Heating technology for refining TiAl alloy ingot microscopic texture

A microstructure and alloy ingot casting technology, applied in the field of metal materials, can solve the problems of ineffective elimination of microstructure casting defects, uneven deformed structure, ingot cracking, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

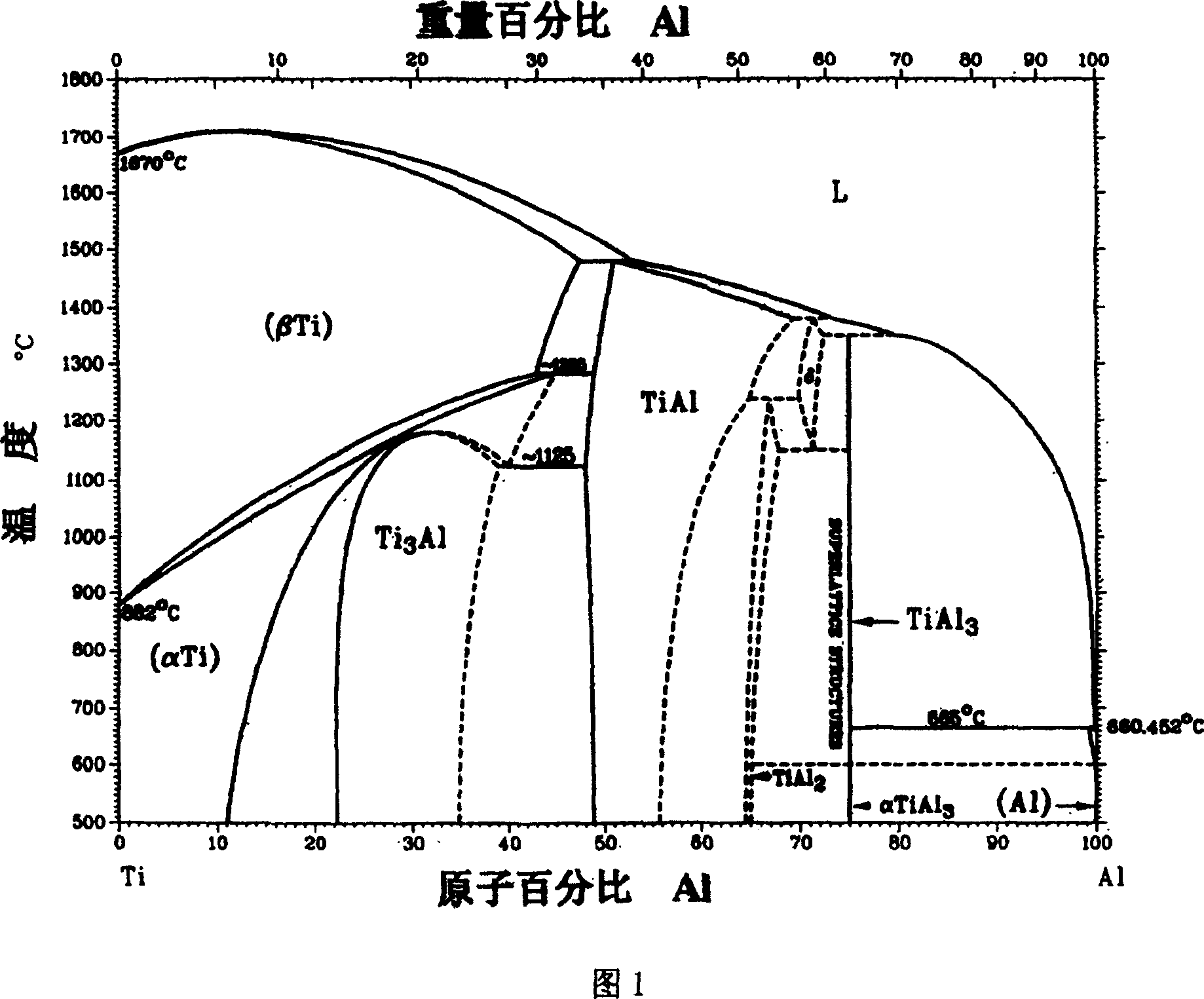

[0015] The TiAl alloy ingots that have been poured or solidified or pulled are subjected to salt bath quenching + aging treatment, and subsequent high-temperature forging deformation. The specific implementation methods are as follows:

[0016] (1) Heat the TiAl alloy ingot to about 10°C to 15°C above Tα temperature, and keep it warm for a certain period of time. The length of this holding time is related to the thickness of the ingot, and the holding time is determined at 1 mm / min. For example, for a cylindrical ingot of 100 mm, the holding time is 50 minutes. Generally, the heat preservation time is preferably no more than 60 minutes.

[0017] (2) Quickly quench the above-mentioned ingot into the salt bath tank, and the time for the ingot to be transferred from the heating furnace to the salt bath tank is 5 to 10 seconds, so as to meet the requirement that the cooling rate of the subsequent salt bath quenching is greater than 100° C. / second, so that The alpha phase can com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com