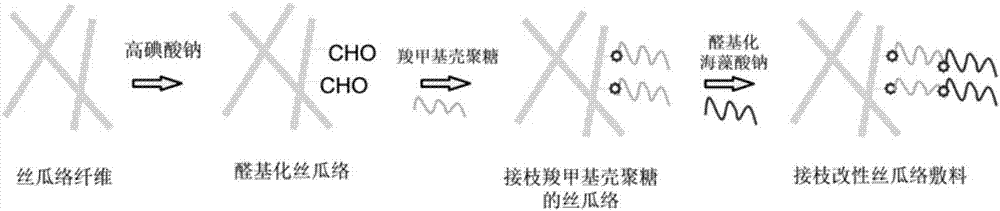

[0022] The preparation method of a kind of loofah anti-adhesion wound dressing of the present invention is to take loofah sponge body as the base material and form by grafting and modifying by Schiff base reaction. The schematic flow chart is as follows: figure 1 As shown, first graft aldehyde groups on the surface of loofah, then graft carboxymethyl chitosan, and finally graft alginate sodium alginate, specifically comprising the following steps:

[0023] Step 1, at room temperature, the loofah is immersed in an aqueous solution of potassium periodate with a concentration of 1.5-3wt% potassium periodate under the condition of avoiding light, stirred and reacted for 4-12 hours, and then washed to obtain the aldylated loofah;

[0024] Step 2, immersing the aldylated loofah in an aqueous carboxymethyl chitosan solution with a concentration of 0.25 to 1.5 wt% at room temperature, and reacting for 5 to 15 minutes to obtain a loofah grafted with carboxymethyl chitosan;

[0025] Ste...

Embodiment 1

[0030] (1) at room temperature, the loofah is immersed in a concentration of 2wt% potassium periodate aqueous solution under light-proof conditions, stirred and reacted for 8 hours, and then cleaned to obtain the aldylated loofah;

[0031] (2) immerse the aldylated loofah at room temperature in the carboxymethyl chitosan aqueous solution with a concentration of 1.5wt%, and react for 15 minutes to obtain the luffa of grafted carboxymethyl chitosan;

[0032] (3) 1.0 g of sodium alginate was dissolved in 100 ml of water at room temperature, then 1 g of sodium periodate was added, stirred for 4 hours in the dark, dialyzed and freeze-dried to obtain formylated sodium alginate;

[0033] (4) Immerse the loofah grafted with carboxymethyl chitosan in an aqueous solution of 1.5 wt% alginate sodium alginate at room temperature, react for 15 minutes, and freeze-dry to obtain the loofah anti-adhesion wound dressing.

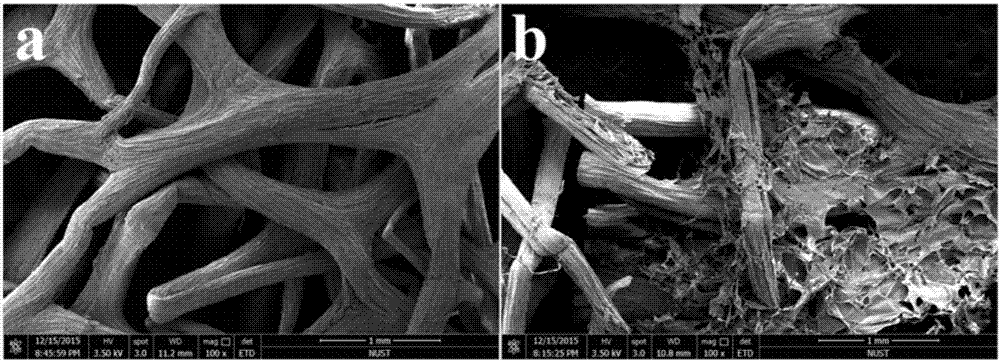

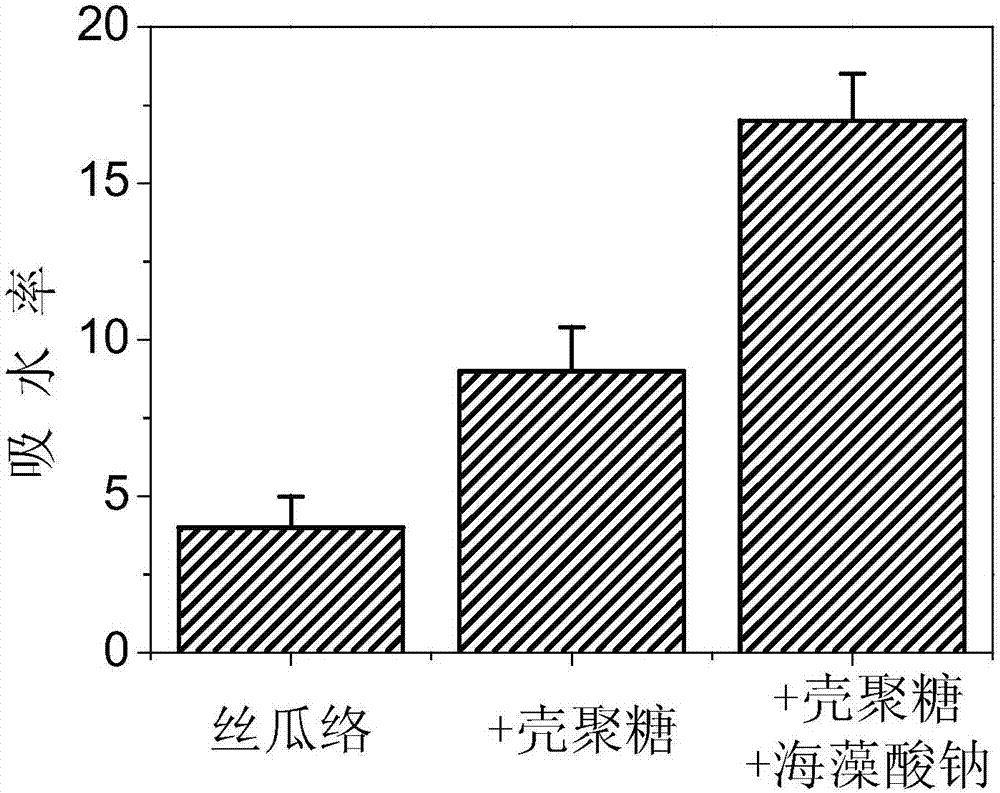

[0034] The microstructure of the dressing before and after modification ...

Embodiment 2

[0036] The specific operation steps are:

[0037] (1) Under room temperature, the loofah is immersed in a concentration of 1.5wt% potassium periodate aqueous solution under light-proof conditions, stirred and reacted for 4 hours, and then cleaned to obtain the aldylated loofah;

[0038] (2) immerse the aldylated loofah at room temperature in the carboxymethyl chitosan aqueous solution of 0.25wt%, and react for 5 minutes to obtain the luffa of grafted carboxymethyl chitosan;

[0039] (3) 1.0 g of sodium alginate was dissolved in 100 ml of water at room temperature, then 0.5 g of sodium periodate was added, stirred for 1 hour in the dark, dialyzed and freeze-dried to obtain formylated sodium alginate;

[0040] (4) The loofah grafted with carboxymethyl chitosan was immersed in 0.25 wt% aqueous solution of alginate alginate at room temperature, reacted for 5 minutes, and freeze-dried to obtain the loofah anti-adhesion wound dressing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com