Control method for cracks in side wall of pipe gallery box type tunnel

A control method and pipe gallery technology, applied in the field of construction, can solve the problems of large size, difficult pouring, stress cracks and other problems of cast-in-place buried tunnels, and achieve the effect of controlling cracks and appearance quality and ensuring service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] The present invention adopts the cast-in-place buried section tunnel in Waihai as the investigation and research object.

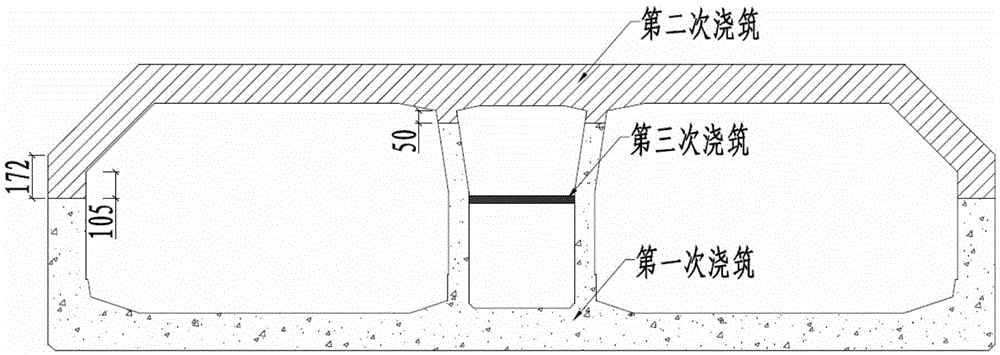

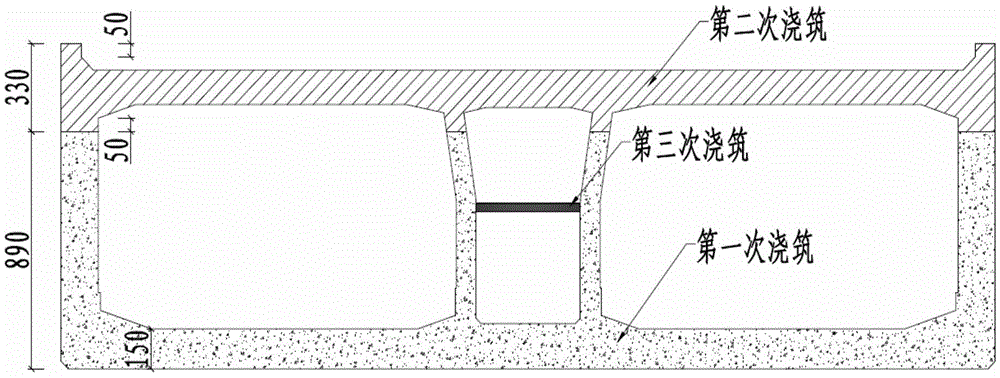

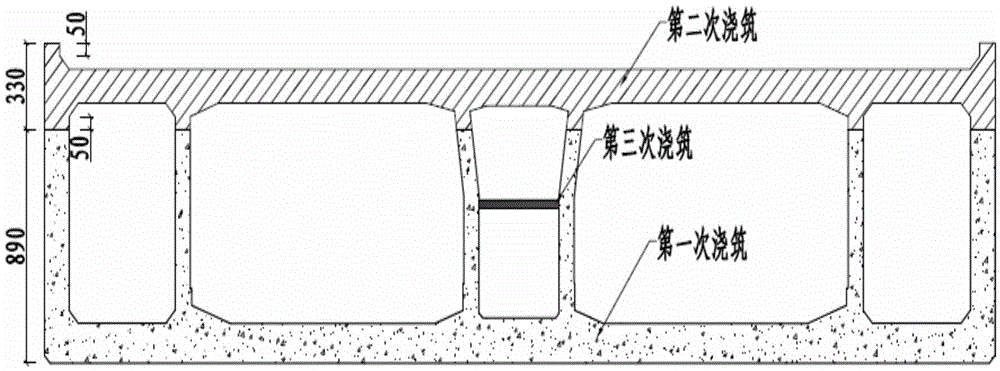

[0052] 1. Using segmental and distributed pouring technology

[0053] The design institute divides the cast-in-place buried section tunnel into 6 sections (respectively marked as CE1~CE6), and the cast-in-place buried section tunnel adopts a single-box double-chamber pipe gallery box-type structure or a single-box four-room pipe gallery box-type structure form. The section CE1 is connected to the immersed tube tunnel, and the section transitions from the standard section of the immersed tube to the double-chamber section of the cast-in-situ buried section, and CE6 returns to the double-chamber section and is connected to the open section.

[0054]The longitudinal length of each section (CE1~CE6) is designed to be 24.7~54m. In order to reduce the risk of concrete cracking, each section is further divided into 2~4 sections for pouring, and the sectio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com