Superstrength high-toughness alloy steel and preparing method thereof

An ultra-high-strength, alloy steel technology, applied in the field of metal materials and processing, to achieve excellent toughness, excellent comprehensive mechanical properties, and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] In the ultra-high-strength and high-toughness alloy steel provided in this embodiment, the mass percentages of each component in the alloy steel are: C is 0.40%, Mn is 0.80%, Si is 1.70%, Cr is 1.00%, Ni is 1.80%, Mo is 0.40%, Nb is 0.030%, V is 0.08%, P≤0.010%, S≤0.005%, La is 0.020%, and the balance is Fe and unavoidable impurities. Under the above composition design, (Cr+Ni) The weight percentage of / Mo is 7:1.

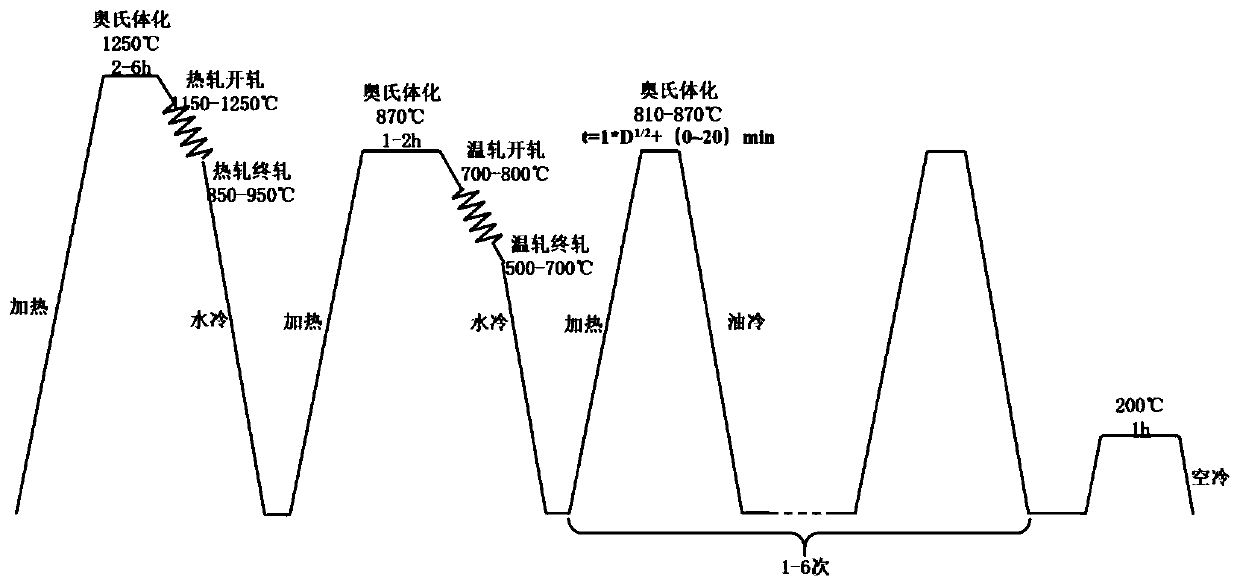

[0033] The preparation method of ultra-high-strength and high-toughness fine-grained alloy steel with the above-mentioned composition, the preparation process includes smelting, hot rolling, large deformation medium temperature rolling, short-term heat treatment, low temperature tempering, some processes such as figure 1 As shown, the specific steps are as follows:

[0034] (1) Melting: According to the alloy steel composition ratio, take alloy elements such as Cr, Ni, Mn, Si and carbon steel with a purity greater than 99%, put the raw materials into a vacu...

Embodiment 2

[0050] In the ultra-high-strength and high-toughness alloy steel provided in this embodiment, the mass percentages of each component in the alloy steel are: C is 0.40%, Mn is 0.80%, Si is 1.70%, Cr is 1.00%, Ni is 2.00%, Mo is 0.50%, Nb is 0.030%, V is 0.08%, P≤0.010%, S≤0.005%, La is 0.020%, and the balance is Fe and unavoidable impurities. Under the above composition design,) (Cr+Ni ) / Mo weight percent is 6:1.

[0051] The preparation method of the ultra-high-strength and high-toughness fine-grained alloy steel with the above-mentioned composition includes smelting, hot rolling, medium-temperature rolling with large deformation, short-term heat treatment, and low-temperature tempering. The specific steps are as follows:

[0052] (1) Melting: According to the alloy steel composition ratio, take alloy elements such as Cr, Ni, Mn, Si and carbon steel with a purity greater than 99%, put the raw materials into a vacuum electric arc furnace, and evacuate to 1×10 -3 Below MPa, eac...

Embodiment 3

[0058] In the ultra-high-strength and high-toughness alloy steel provided in this embodiment, the mass percentages of each component in the alloy steel are: C is 0.40%, Mn is 0.80%, Si is 1.70%, Cr is 1.00%, Ni is 1.80%, Mo is 0.35%, Nb is 0.030%, V is 0.08%, P≤0.010%, S≤0.005%, La is 0.020%, and the balance is Fe and unavoidable impurities. Under the above composition design, (Cr+Ni) The weight percentage of / Mo is 8:1.

[0059] The preparation method of the ultra-high-strength and high-toughness fine-grained alloy steel with the above-mentioned composition includes smelting, hot rolling, medium-temperature rolling with large deformation, short-term heat treatment, and low-temperature tempering. The specific steps are as follows:

[0060] (1) Melting: According to the alloy steel composition ratio, take alloy elements such as Cr, Ni, Mn, Si and carbon steel with a purity greater than 99%, put the raw materials into a vacuum electric arc furnace, and evacuate to 1×10 -3 Below...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com