Spring steel wire processing process for increasing fatigue performance of high strength spring steel wire

A technology of spring steel wire and fatigue performance, which is applied in the field of spring steel wire processing technology, can solve the problems such as the negative impact of fatigue life of high-strength spring steel wire, and achieve the effects of reducing impact, improving toughness, and increasing fatigue life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

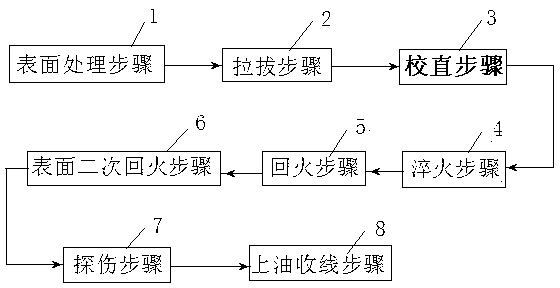

Image

Examples

Embodiment 1

[0025] Deoxidize the surface of the high-strength spring steel wire first: Pickling can be used to remove the oxide scale on the surface of the material. The concentration of hydrochloric acid is 8%, and the pickling time is 30 minutes. Phosphate after pickling to facilitate drawing. Then it is drawn: the wire rod of a specific specification is drawn through a die, and the drawing ratio does not exceed 40%. Then use the roller to make it straighter. The straighter steel wire material is quenched in an intermediate frequency heating equipment, the heating temperature is controlled at about 900 ℃, and quenching oil or water vapor can be used for cooling. After two times of tempering, the first tempering is in the intermediate frequency heating equipment, and the tempering temperature is controlled at about 350℃; then the surface of the material is tempered twice, and the surface is tempered in the high frequency heating equipment. After tempering, the surface temperature of the...

Embodiment 2

[0027] Deoxidize the surface of the high-strength spring steel wire first: Pickling can be used to remove the oxide scale on the surface of the material. The concentration of hydrochloric acid is 25%, and the pickling time is 5 minutes. Boronization after pickling to facilitate drawing. Then it is drawn: the wire rod of a specific specification is drawn through a die, and the drawing ratio does not exceed 40%. Then use the roller to make it straighter. The straighter steel wire material is quenched in an intermediate frequency heating device. The heating temperature is controlled at about 1050°C, and quenching oil or water vapor can be used for cooling. After two times of tempering, the first tempering is in the intermediate frequency heating equipment, and the tempering temperature is controlled at about 550℃; then the surface of the material is tempered twice, and the surface is tempered in the high frequency heating equipment. After tempering, the surface temperature of th...

Embodiment 3

[0029] Deoxidize the surface of the high-strength spring steel wire: pickling can be used to remove the oxide scale on the surface of the material. The concentration of hydrochloric acid is 15%, and the pickling time is 20 minutes. Boronization after pickling to facilitate drawing. Then it is drawn: the wire rod of a specific specification is drawn through a die, and the drawing ratio does not exceed 40%. Then use the roller to make it straighter. The straighter steel wire material is quenched in an intermediate frequency heating device. The heating temperature is controlled at about 980°C, and quenching oil or water vapor can be used for cooling. After two times of tempering, the first tempering is in the intermediate frequency heating equipment, and the tempering temperature is controlled at about 450℃; then the surface of the material is tempered twice, and the surface is tempered in the high frequency heating equipment. Tempering, the surface temperature of the material i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com