Heating technology for refining TiAl alloy ingot microscopic texture

A technology for microstructure and alloy ingot casting, applied in the field of metal materials, can solve the problems of ingot cracking, uneven deformation structure, and inability to effectively eliminate microstructure casting defects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

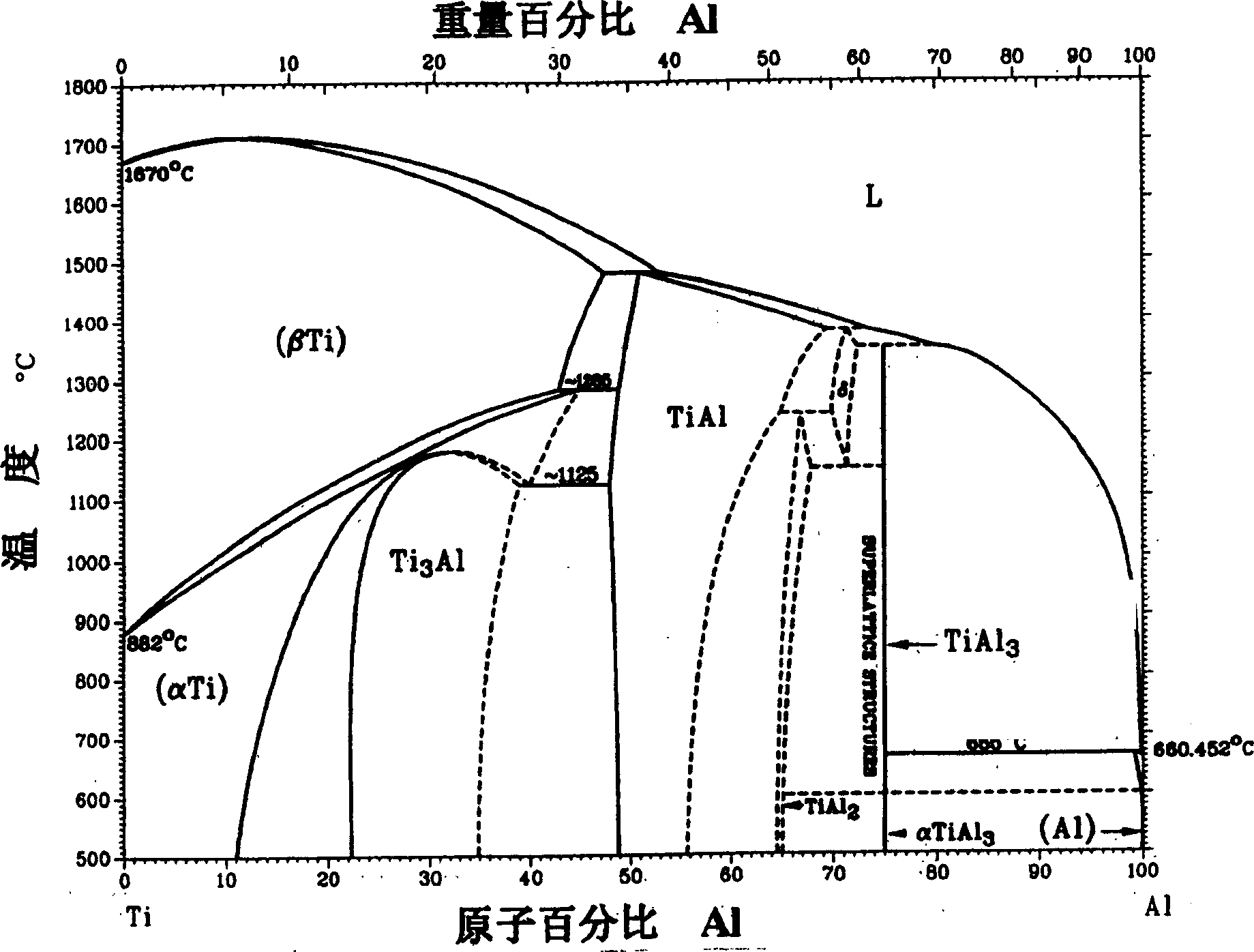

[0014] The TiAl alloy ingots that have been poured or solidified or pulled are subjected to salt bath quenching + aging treatment, and subsequent high-temperature forging deformation. The specific implementation methods are as follows:

[0015] (1) Heating the TiAl alloy ingot to T a The temperature is about 10°C to 15°C above the temperature, and the temperature is kept for a certain period of time. The length of this holding time is related to the thickness of the ingot, and the holding time is determined at 1 mm / min. For example, for a cylindrical ingot of 100 mm, the holding time is 50 minutes. Generally, the heat preservation time is preferably no more than 60 minutes.

[0016] (2) Quickly quench the above-mentioned ingot into the salt bath tank, and the time for the ingot to be transferred from the heating furnace to the salt bath tank is 5 to 10 seconds, so as to meet the requirement that the cooling rate of the subsequent salt bath quenching is greater than 100° C. / s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com