Method and apparatus for increasing fatigue notch capability of airfoils

一种翼型件、设备的技术,应用在金属加工设备、制造工具、抛光机床等方向,能够解决激光冲击处理昂贵等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

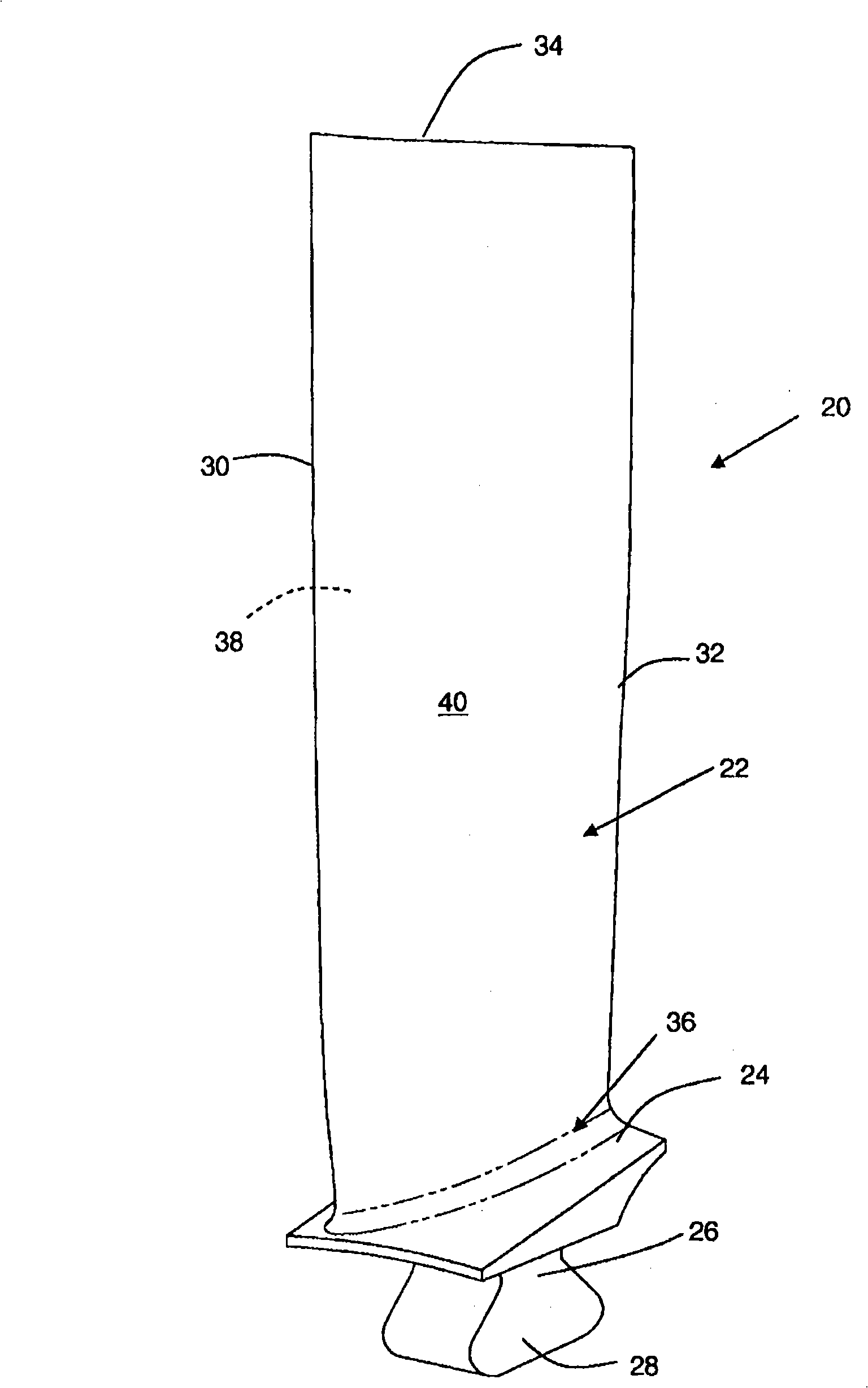

[0016] Referring to the drawings, in which like numerals denote like elements throughout the various views, figure 1 An exemplary gas turbine engine compressor blade 20 is shown prior to processing. This component is only used as an example of a part to which the method of the invention can be applied. The invention is equally applicable to other types of components that are susceptible to cracking due to fatigue or damage, such as compressor stator vanes, fan blades, turbine blades, shafts and rotors, mounts, actuator hardware, and the like. The part may be made of metal alloys, ceramics or composite materials such as carbon fiber composites. Usually, the blade is made of alloys based on titanium, iron or nickel. Examples of commercially available alloys of this type include Ti 6-4, Ti 6-2-4-2, A-286, C 450, and In 718. Compressor blade 20 includes an airfoil 22 , a platform 24 and a shank 26 . In this particular example, the handle 26 includes a dovetail 28 that is recei...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com