Hollow wall plastic steel wound drainage pipe material and manufacturing method thereof

A technology for drainage pipes and manufacturing methods, applied in the direction of pipes, rigid pipes, pipes/pipe joints/fittings, etc., can solve the problems of poor foundation adaptability and low ring stiffness, and achieve good sealing, high ring stiffness, and excellent mechanical properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

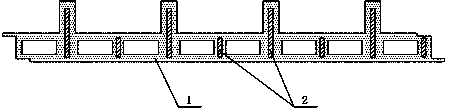

[0019] exist figure 1 Among them, the hollow-wall plastic-steel winding drainage pipe includes a mixed material 1 and a high-strength steel strip 2, the periphery of the high-strength steel belt 2 is covered with a mixed material 1, and the high-strength steel belt 2 includes a long steel belt and a short steel belt, Long steel strips and short steel strips are arranged alternately in compound 1.

[0020] The yield strength of the high-strength steel strip 2 is 220 Mpa, the tensile strength is 450 Mpa, and the elongation at break is 55%.

[0021] The manufacturing method of the hollow-walled plastic-steel winding drainage pipe is as follows:

[0022] 1. Make the mixed ingredient 1, select 100 parts of high-density polyethylene 100 grade PE100 resin, 25 parts of ethylene-vinyl acetate copolymer EVA resin, 4 parts of rosin resin and 2 parts of black masterbatch, mix and set aside;

[0023] 2. Select the corresponding high-strength steel strip 2 and load it into the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com