Tread profile of a vehicle tire

A tread and stripe technology, applied to tire tread/tread pattern, vehicle parts, tire parts, etc., to achieve the effect of improving retreadability, improving durability, and reducing the risk of foreign matter intruding into the groove bottom

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

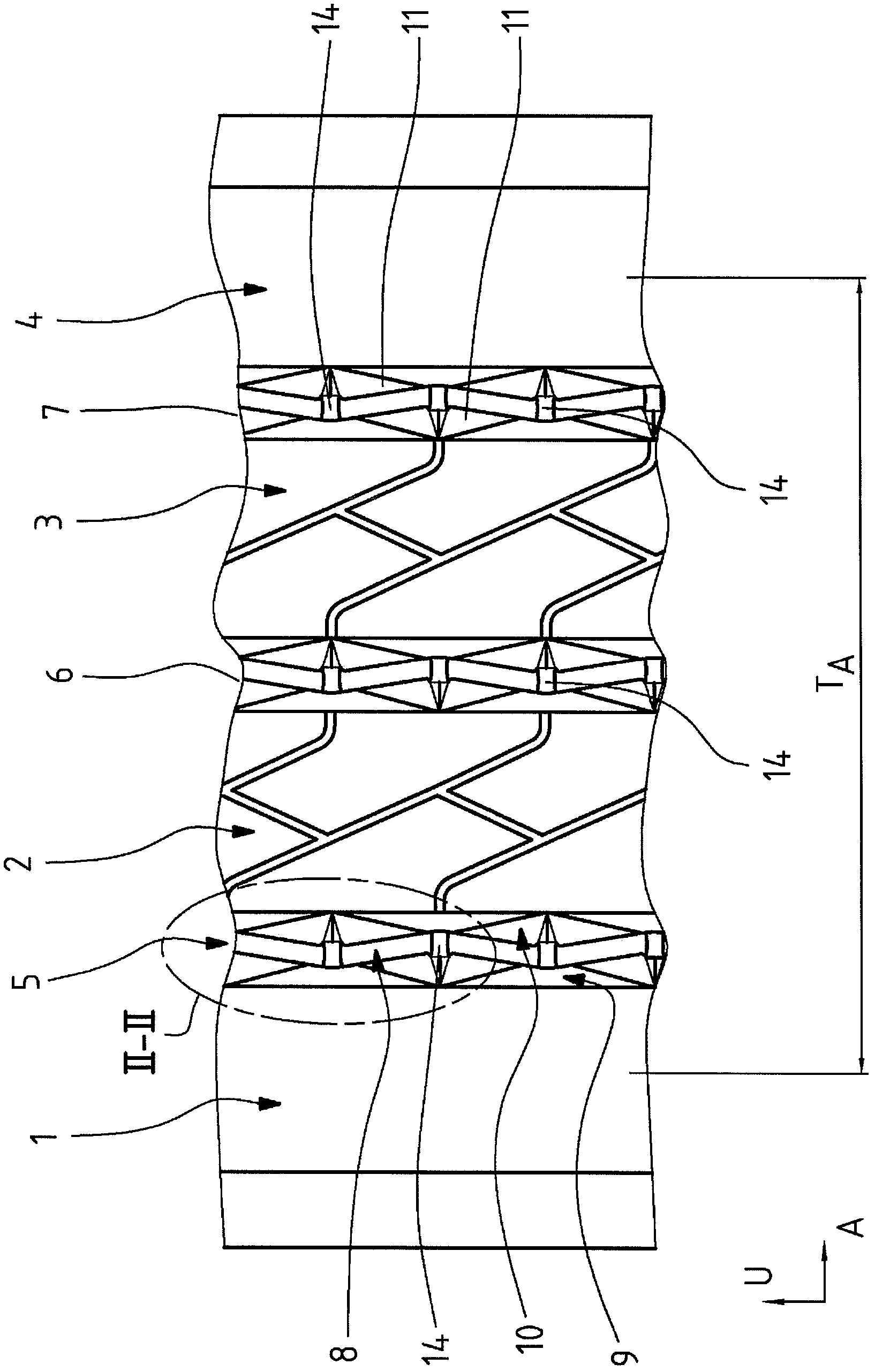

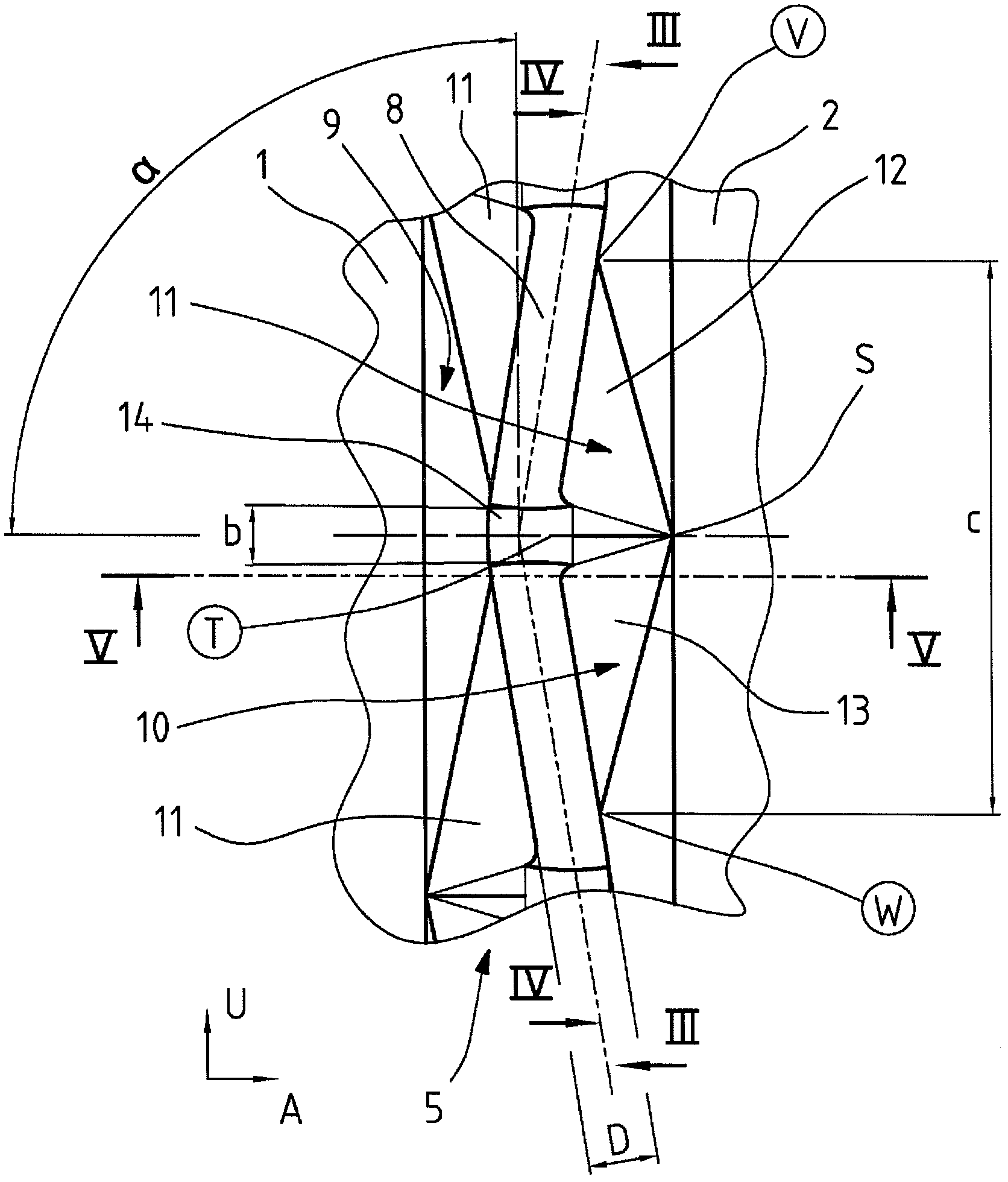

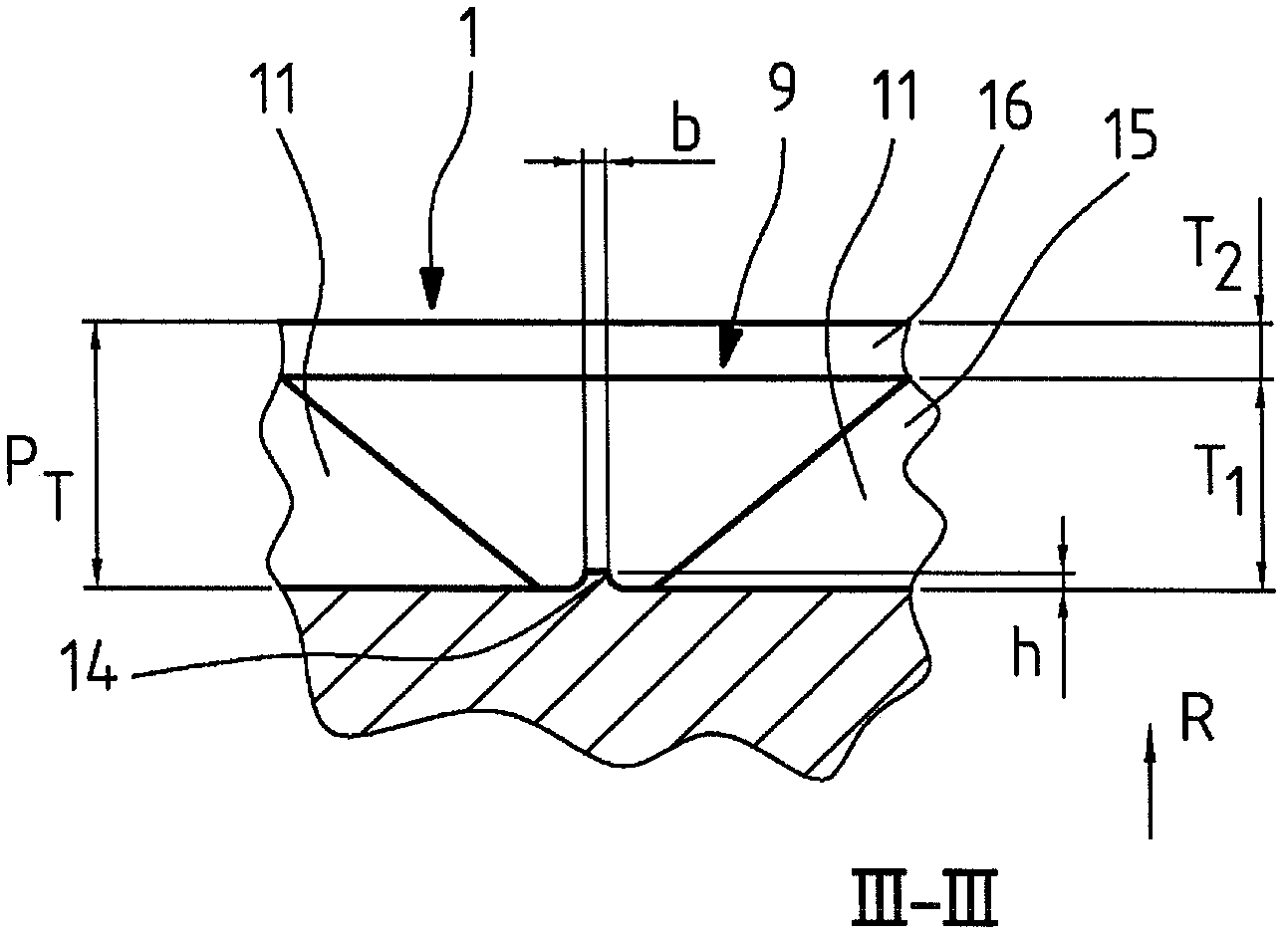

[0048] Figure 1 to Figure 5 Shown is a tread pattern of a vehicle pneumatic tire of a commercial vehicle tire, such a tread pattern with adjacent to each other in the axial direction A of the vehicle pneumatic tire, correspondingly in the entire circumferential direction of the vehicle pneumatic tire Circumferential ribs 1 , 2 , 3 and 4 extending upward and oriented in the circumferential direction U. The circumferential ribs 1 and 2 pass through a circumferential groove 5 , the circumferential ribs 2 and 3 pass through a circumferential groove 6 , and the circumferential ribs 3 and 4 pass through a circumferential groove 7 correspondingly in the known manner in the axial direction A spaced apart from each other. The circumferential grooves 5 , 6 and 7 extend over the entire circumference of the vehicle pneumatic tire and are oriented in the circumferential direction U. as in figure 1 As can be seen in , the circumferential ribs 1 and 4 are correspondingly formed as shoul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com