Heat exchanger of an internal combustion engine

a technology of heat exchanger and internal combustion engine, which is applied in the direction of heat exchanger recovery, exhaust treatment, stationary tubular conduit assembly, etc., can solve the problems of high thermal and mechanical stress of heat exchanger, and the application of heat exchanger in vehicles is also associated with high stress, so as to improve the service life of the mount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

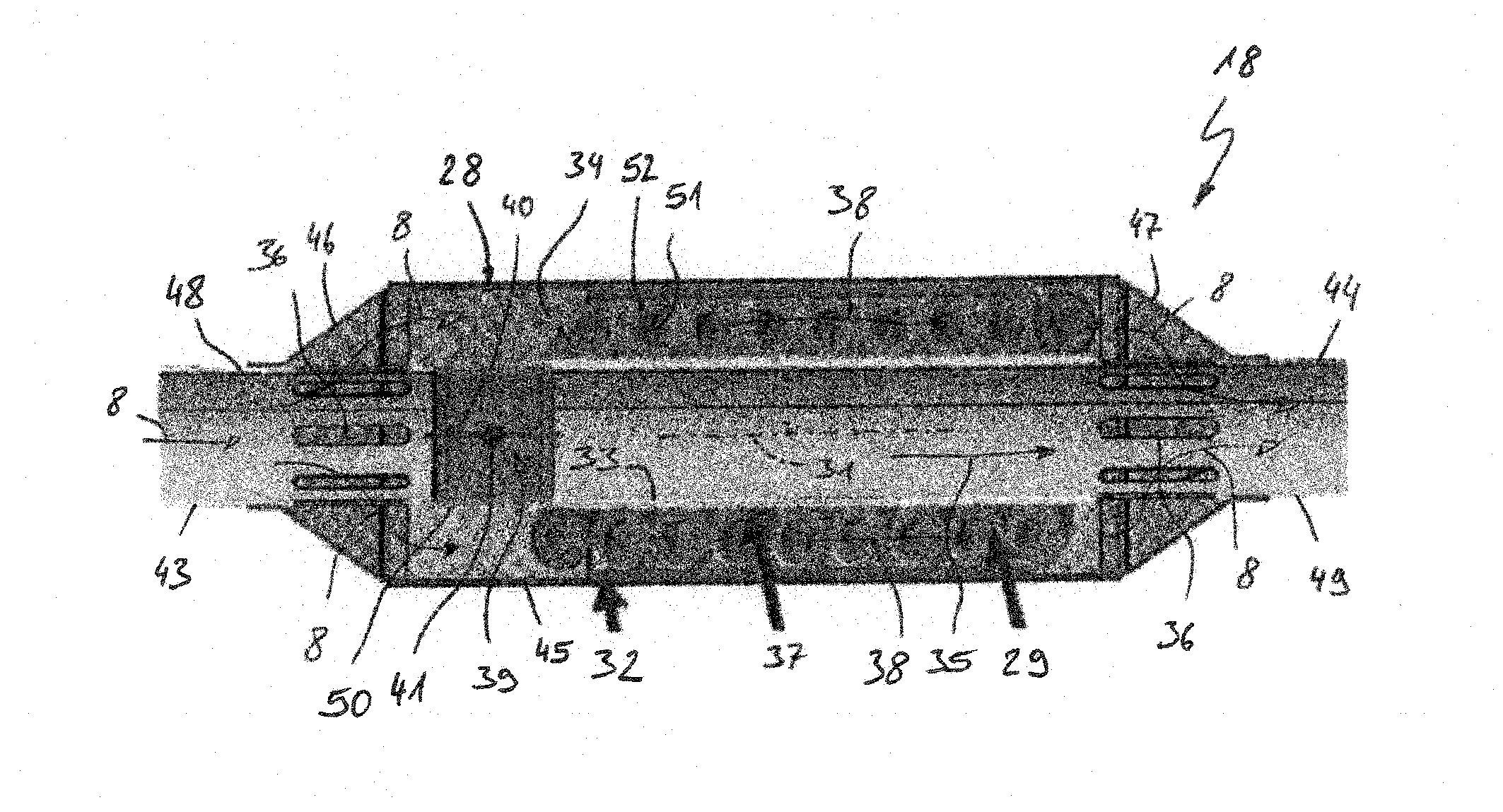

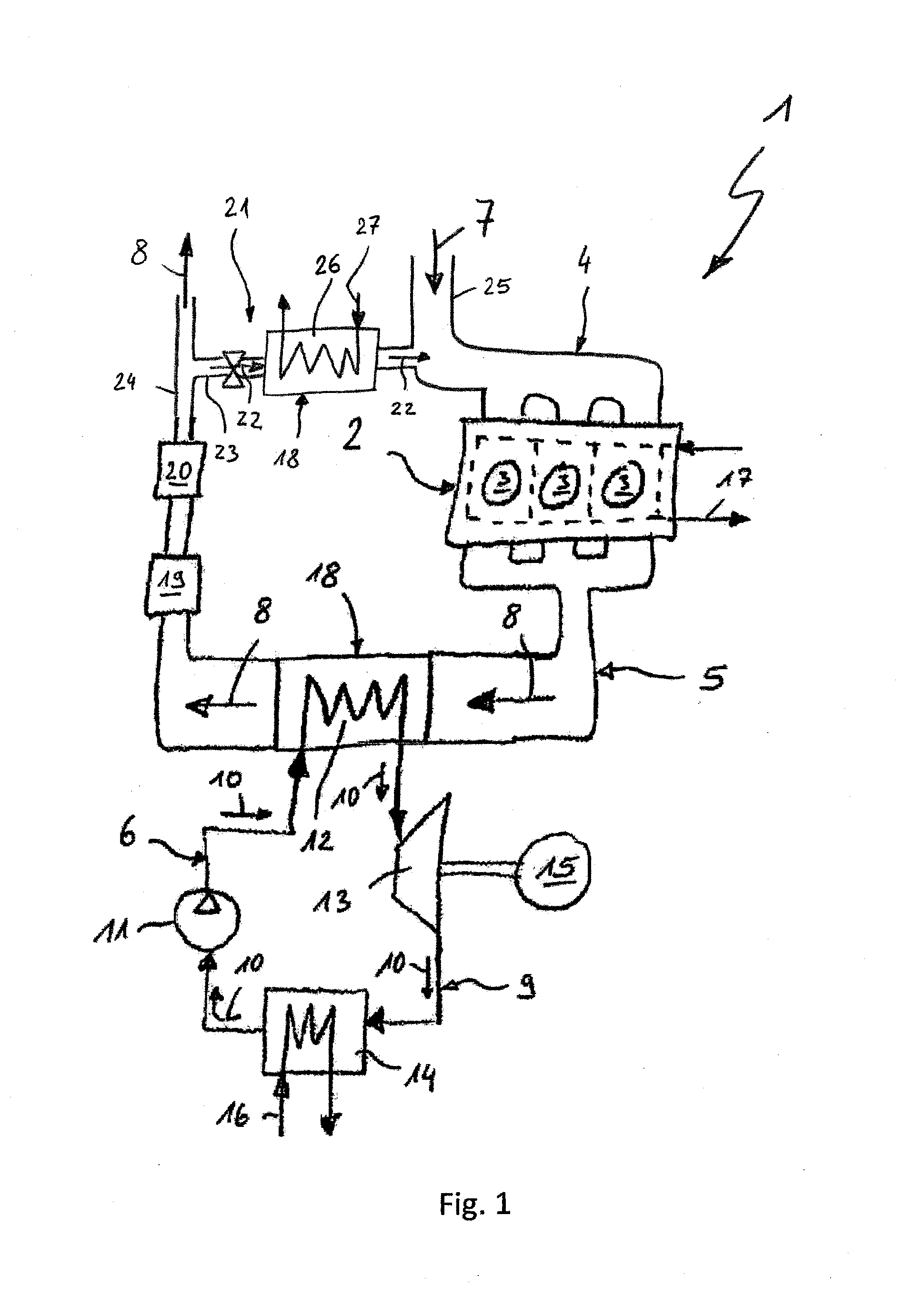

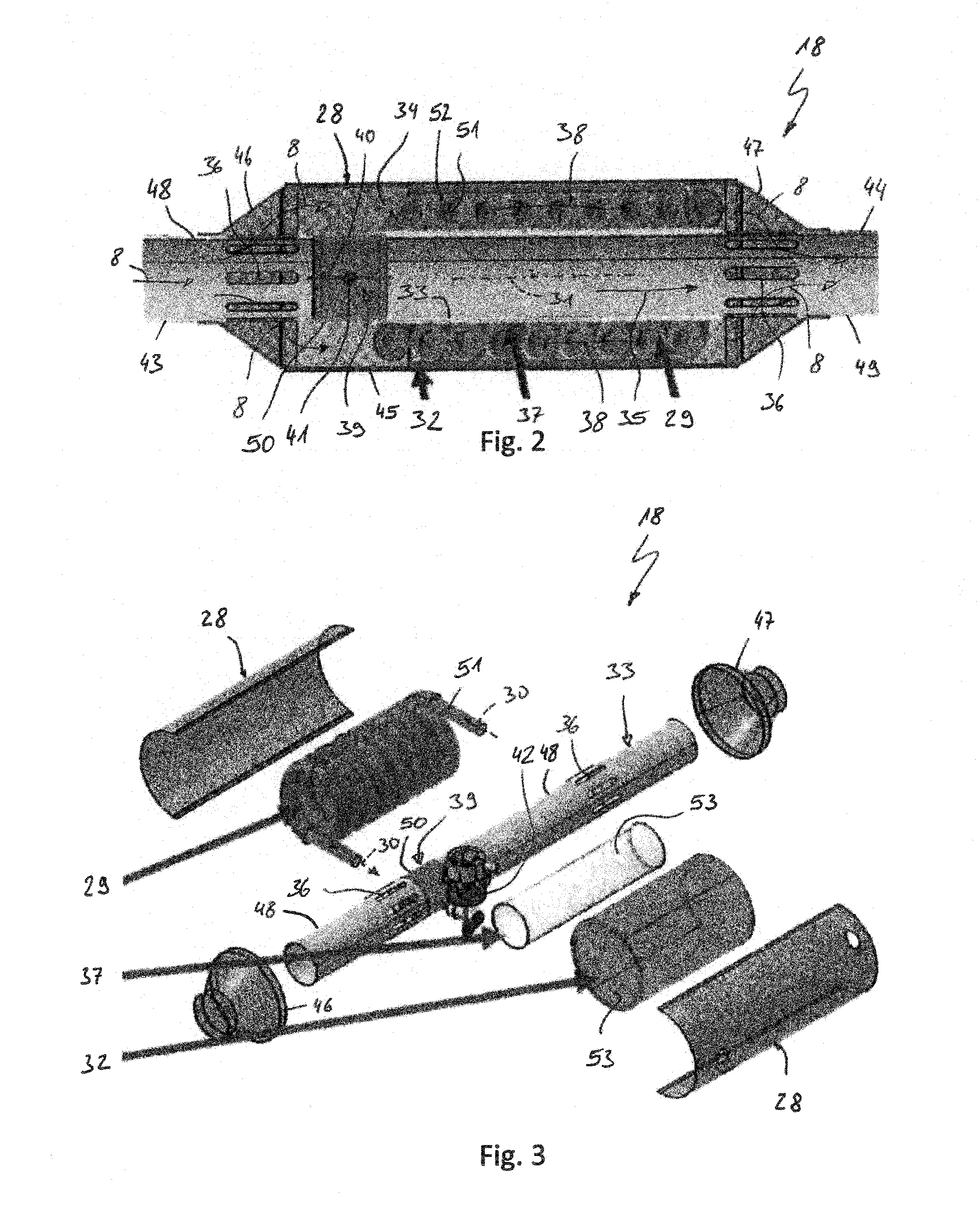

[0030]Referring to the drawings in particular, corresponding to FIG. 1, an internal combustion engine 1 comprises, in the usual manner, an engine block 2 with a plurality of combustion chambers 3, a fresh air feed unit 4 for feeding fresh air to the combustion chambers 3, an exhaust system 5 for removing exhaust gas from the combustion chambers 3 and a waste heat utilization unit 6 for utilizing the heat being carried in the exhaust gas. A fresh air stream 7 being carried in the fresh air feed unit 4 is indicated by an arrow. An exhaust gas stream 8 being carried in the exhaust system 5 is indicated by arrows. The waste heat utilization unit 6 comprises a waste heat utilization circuit 9, in which a working medium circulates, wherein a working medium stream 10 is indicated by arrows. A delivery means 11 for driving the working medium, an evaporator 12 for evaporating the working medium, an expansion engine 13 for expanding the working medium and a condenser 14 for condensing the wor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com