Method of improving quality and reliability of welded rail joint properties by ultrasonic impact treatment

A technology of ultrasonic shock and pulse treatment, applied in heat treatment furnaces, welding equipment, welding equipment, etc., can solve problems such as internal cracks, inclusions, porosity, low tensile ductility, etc., to reduce internal stress and optimize heat exchange The effect of exchanging with quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

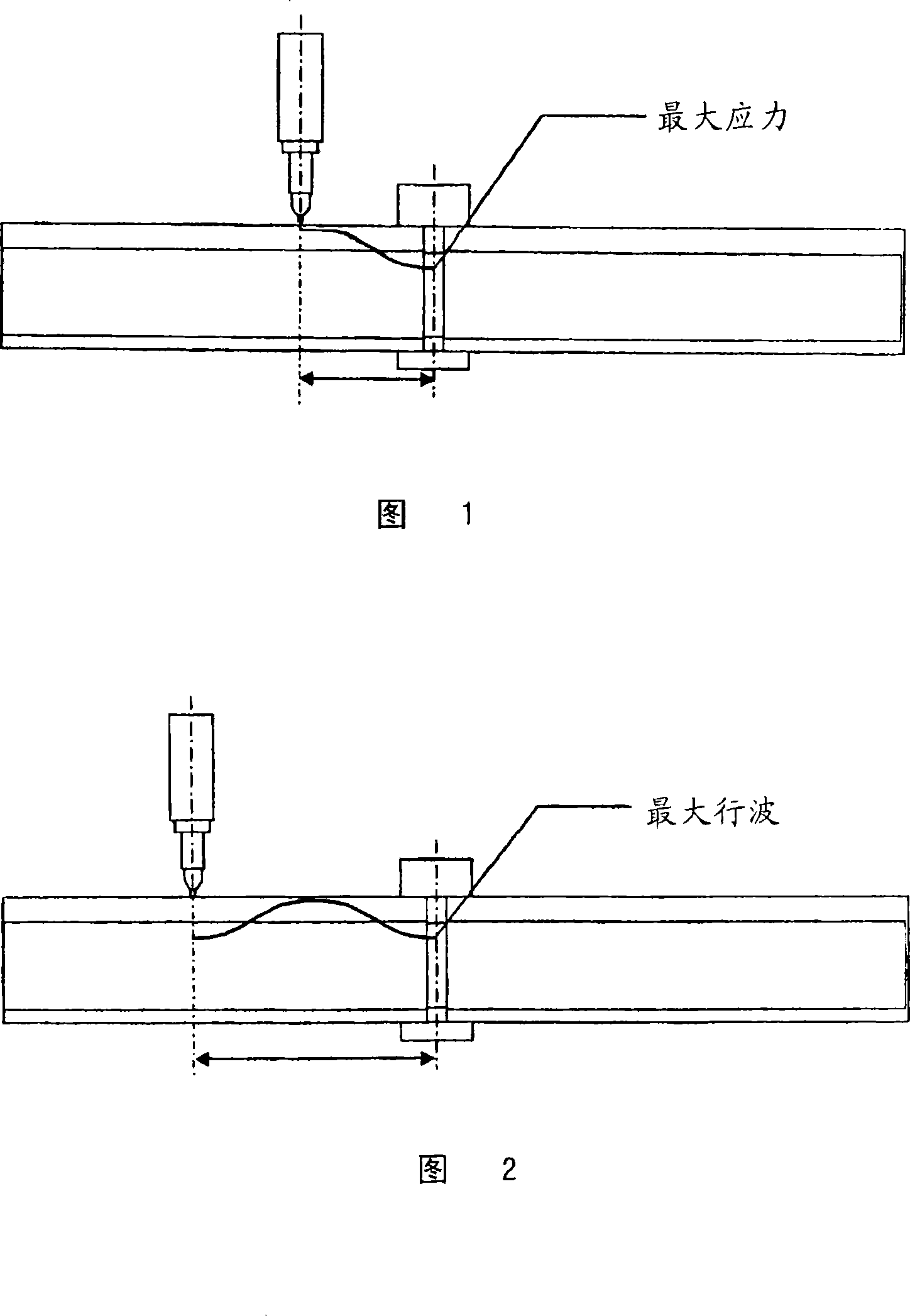

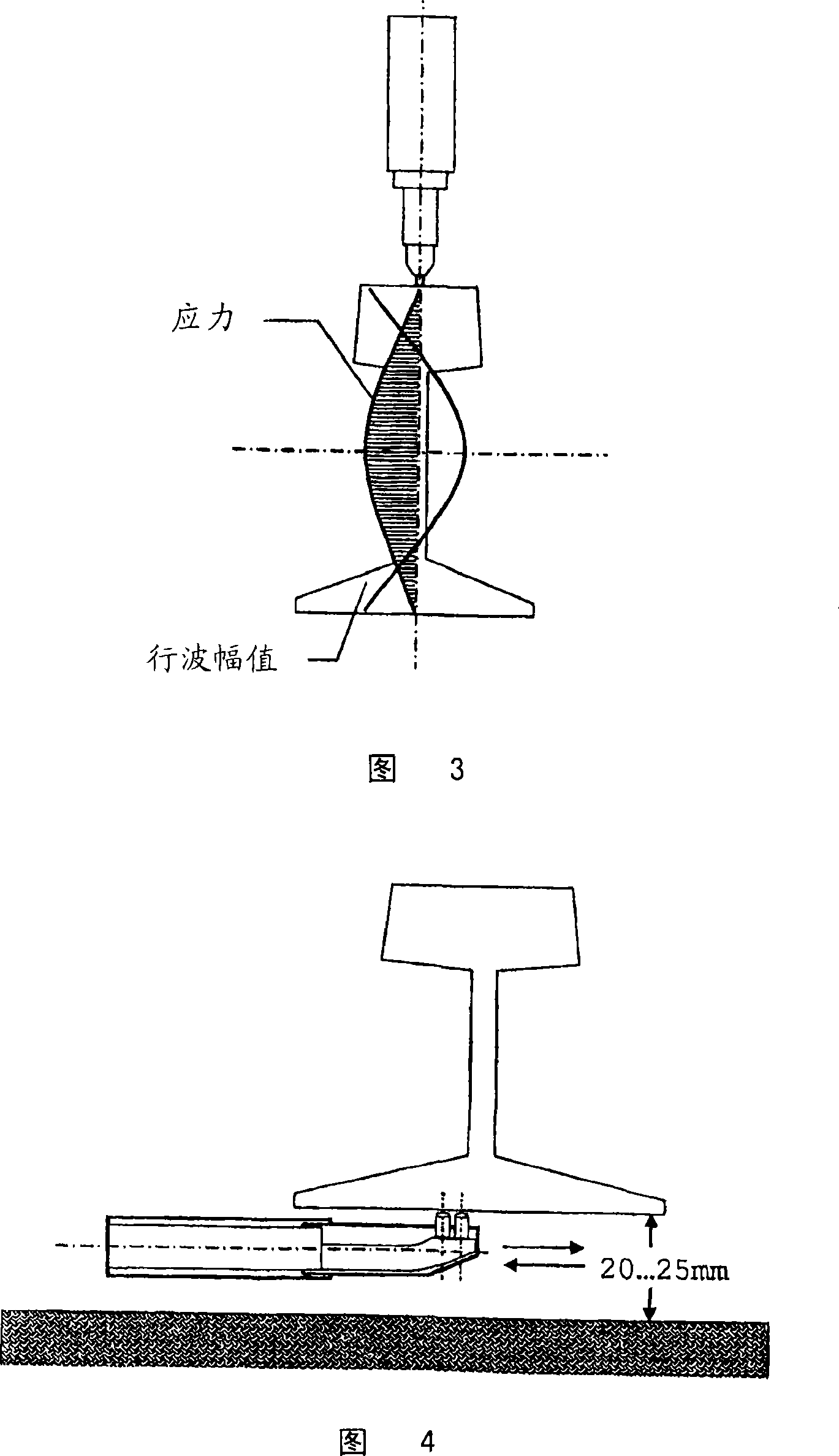

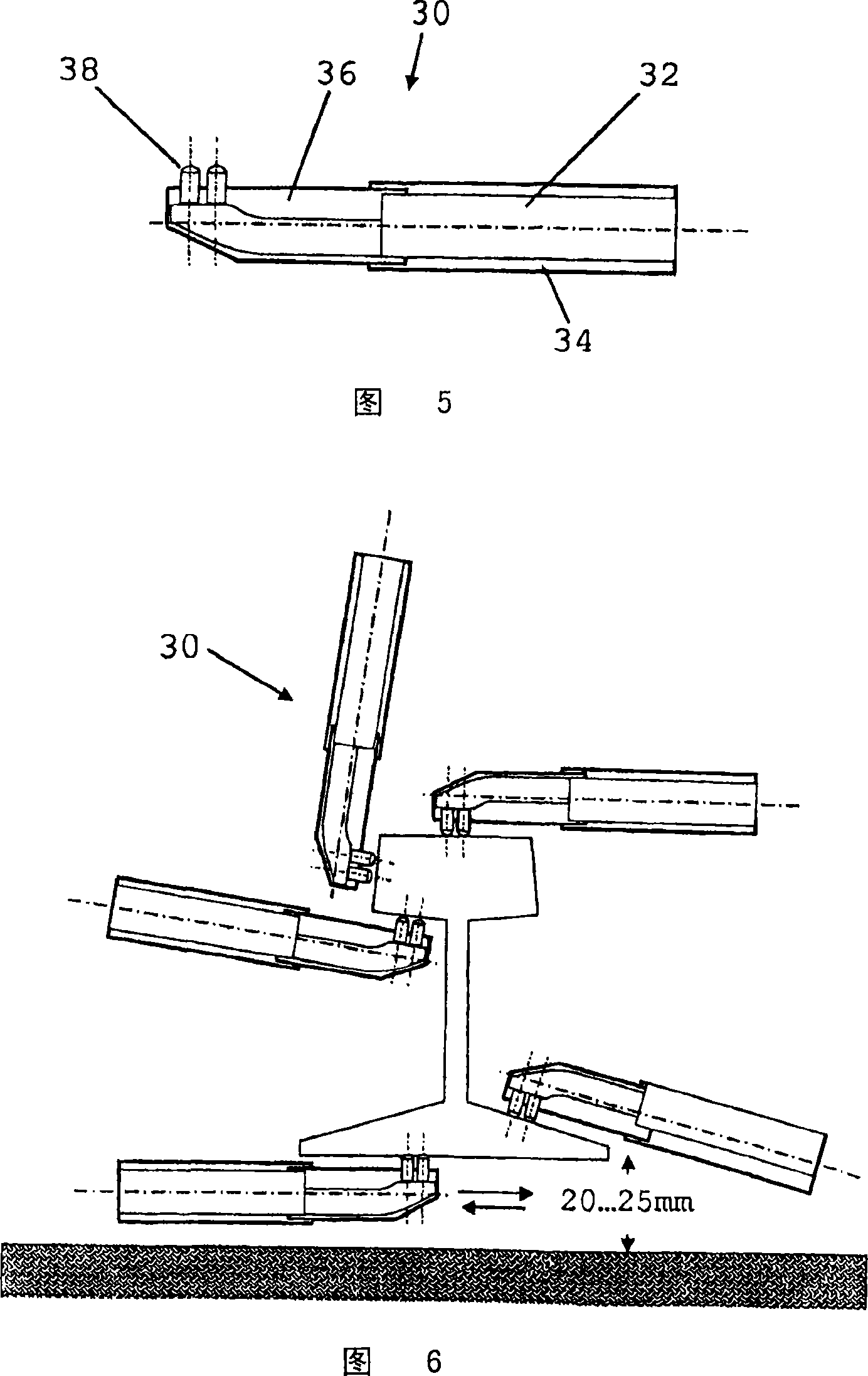

[0086] The present invention relates to the repair of parts of rails joined together by welding by reworking the welded joints using the Ultrasonic Impact Treatment (UIT) process before welding, during welding, after welding, or during repairing of the rails. improvements in the performance of the segment, such as heat or heat flux welding, such as thermite or copper heat welding, and welding processes such as arc welding, gas pressure welding, and flash welding, where reprocessing includes the use of ultrasonic An impact tool applies an ultrasonic impact treatment either manually or automatically, continuously or in batches, to treat a joint around a joint and / or a length of track for the purpose of improving fatigue life and / or other properties of welded track sections.

[0087] The ultrasonic shock treatment according to the invention results in a reduction, compensation and redistribution of the internal stresses and produces favorable compressive stresses in the welded joi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com