Crosscutting tool for high-speed crosscutting

A cross-cutting and tooling technology, applied in the direction of knives, manufacturing tools, shearing devices, etc. used in shearing machines, can solve the problems of reduced operation efficiency, large energy consumption, noise level and total strain, etc., to achieve excellent contact Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

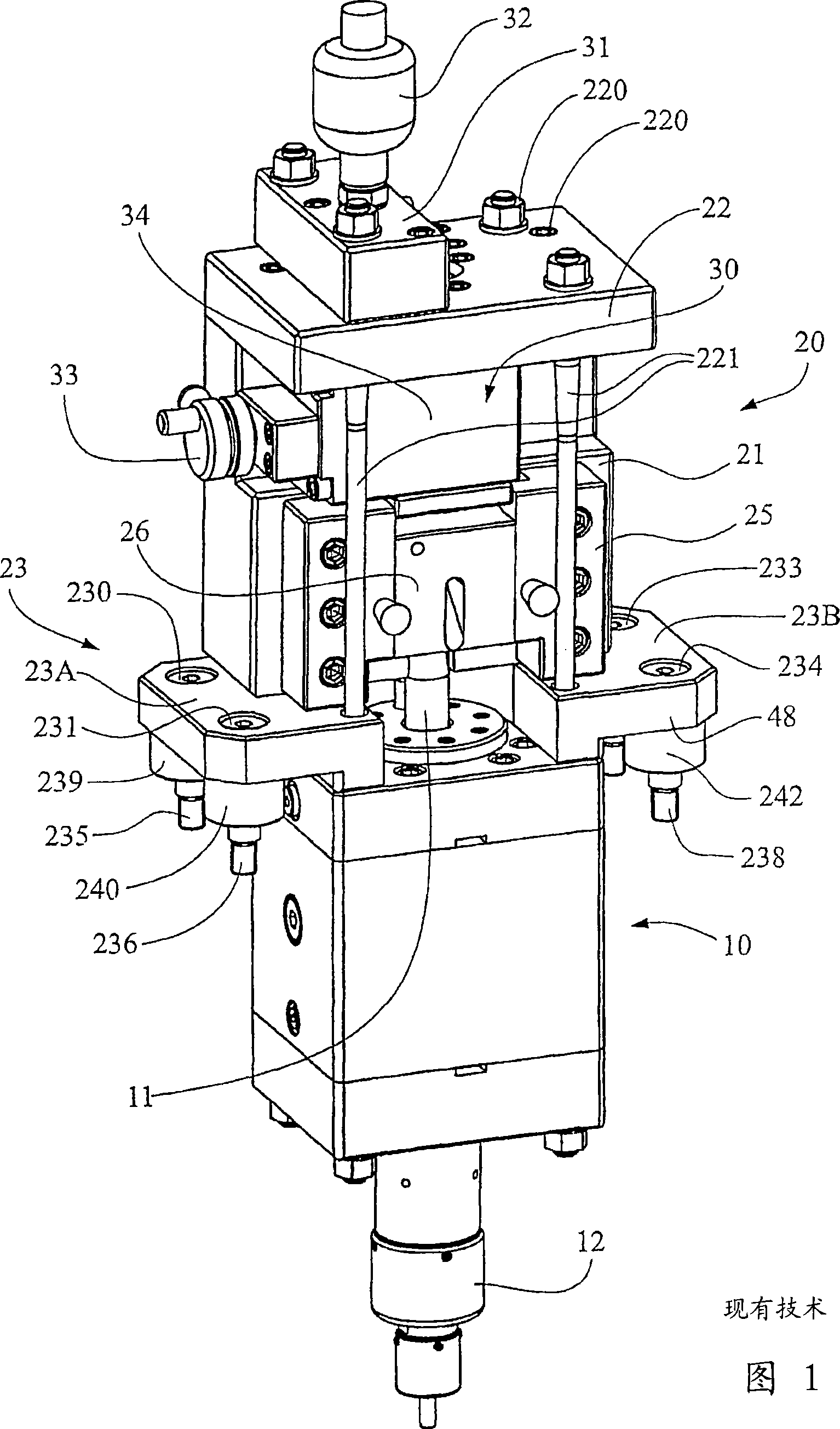

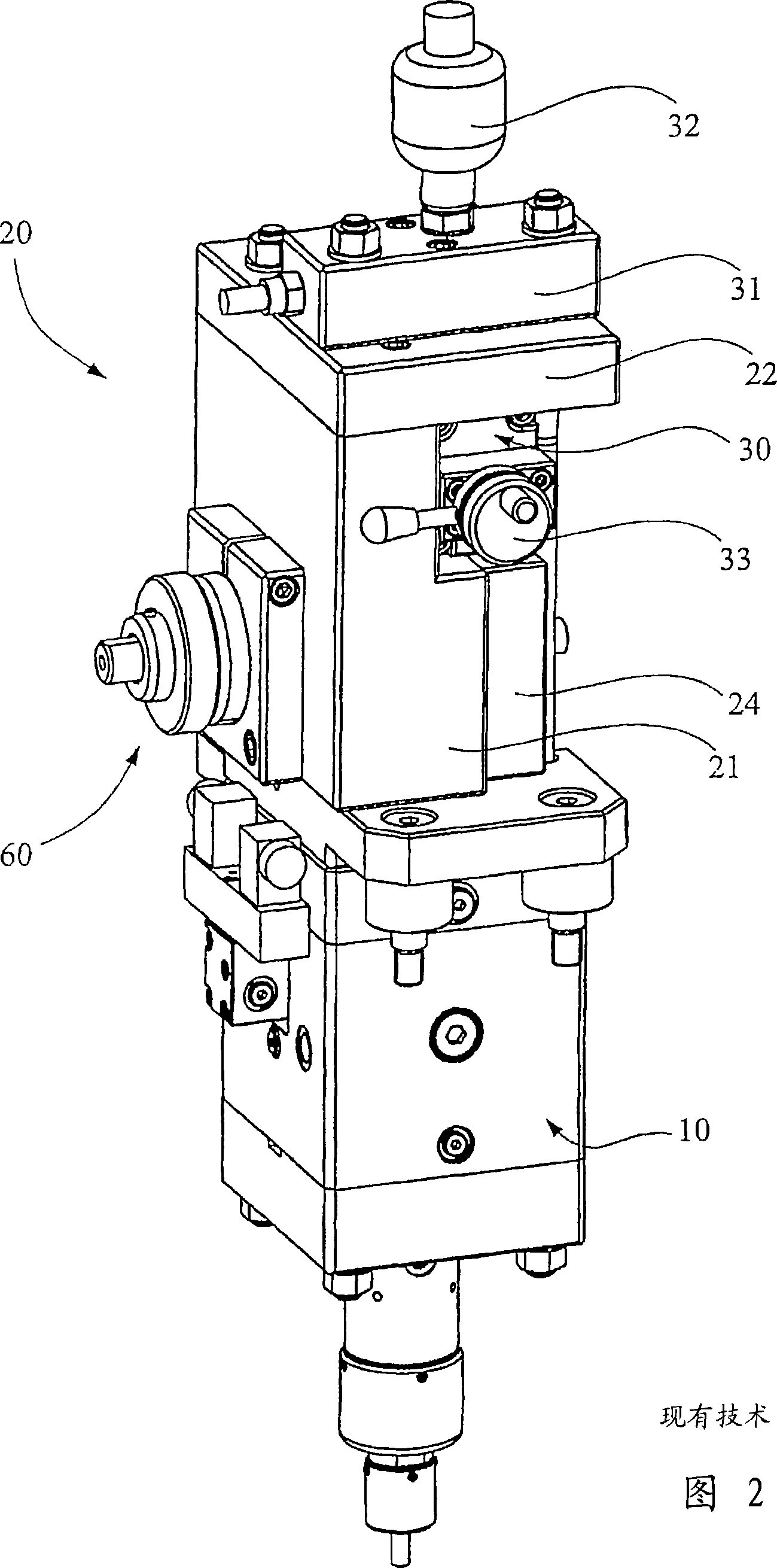

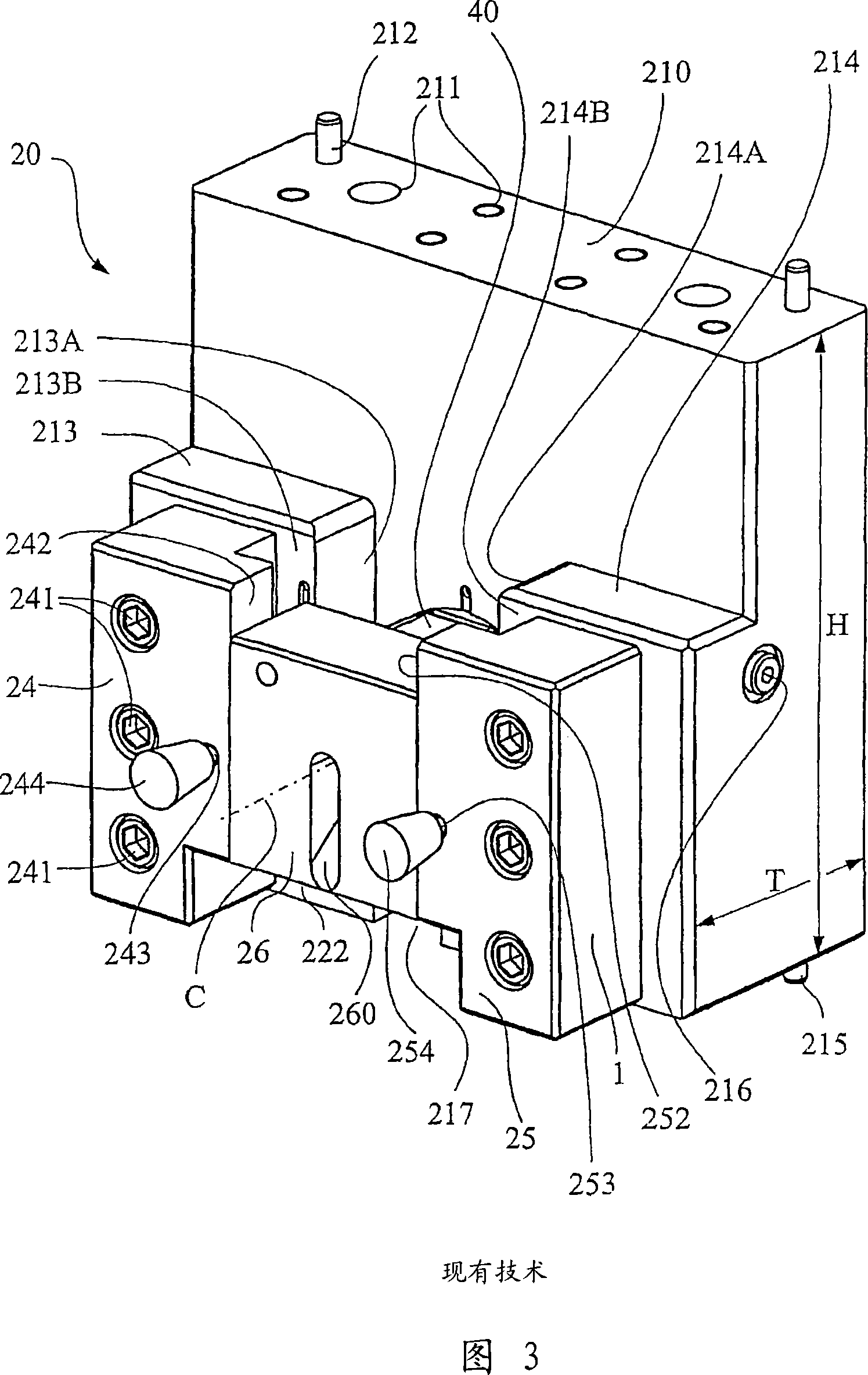

[0037] Fig. 1 illustrates a perspective view from an obliquely upward direction of a modular unit in the prior art. The tool device comprises a percussion unit 10 , a tool housing 20 and a damper 30 . A movable cross-cutting tool 40 and a fixed cross-cutting tool 50 are provided within the tool housing 20 . The impact piston 11, driven by the impact unit 10, is capable of giving a high-kinetic blow from the bottom up to the movable cross-cutting tool 40 in a known manner, the fixed cross-cutting tool 50 resting on the workpiece (not shown) to be cut. Apply a resistance to it. The damper 30 is arranged to resist the impact action of the movable cross-cutting tool 40 after the cut has been completed. The percussion unit 10 and damper 30, associated damper housing 34, hydraulic block 31 and pressure accumulator 32 will not be described in detail here as they are not relevant to the invention. However, it should be mentioned that the protruding wheel 33 on the damper 30 constit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com