Electrical energy storage element, method and apparatus for producing said electrical energy storage element

A technology for electric energy storage and components, which is applied in the direction of electrical components, battery electrodes, and final product manufacturing, and can solve problems such as energy density reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

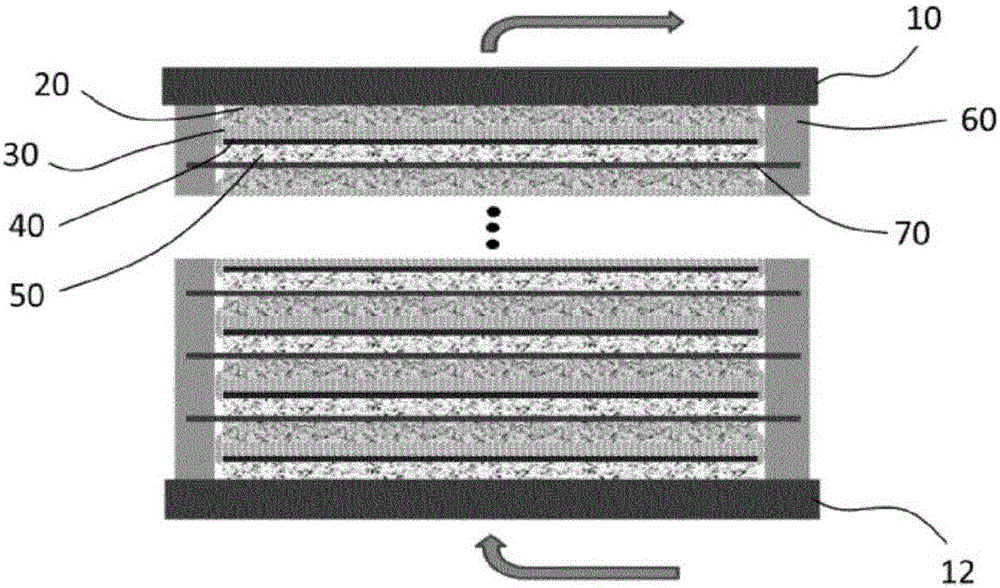

[0062] An electrical energy storage element according to the invention can be manufactured using an aluminum conductive carrier film 70 having a thickness of 15 μm and a width of 100 mm.

[0063] To manufacture the cathode 20, coating was carried out by a roll-to-roll process using a suspension of LNMO in N-methyl-2-pyrrolidone (NMP) on one side of the support film. The composition of the cathode 20 thus obtained was 92 wt.% LNMO, 4 wt.% conductive additive and 4 wt.% PVDF. In this respect, obtain 50.6Ah / m 2 surface capacity. Apply intermittently.

[0064] To produce the anode 50 , a suspension of LTO in NMP is used on the other side of the carrier film 70 in a second coating step. The composition of the resulting anode was 92 wt.% LTO, 4 wt.% conductive additive and 4 wt.% PVDF. In this respect, obtain 52.9Ah / m 2 surface capacity. Apply intermittently.

[0065] The dry electrode strip, coated on both sides with active anode material and cathode material respectively, w...

example 2

[0075] To produce a stack of electrochemical cells, the bottom plate 12 is clamped into a fixing device for fixing the plate from below. The electrodes are provided and placed on the bottom plate 12 with the aid of vacuum tongs in such a way that the coated surfaces face each other. Thereafter, the environment was evacuated to a pressure of 20 mbar, and the electrodes were subsequently pressed onto the base plate 12 by a punch press with a compression force of 10 kPa. In this process, the two-component adhesive is heated to 80°C by a heat carrier for curing.

[0076] Subsequently, the next electrode is provided and placed; the environment is evacuated; the electrode is pressed; and the adhesive is heated. These steps were repeated until 351 electrodes were stacked on the base plate.

[0077] In the final steps, the top plate 10 is provided by grippers and placed on the stack; the environment is then evacuated; the top plate 10 is pressed; and the adhesive is heated.

example 3

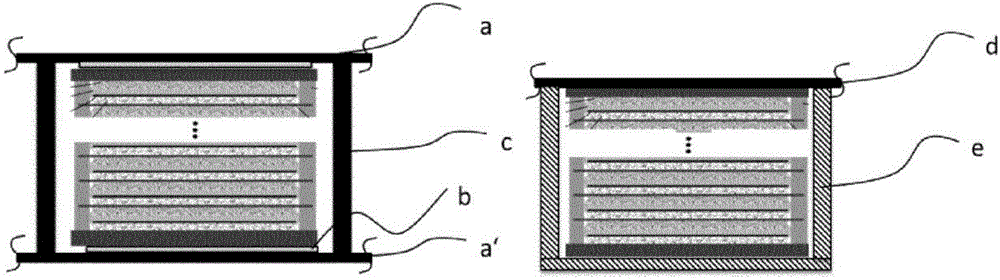

[0079] figure 2 A possible installation on the lower body of the vehicle is shown on the left. a = middle vehicle body; a' = lower vehicle body; b = heat-conducting insulating layer, joint; c = vehicle support; on the right side the mounting on the underside of the solar module is shown: d = solar module; e = module frame.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com