Autofrettage process for a pump fluid end

A treatment method and prestressing technology, applied in the field of prestressing treatment, can solve the problem of cylinder block being susceptible to fatigue damage and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

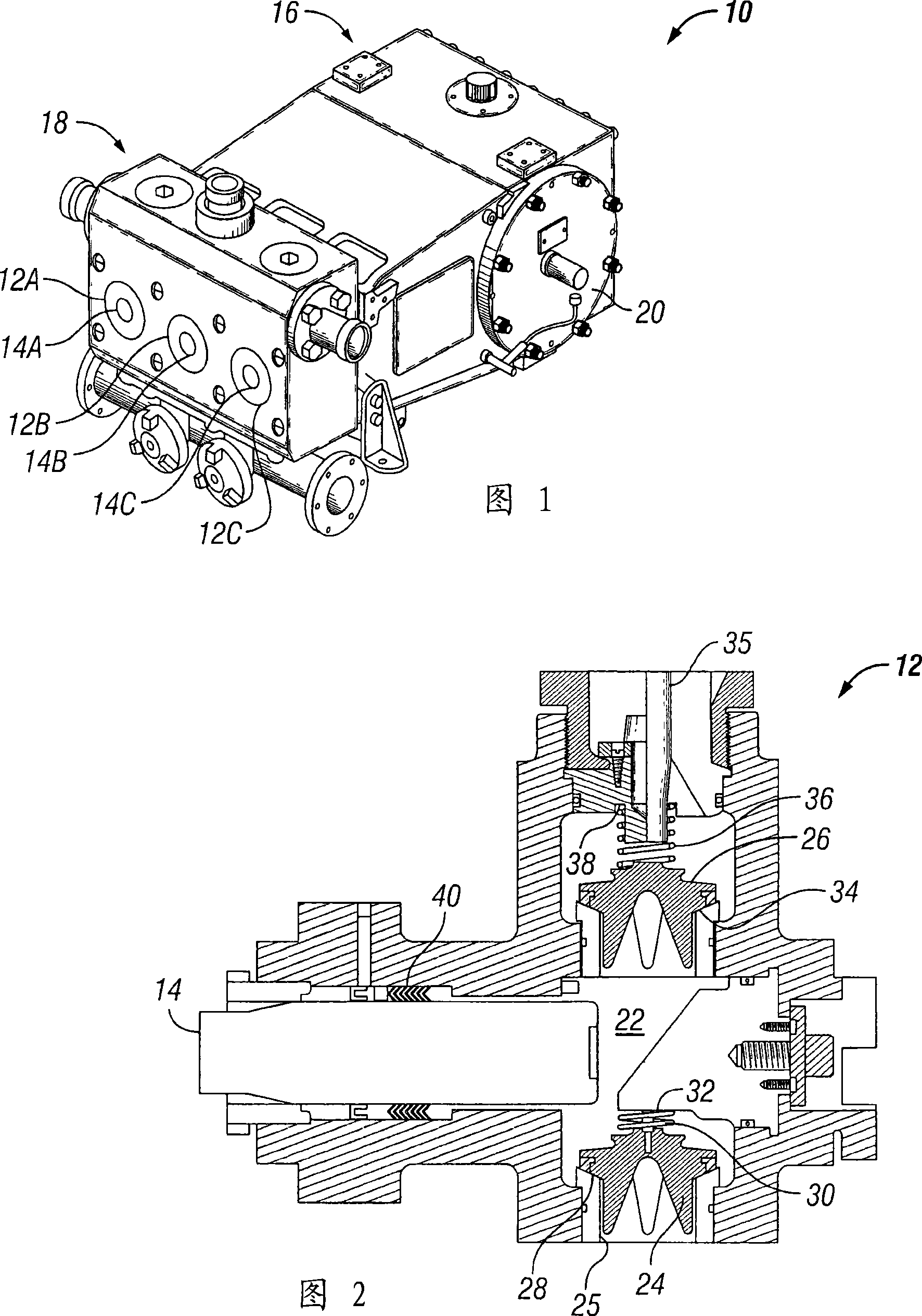

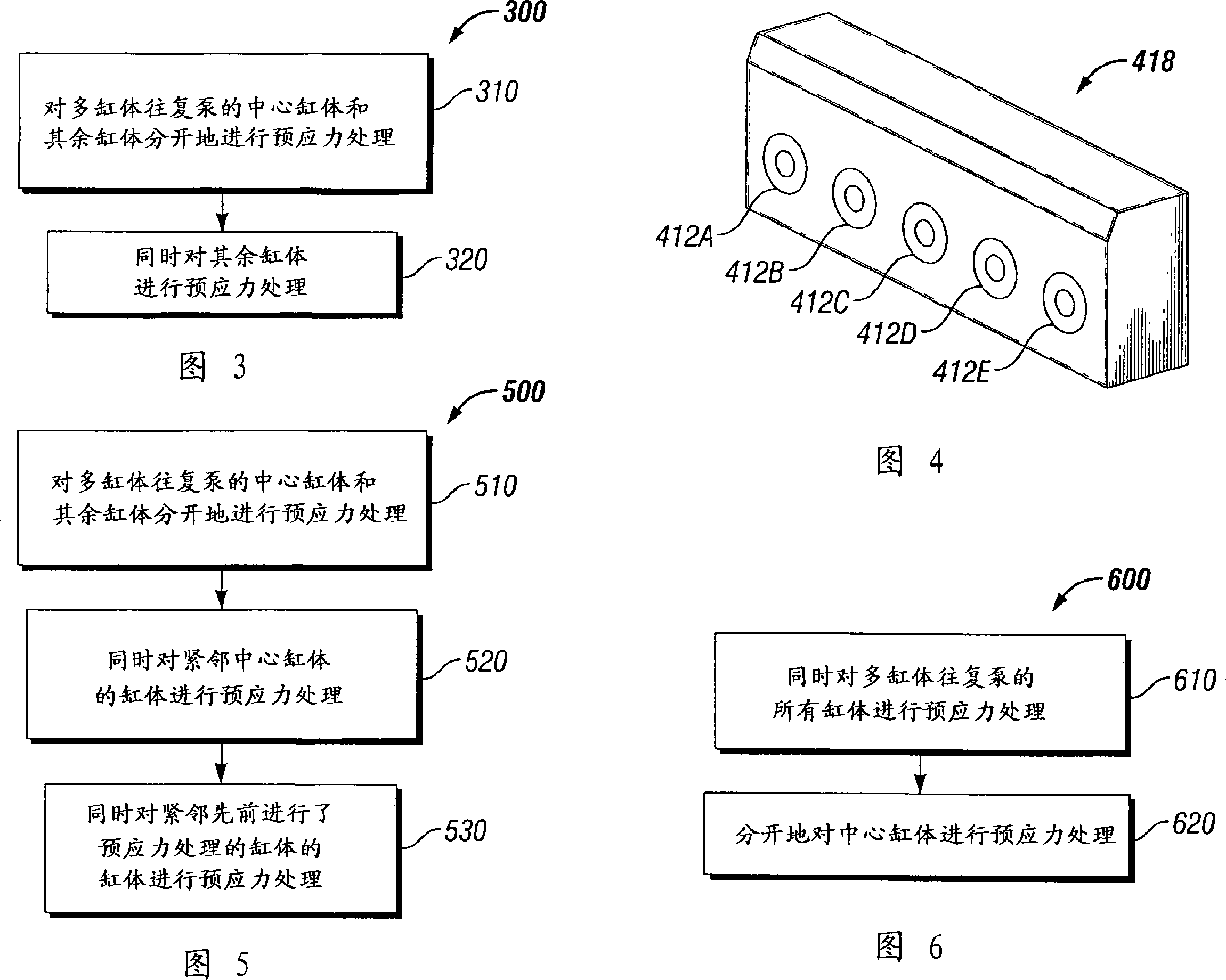

[0012] As mentioned above, in oil and gas wells, multi-cylinder reciprocating pumps are often used to pump bottomhole high-pressure fracturing fluids to increase well productivity. One embodiment of such a pump 10 is shown in FIG. 1 . In the illustrated embodiment, the pump 10 is a triplex pump having three cylinders 12A-12C, each cylinder having a corresponding piston 14A-14C arranged to move relative thereto. For the purposes of this document, the central cylinder of the three cylinders will be referred to as the central cylinder 12B, while the remaining two cylinders will be referred to as the side cylinders 12A, 12C. However, as discussed further below, the pump 10 may be a pump having any suitable number of cylinders, such as a five cylinder pump (pentaplex pump) or a seven cylinder pump (septax pump).

[0013] As will be described further below, in the embodiment shown in this figure, the pump 10 includes two parts, a power end 16 and a fluid end 18 . The power end 16 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com