Casting magnesium alloy with high strength and toughness and preparation method thereof

A casting magnesium alloy, high-strength and high-toughness technology, applied in the field of metal material magnesium alloy, can solve the problems of high cost, unsuitable preparation of high-performance structural parts, difficulty in adding Zr elements, etc., to achieve increased strength, excellent aging strengthening ability, enhanced Effect of Age Hardening Ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] In this embodiment, the components and weight percentages of the high-strength and high-toughness cast magnesium alloy are: 8.0% Zn, 0.5% Al, 0.5% Cu, 0.5% Mn, and the rest are Mg and unavoidable impurity elements, and the impurity element content is < 0.01%.

[0027] The preparation method is as follows:

[0028] (1) Ingredients: The raw materials are metal Mg, metal Zn, metal Al, metal Cu and Mg-10wt.%Mn master alloy. The components of the alloy and their weight percentages are: 8.0%Zn, 0.5%Al, 0.5%Cu, 0.5%Mn, the rest is Mg;

[0029] (2) Melting: Use an iron crucible to melt in a resistance furnace, control the melting temperature to 740°C, and use CO 2 and SF 6 Mixed as shielding gas (by volume percentage, 99% CO 2 +1%SF 6 ), the raw material is preheated at 200°C, firstly add metal Mg, after metal Mg is completely melted, add metal Cu, smelt for 15 minutes, then add Mg-Mn intermediate alloy, smelt for 15 minutes, finally add metal Zn and Al, smelt for 10 minut...

Embodiment 2

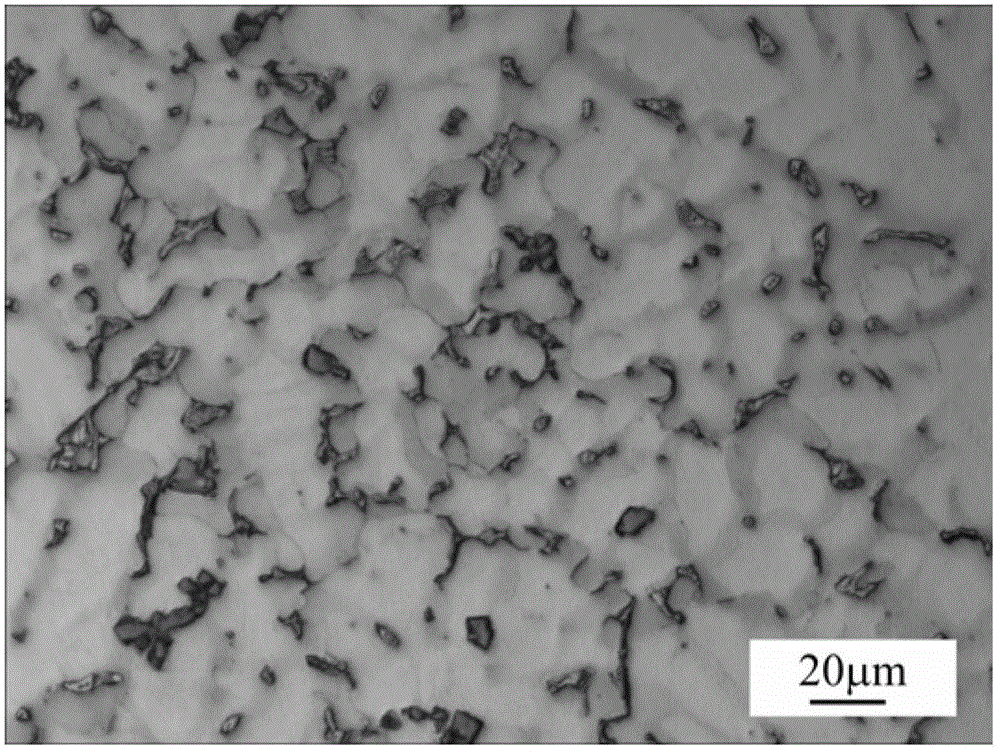

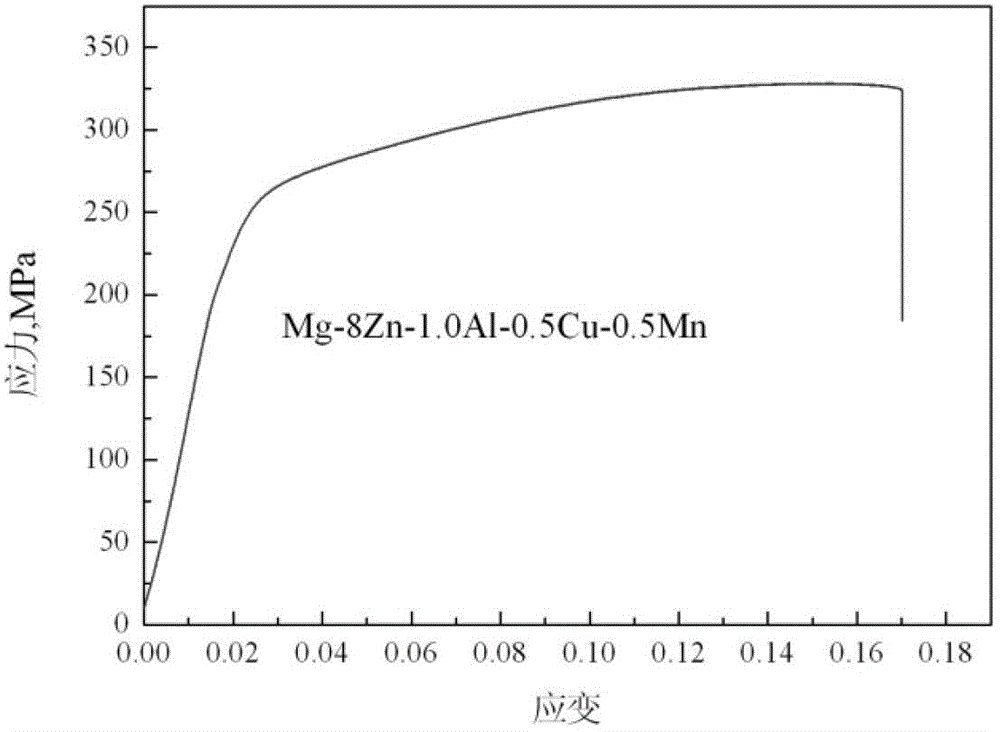

[0034] In this embodiment, the components and weight percentages of the high-strength and high-toughness cast magnesium alloy are: 8.0% Zn, 1.0% Al, 0.5% Cu, 0.5% Mn, and the rest are Mg and unavoidable impurity elements, and the impurity element content is < 0.01%.

[0035] The preparation method is as follows:

[0036] (1) Ingredients: The raw materials are metal Mg, metal Zn, metal Al, metal Cu and Mg-10wt.%Mn master alloy. The components of the alloy and their weight percentages are: 8.0%Zn, 1.0%Al, 0.5%Cu, 0.5%Mn, the rest is Mg;

[0037] (2) Melting: Use an iron crucible to melt in a resistance furnace, control the melting temperature to 740°C, and use CO 2 and SF 6 Mixed as shielding gas (by volume percentage, 99% CO 2 +1%SF 6 ), the raw material is preheated at 200°C, firstly add metal Mg, after metal Mg is completely melted, add metal Cu, smelt for 15 minutes, then add Mg-Mn intermediate alloy, smelt for 15 minutes, finally add metal Zn and Al, smelt for 10 minut...

Embodiment 3

[0044] In this embodiment, the components and weight percentages of the high-strength and high-toughness cast magnesium alloy are: 8.0% Zn, 0.5% Al, 1.0% Cu, 0.5% Mn, the rest are Mg and unavoidable impurity elements, and the impurity element content is < 0.01%.

[0045] The preparation method is as follows:

[0046] (1) Ingredients: The raw materials are metal Mg, metal Zn, metal Al, metal Cu and Mg-10wt.%Mn master alloy. The components of the alloy and their weight percentages are: 8.0%Zn, 0.5%Al, 1.0%Cu, 0.5%Mn, the rest is Mg;

[0047] (2) Melting: Use an iron crucible to melt in a resistance furnace, control the melting temperature to 750°C, and use CO 2 and SF 6 Mixed as shielding gas (by volume percentage, 99% CO 2 +1%SF 6 ), the raw material is preheated at 200°C, firstly add metal Mg, after metal Mg is completely melted, add metal Cu, smelt for 15 minutes, then add Mg-Mn intermediate alloy, smelt for 15 minutes, finally add metal Zn and Al, smelt for 10 minutes ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com