Preparation method for railway freight car coupler tail frame integral forging

An integral forging technology for railway wagons, applied in the field of coupler frames of railway wagons, can solve the problems of short fatigue life, low strength, fracture, etc., and achieve the effect of improving comprehensive mechanical properties, increasing strength and service life, and consistent material properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

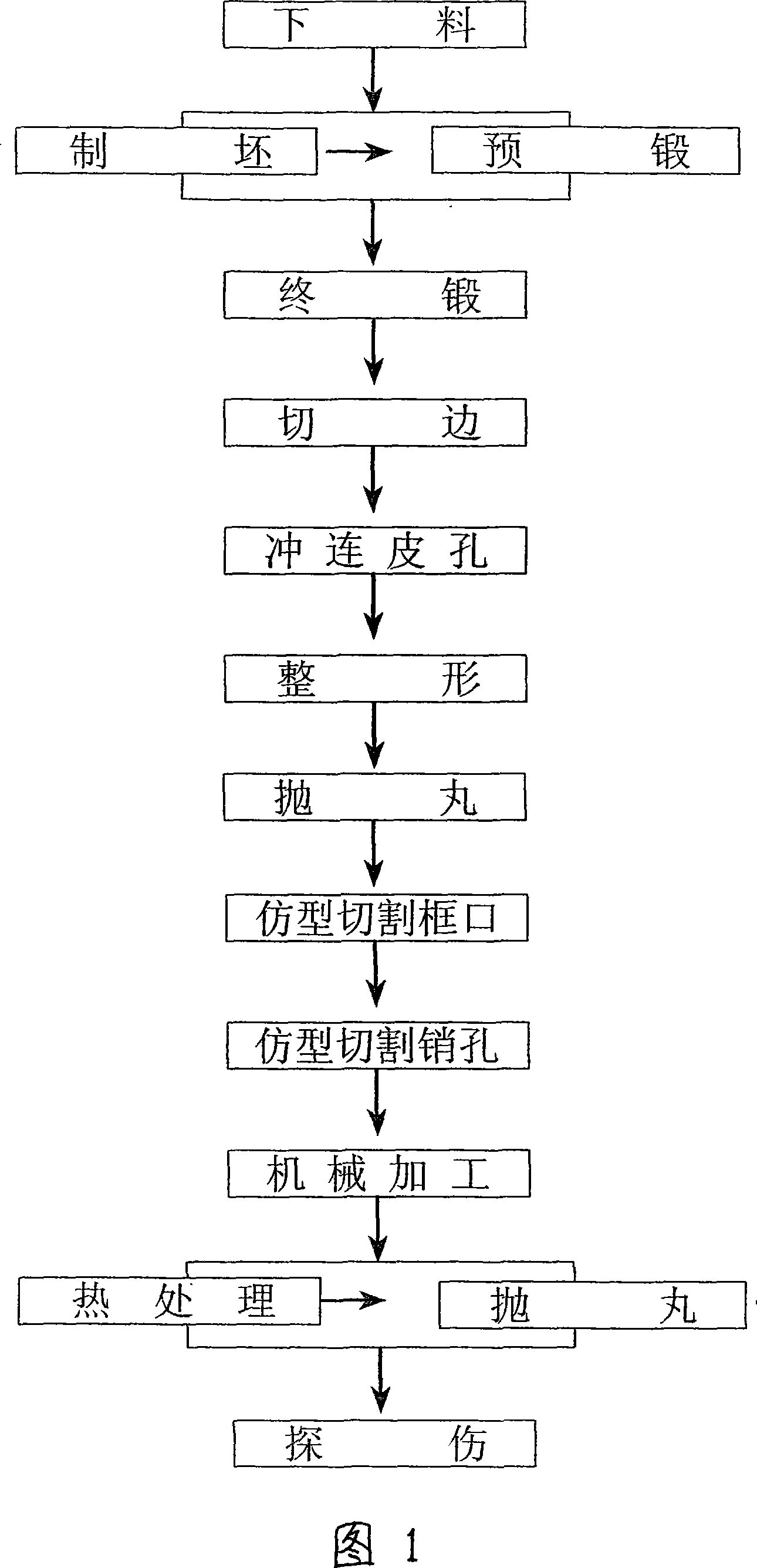

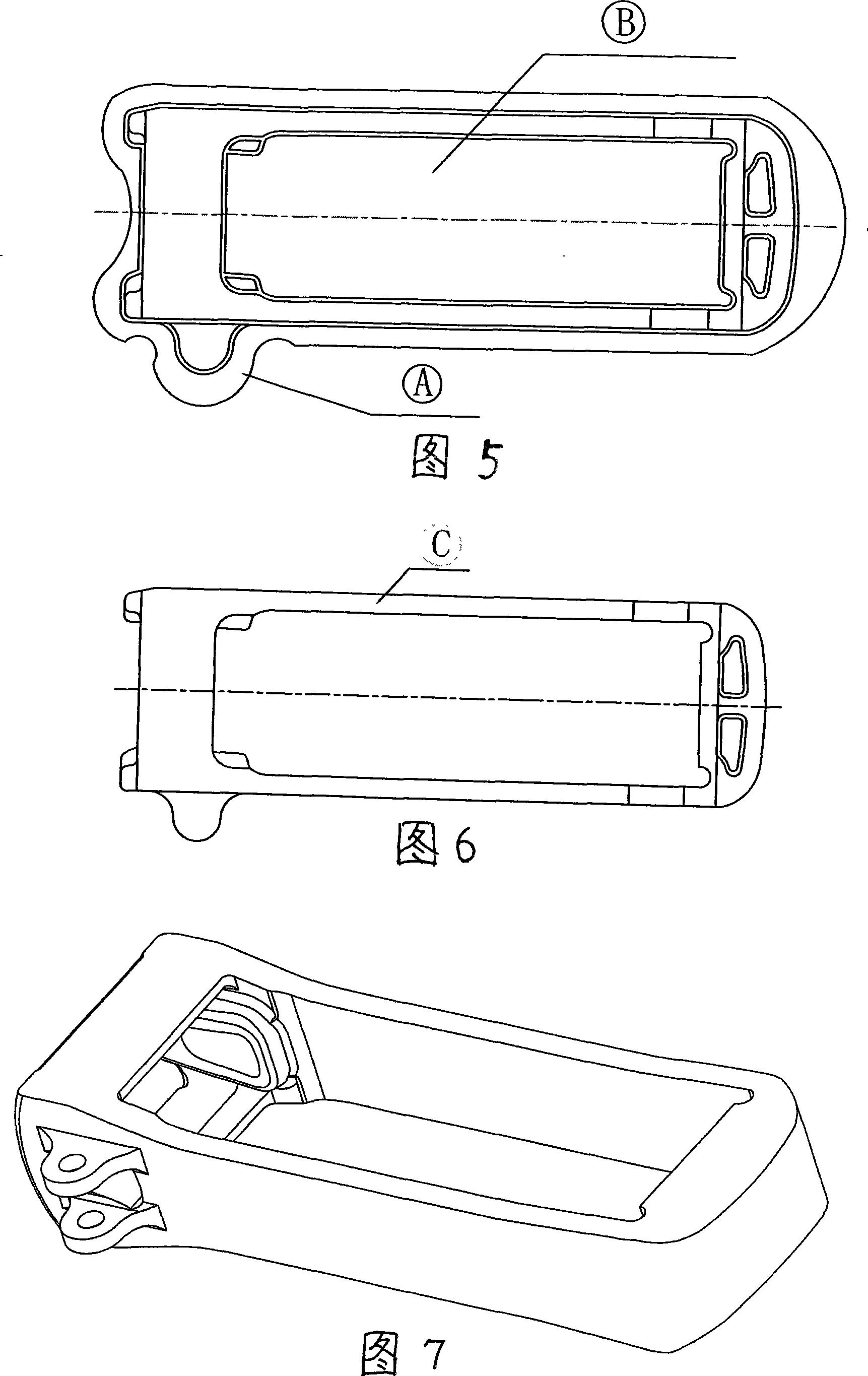

[0030] Referring to the accompanying drawings, the overall size of the coupler frame is now set as: length 932mm, width 200mm, height 366mm, frame plate thickness 28mm as an example for further description as follows:

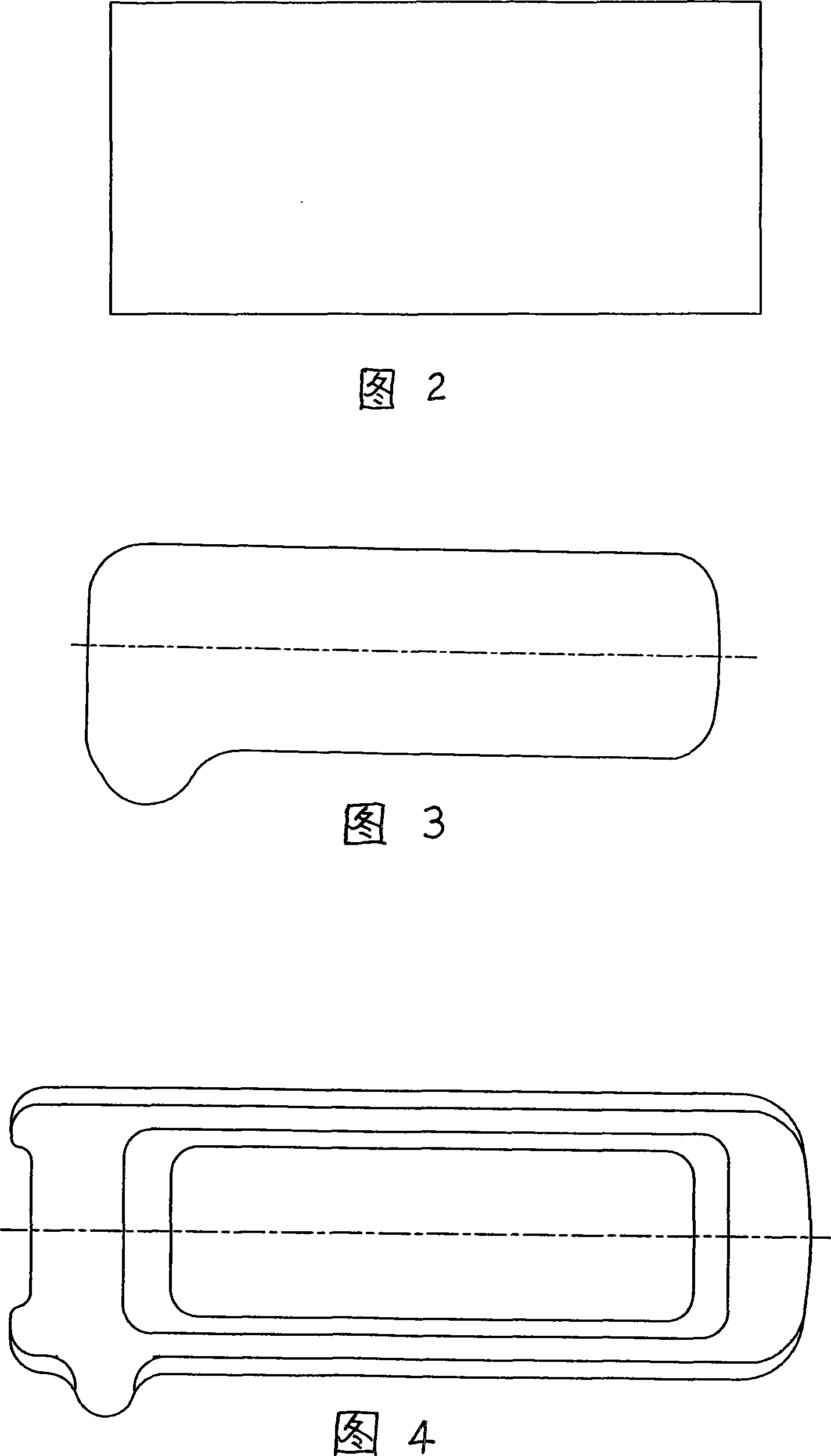

[0031] (1) Use a sawing machine to cut the material according to the process size (φ185mm round outline), see Figure 2;

[0032] (2) Billet making: Forging billet is to heat the blanked round steel, and then free forge it with an anvil on a 5-ton satin hammer to forge a blank that is similar in shape to the pre-forged blank. The quality of the blank directly affects forging The quality of the blank, the shape of the blank is shown in Figure 3;

[0033] (3) Pre-forging: Since the size and weight of the satin piece is as large as 150 kg, a forging force of 8,000 tons is required for a large friction press to forge with a pre-forging die, as shown in Figure 4 after forming;

[0034] (4) Final forging

[0035] After the pre-forged forging is reheated, put it into...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com