Thermostable polycrystalline diamond composite piece and preparation method thereof

A polycrystalline diamond, thermally stable technology, used in drilling equipment, earth-moving drilling, drill bits, etc., can solve the problem of reducing the mechanical properties of the polycrystalline diamond composite sheet and the cemented carbide substrate. The bonding strength of the polycrystalline diamond layer and the cemented carbide substrate, etc. problems, to achieve the effects of high social value and economic benefits, high thermal stability and wear resistance, and excellent comprehensive mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

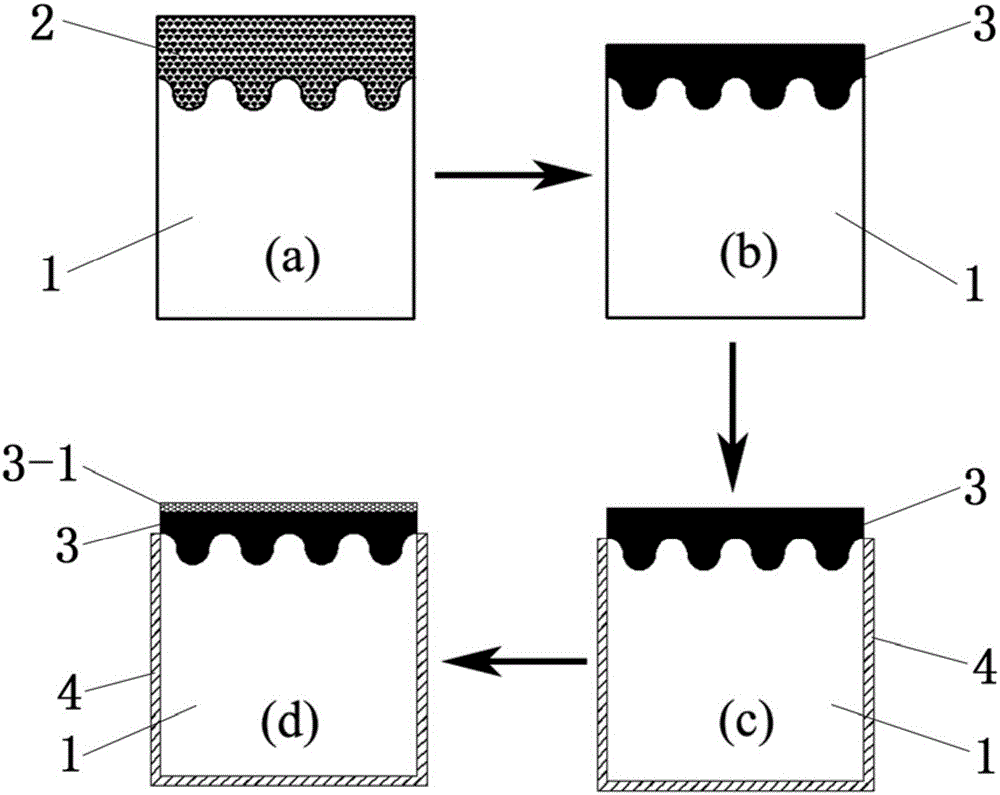

[0031] The thermally stable polycrystalline diamond compact of the present embodiment is prepared by the following method (the preparation process is as follows: figure 1 shown):

[0032] 1) Put the diamond powder with a particle size of 6-12 μm and the metal catalyst Co powder with a particle size of 1-3 μm into a metal cup (molybdenum cup) that acts as a shield, and then put it into a tungsten-cobalt cemented carbide substrate. Assembled into assembly blocks (such as figure 1 (a), wherein 1 is a cemented carbide substrate, and 2 is a mixture of diamond micropowder and metal catalyst); the assembly block is placed in a vacuum furnace, and the vacuum degree is 6.0 × 10 -3 Pa, the temperature is 500 ℃ under the condition of vacuum heat treatment for 2h;

[0033] Put the assembly blocks that have undergone vacuum heat treatment into the pressure transmission medium, and keep them warm for 10 minutes at a sintering pressure of 5.2GPa and a sintering temperature of 1400°C for hi...

Embodiment 2

[0038] The thermally stable polycrystalline diamond composite sheet of the present embodiment is prepared by the following method (the preparation process is the same as in Example 1):

[0039] 1) Put the diamond powder with a particle size of 15-25 μm and the metal catalyst nickel-iron alloy ball mill with a particle size of 1-3 μm into the metal cup (tantalum cup) that acts as a shield, and then put it into the tungsten-titanium-cobalt cemented carbide substrate , assembled into assembly blocks; place the assembly blocks in a vacuum furnace at a vacuum degree of 6.0×10 -3 Pa, the temperature is 700 ℃ under the condition of vacuum heat treatment for 5h;

[0040] Put the vacuum heat-treated assembly block into the pressure transmission medium, keep it warm for 15 minutes at a sintering pressure of 5.5GPa and a sintering temperature of 1500°C for high-temperature and high-pressure synthesis, demould after synthesis and pre-process to obtain a polycrystalline diamond composite; ...

Embodiment 3

[0045] The thermally stable polycrystalline diamond composite sheet of the present embodiment is prepared by the following method (the preparation process is the same as in Example 1):

[0046] 1) Mix the mixed diamond powder with a particle size of 6-12 μm and 15-25 μm (the mass ratio of the two particle sizes of diamond powder is 1:1) and the metal catalyst Co powder with a particle size of 1-3 μm, and then load it into the ball mill. Shielding effect of the metal cup (molybdenum cup), and then put the tungsten titanium tantalum carbide substrate, assembled into an assembly block; the assembly block is placed in a vacuum furnace at a vacuum degree of 6.0 × 10 -3 Pa, the temperature is 600 ℃ under the condition of vacuum heat treatment for 5h;

[0047] Put the vacuum heat-treated assembly block into the pressure transmission medium, keep it warm for 30 minutes under the conditions of sintering pressure 5.8GPa and sintering temperature 1500°C for high-temperature and high-pres...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Young's modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com