Patents

Literature

139results about "Stress reducing fuel injection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

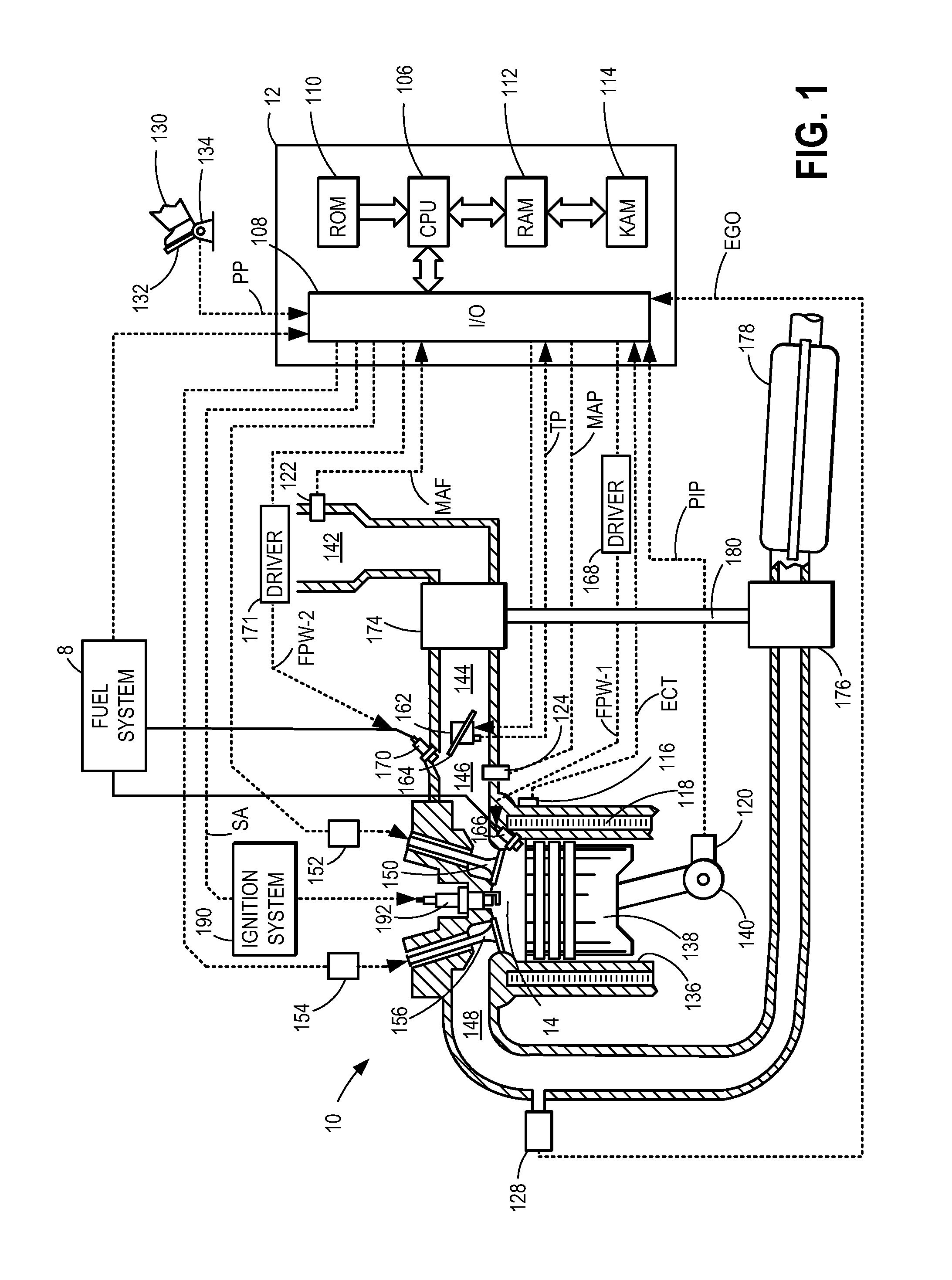

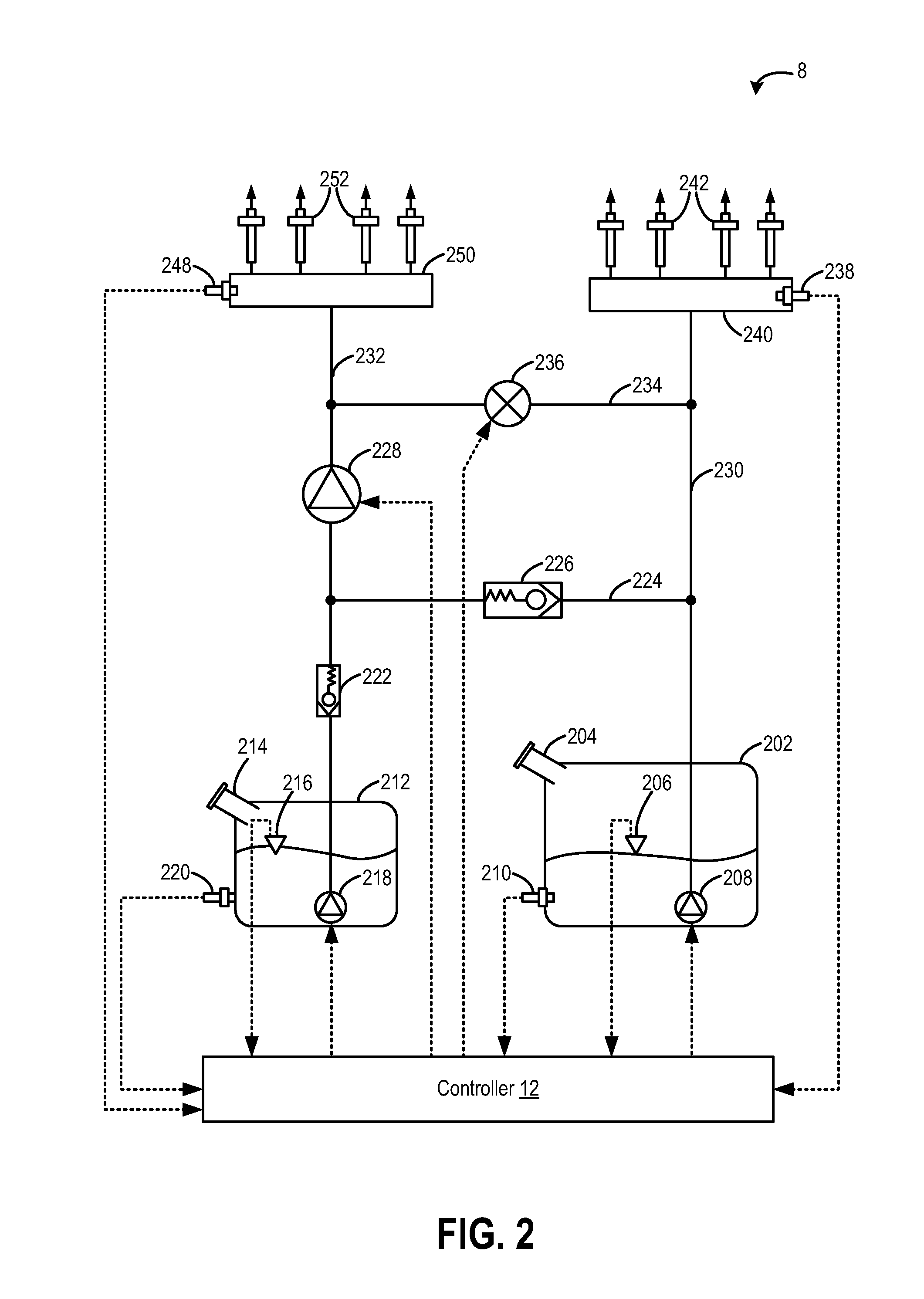

Direct injection fuel pump

ActiveUS20140224209A1Reduce degradation rateImprove fuel pump lubricationElectrical controlWear reducing fuel injectionLubricationFuel pump

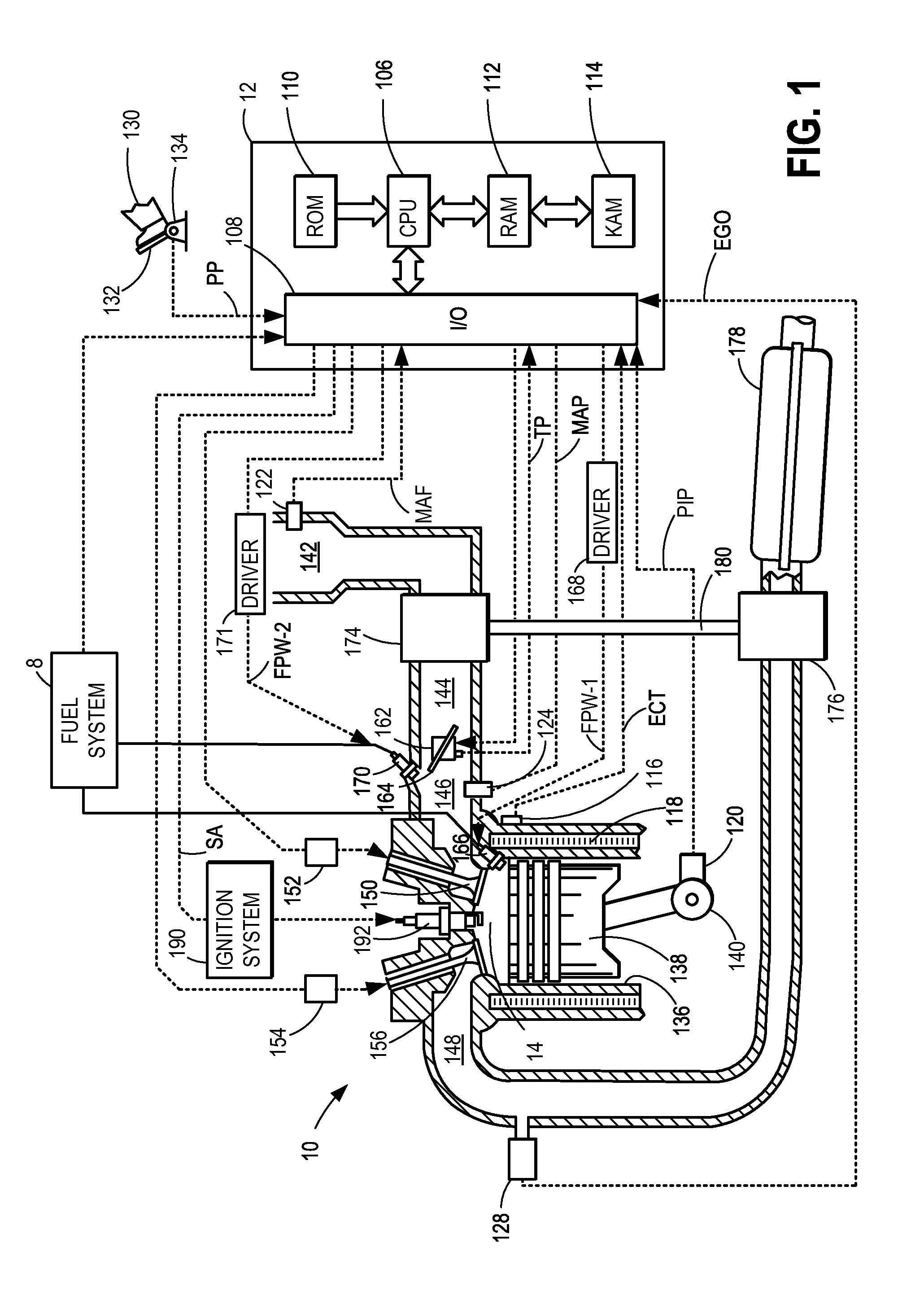

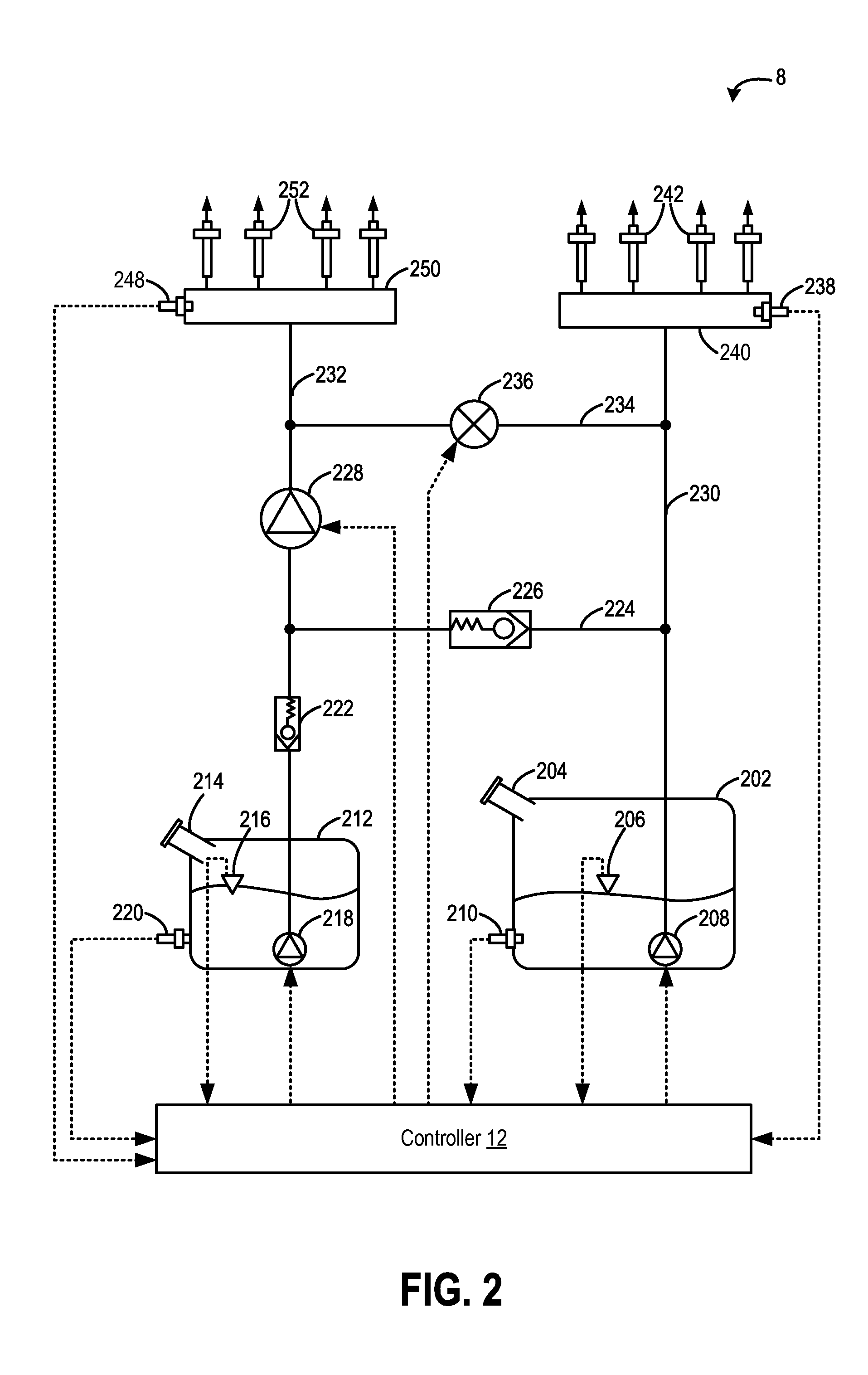

Methods and systems are provided for a direct injection fuel pump. The methods and system control pressure within a compression chamber so as to improve fuel pump lubrication.

Owner:FORD GLOBAL TECH LLC

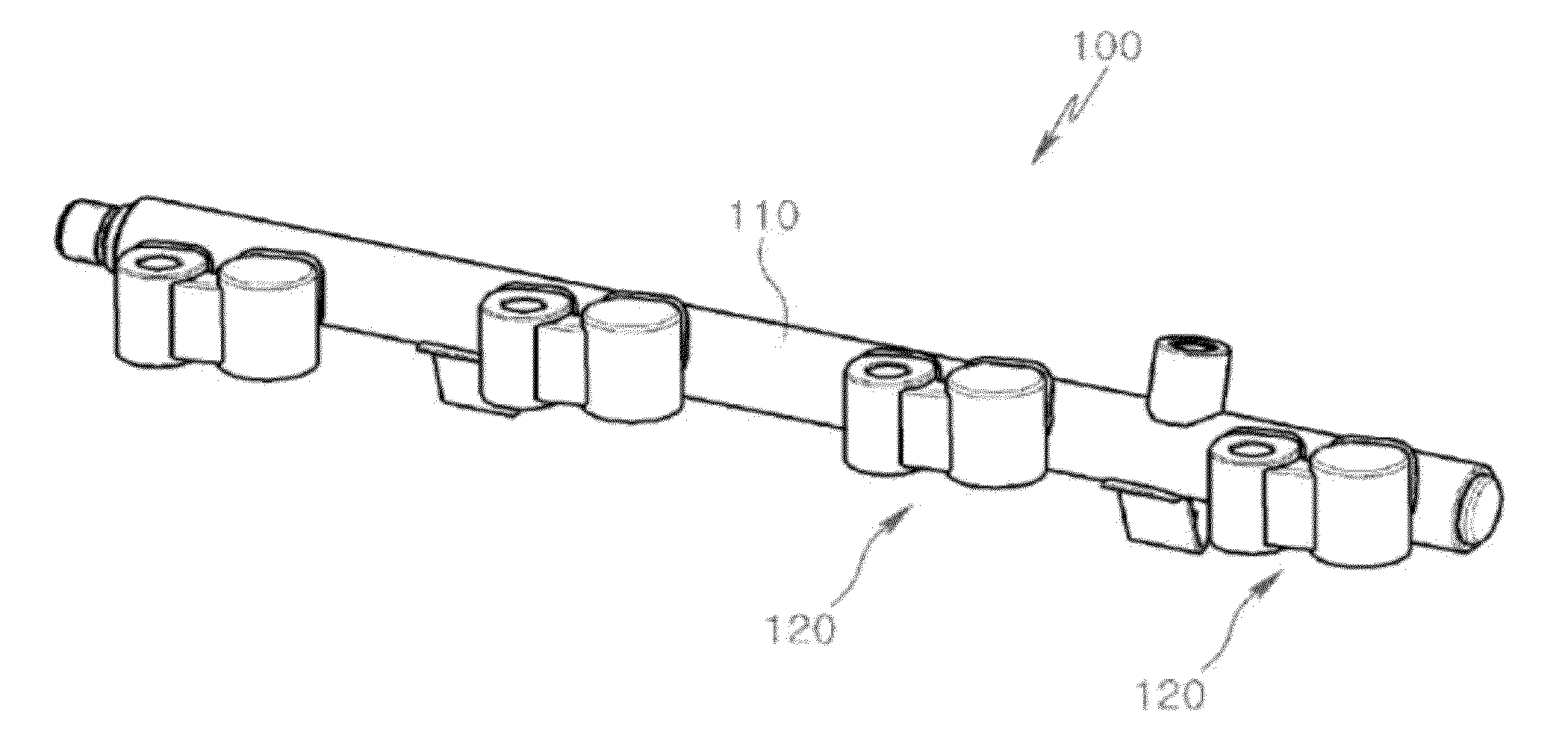

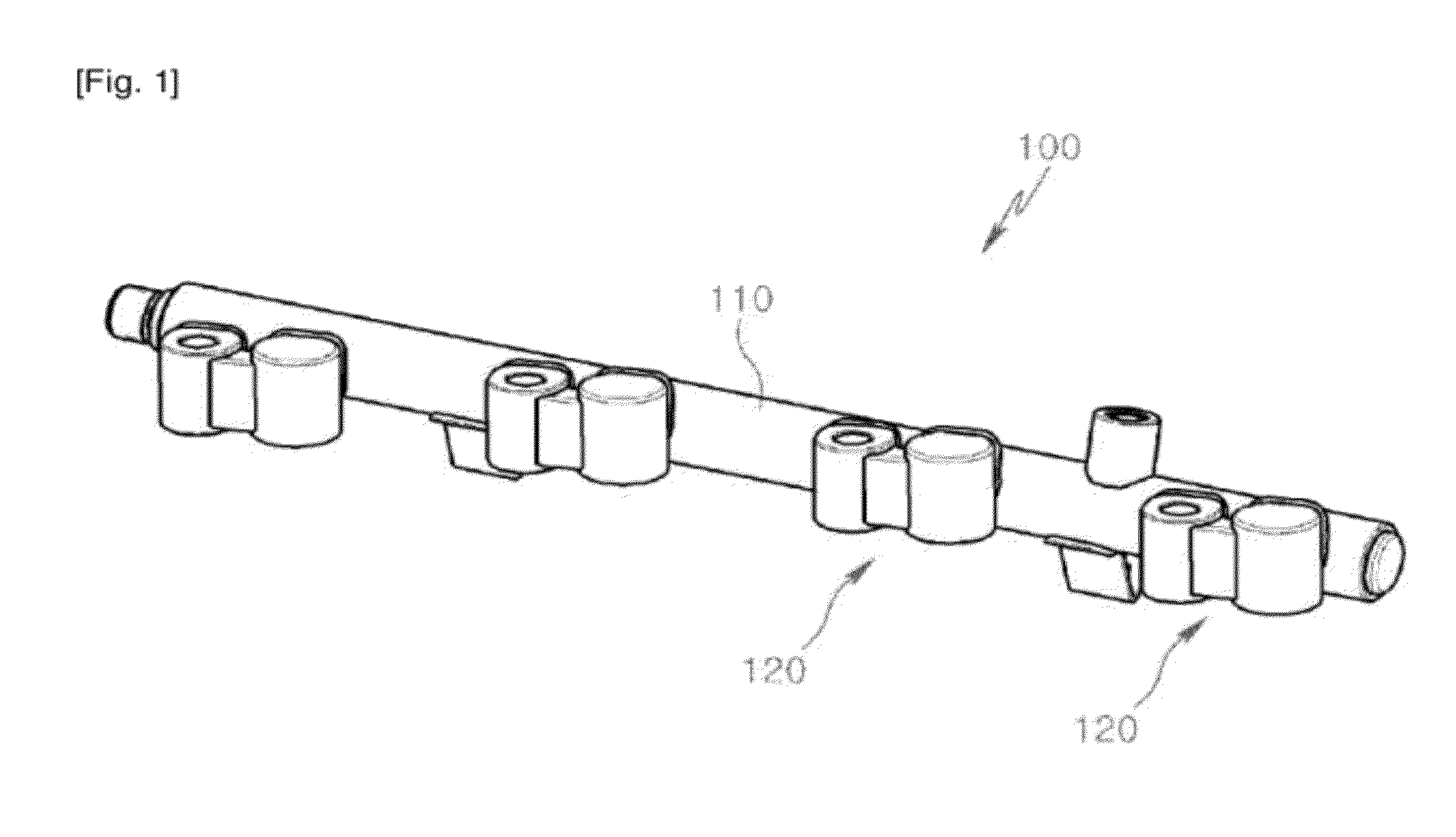

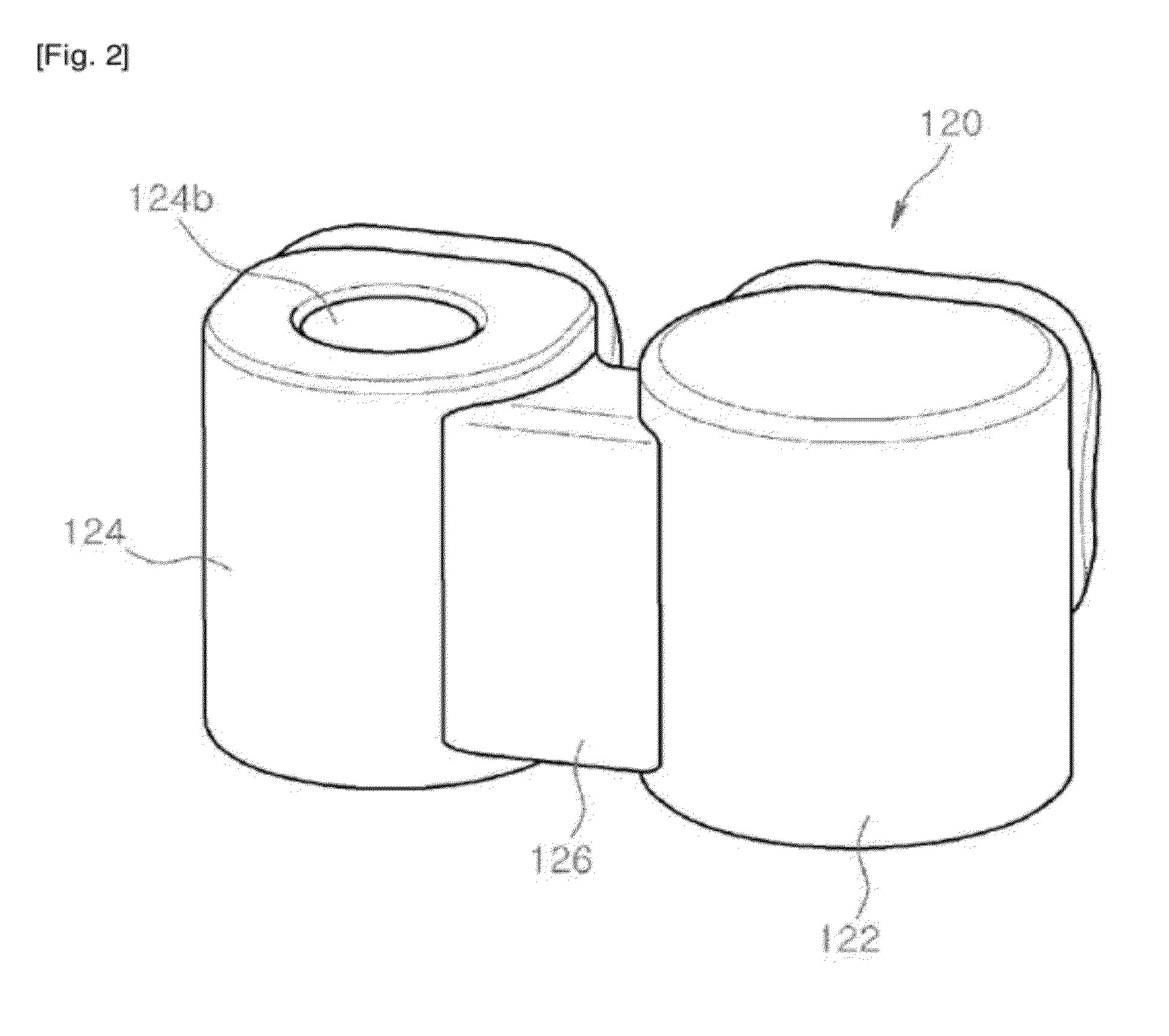

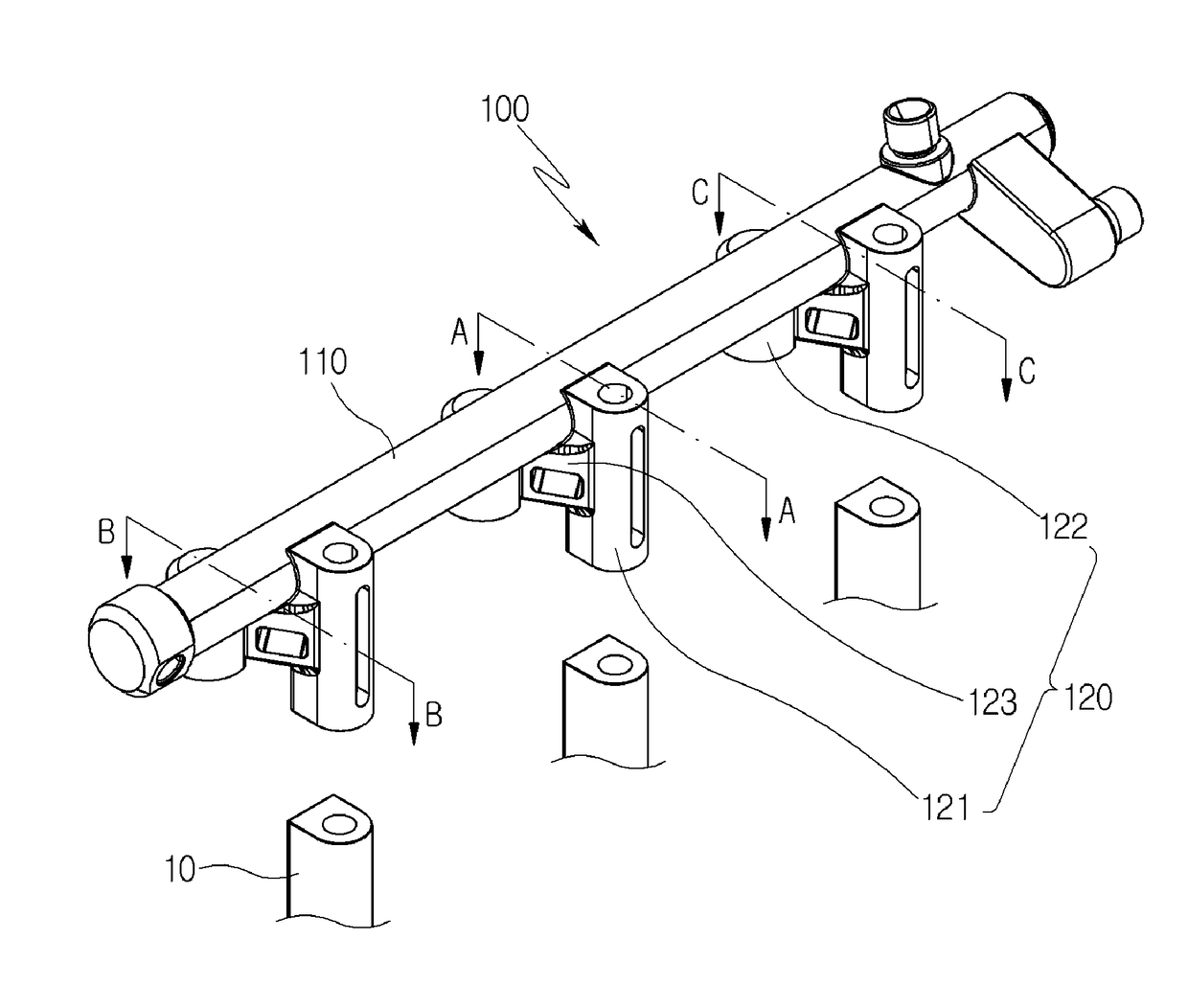

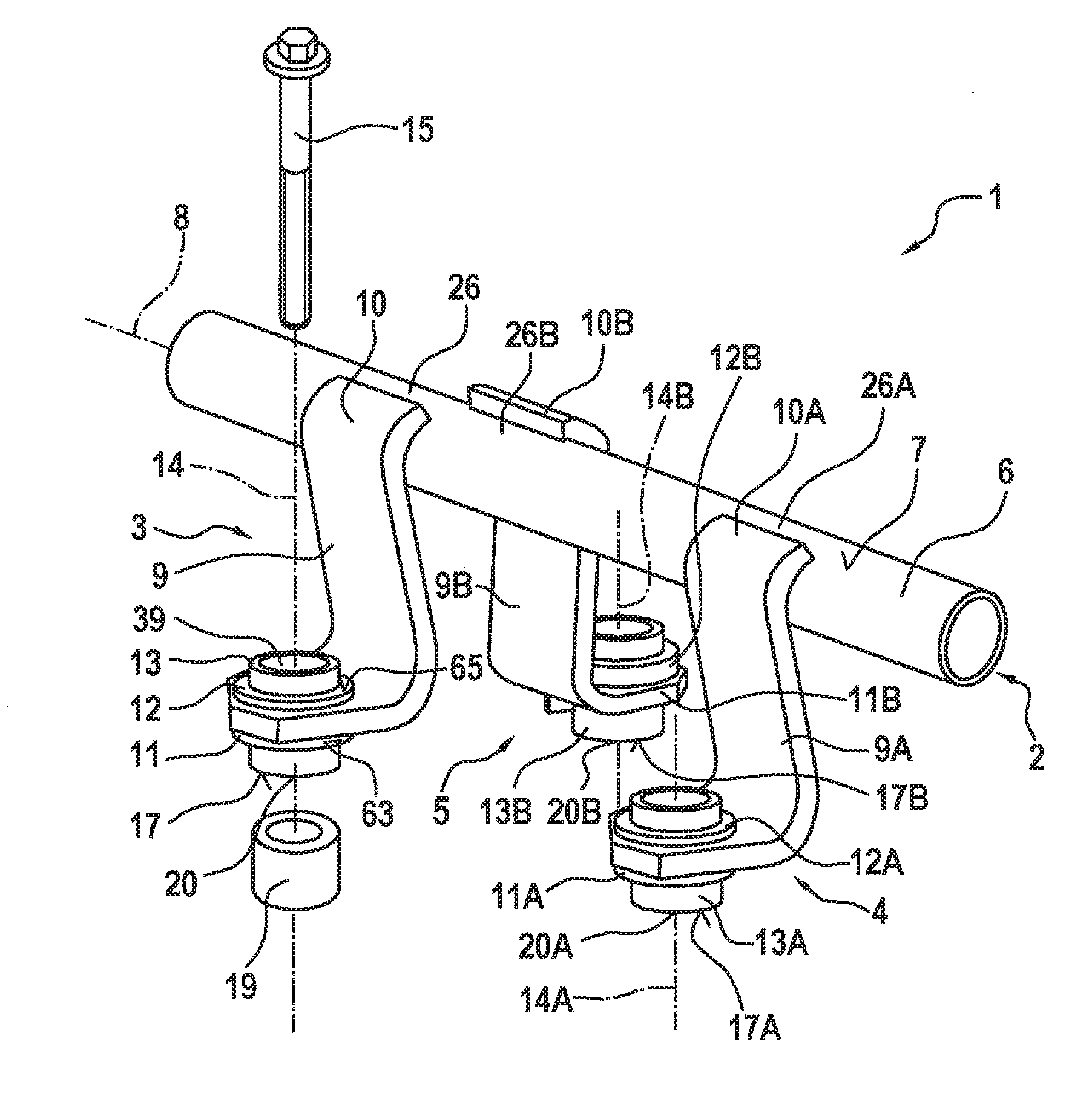

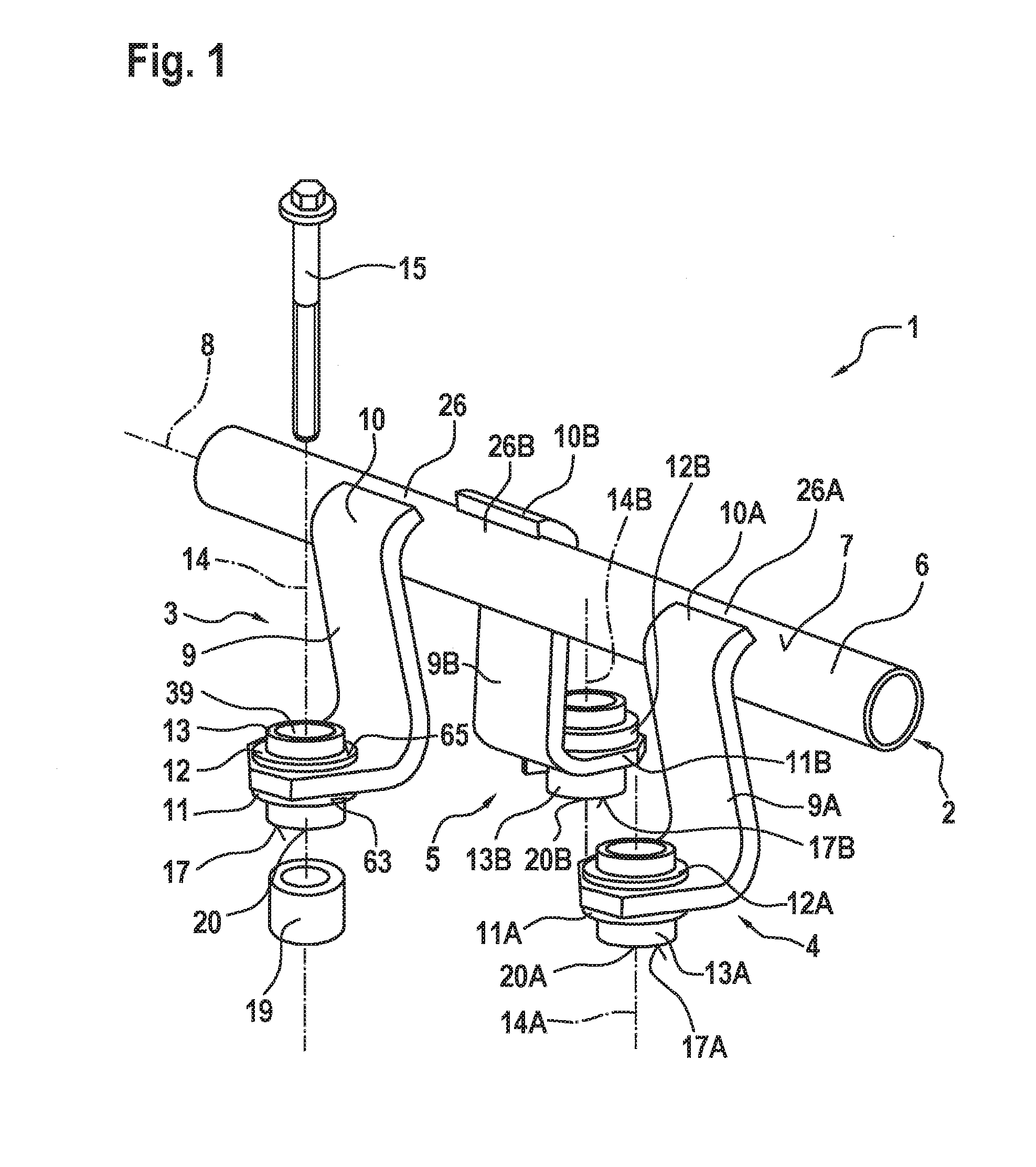

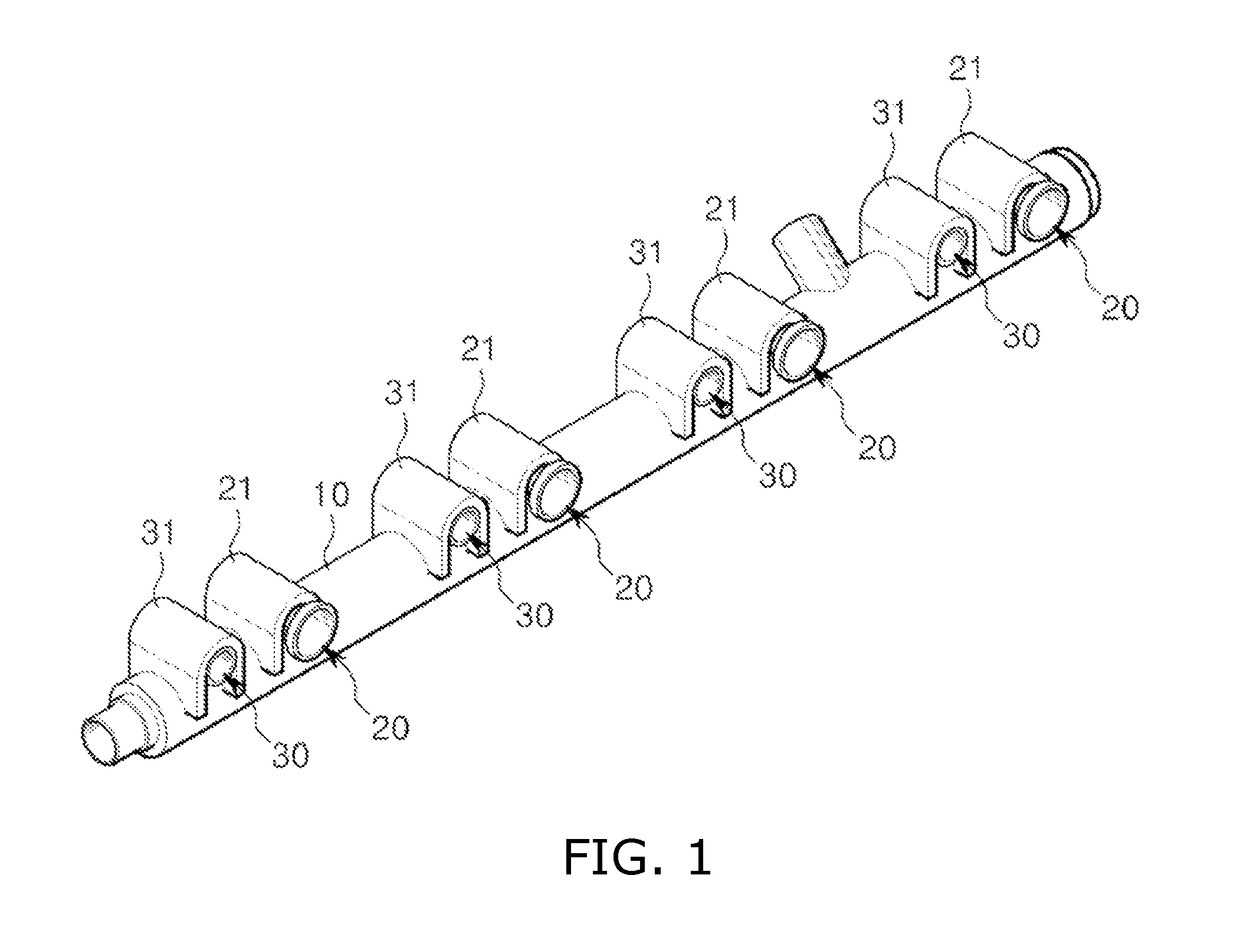

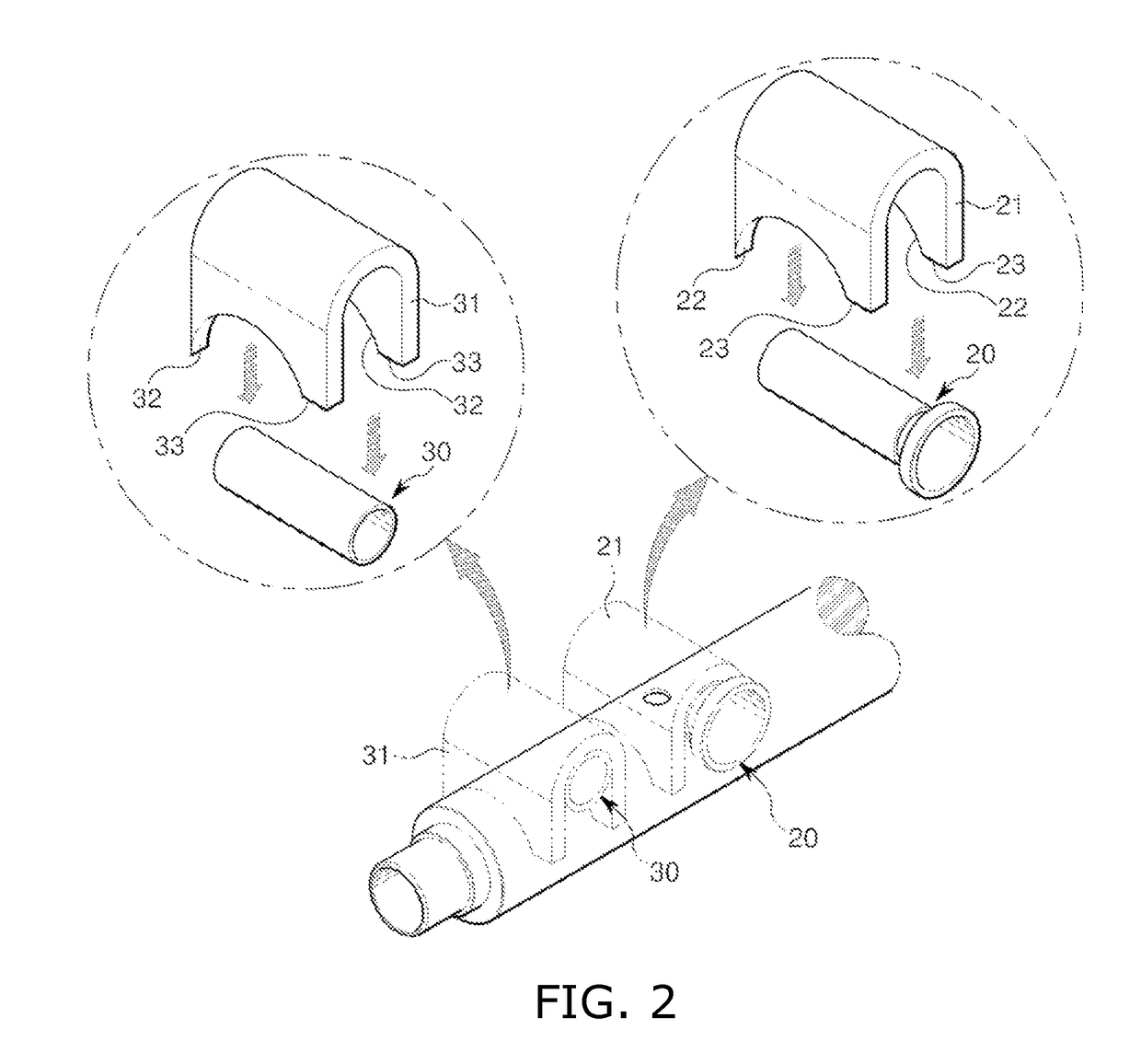

Mounting structure for a direct injection fuel rail

ActiveUS20120138020A1Prevent thermal deformationImprove fatigue resistanceMachines/enginesStress reducing fuel injectionStress concentrationFatigue fractures

The present invention relates to a mounting structure for a direct injection fuel rail. Specifically, a mounting structure 120 for a direct injection fuel rail comprises a mount unit 124 and an injector cup 122 combined with a main pipe 110, wherein the injector cup 122 and the mount unit 124 are connected to and integrated with each other via a bridge 126, wherein the injector cup 122 is bonded to the main pipe 110, and wherein the mount unit 124 is separated from the main pipe 110. As such, concentration of stress due to displacement may be prevented, resistance against fatigue fracture may be increased, thermal deformation and additional concentration of stress may be prevented, manufacturability may be improved, and precise assembling positions may be easily ensured.

Owner:KEFICO

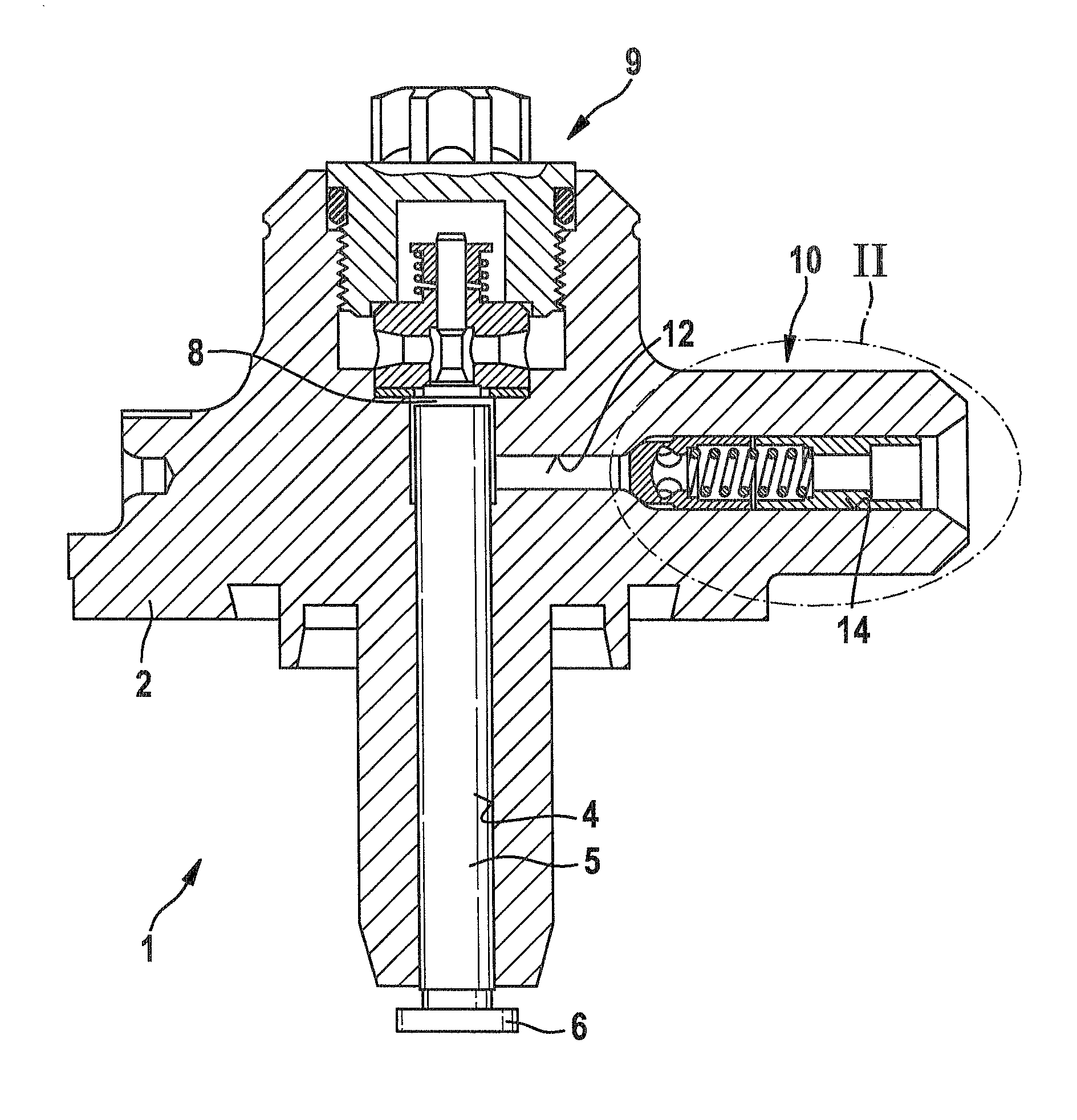

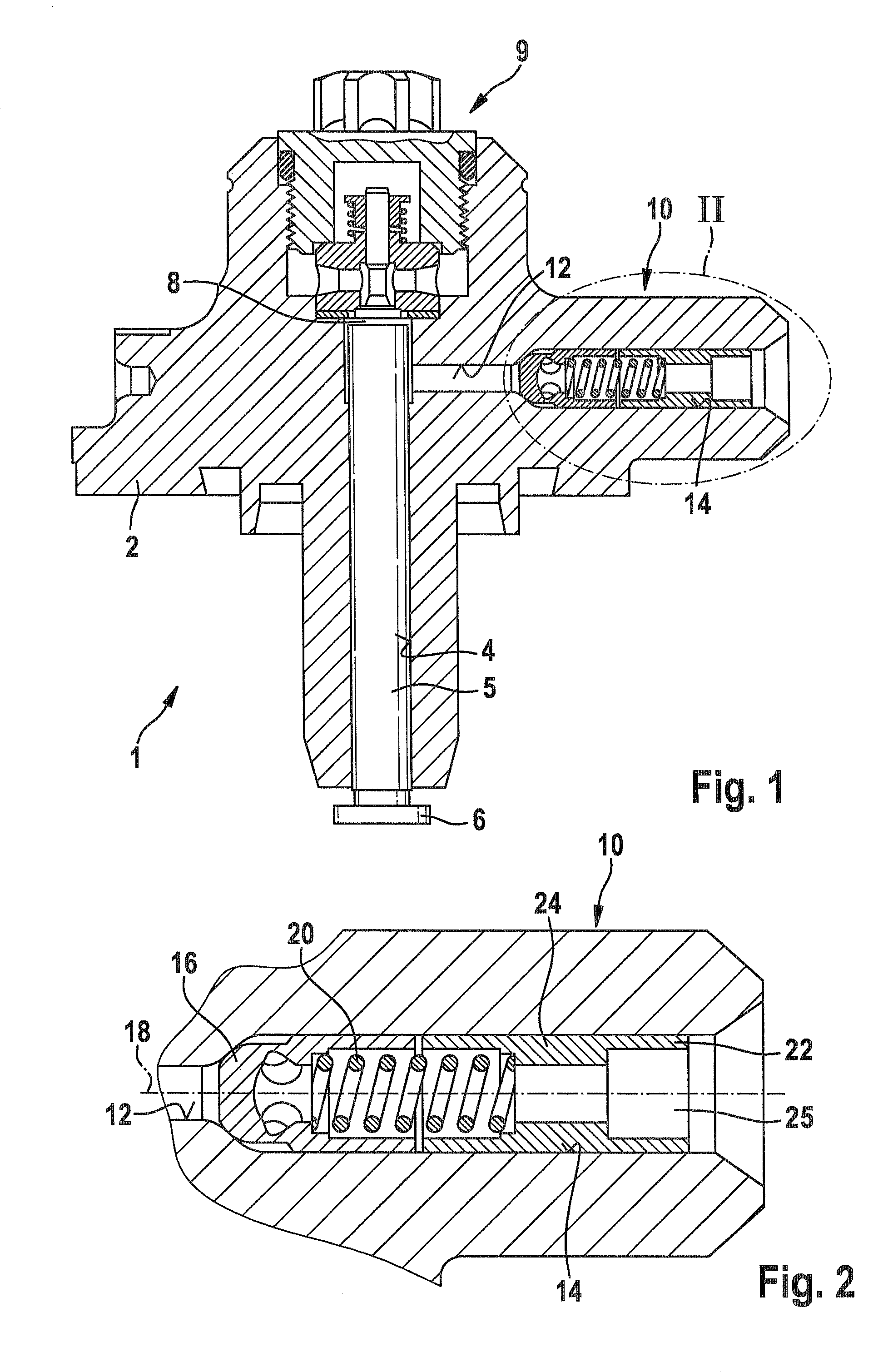

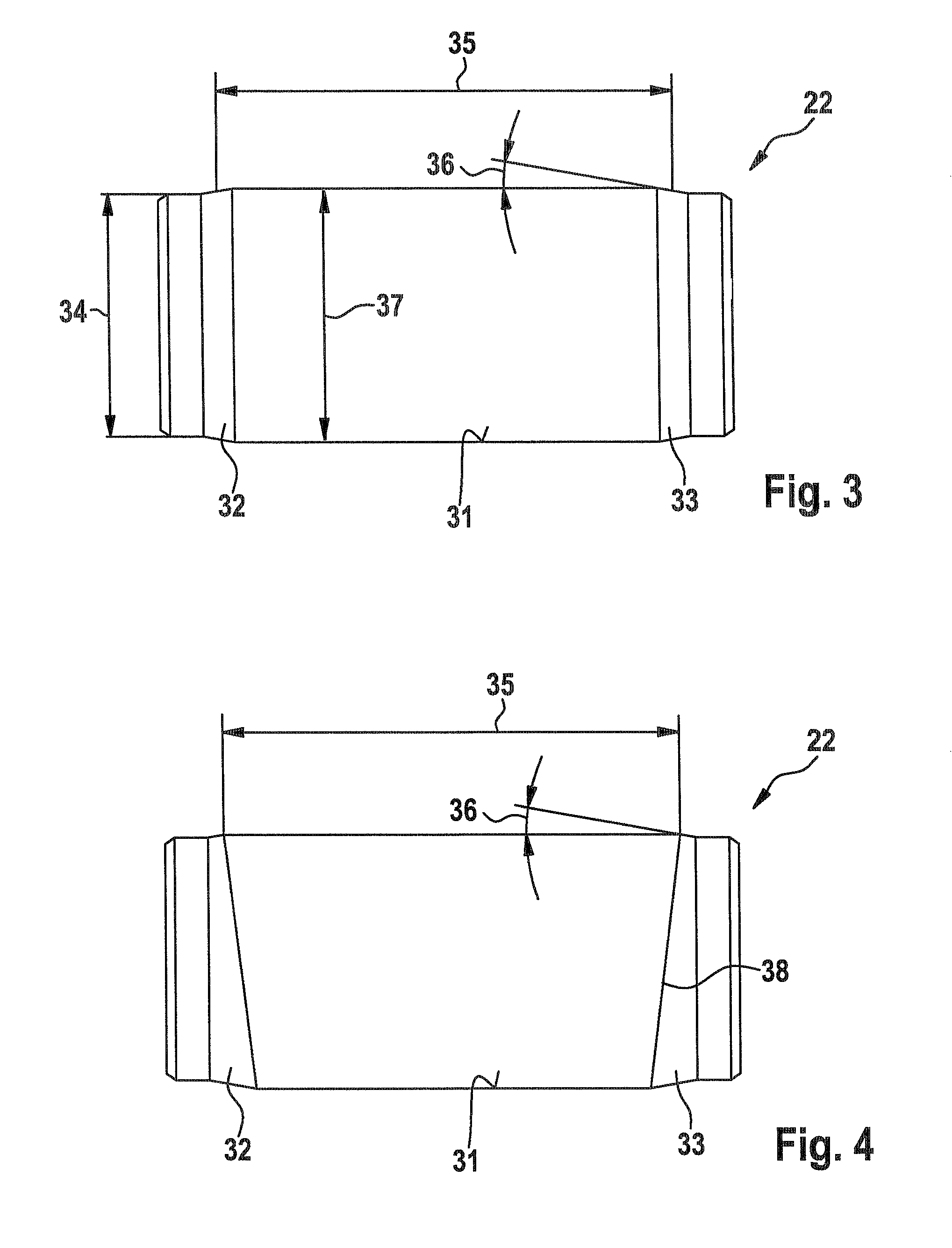

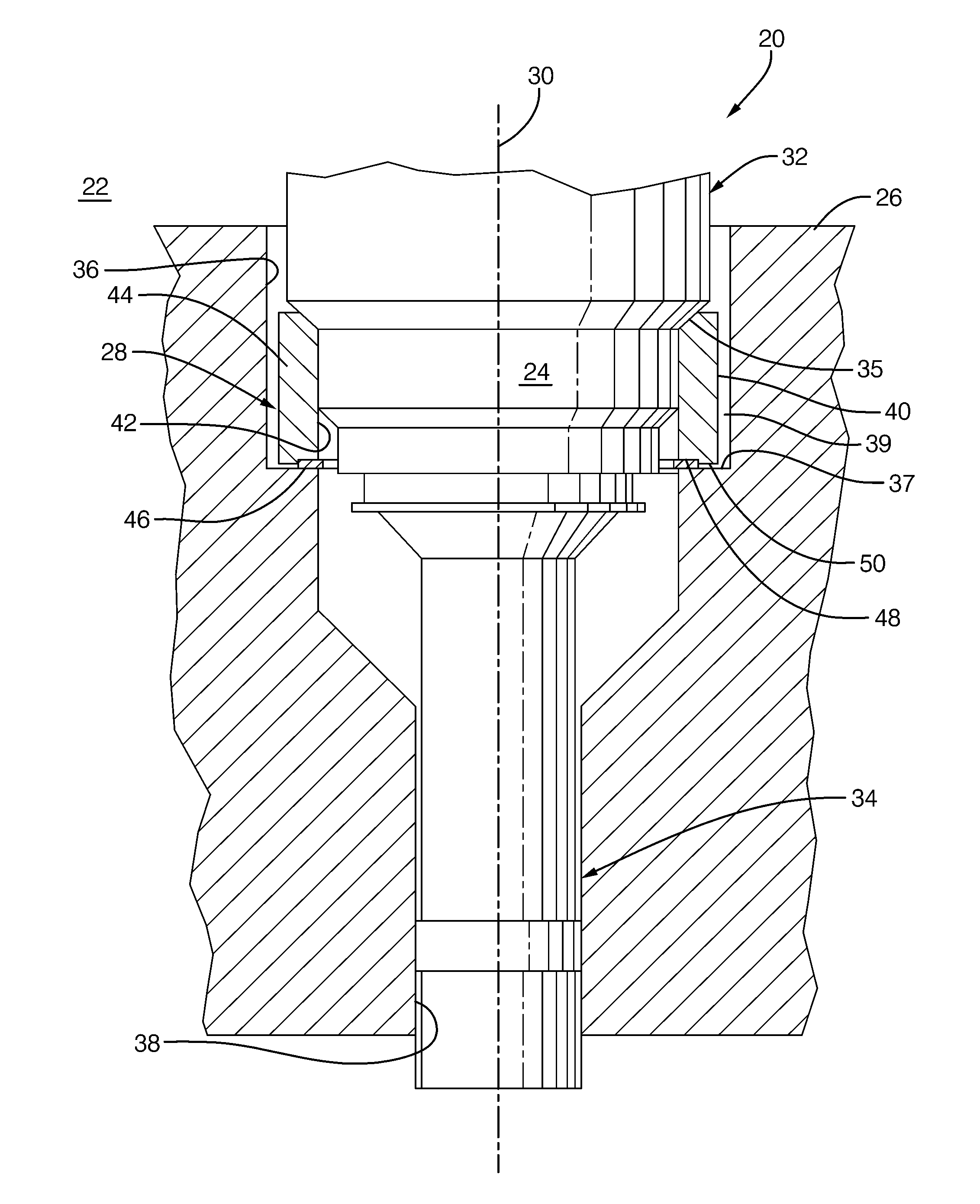

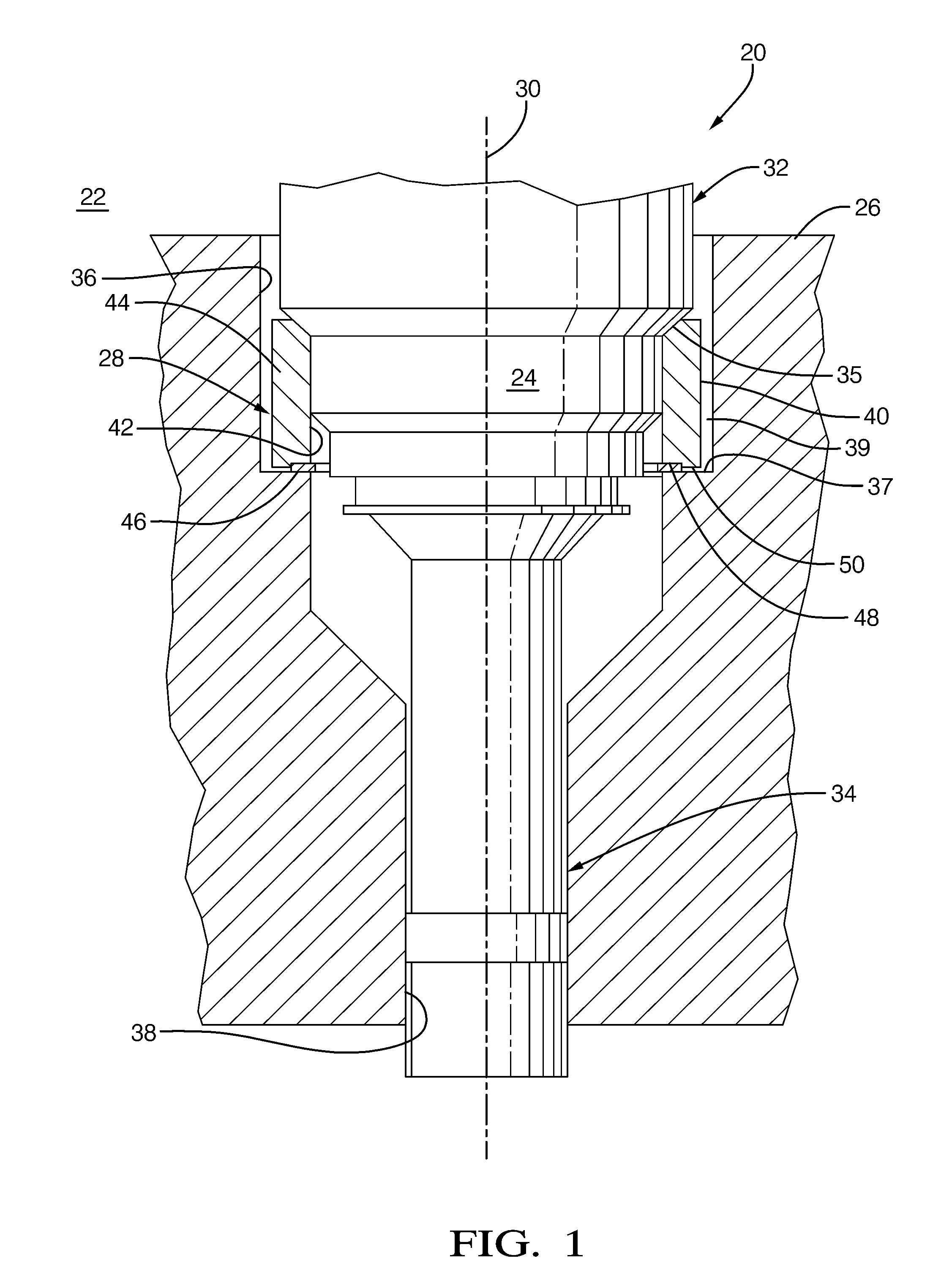

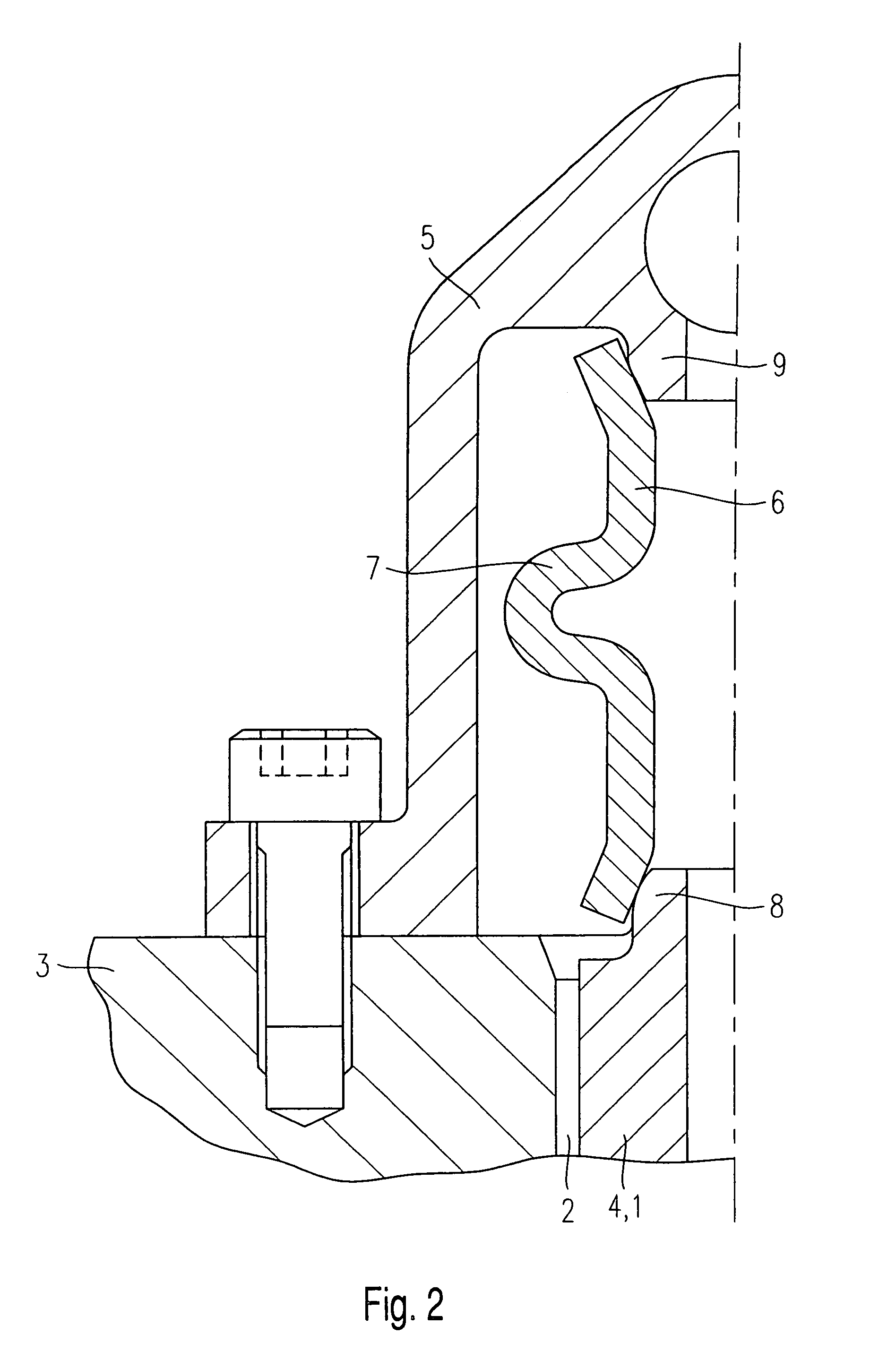

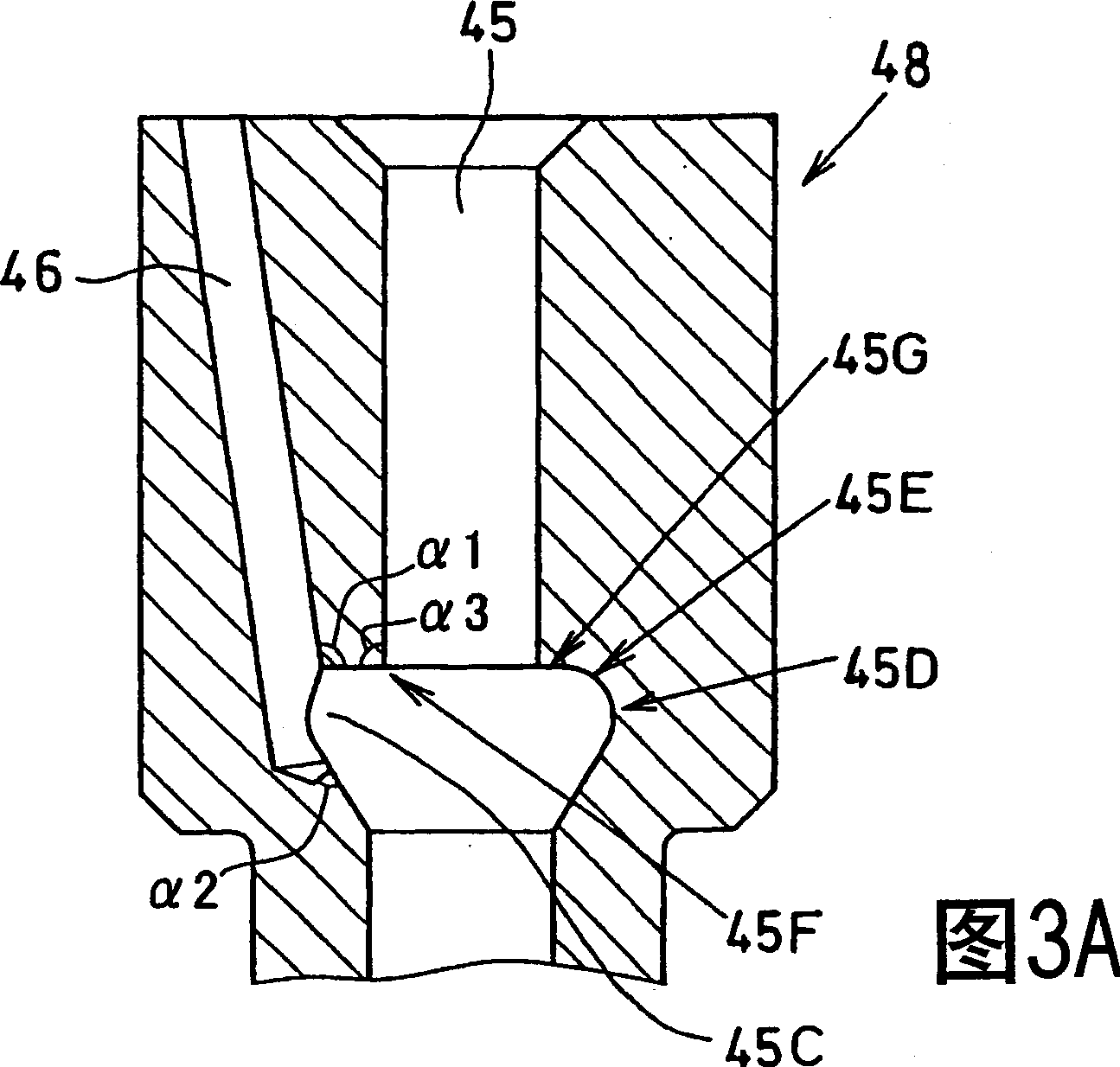

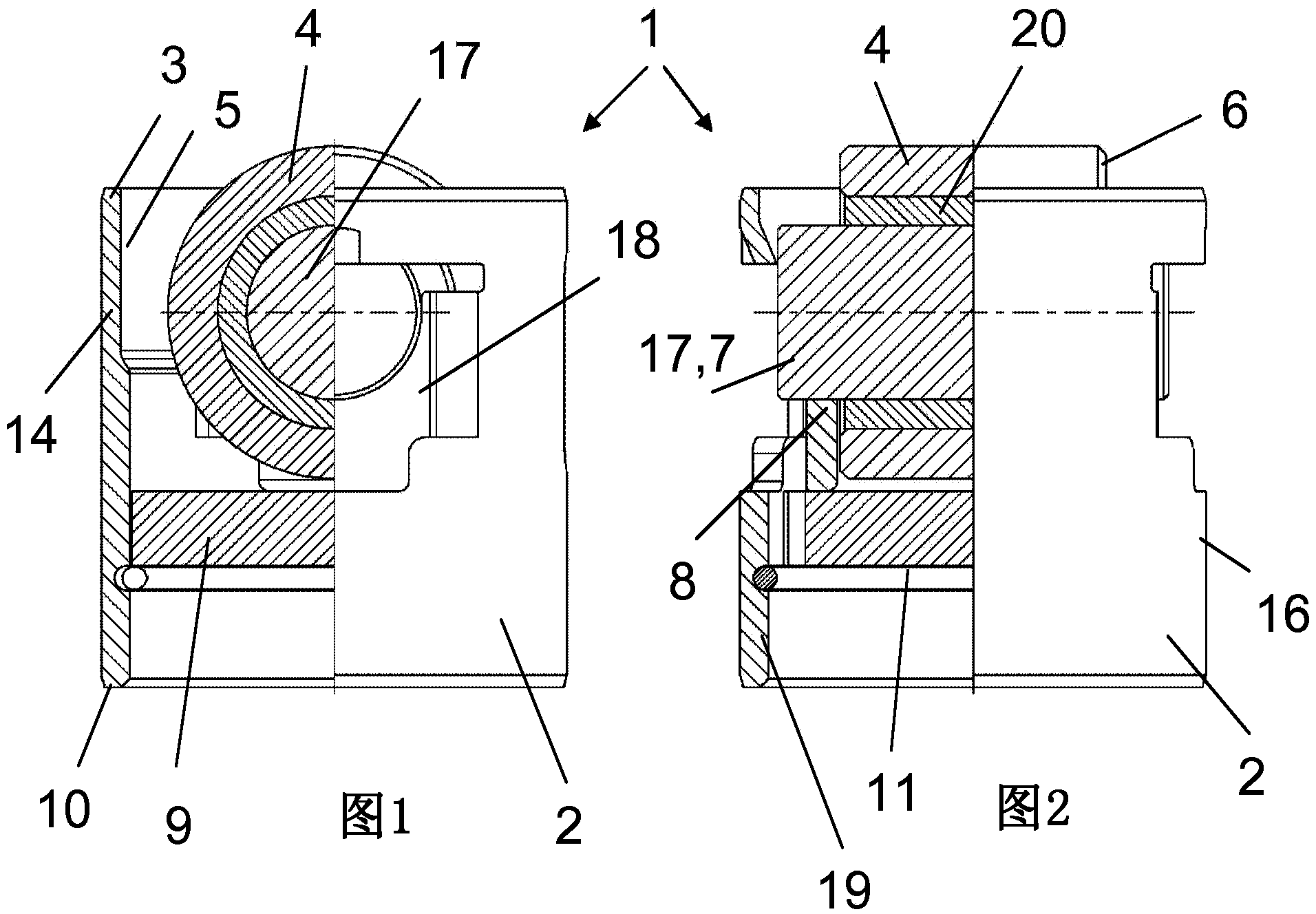

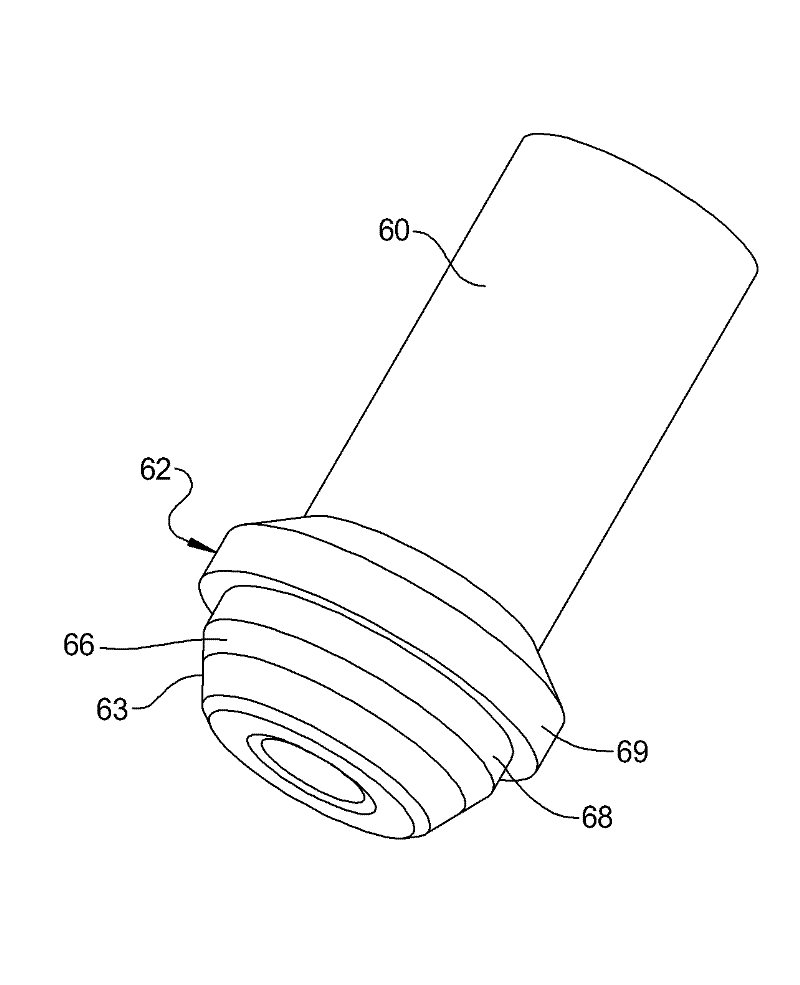

Spring retaining sleeve

ActiveUS8757198B2Cheap productionReduce impactOperating means/releasing devices for valvesCheck valvesEngineering

A spring retaining sleeve includes a cylinder press-fit connection surface which has a press-fit diameter and a press-fit length. To enable cost-effective production of a stable press-fit assembly, at least one end of the cylinder press-fit connection surface, an optimized insertion chamfer for long press-fit assemblies is provided with a ratio of press-fit diameter to press-fit length of greater than thirty five percent.

Owner:ROBERT BOSCH GMBH

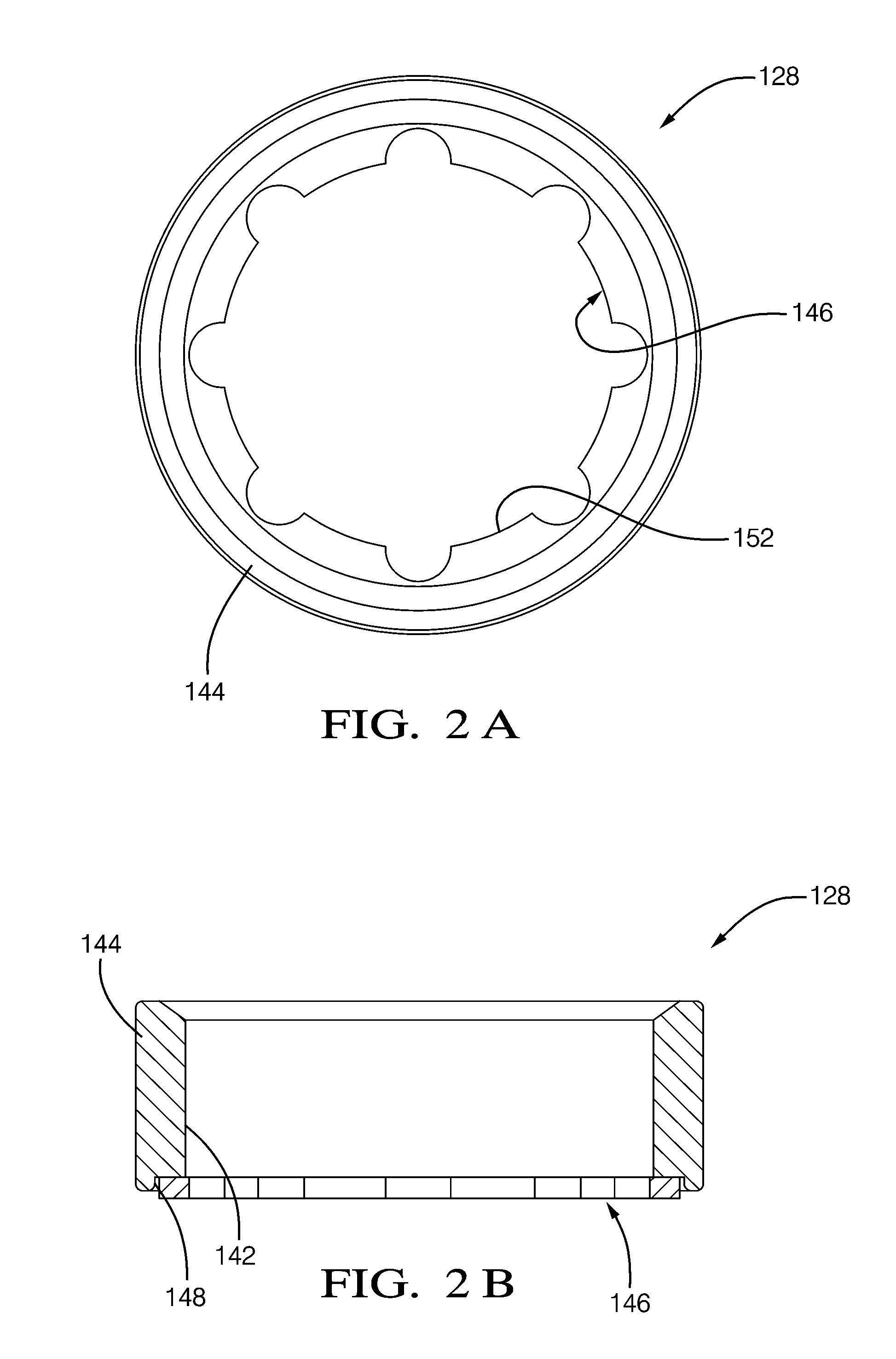

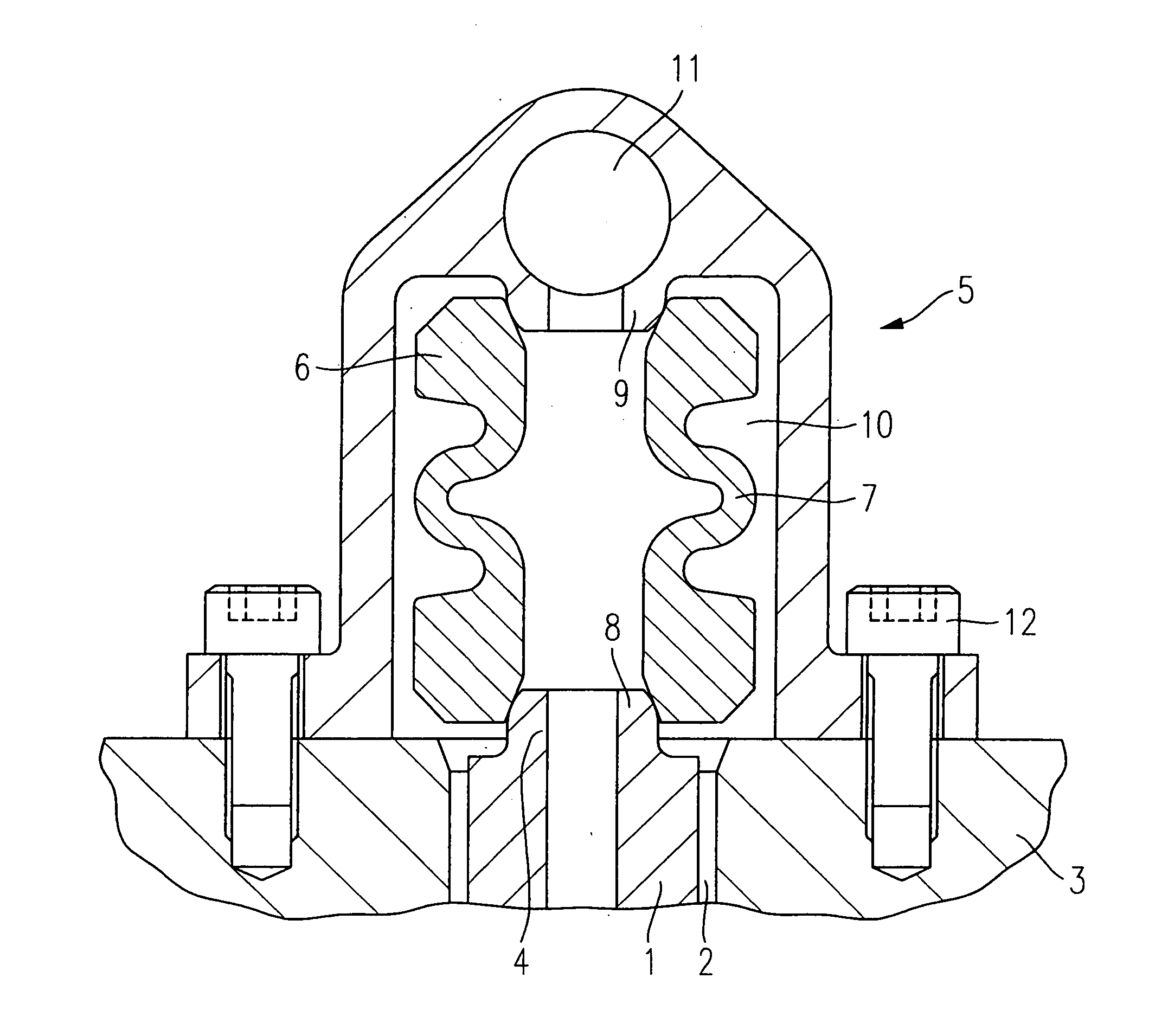

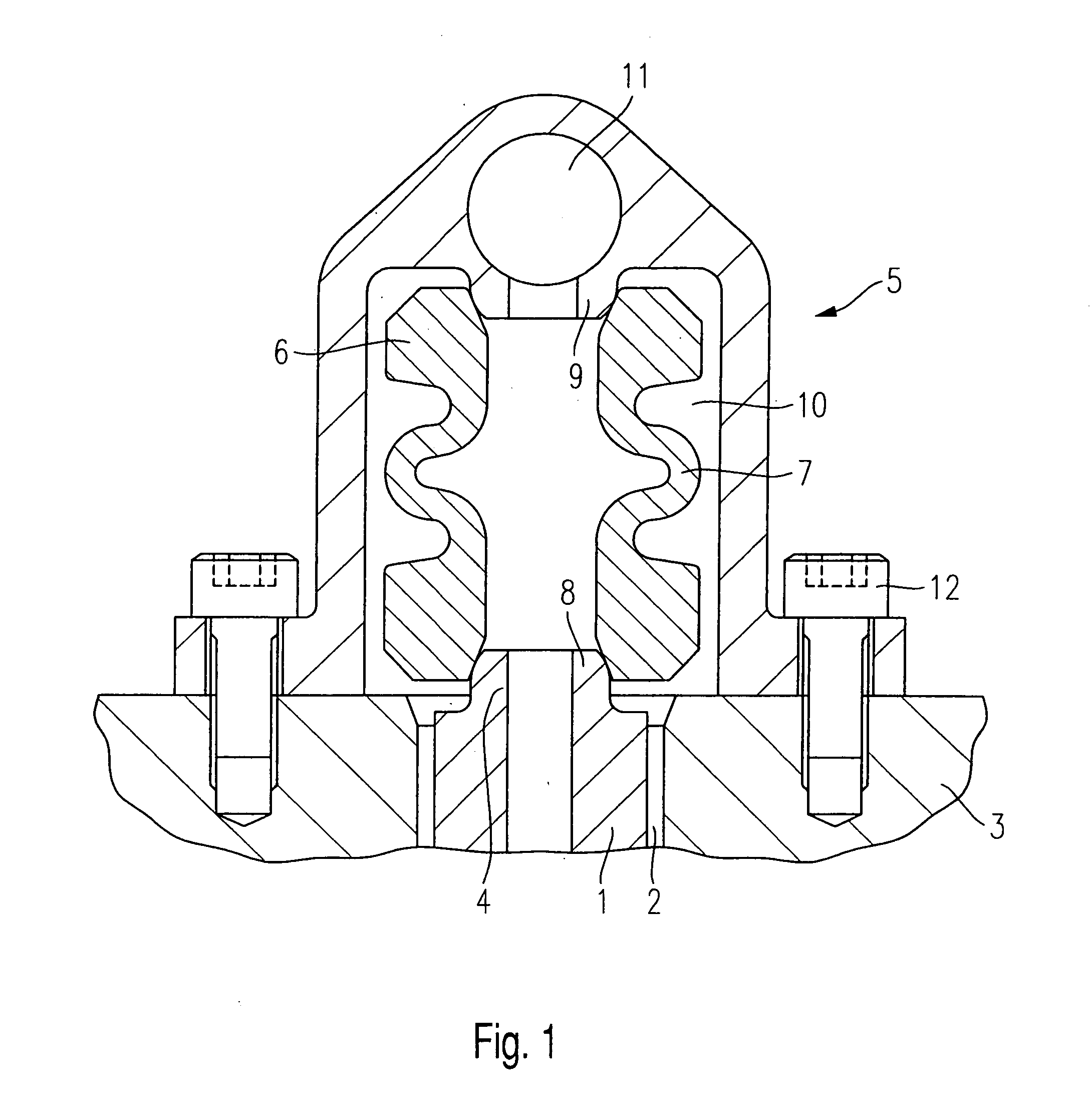

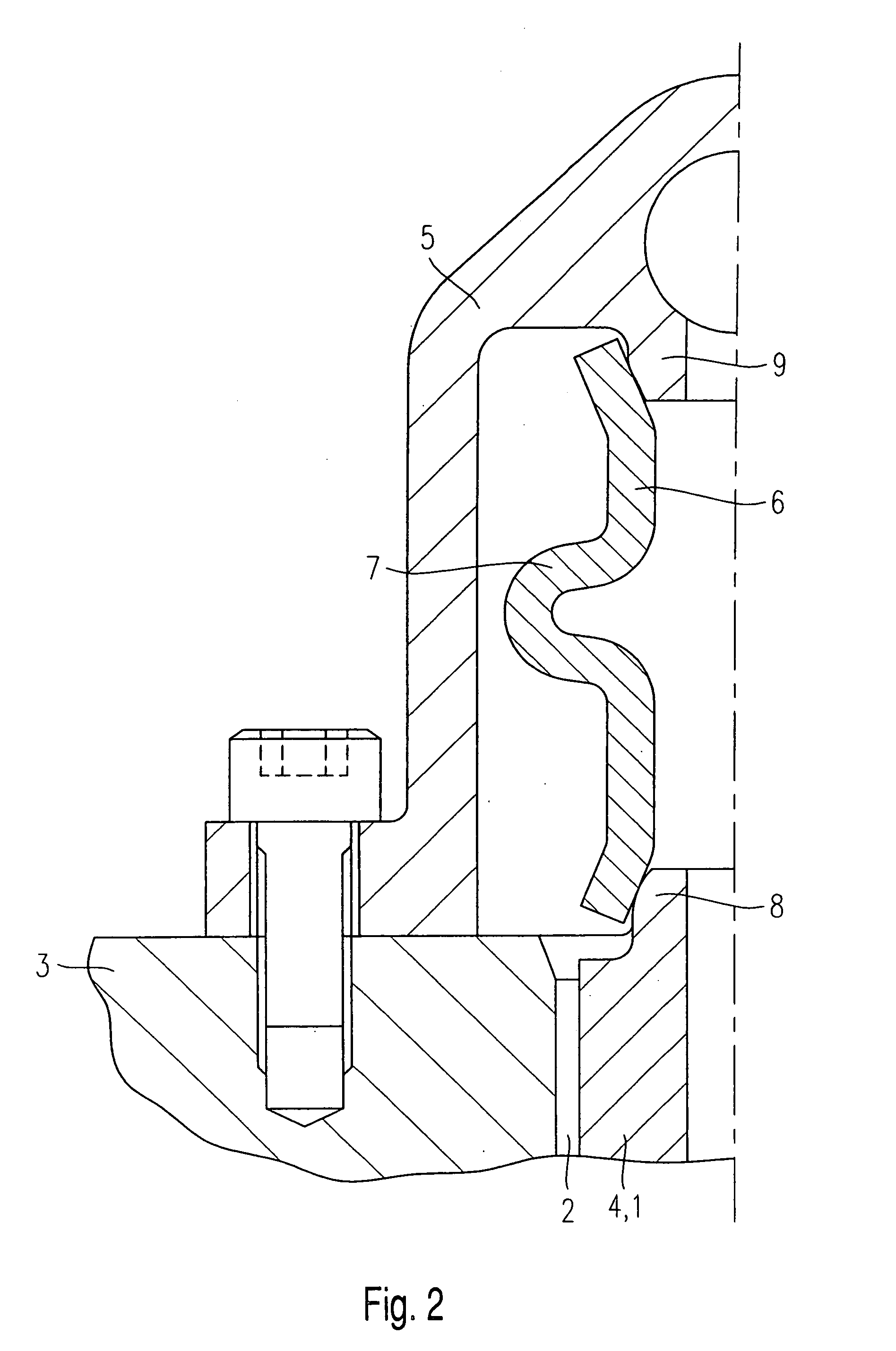

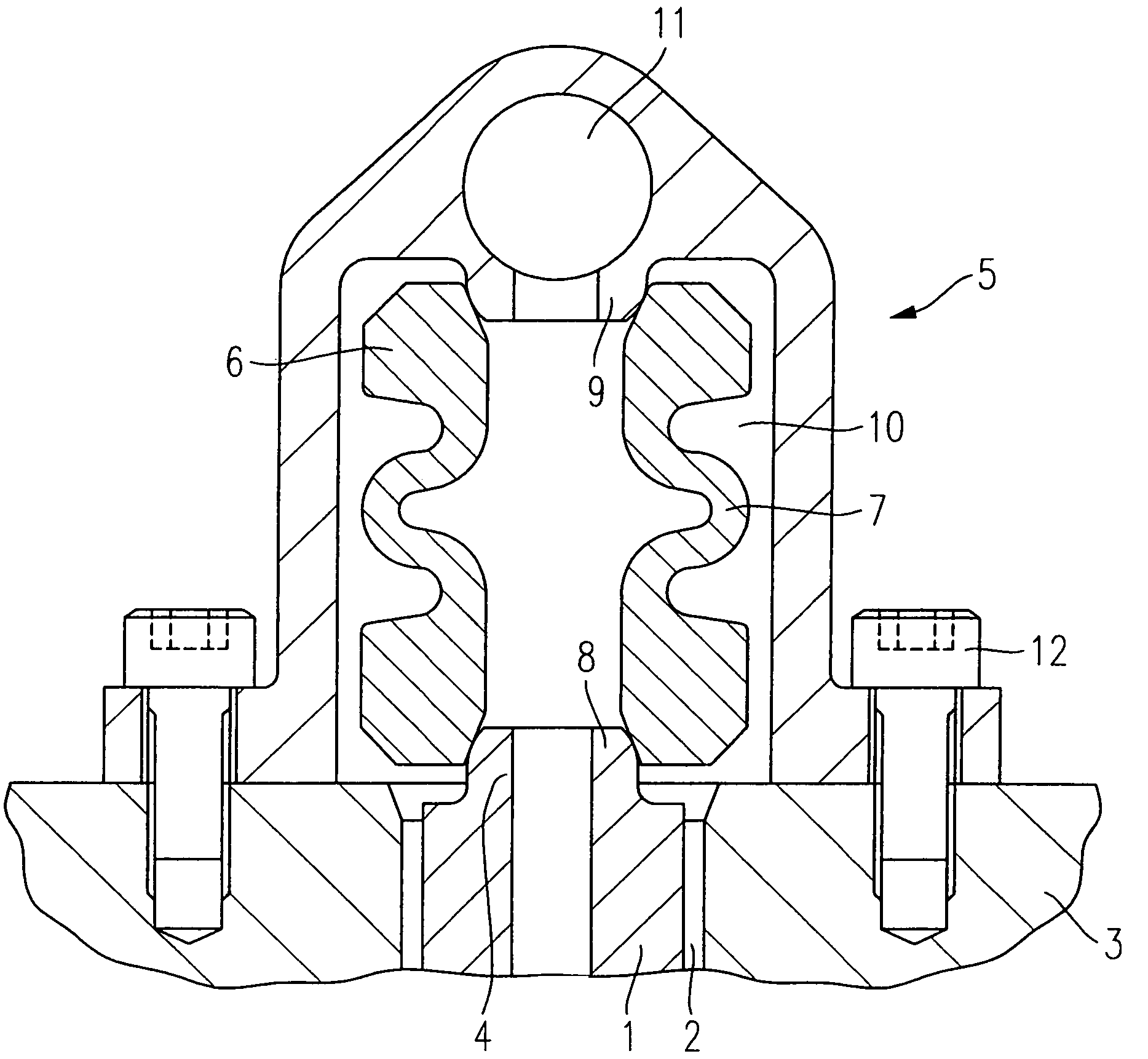

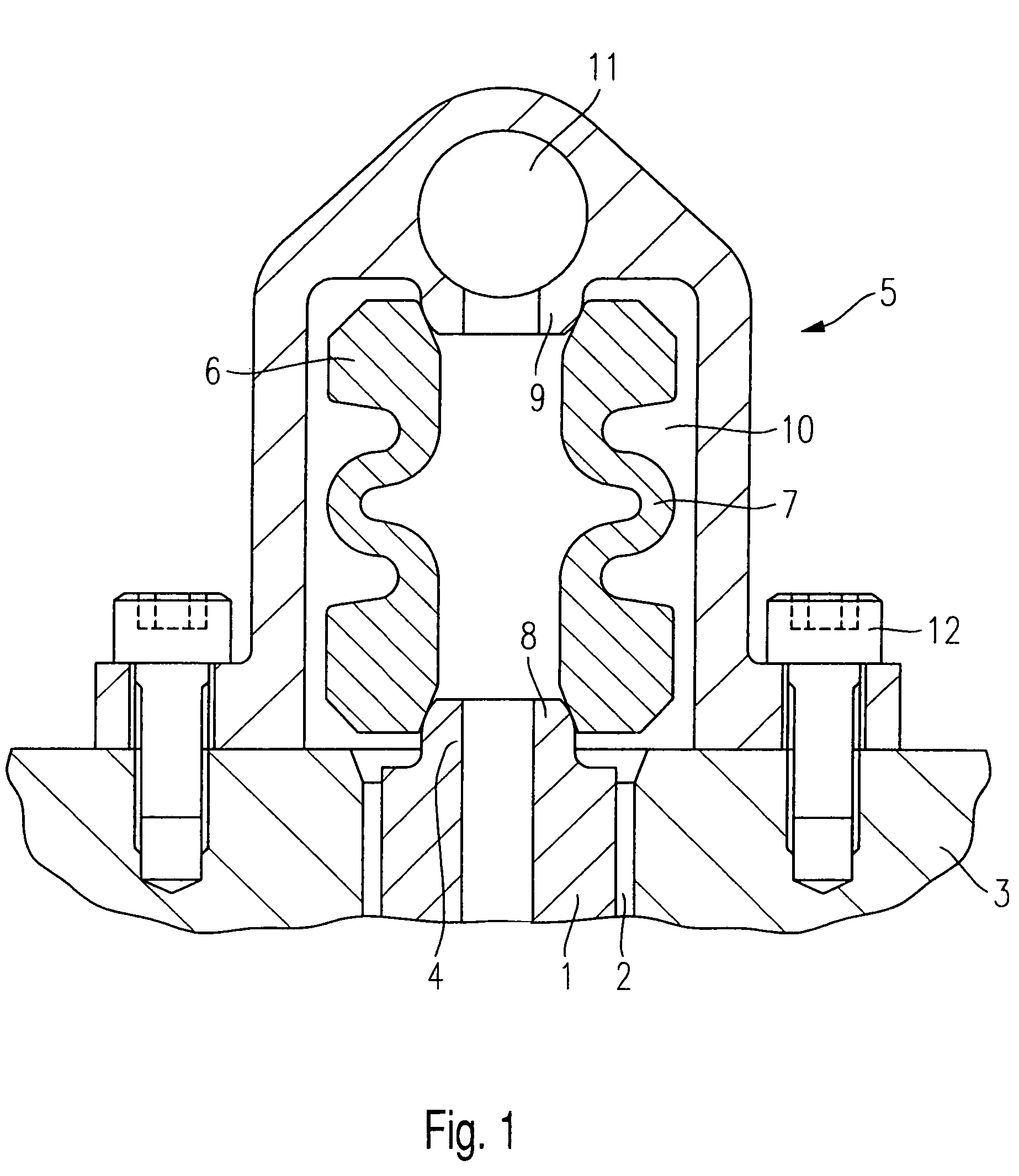

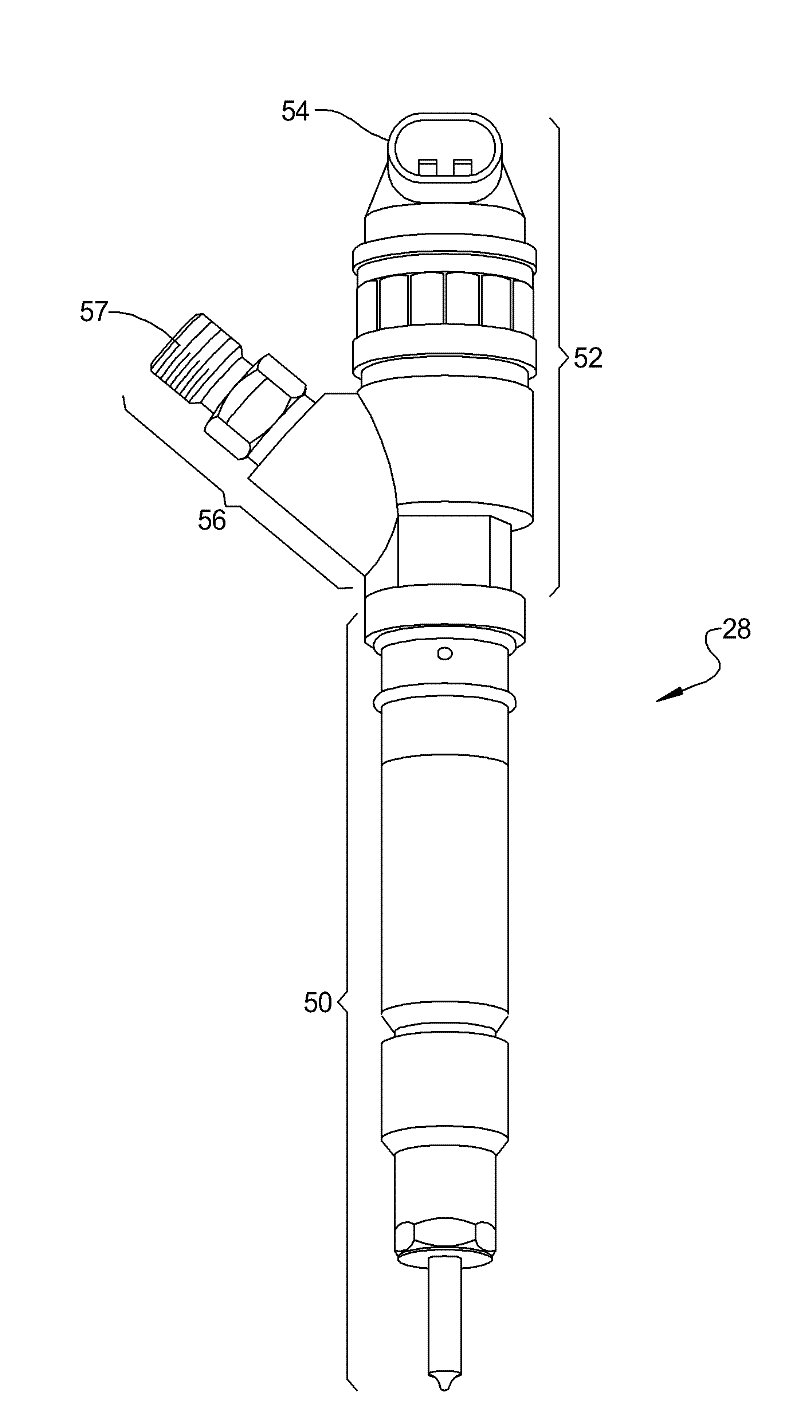

Isolater for fuel injector

InactiveUS20110265767A1Sufficient compressibilitySufficient resilienceNoise reducing fuel injectionMachines/enginesThermal isolationInjector

A fuel injector-engine component assembly includes an engine component with a stepped bore defined along an axis and having a stepped bore stop surface facing axially upward. A fuel injector extending along the axis is disposed in the stepped bore and includes a fuel injector stop surface facing axially downward and axially opposing the stepped bore stop surface. An isolation ring is disposed between the engine component and fuel injector stop surfaces for axially isolating the fuel injector from the engine component. The isolation ring includes a rigid support member for limiting the axial motion of the engine component and fuel injector stop surfaces together. The isolation ring also includes a resilient and compliant isolation member located axially between the engine component and fuel injector stop surfaces to provide acoustic and thermal isolation between the fuel injector and the engine component below a predetermined pressure of the fuel injector.

Owner:DELPHI TECH INC

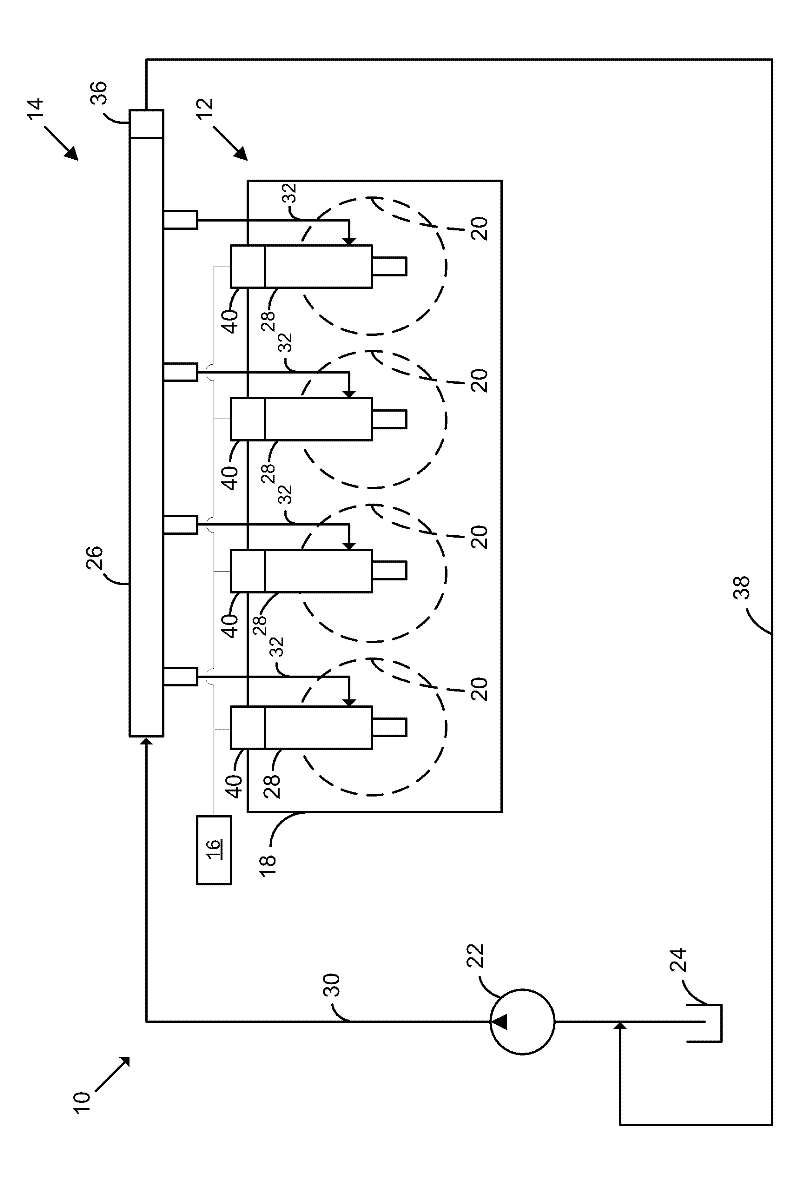

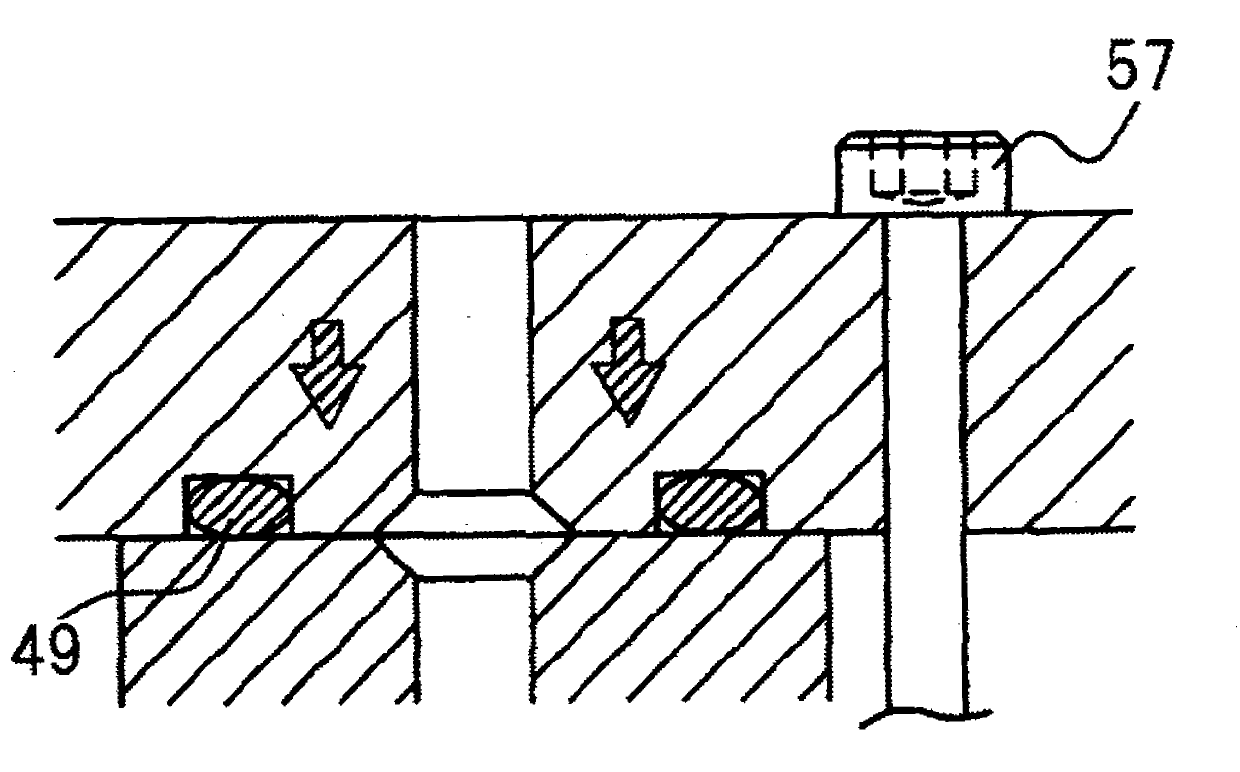

Fuel injection system

InactiveUS20060021601A1Simple wayEasy to assembleWear reducing fuel injectionLow pressure fuel injectionCombustion chamberCylinder head

A fuel injection system, in particular for direct injection of fuel into the combustion chamber of an internal combustion engine has a plurality of fuel injectors, whose injection ends, at least, are situated in receptacle bore holes of a cylinder head. The inlet side of the fuel injectors has a connecting piece, which engages with a supply line segment. Pressurized fuel is supplied to the fuel injector via the supply line segment. The connecting piece is sealed off from the supply line segment by a gasket. The gasket has a sleeve-shaped design and has a plastically deformable shaped area, which is plastically deformed during the assembly of the supply line segment with the connecting piece, and has elastic properties while in operation.

Owner:ROBERT BOSCH GMBH

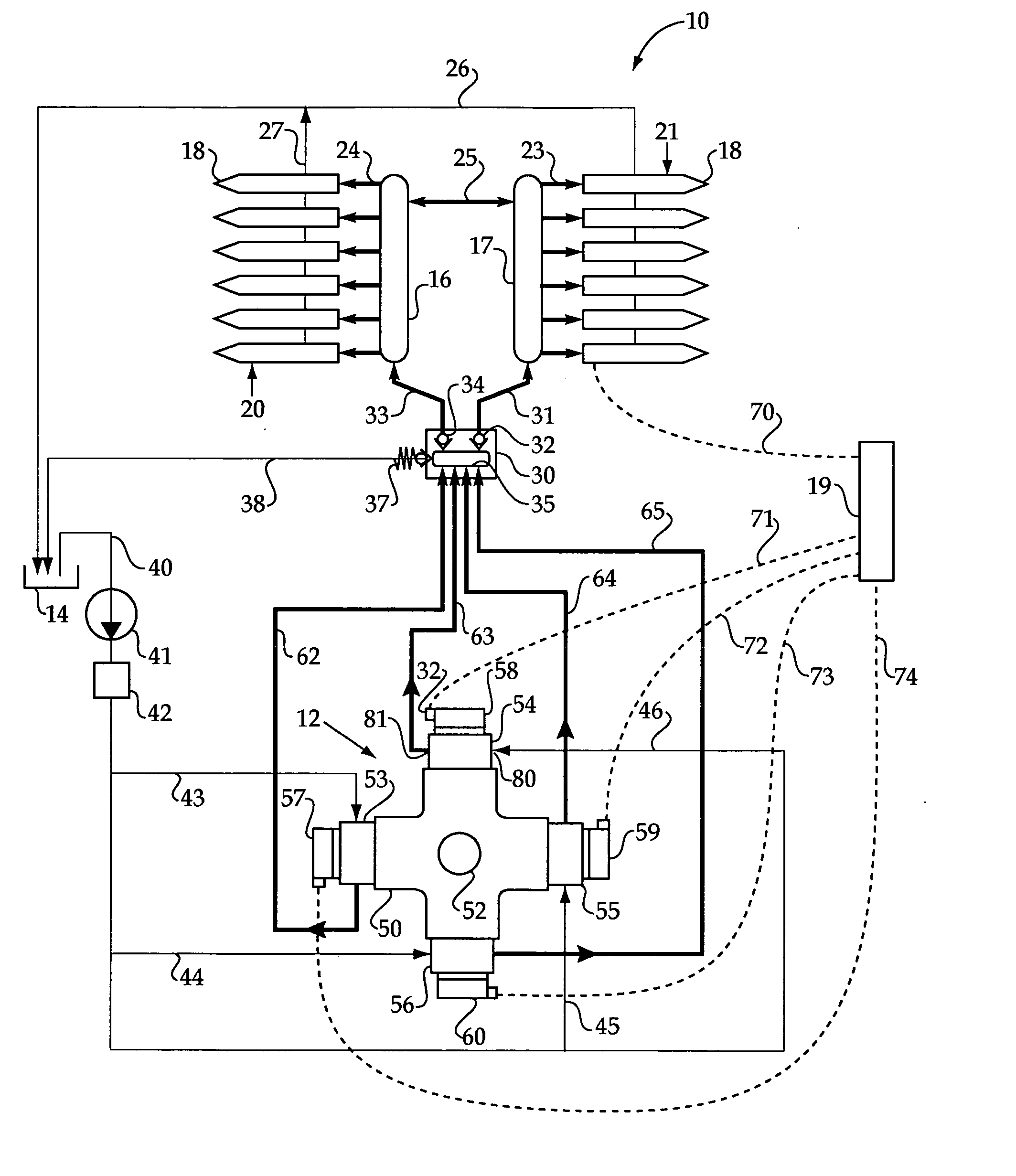

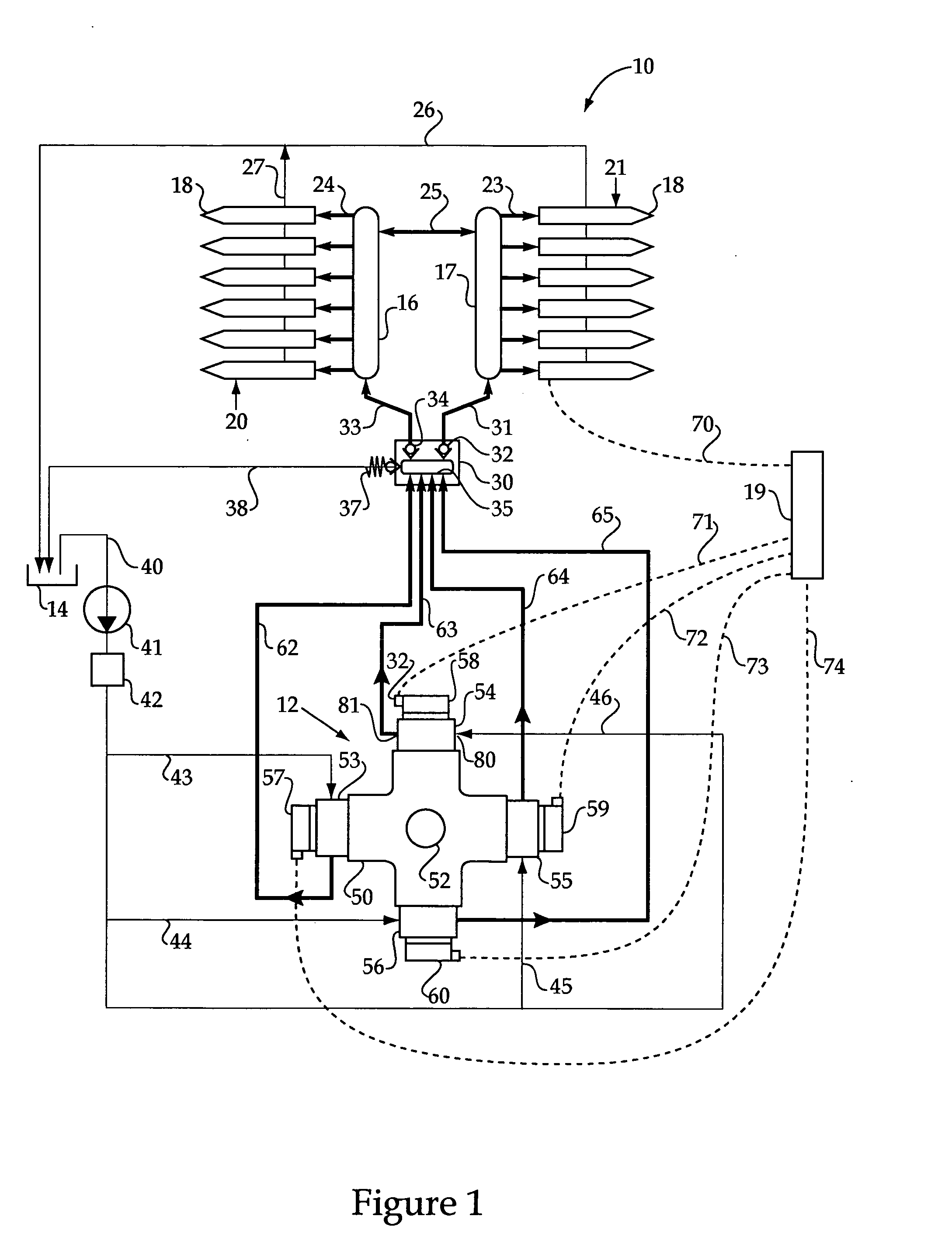

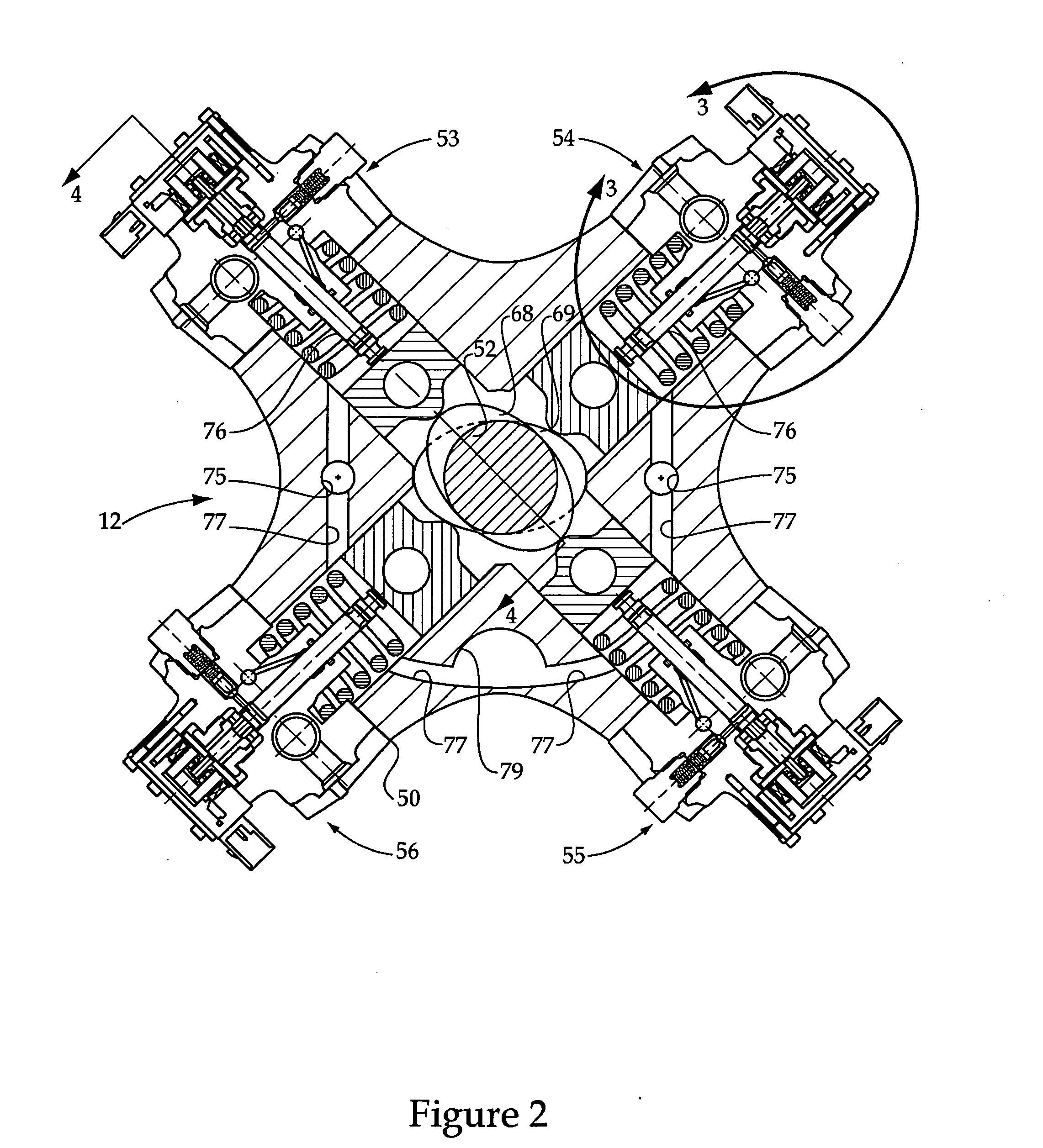

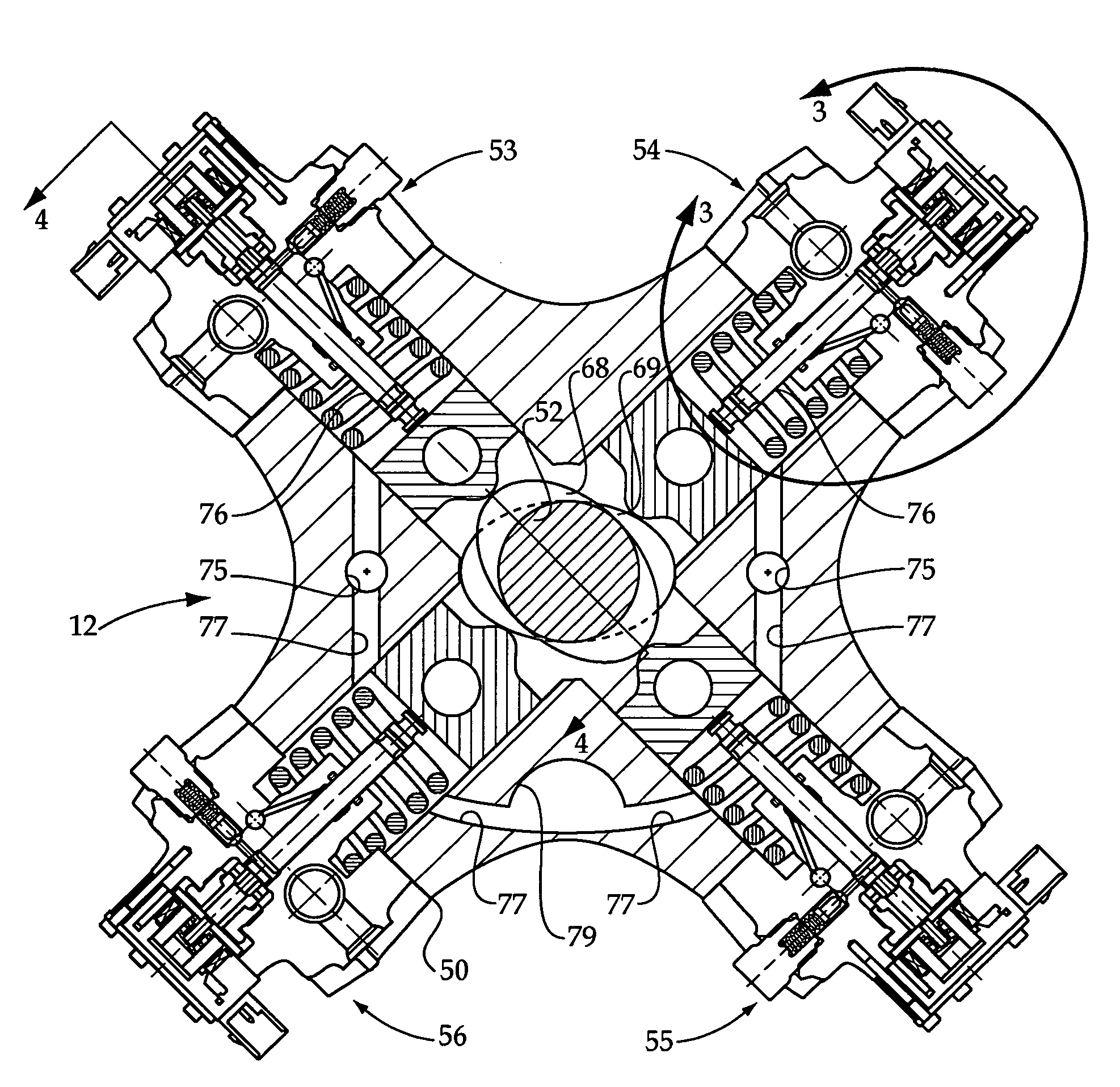

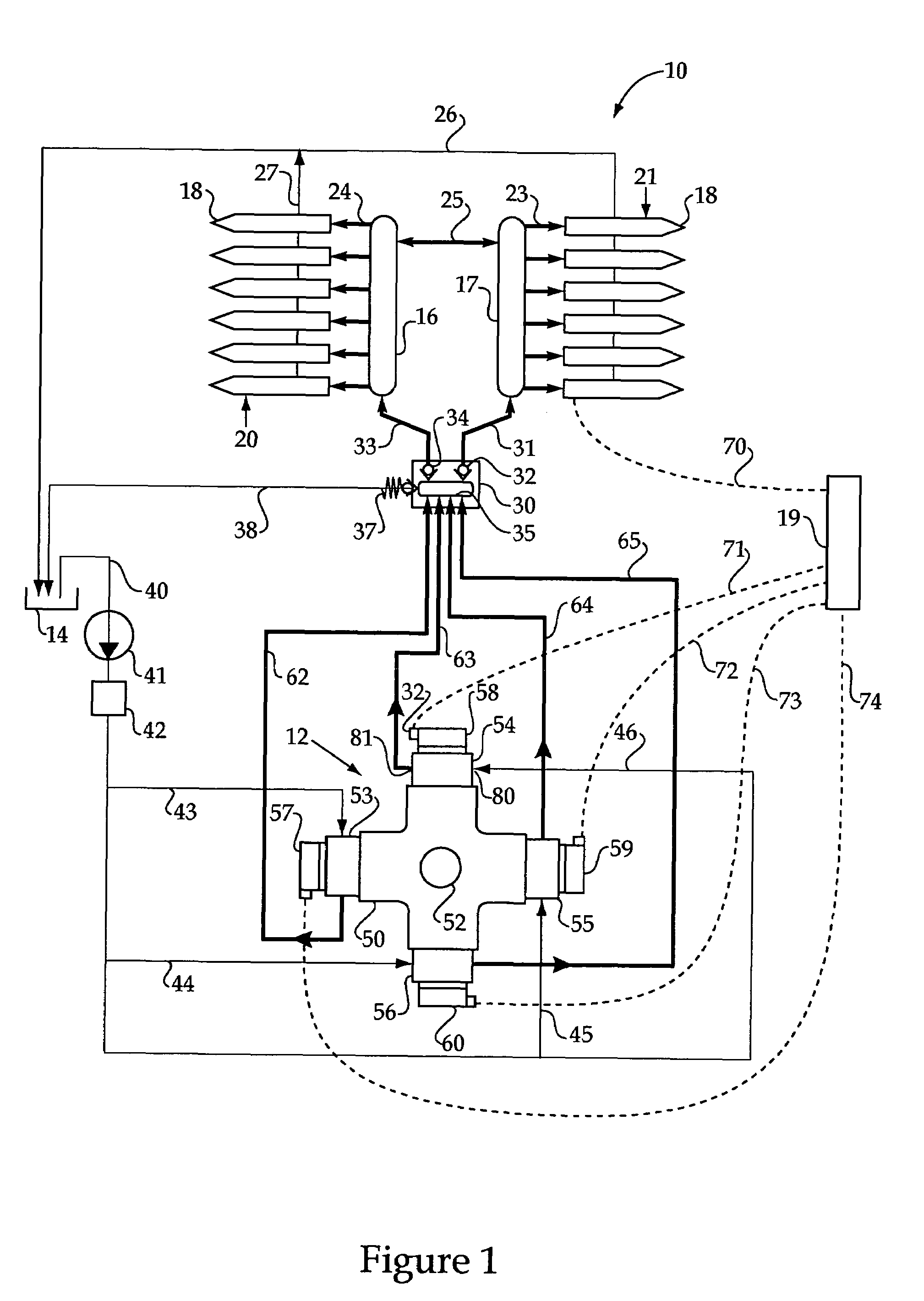

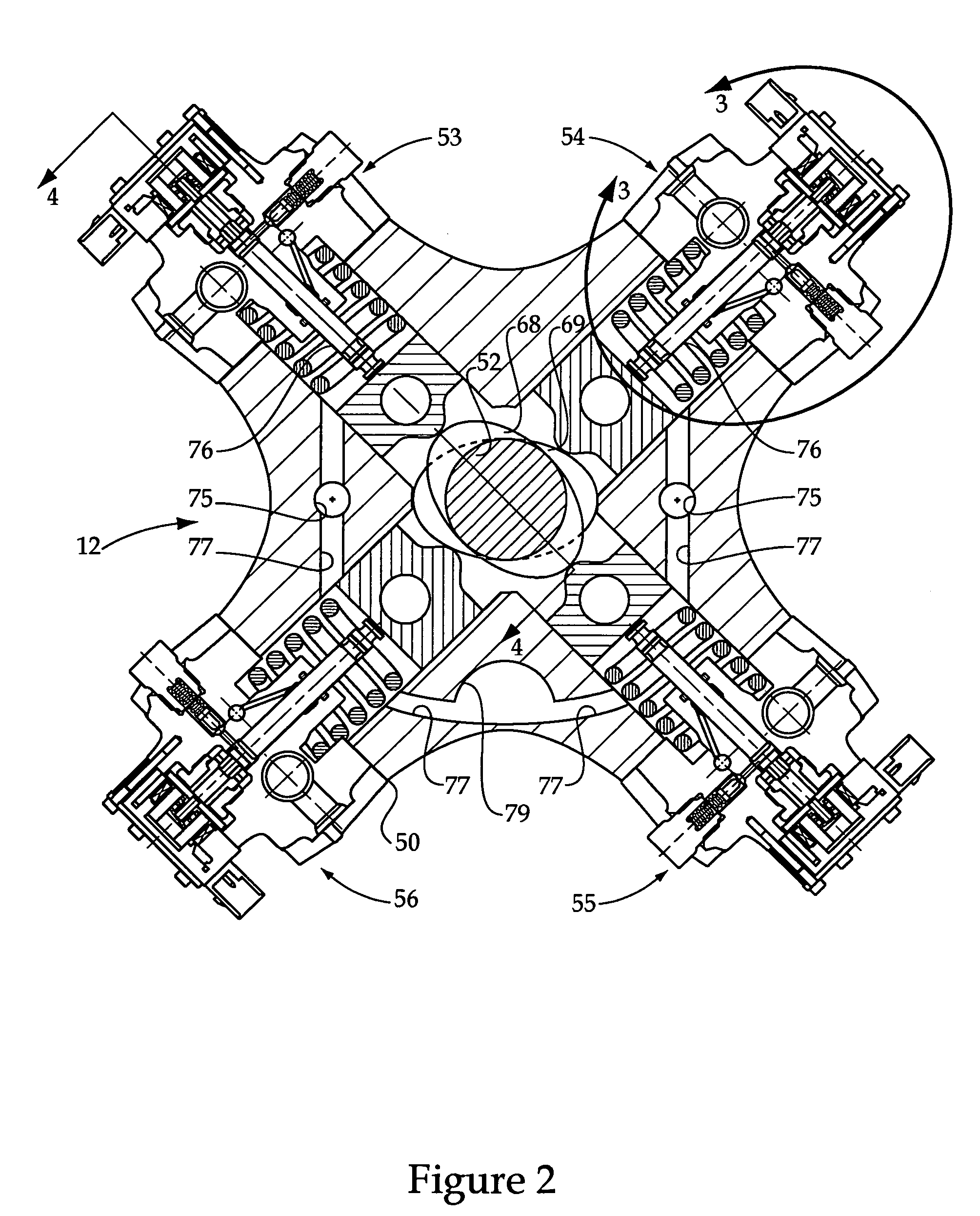

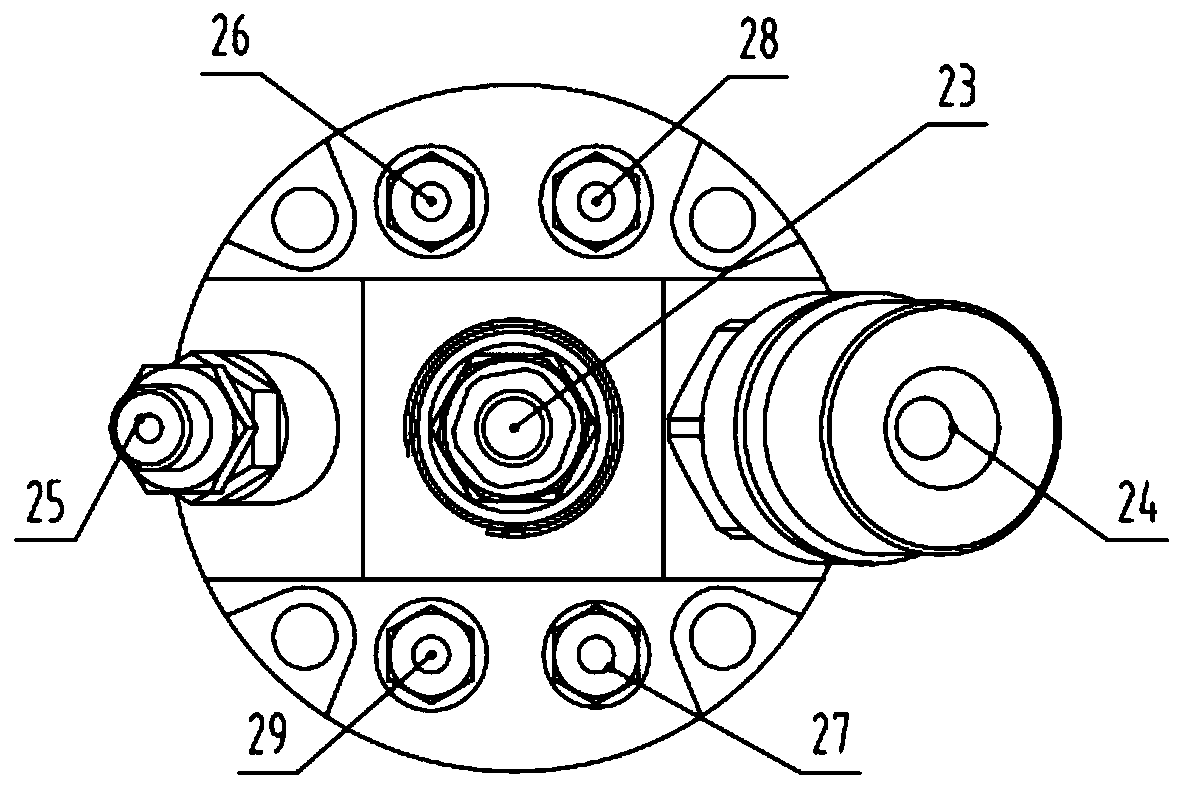

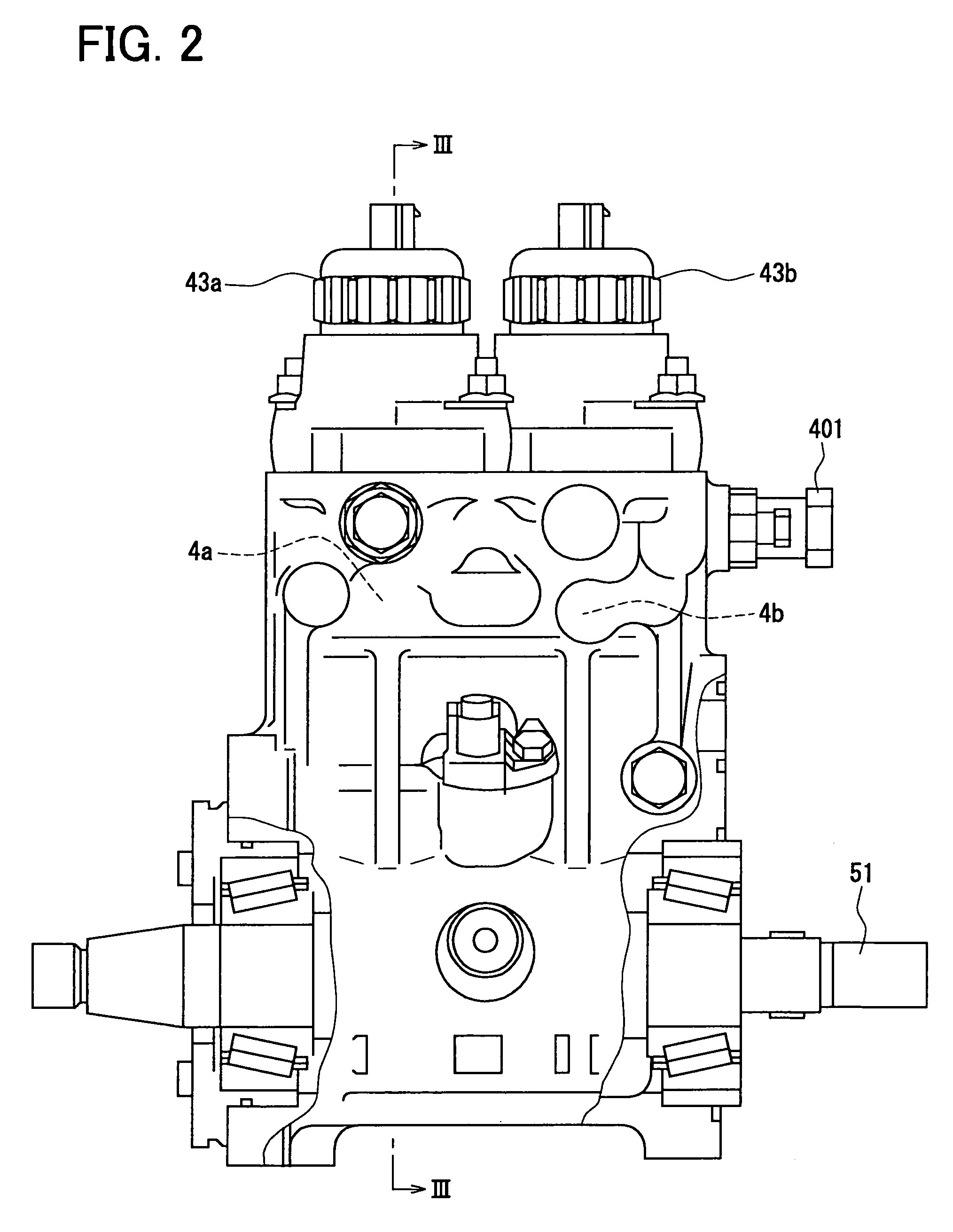

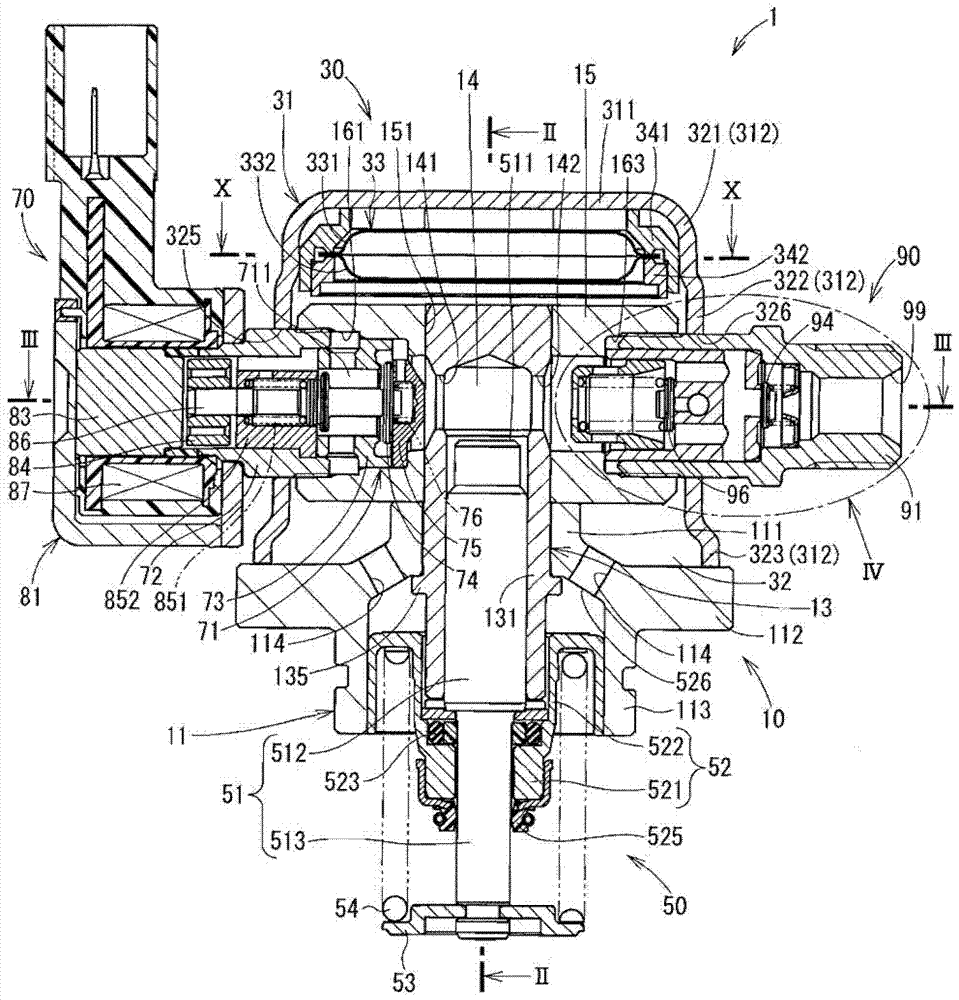

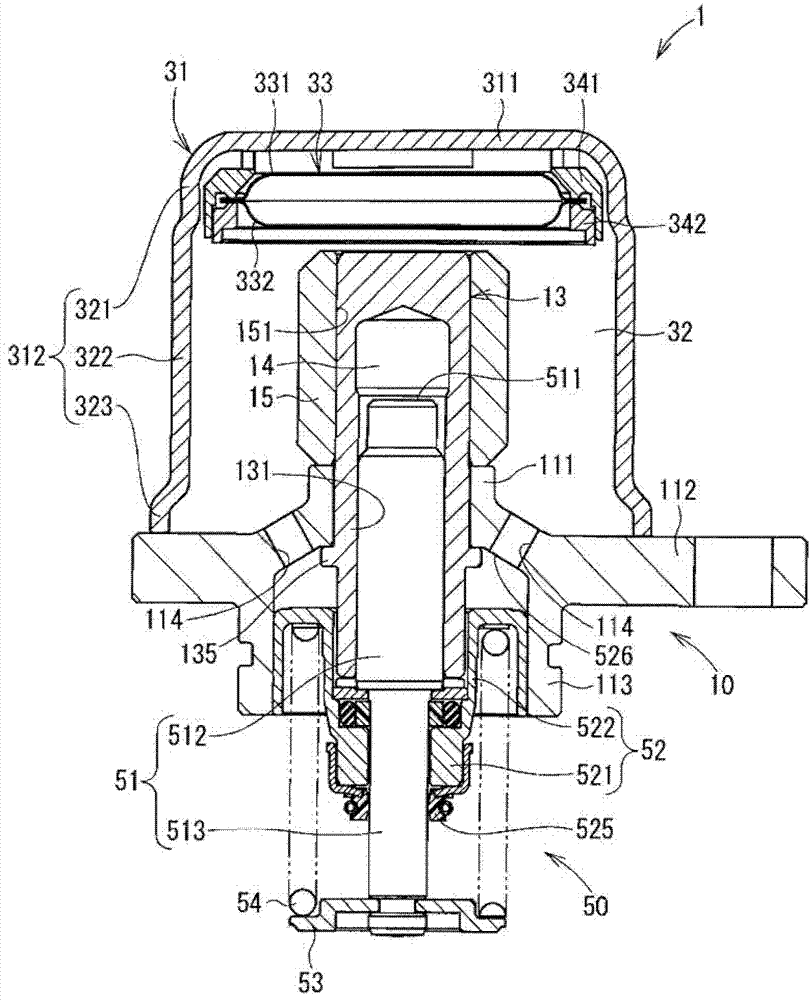

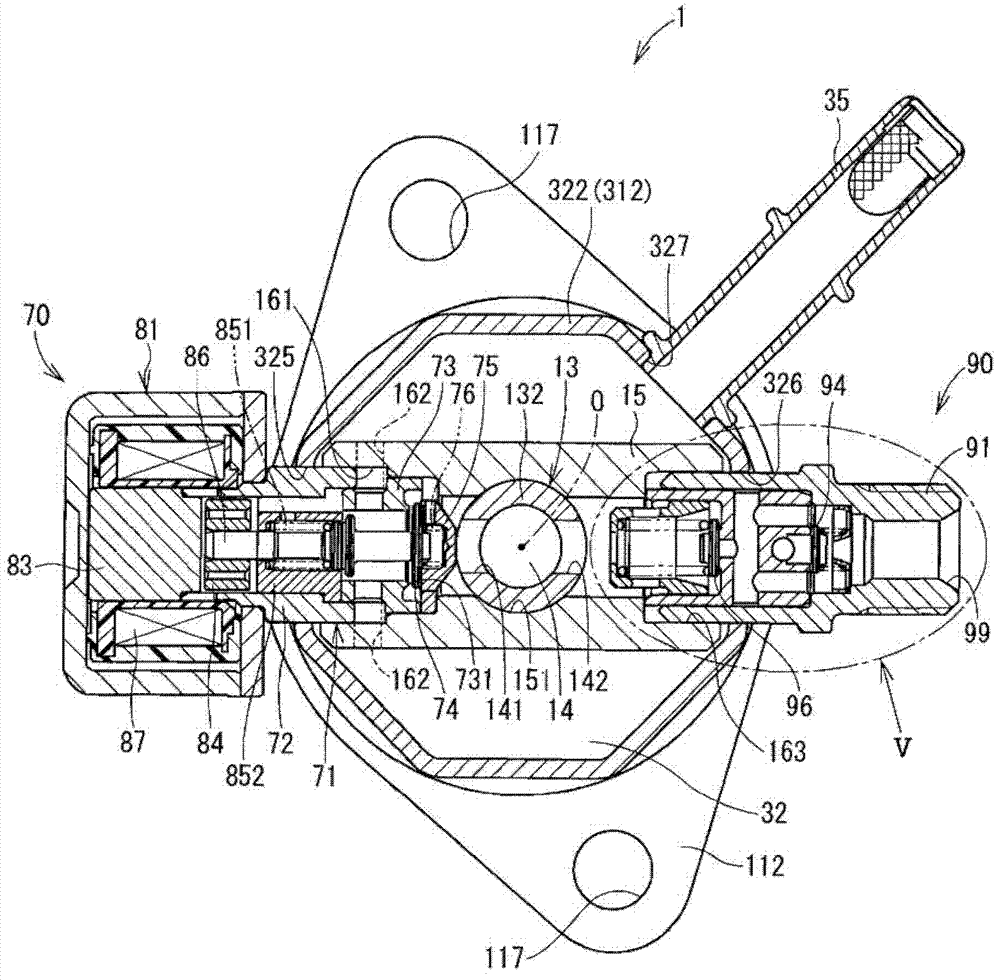

Opposed pumping load high pressure common rail fuel pump

A high volume high pressure common rail pump for a fuel system includes pairs of pump head assemblies in phase with each other but oriented in opposition to one another about a rotating cam shaft. Pump pistons in the pump head assemblies simultaneously undergo pumping strokes via a shared two lobe cam of the rotating cam shaft. The pump may include two pairs of pump head assemblies, and each head assembly may include two pump pistons. The cam shaft includes two cams sufficiently out of phase with one another that the cam shaft always has a positive torque even when the cam lobes are symmetrical. In addition, because the pumping is done simultaneously on opposite sides of the cam shaft, the forces on the cam shaft are balanced and its support bearings experience less wear and tear.

Owner:CATERPILLAR INC

Fuel injection system

InactiveUS7188611B2Easy to assembleElastic spring constantWear reducing fuel injectionLow pressure fuel injectionCombustion chamberCylinder head

Owner:ROBERT BOSCH GMBH

Opposed pumping load high pressure common rail fuel pump

A high volume high pressure common rail pump for a fuel system includes pairs of pump head assemblies in phase with each other but oriented in opposition to one another about a rotating cam shaft. Pump pistons in the pump head assemblies simultaneously undergo pumping strokes via a shared two lobe cam of the rotating cam shaft. The pump may include two pairs of pump head assemblies, and each head assembly may include two pump pistons. The cam shaft includes two cams sufficiently out of phase with one another that the cam shaft always has a positive torque even when the cam lobes are symmetrical. In addition, because the pumping is done simultaneously on opposite sides of the cam shaft, the forces on the cam shaft are balanced and its support bearings experience less wear and tear.

Owner:CATERPILLAR INC

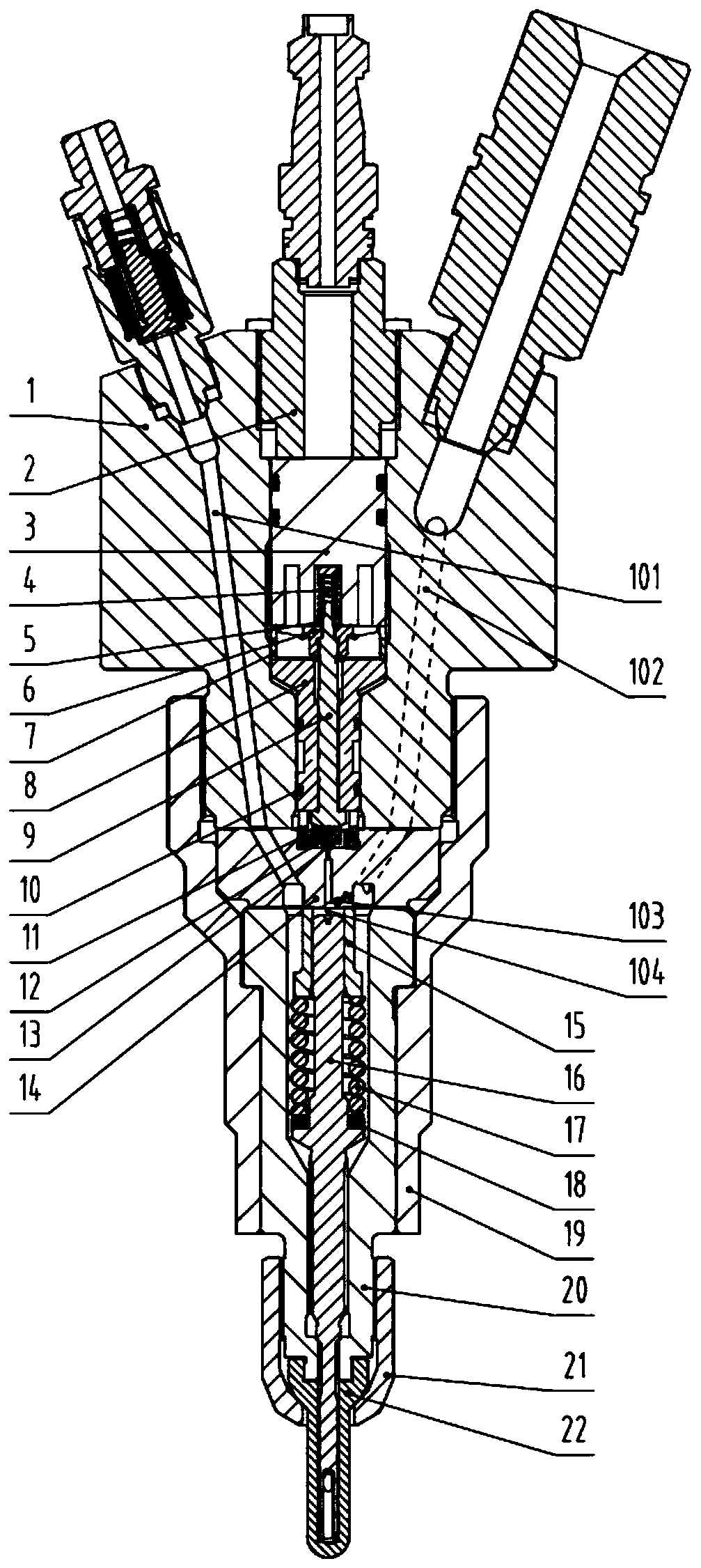

Electronically-controlled common rail heavy oil injector

ActiveCN110594061AChange the work schedule at any timeSave spaceCorrosion preventing fuel injectionMachines/enginesVena contracta diameterCommon rail

The invention relates to an electronically-controlled common rail heavy oil injector which comprises an injector body, an electro-hydraulic control member and a nozzle member. In the electro-hydrauliccontrol member, a ring groove is formed in the middle of the outer side of a guide sleeve, a transverse through hole is formed in the middle of the groove to directly communicate with a middle hole of the guide sleeve, the two sides of the ring groove are provided with seal rings, and the interior of the oil injector is divided into three chambers. A control valve core guide section is provided with three ring grooves, and the second ring groove is in communication with the transverse through hole in the middle of the guide sleeve. An electromagnetic component is in contact with cooling oil,a cooling oil circuit is isolated from a fuel oil circuit by means of dynamic sealing, static sealing and drainage manners, and corroding and thermal damage of heavy oil to electronic components can be effectively prevented; and a sinking groove is formed in the middle of the top end of an orifice plate, a ball valve seat guide sleeve can be sleeved with the sinking groove of the orifice plate tobe in clearance fit with a ball valve seat, and a certain guiding ability for axial movement of the ball valve seat is achieved.

Owner:CHONGQING HONGJIANG MACHINERY

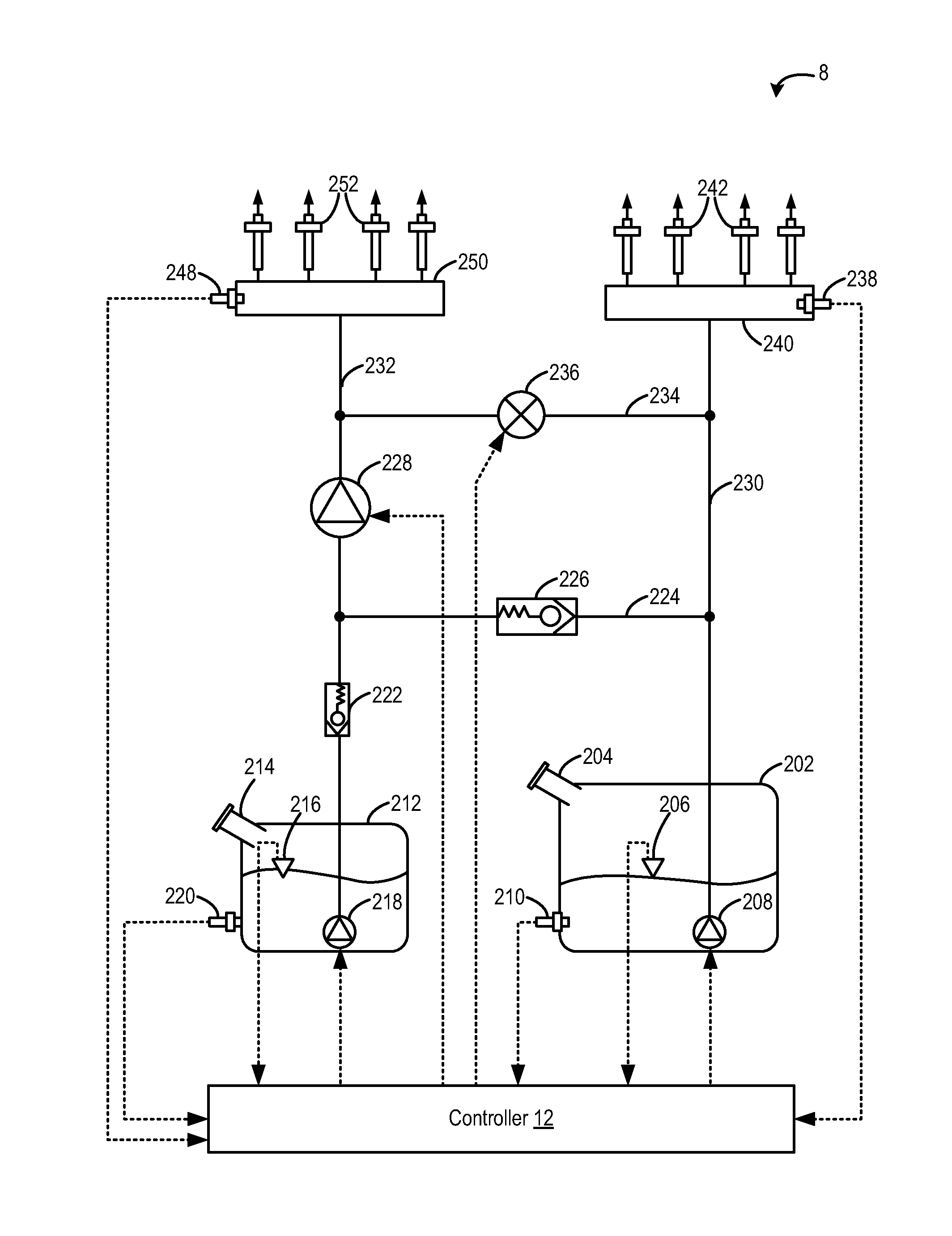

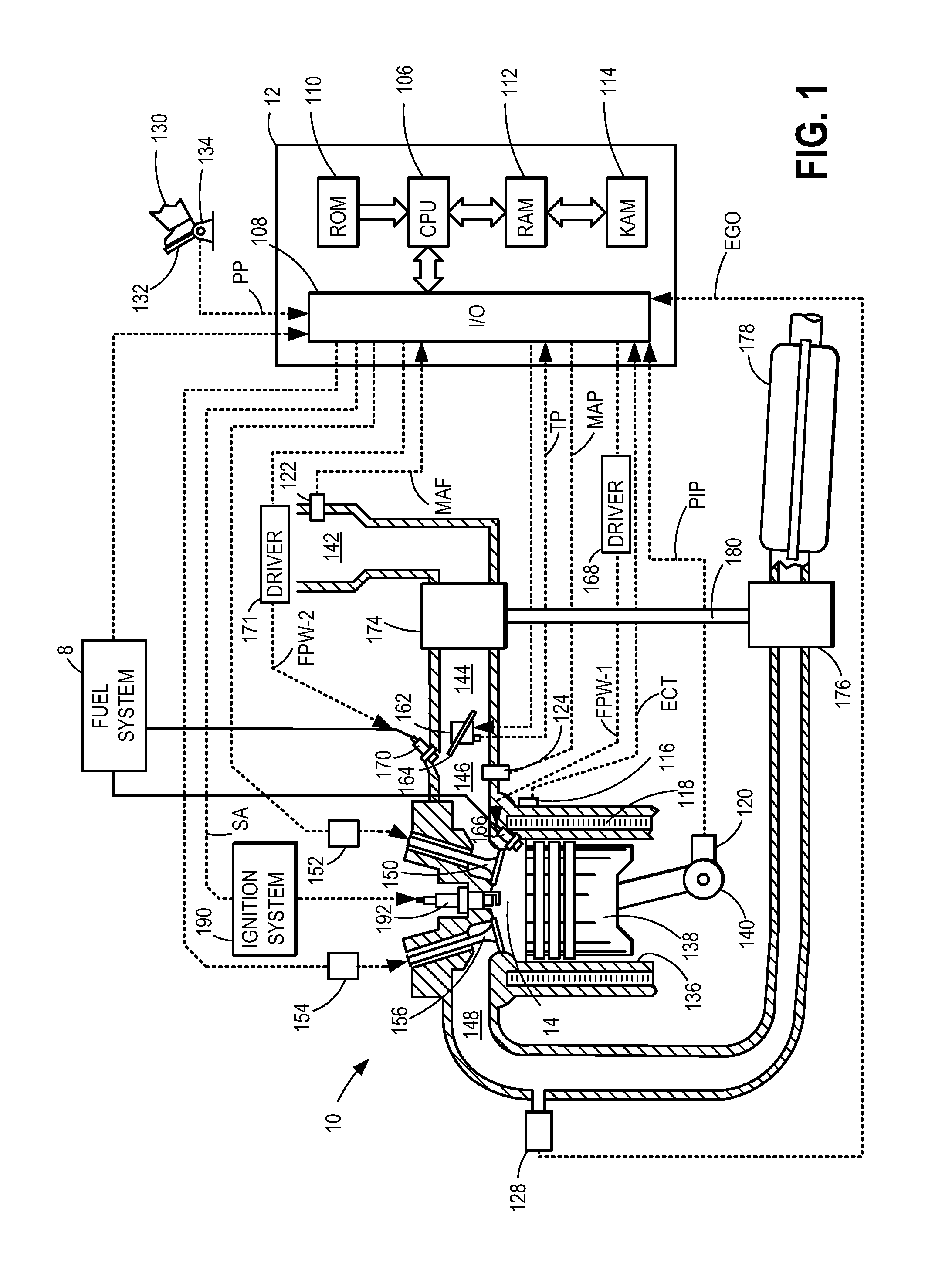

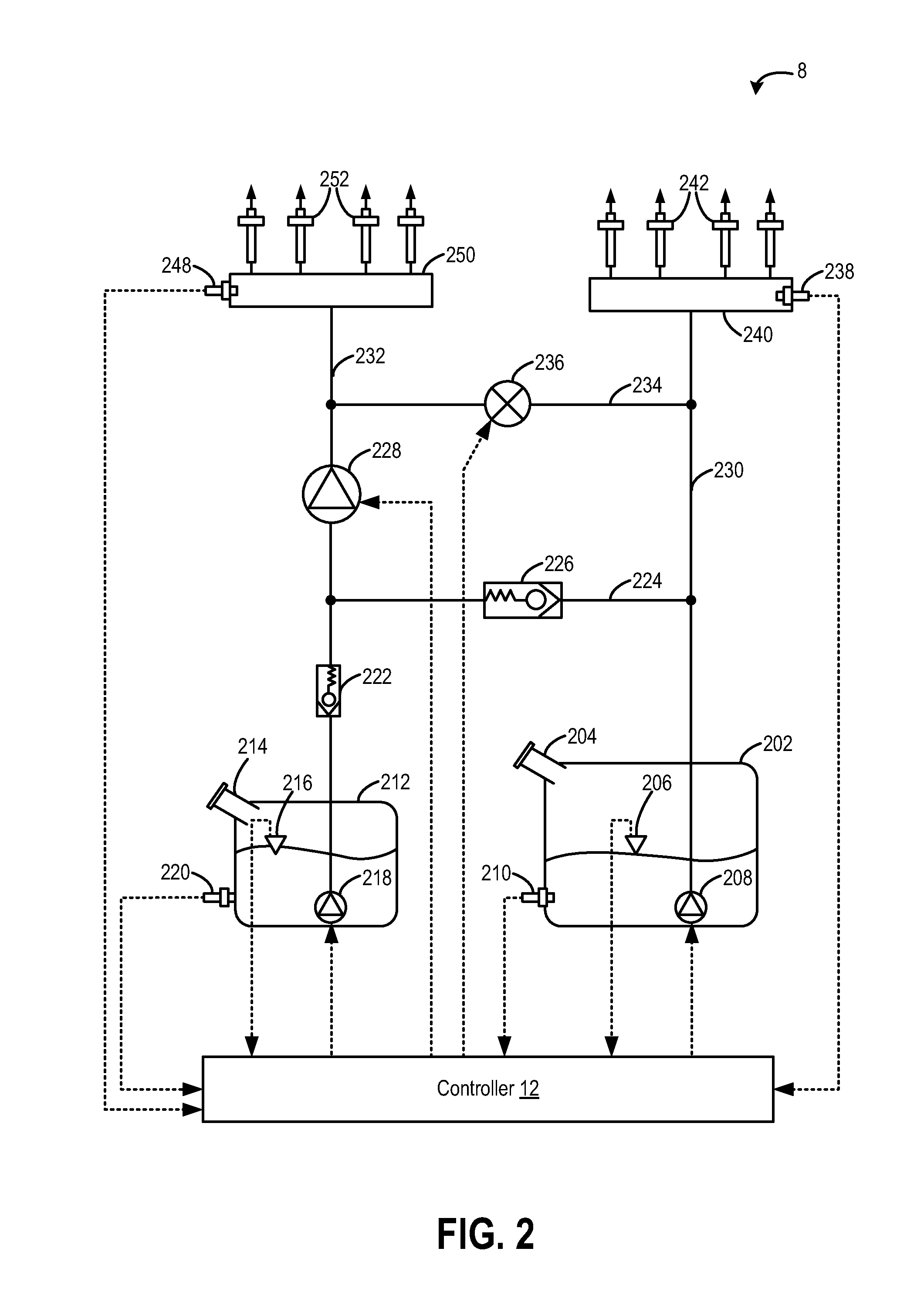

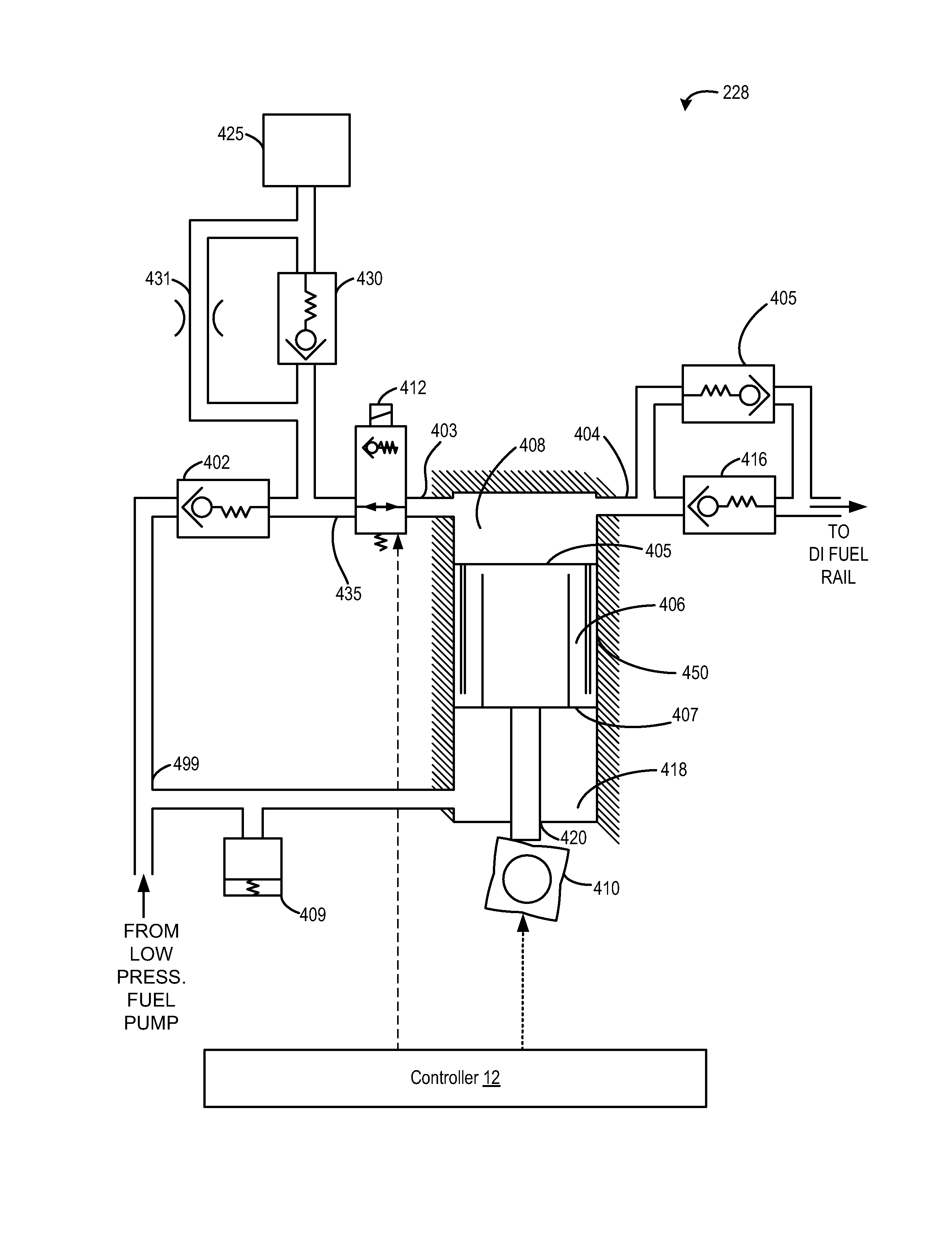

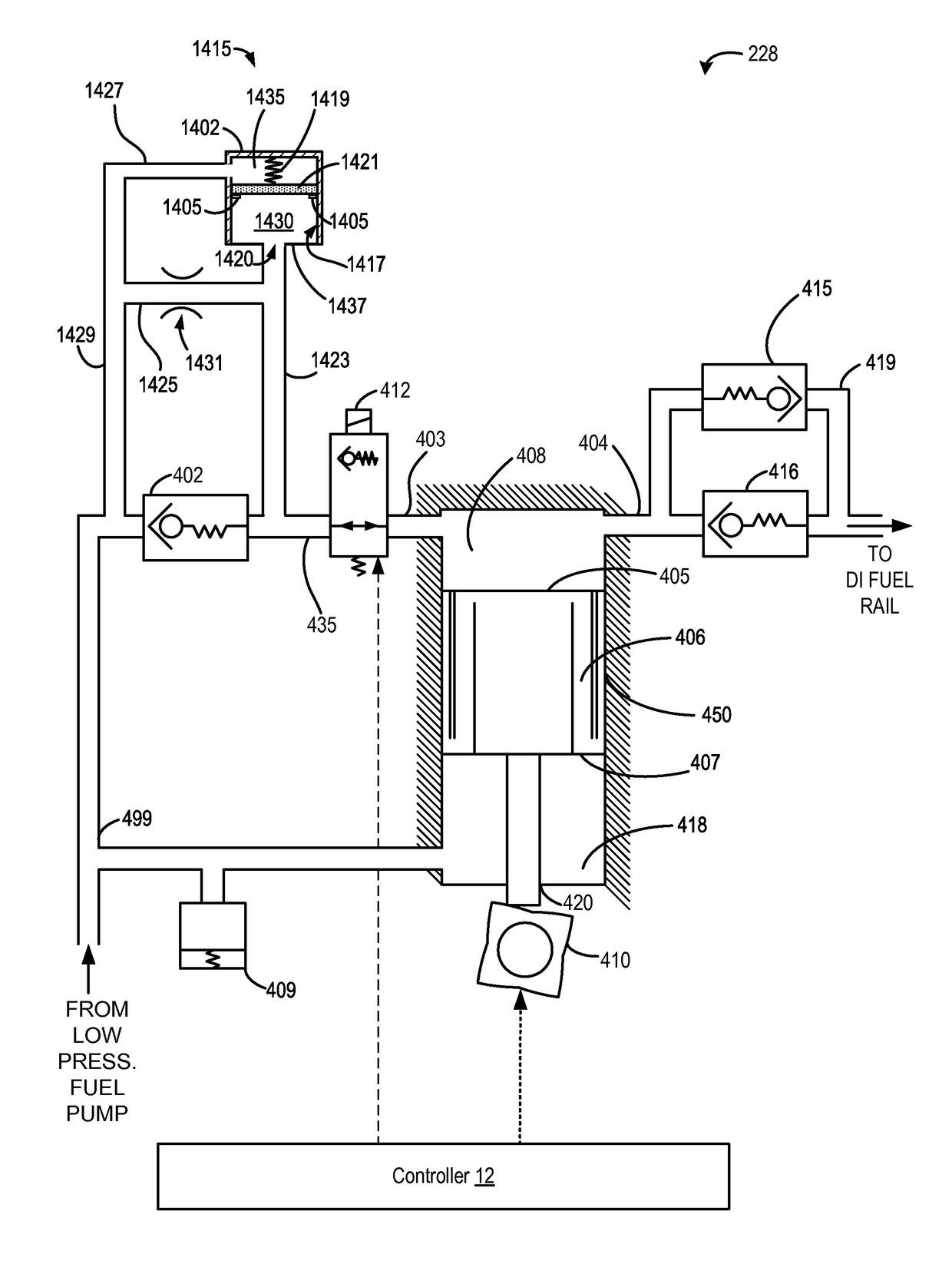

Direct injection fuel pump

ActiveUS20150075484A1Reduce lubricationIncreased power consumptionWear reducing fuel injectionNoise reducing fuel injectionLubricationFuel pump

Methods and systems are provided for a direct injection fuel pump. The methods and system control pressure within a compression chamber so as to improve fuel pump lubrication.

Owner:FORD GLOBAL TECH LLC

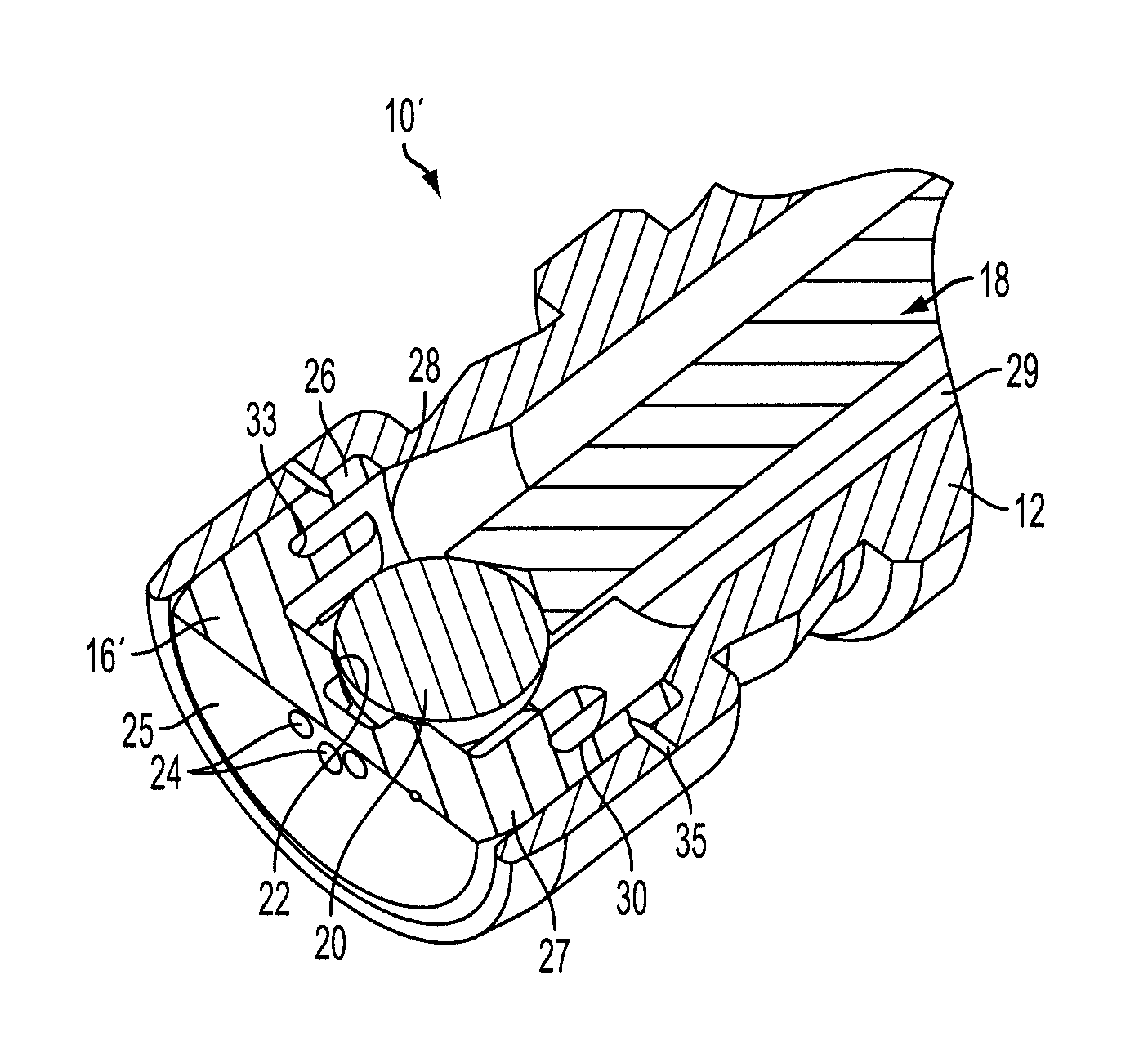

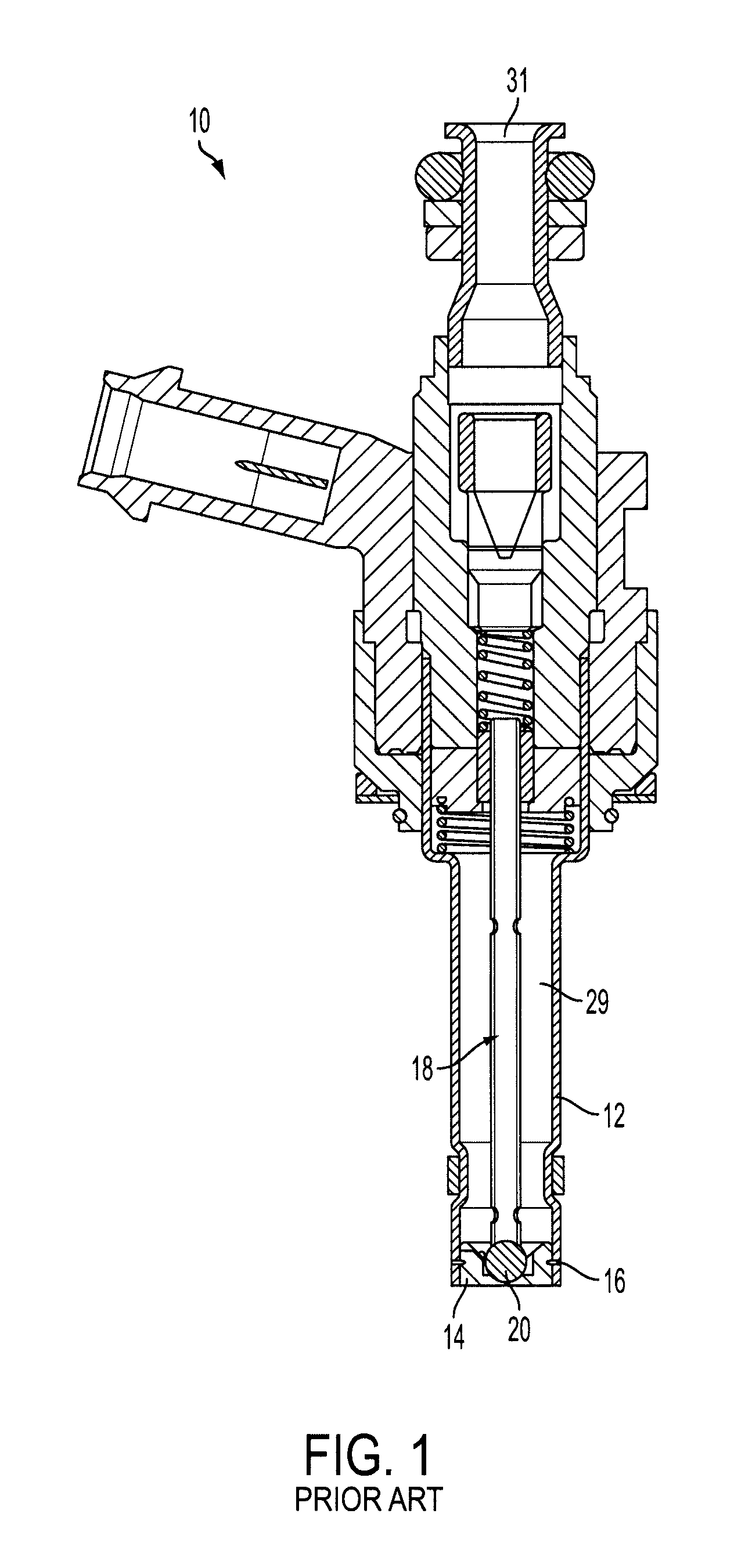

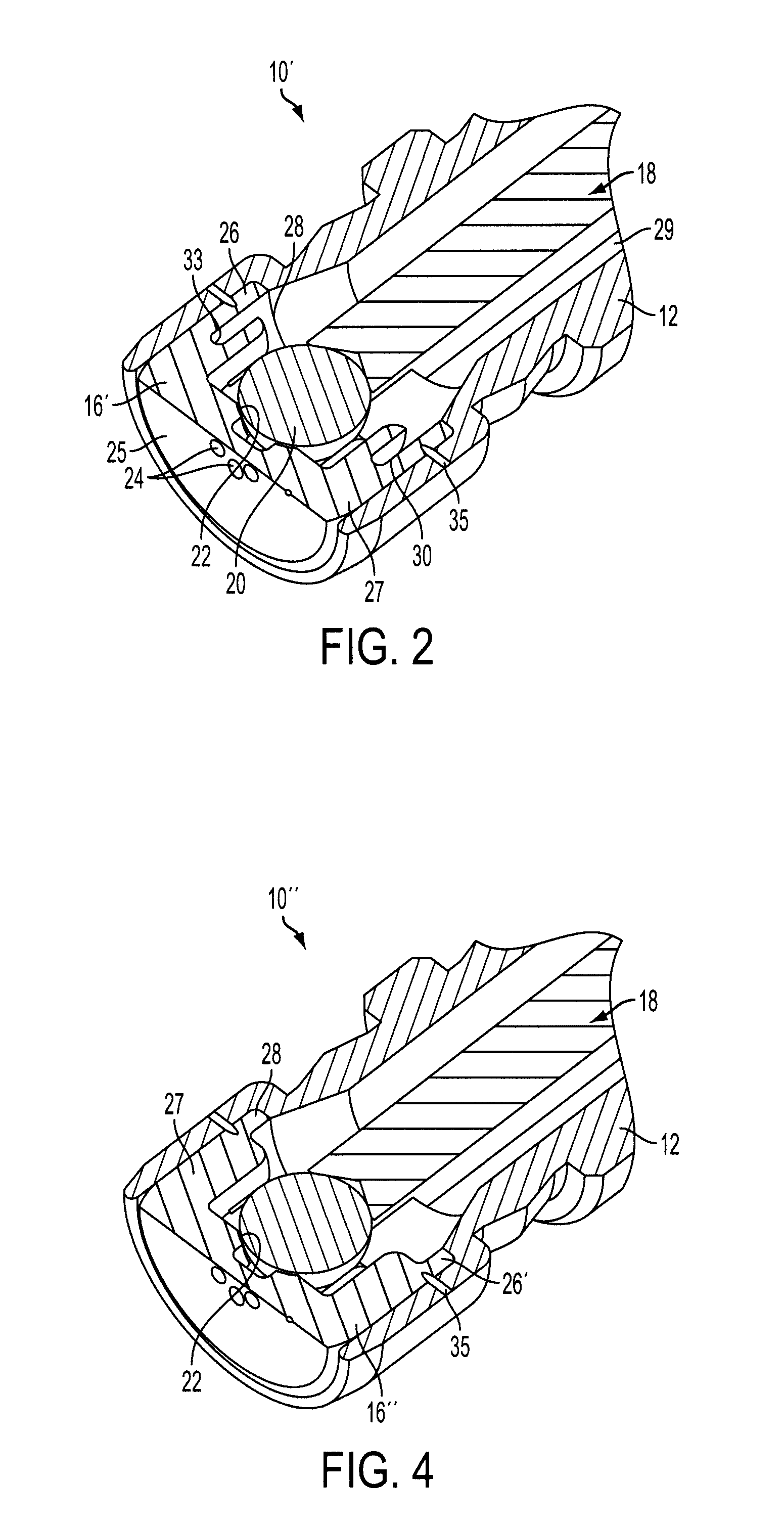

High Pressure Fuel Injector Seat That Resists Distortion During Welding

A valve seat (16′) for a fuel injector (10) includes a main body (27) having a proximal and a distal end with at least one orifice (24) extending through the main body. A seating surface (22) is provided on the main body to receive a closure member (20) of a fuel injector such that when the closure member engages the seating surface, the at least one orifice is closed. A guide surface (36) is provided on the main body to guide movement of the closure member. An annular wall (26) extends in a cantilever manner from the main body at the distal end thereof and defines an outer peripheral portion of the valve seat. The wall is constructed and arranged to deform during welding at the wall so as to isolate effects of the welding from the seating surface and the guide surface.

Owner:CONTINENTAL AUTOMOTIVE SYST INC

Steel pipe as fuel injection pipe

ActiveUS20090078341A1Reduce black smoke emissionReduce carbon dioxide emissionsFurnace typesMachines/enginesInternal pressureNon-metallic inclusions

To provide a steel pipe as a fuel injection pipe with high material strength, high internal pressure limit free from fatigue failure, prolonged fatigue life, and high reliability. A steel pipe as a fuel injection pipe of 500 N / mm2 or higher tensile strength comprising, by mass, C: 0.12 to 0.27%, Si: 0.05 to 0.40%, and Mn: 0.8 to 2.0%, and the balance being Fe and impurities, the contents of Ca, P, and S in the impurities being Ca: 0.001% or less, P: 0.02% or less, and S: 0.01% or less, respectively, characterized in that the maximum diameter of nonmetallic inclusions present in at least in a region extending from the inner surface of the steel pipe to a depth of 20 μm is 20 μm or less. Further, this steel pipe may contain, in place of a portion of Fe, at least one selected from among Cr: 1% or less, Mo: 1% or less, Ti: 0.04% or less, Nb: 0.04% or less, and V: 0.1% or less.

Owner:NIPPON STEEL CORP +1

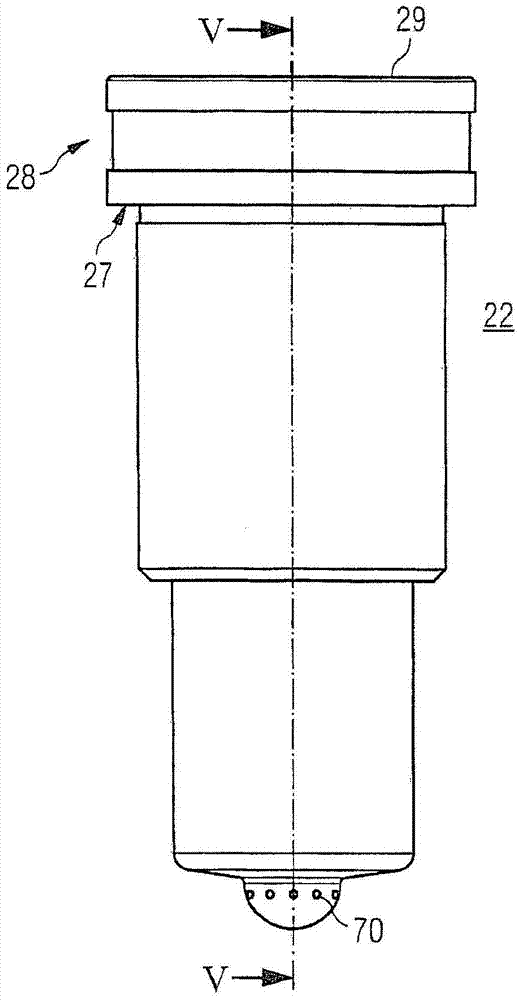

Injection nozzle

InactiveCN104334866ACavitation reductionExtended service lifeWear reducing fuel injectionMachines/enginesSpray nozzleEngineering

An injection nozzle (22) for mounting to a nozzle holder of a fuel injection system (1) of an internal combustion engine may comprise a sealing face (29) for providing a sealed connection to the nozzle holder, a needle guiding bore (34) for guiding a needle between a fuel injection state and a sealed state of the fuel injector. The needle guiding bore (34) may extend through the sealing face (29), being fluidly connected, at an injection side of injection nozzle (22), to an outside of the injection nozzle (22) via a plurality of nozzle spray holes (70). The needle guiding bore (34) may be widened to form a high pressure fuel chamber (36). A high pressure supply bore (38) may extend through the sealing face (29) and fluidly connect an opening in the sealing face (29) with the high pressure fuel chamber (36). A radial outer section (60) of a wall of the fuel supply channel (38) may smoothly transition into a wall of the high pressure fuel chamber (36). The high pressure supply bore (38) may be provided in a drop-like, rounded shape.

Owner:CATERPILLAR MOTOREN

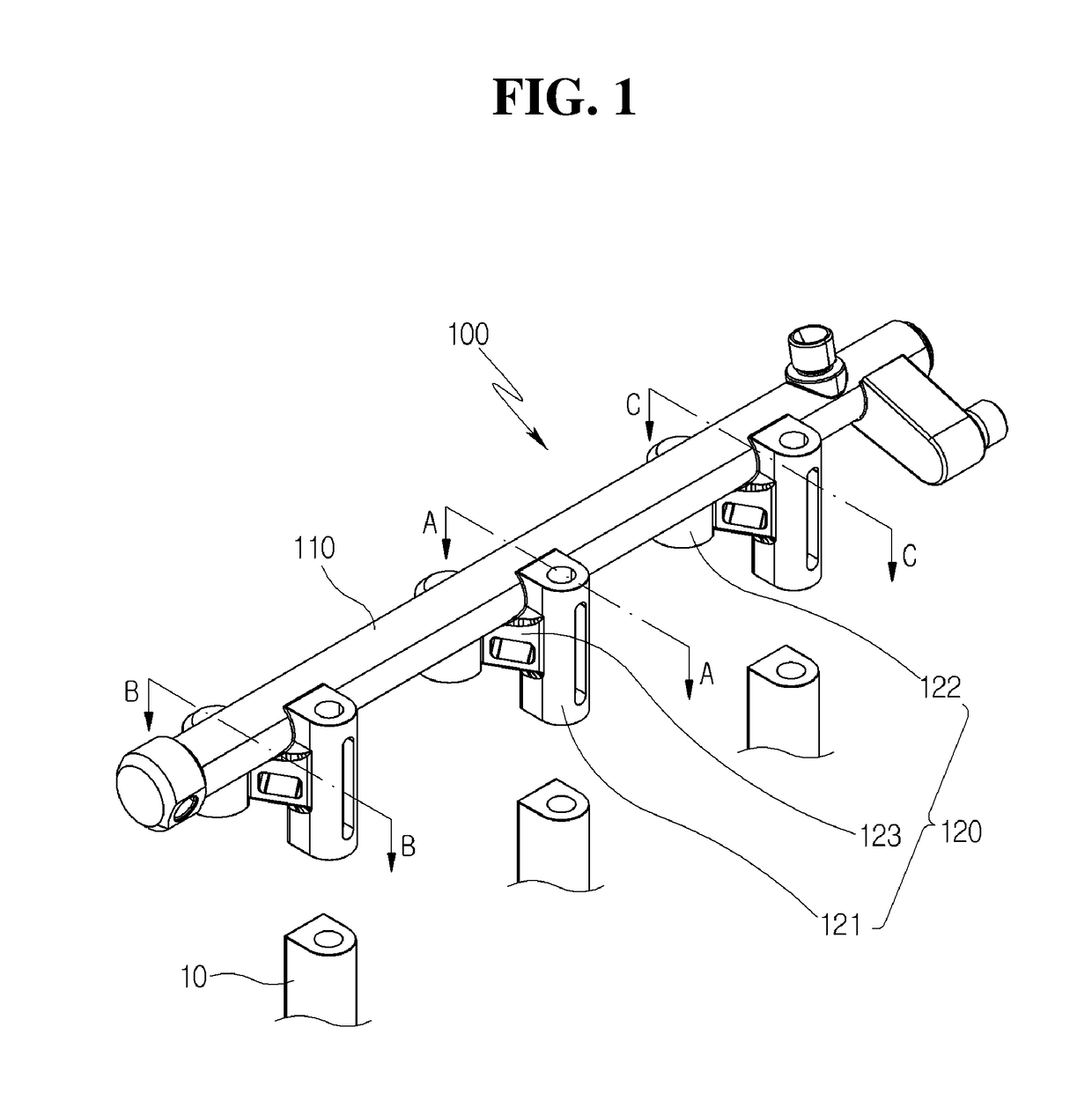

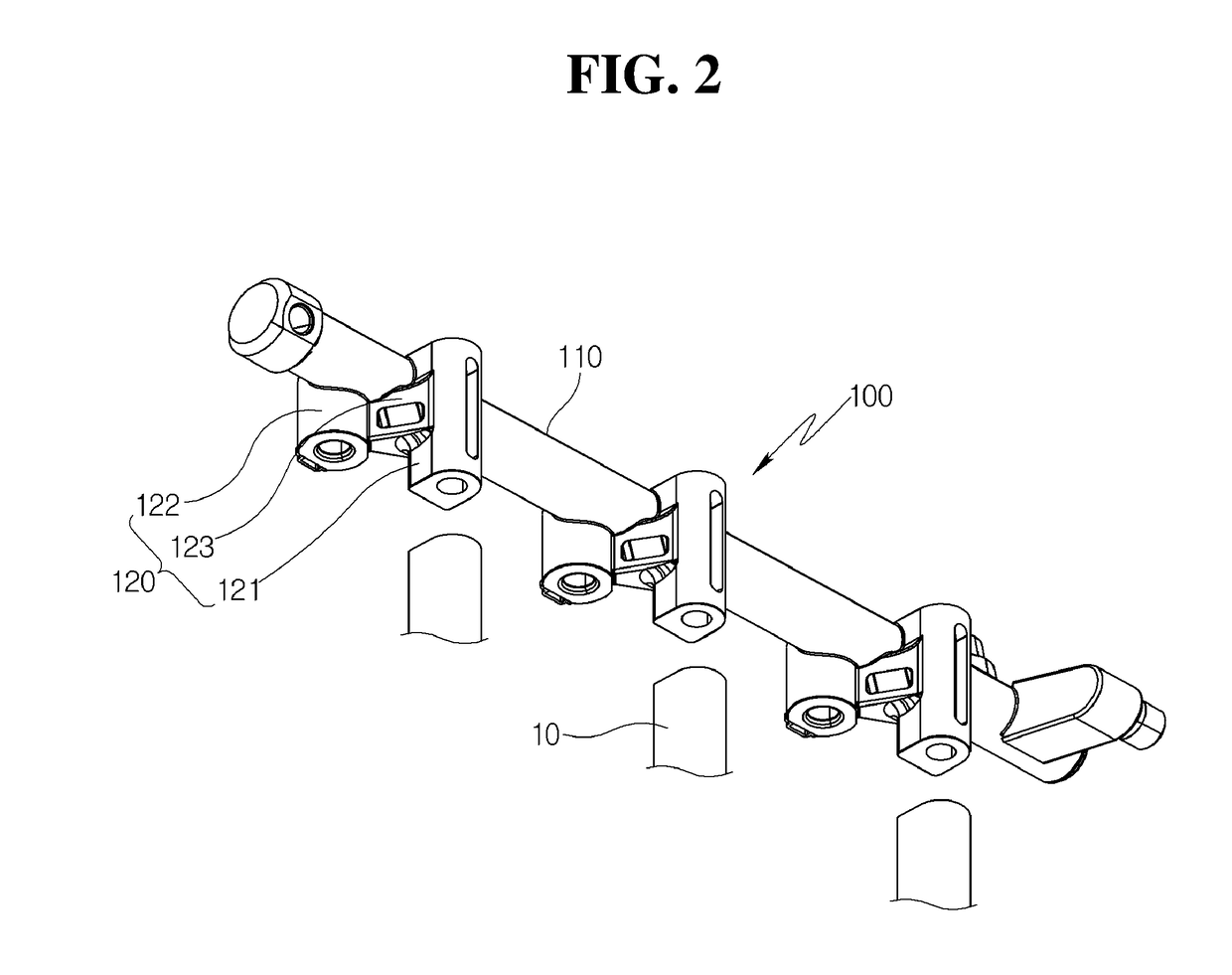

Mounting structure of fuel rail

ActiveUS20180230954A1Distribute stress concentrationImprove fatigue strengthWear reducing fuel injectionMachines/enginesStress concentrationInjector

Disclosed herein is a mounting structure of a fuel rail, including a mounting boss part having a through-hole formed in a longitudinal direction and a first mating surface formed at an outer surface, an injector cup part provided separately from the mounting boss part and having a second mating surface formed at an outer surface and a flow path hole formed at one side of the second mating surface to be connected to the main pipe for transferring fuel to an injector, and a bridge part connecting the mounting boss part and the injector cup part and having a third mating surface. The mounting structure of the fuel rail can effectively distribute stress concentration by increasing contact area with the main pipe, thereby improving fatigue strength.

Owner:HYUNDAI KEFICO CORP

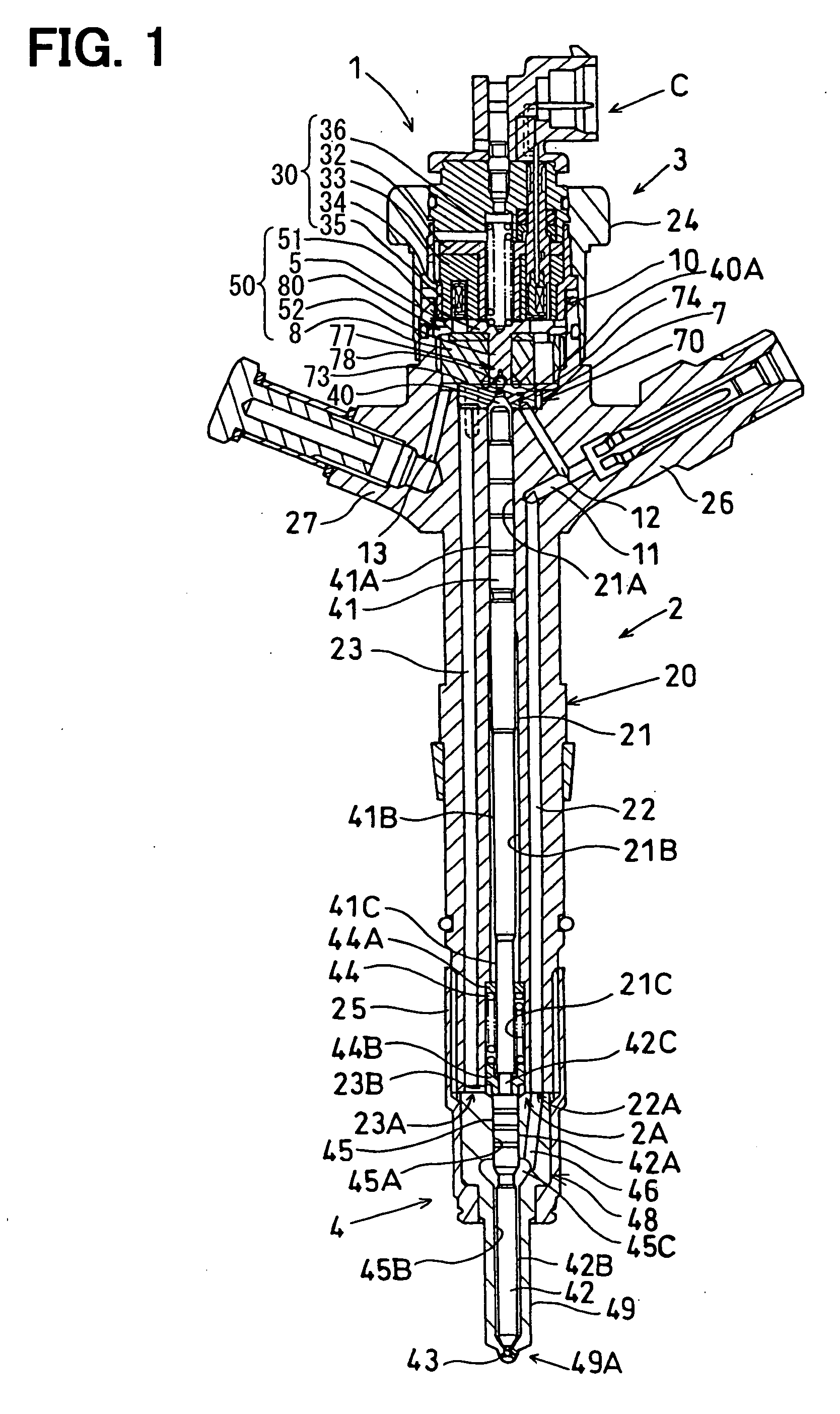

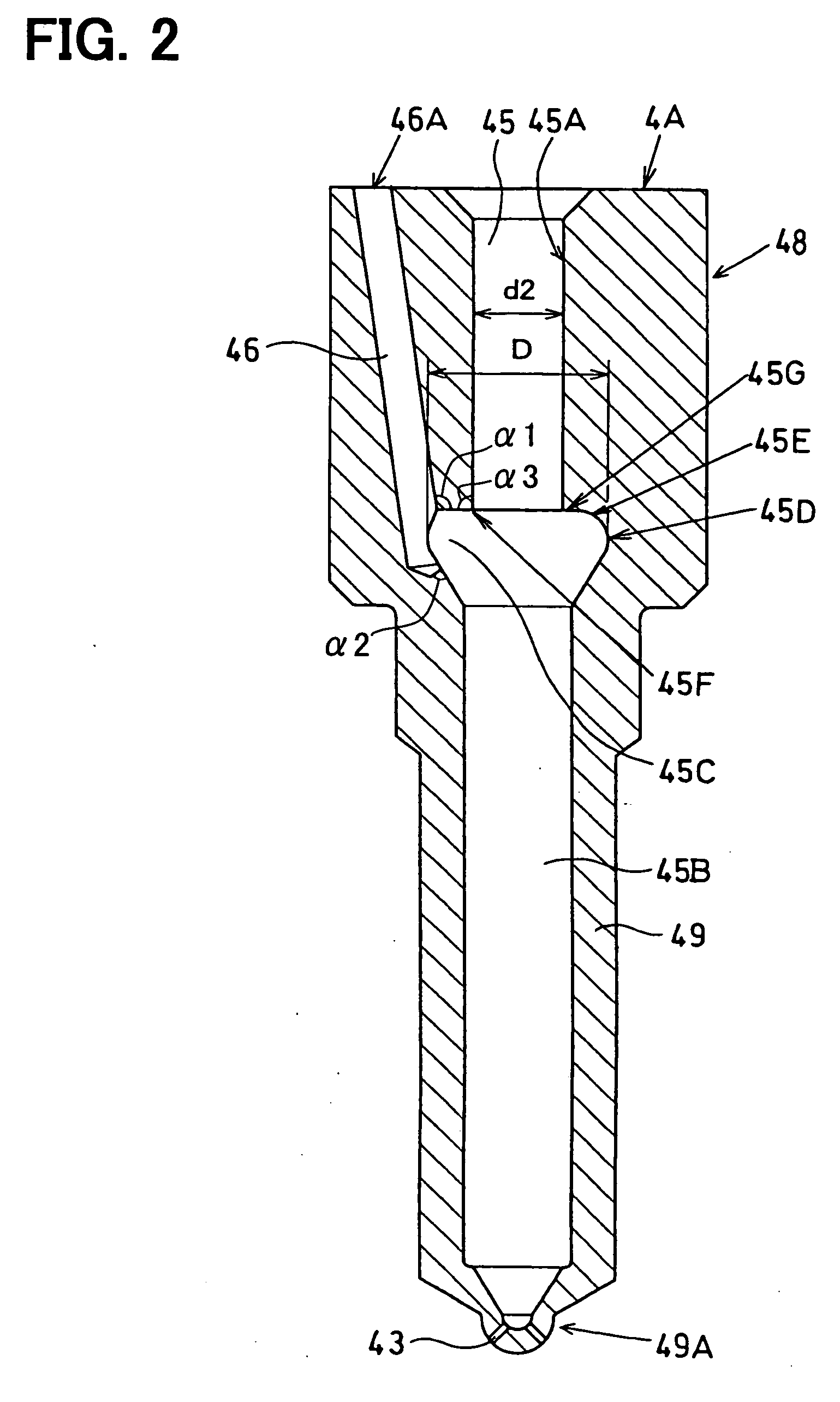

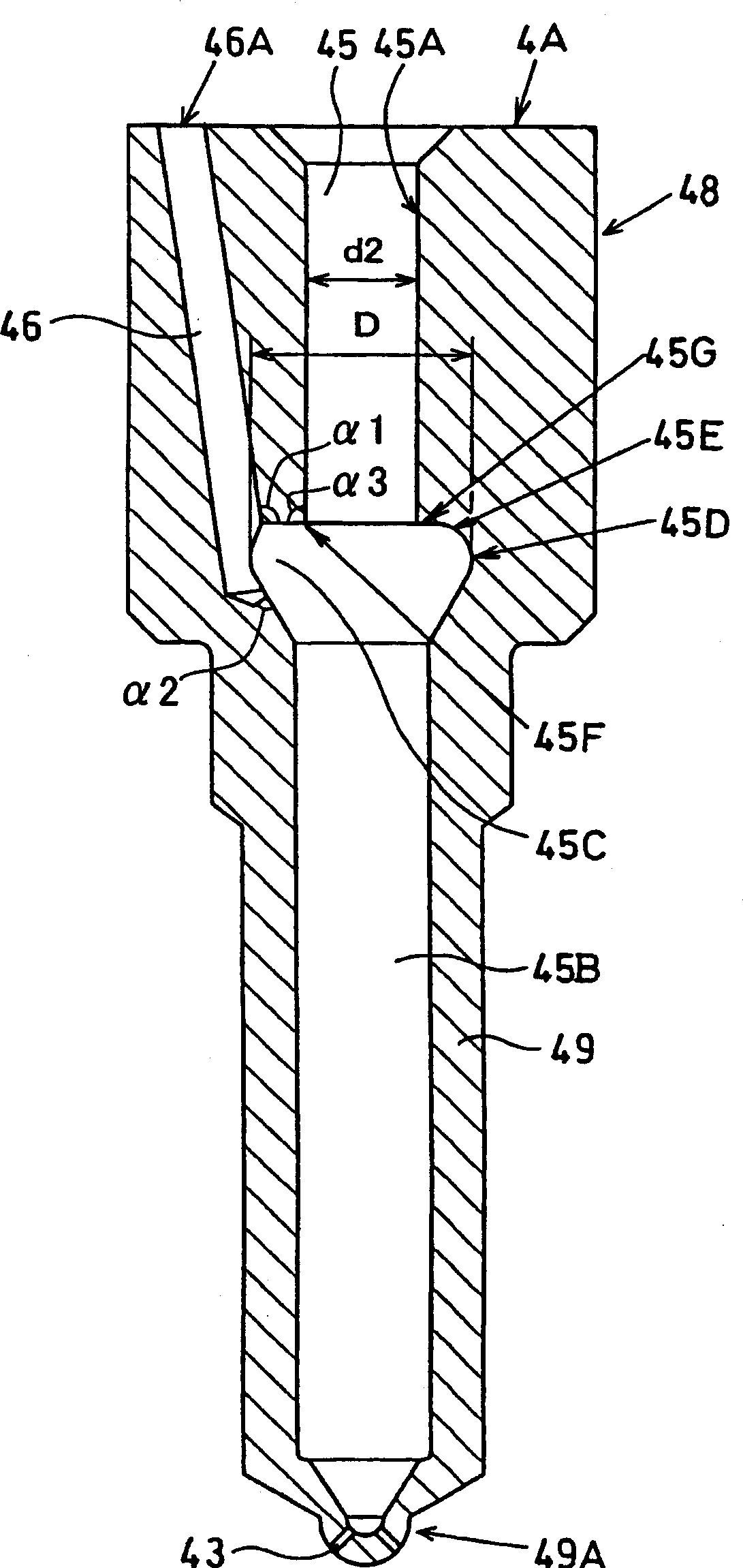

Fuel injector reducing stress concentration

InactiveUS20060157582A1Relieve stressReduce stress concentrationSpray nozzlesMachines/enginesStress concentrationMaximum diameter

On an inner wall of a bag-shaped hole portion of a nozzle body, a cross angle between the bag-shaped hole portion and a needle hole or an oblique high-pressure fuel passage of the nozzle body is made obtuse, i.e. at 90 degrees or larger, through an electrochemical machining process with a suitably-shaped electrode or through after-processing with a boring tool having a predetermined shape. The center of the bag-shaped hole portion may be deviated toward the high-pressure fuel passage or the high-pressure fuel passage may be connected to a maximum diameter portion of the bag-shaped hole portion to provide the obtuse cross angle. Thus, excessive stress on the inner wall of the bag-shaped hole portion or a breakage of the nozzle body due to a crack can be inhibited.

Owner:DENSO CORP

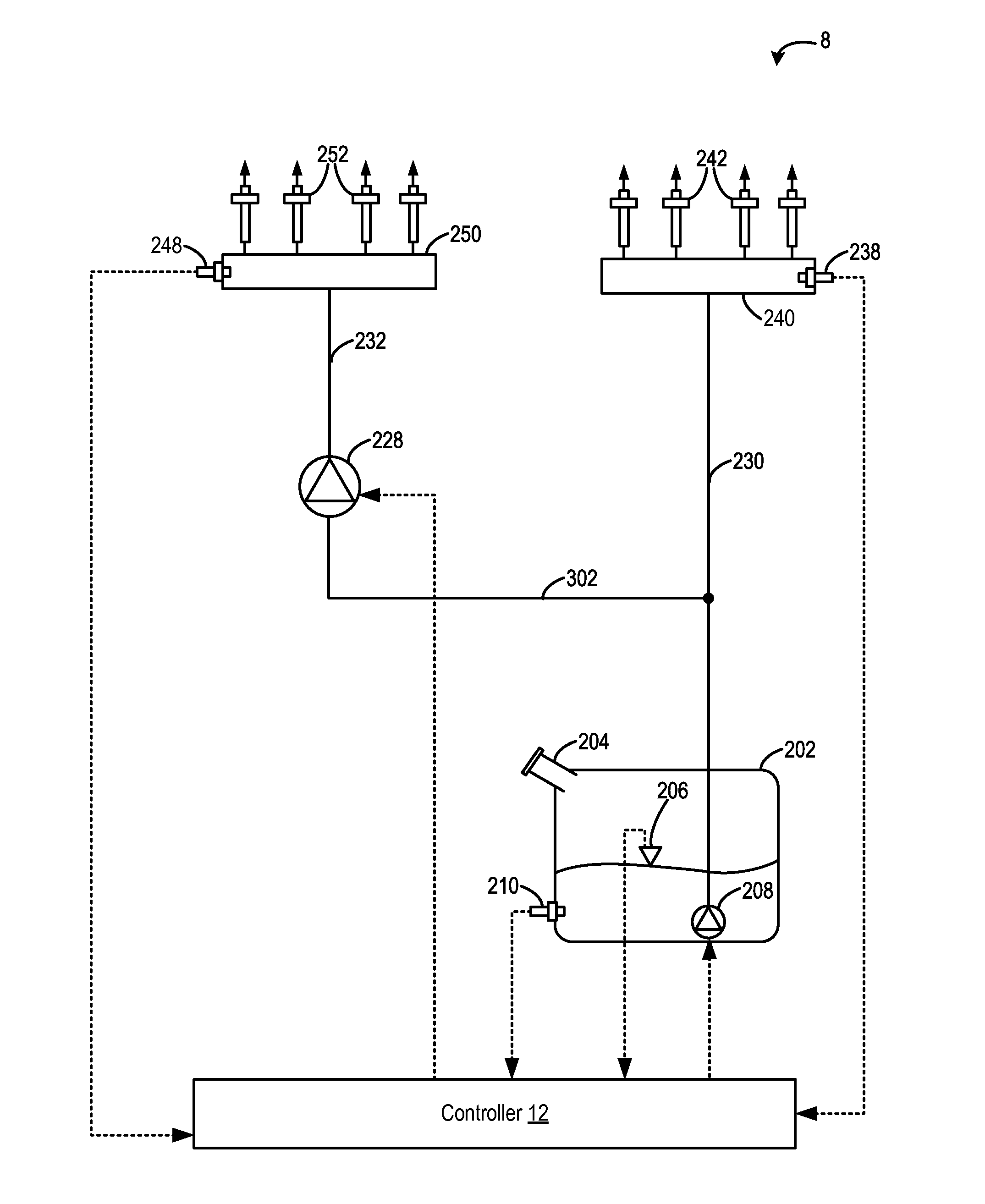

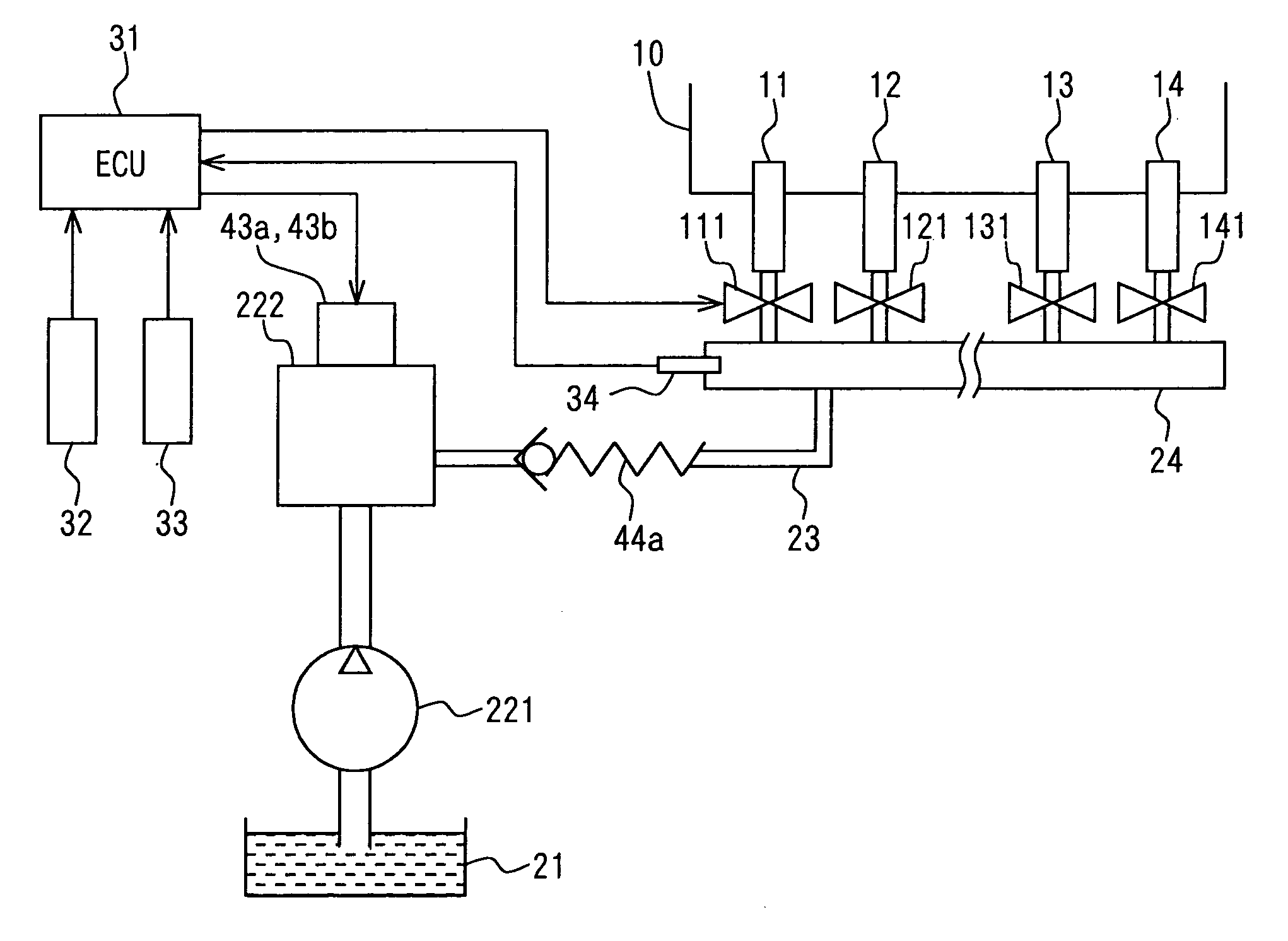

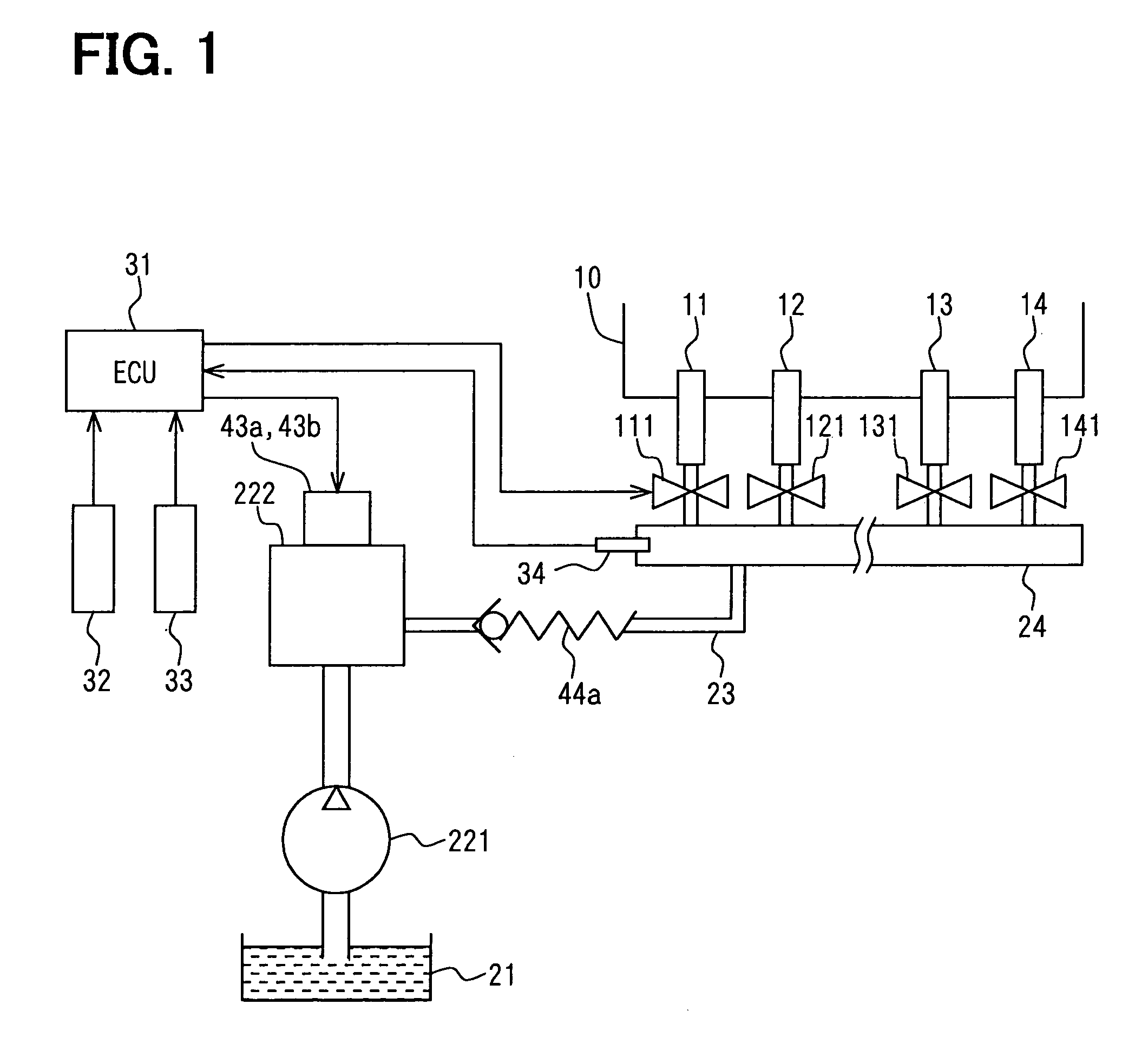

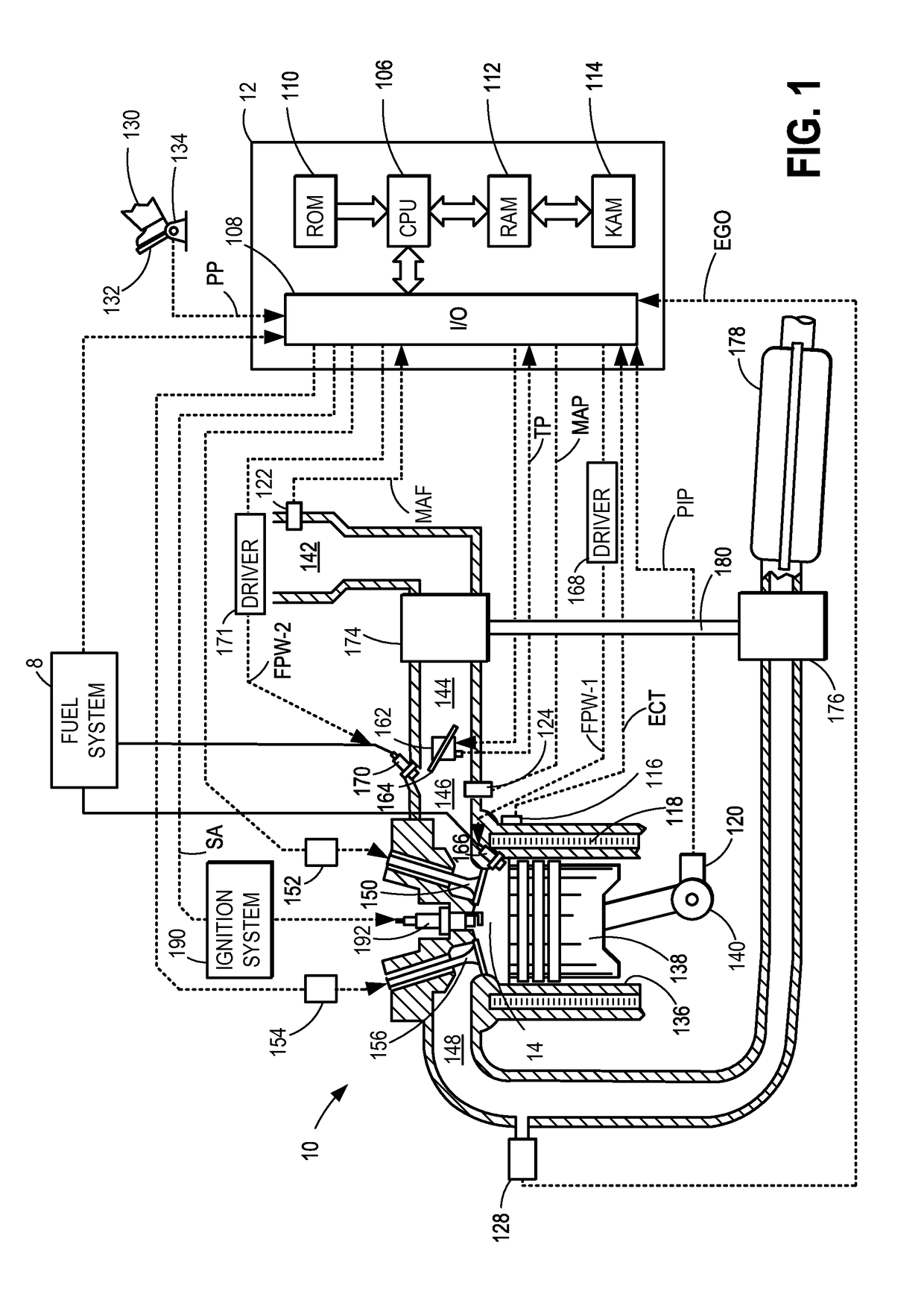

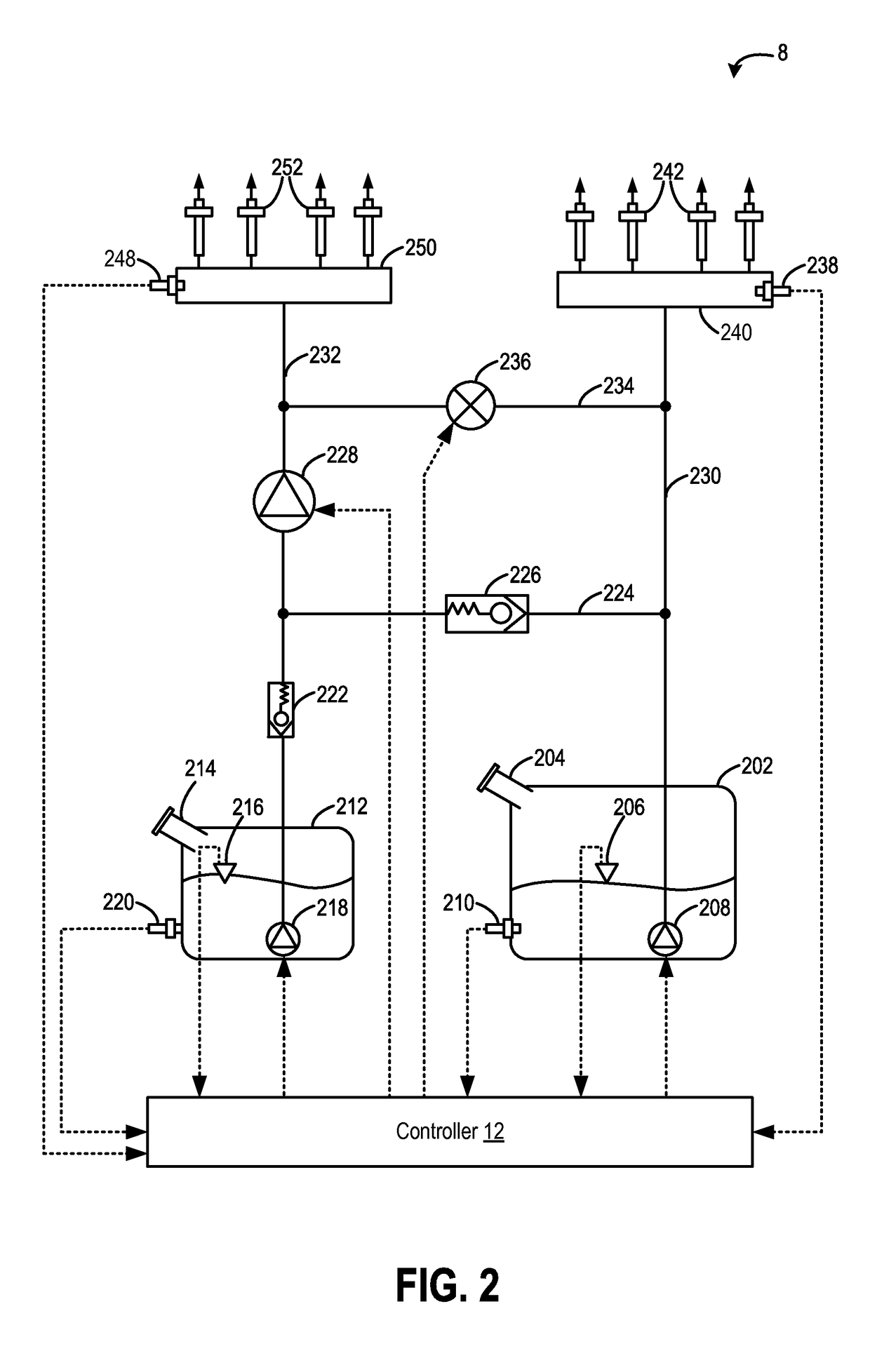

Fuel supply device of an internal combustion engine

ActiveUS7017554B2High precisionSimple structureElectrical controlVehicle fittingsExternal combustion engineInternal combustion engine

A fuel supply device includes a fuel pump, a plurality of valves, and a controller. The fuel pump includes a plurality of pressure chambers each having a volume that is expanded and contracted by the engine. The plurality of valves open and close the pressure chambers. An expansion time and a contraction time of the pressure chambers are each different. The fuel pump is operable to sealingly store fuel in the pressure chambers by closing the valves. The controller sets closing times for the valves in accordance with a required quantity of fuel to be force fed. The controller switches between a normal control in which all of the pressure chambers sequentially force feed fuel and a thinned-out control in which the force fed fuel is thinned out by stopping closing at least one of the valves.

Owner:DENSO CORP

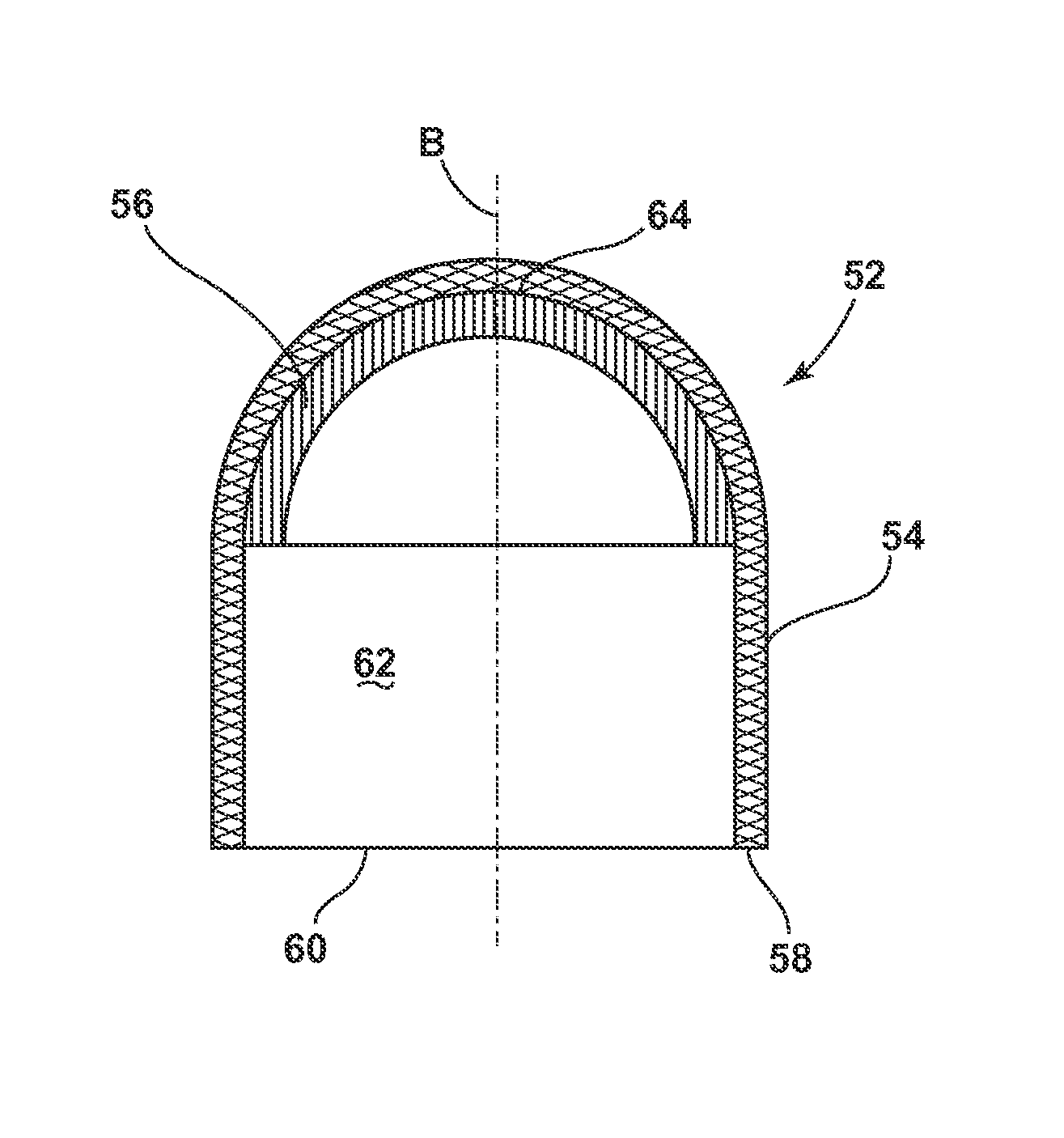

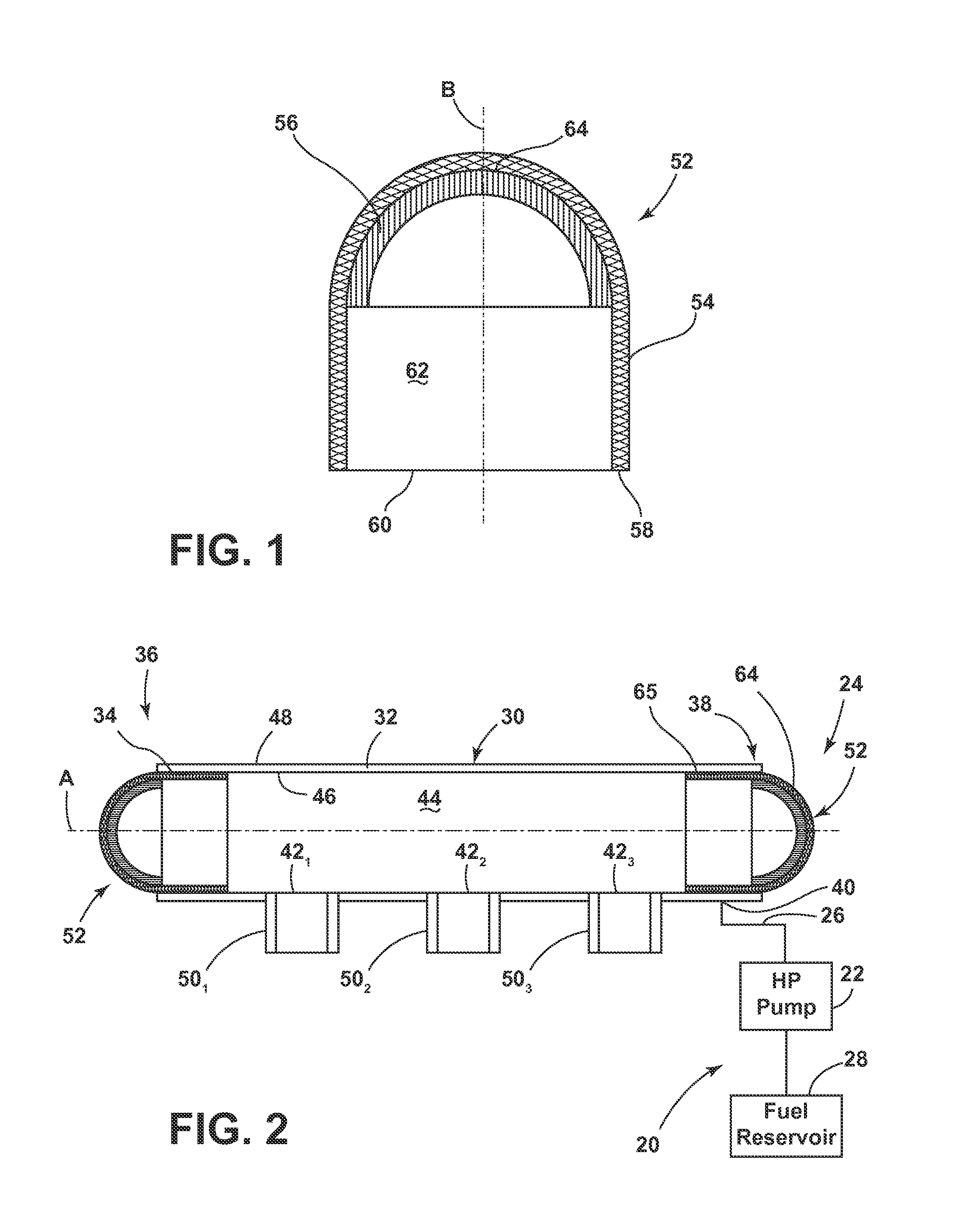

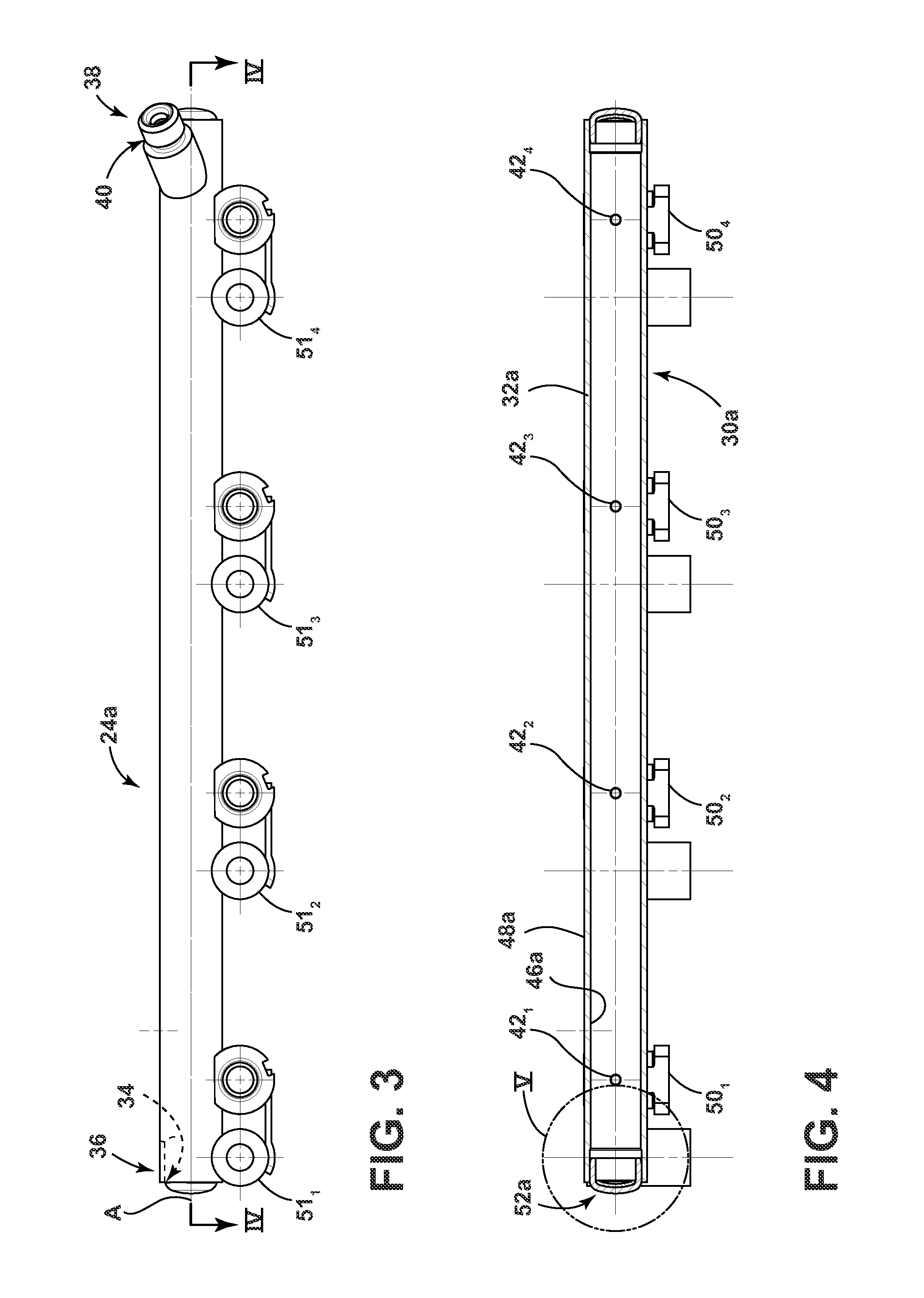

Reinforced end cap assembly for pressure vessel

InactiveUS20160341167A1Low costConserve costLow pressure fuel injectionFluid pressure injection controlEngineeringHigh pressure

A fuel rail or pressure vessel assembly extends along a longitudinal axis and includes a fluid conduit having an opening at either or both of the longitudinal ends of the conduit. The conduit has an inlet coupled to a high-pressure fuel source, a plurality of outlets, and a conduit interior that forms a fluid flow passageway between inlet and outlets. An end cap assembly is mounted to cover and close each fluid conduit opening. The end cap assembly includes a cup having a free edge that defines an aperture that leads to a cup interior. The cup has an inner surface facing the conduit interior. The end cap assembly also includes a reinforcement that is mounted to the inner surface of the cup. Both the cup and the reinforcement can be stamped metal components and are brazed together.

Owner:MILLENNIUM INDS

Hochdruckpumpe

ActiveCN102734022ASimple structureReduce weightPositive displacement pump componentsFuel injecting pumpsEngineeringHigh pressure

A high-pressure pump is comprised of a lower housing, an upper housing and a cover, which are formed independently from each other. Thereby, shapes of the above can be simplified. Although the cylinder and the plunger receive a fuel pressure during a pressurization stroke, the upper housing and the cover do not receive fuel pressure directly from a pressurization chamber. Therefore, the upper housing and the cover can be made thin and light as much as possible.

Owner:DENSO CORP

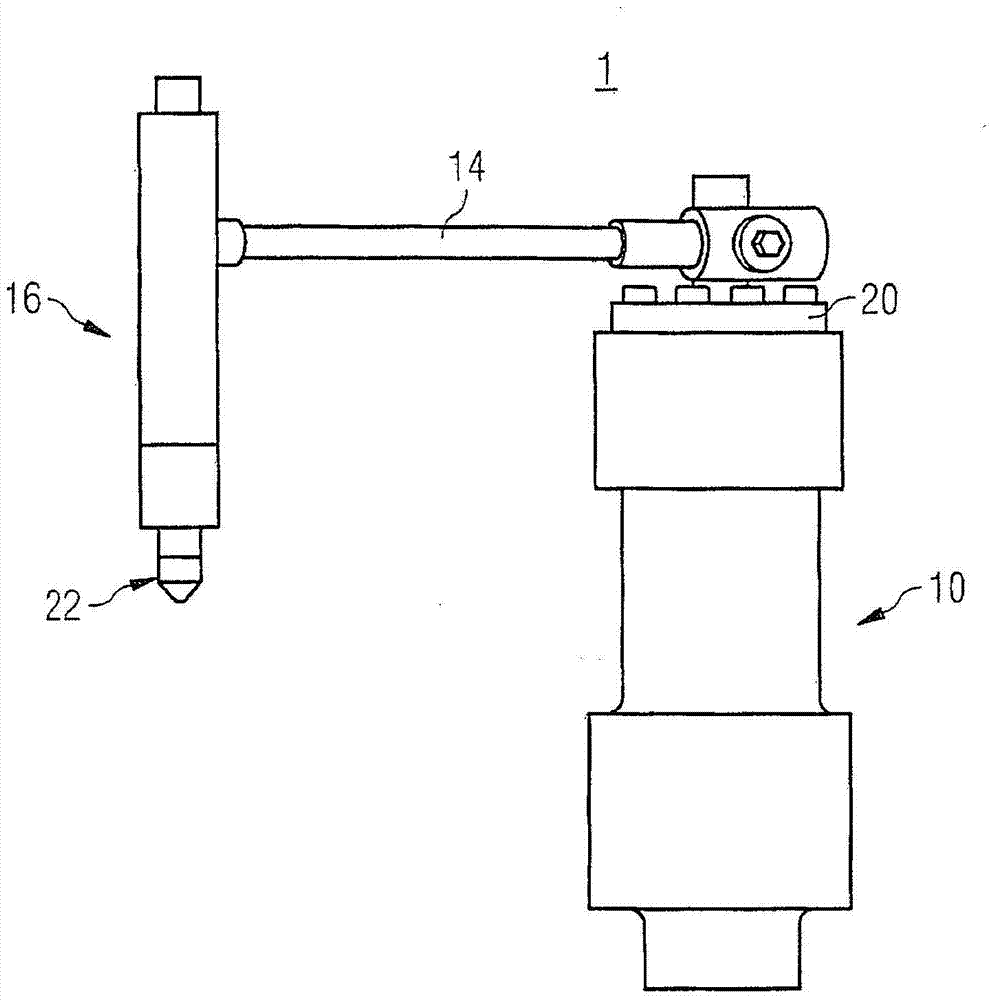

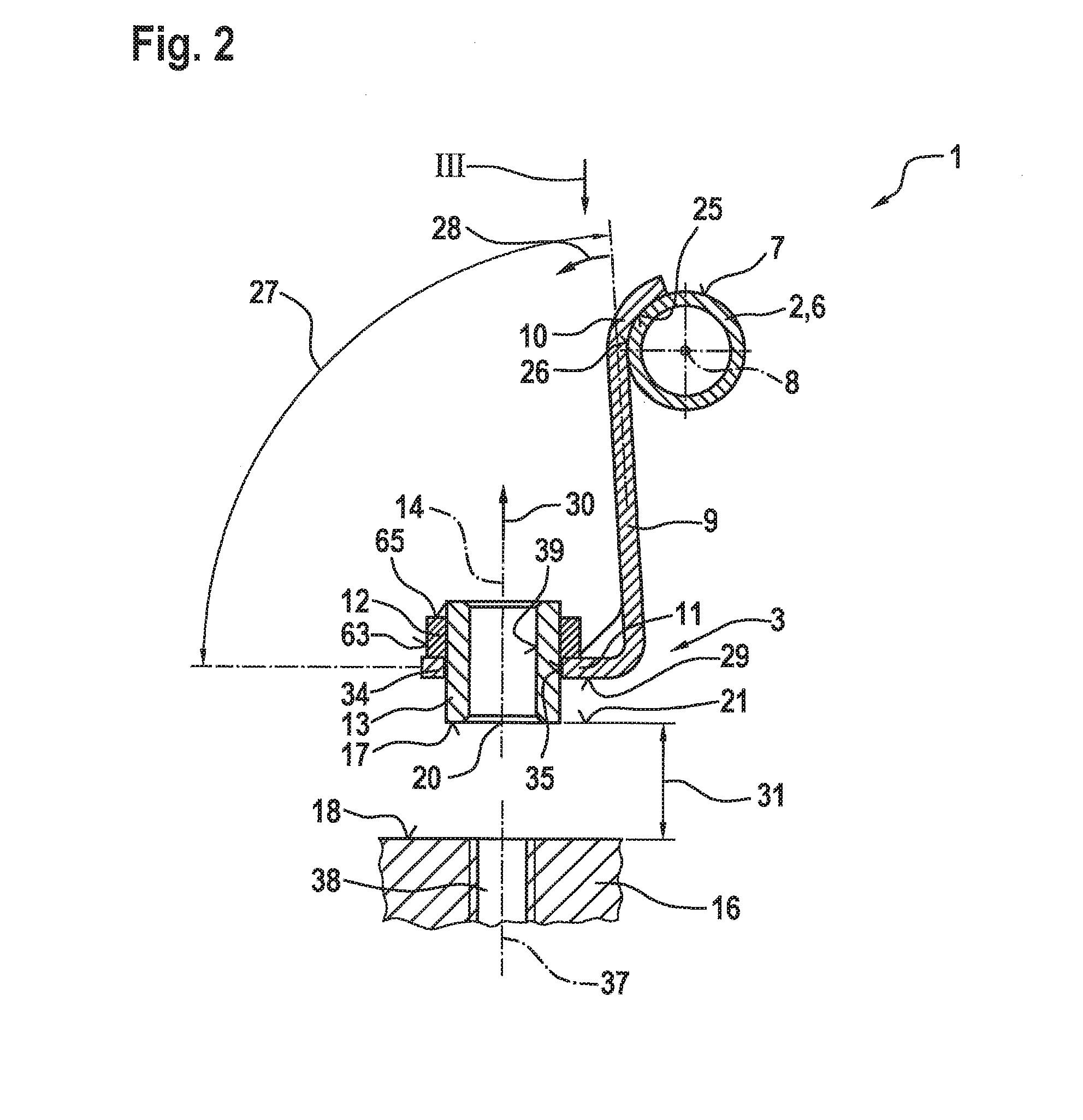

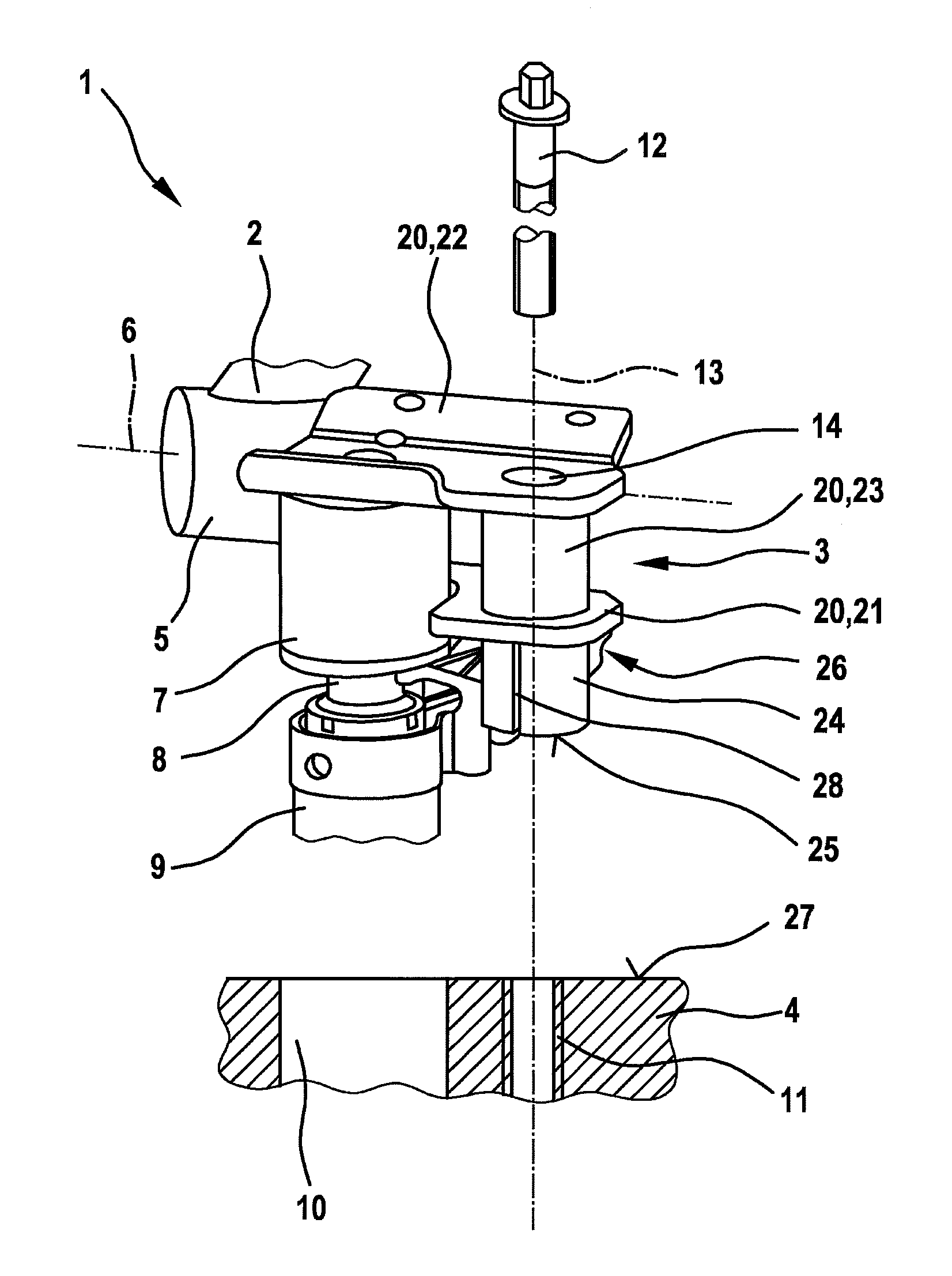

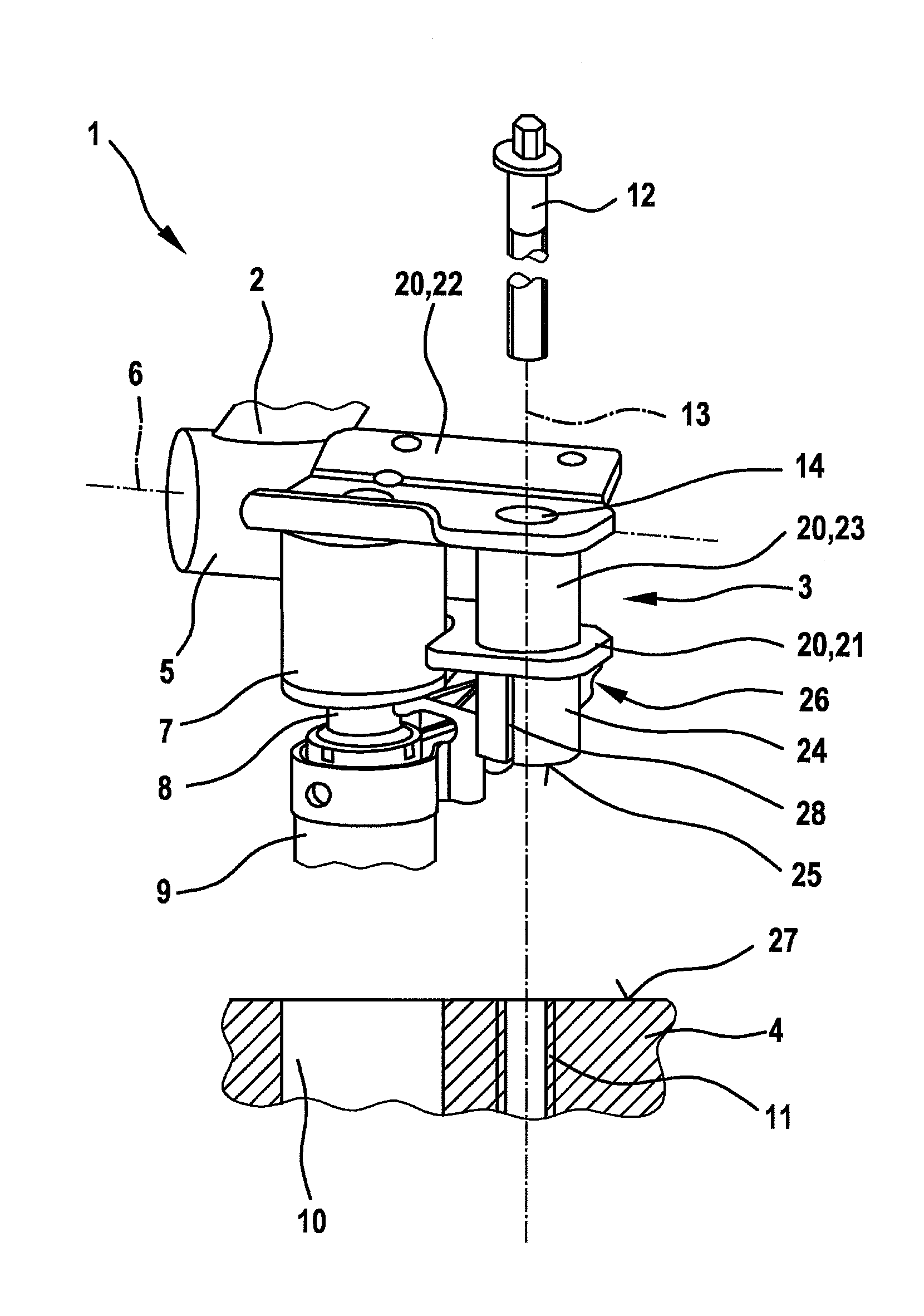

Holder for fastening a fuel distributor to an internal combustion engine, and connecting method

ActiveUS20160305387A1OptimizationReduce manufacturing costMachine supportsNoise reducing fuel injectionInternal combustion engineDistributor

A holder (3) serves for fastening a component (2), in particular a fuel distributor (2), onto an internal combustion engine (16). A holding element (9) that has a component-side connecting segment (10) is provided. The holding element (9) is connectable at the component-side connecting segment (10) to the component (2). The holding element (9) furthermore has a fastening-means-side connecting segment (11) at which the holding element (9) is fastenable via a fastening means (15) onto the internal combustion engine (16). A receiving part (12) and a fastening sleeve (13) are provided. The receiving part (12) serves to connect the fastening sleeve (13) to the fastening-means-side connecting segment (11) of the holding element (9). The fastening sleeve (13) has a through opening (39) through which the fastening means (15) is guidable. An assemblage (1) having such a holder (3) is also described. A connecting method is furthermore described.

Owner:ROBERT BOSCH GMBH

Fuel injector reducing stress concentration

InactiveCN1804388AReduce stress concentrationIncrease stressMachines/enginesStress reducing fuel injectionStress concentrationMaximum diameter

Owner:DENSO CORP

Direct injection fuel pump

ActiveUS9429124B2Reduce degradation rateFully lubricatedElectrical controlWear reducing fuel injectionLubricationFuel pump

Methods and systems are provided for a direct injection fuel pump. The methods and system control pressure within a compression chamber so as to improve fuel pump lubrication.

Owner:FORD GLOBAL TECH LLC

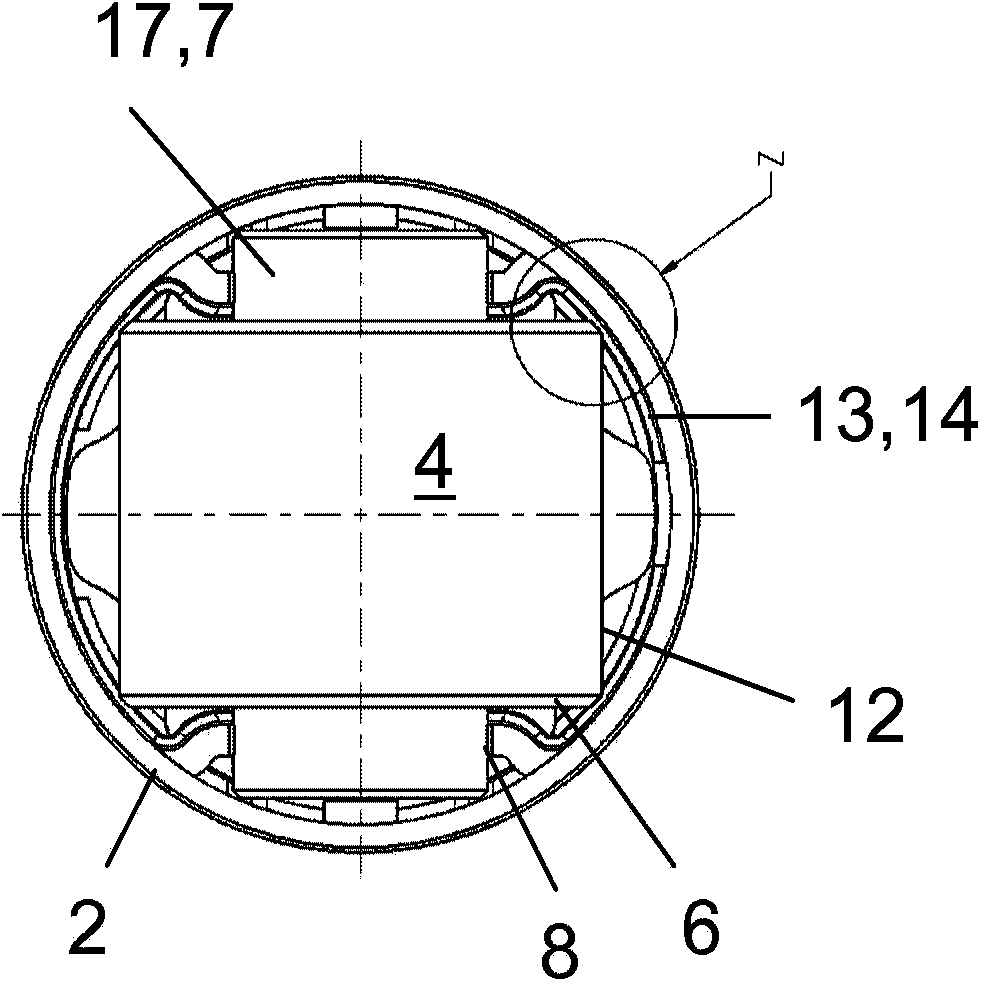

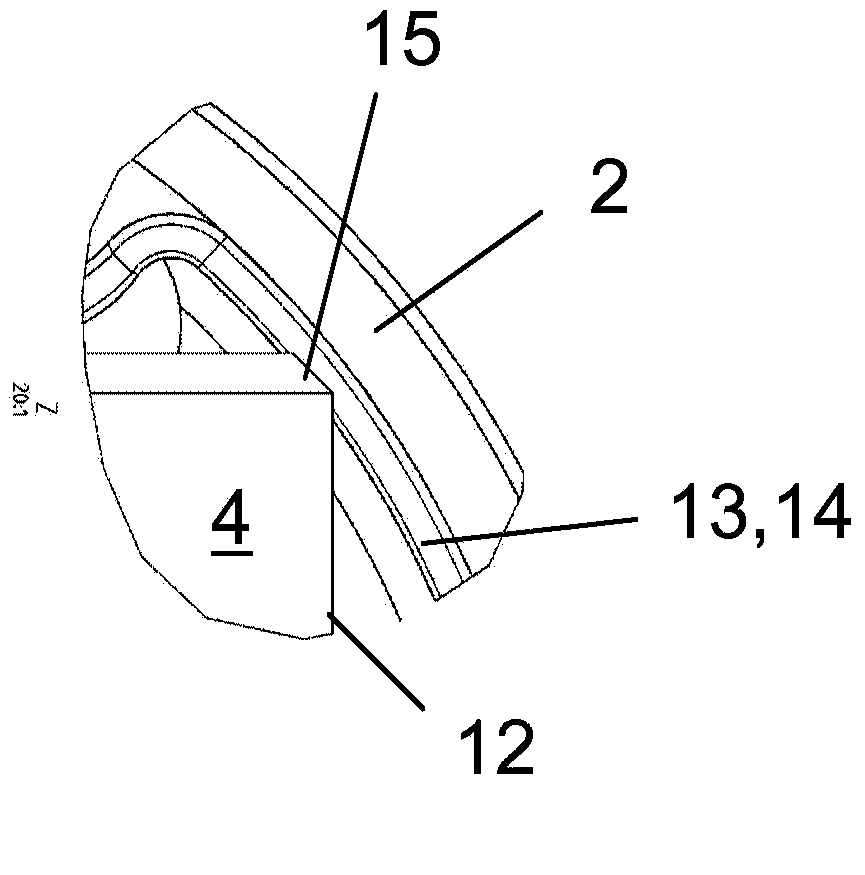

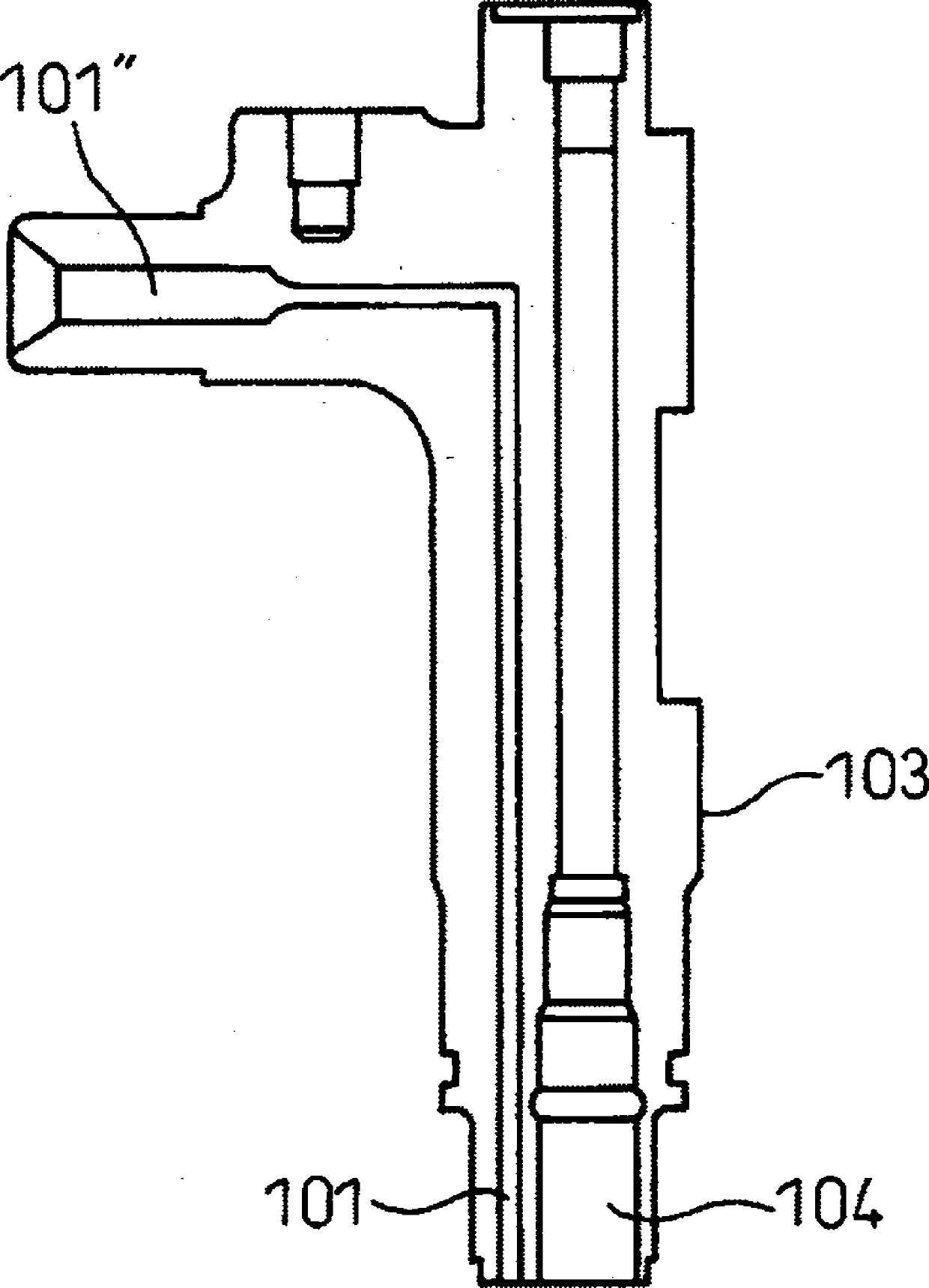

Plunger

ActiveCN104395598ACompact buildIncrease the diameterValve arrangementsFuel injecting pumpsEngineeringFuel injection

The invention relates to a plunger (1) for a fuel injection pump, having a tube-like housing (2), which accommodates a roller (4) for the running of a periodic lift generator inside the inner jacket (5) thereof in the region of a first ring end (3). Said roller has axial stumps (7) projecting from the end faces (6) of the roller, by means of which stumps the roller sits in recesses (8) in the housing (2), wherein the housing (2) is penetrated axially by a bridge piece (9) underneath the roller (4), the underside (11) of which bridge piece, which faces a second ring end (10) of the housing (2), acts as a rest for a plunger following part. The inner jacket (5) of the housing (2), proceeding from the first ring end thereof in the direction of the second rind end (3, 10) and at least in the circumferential section (13) thereof, which surrounds an outer jacket (12) of the roller (4), has a pocket-like thinned portion of material (14), which levels out under a half of the height of the roller (4) and into which the ring edges (15) of the roller (4) project.

Owner:SCHAEFFLER TECH AG & CO KG

Structure of gdi fuel delivery pipe

ActiveUS20180128223A1Improve repetition durabilityReduce weightNoise reducing fuel injectionLow pressure fuel injectionEngineeringHollow form

Disclosed herein is the structure of a GDI fuel delivery pipe. The structure of a GDI fuel delivery pipe includes: a main pipe configured to flow fuel through a hollow formed therein; a plurality of injector cups formed in cylindrical shapes having open lower ends, and configured to be coupled and fastened to the main pipe, to flow fuel therethrough, and to be coupled to respective injectors; a plurality of mount M holders configured to form tubular parts each having a bolt hole in a lengthwise direction, and to be coupled and fastened to the main pipe; and fastening members configured to fasten the plurality of injector cups or mount holders to the main pipe by being coupled to the outer circumferential surface of the main pipe at both left and right ends thereof while surrounding the outer circumferences of the plurality of injector cups or mount holders.

Owner:DONGBO IND

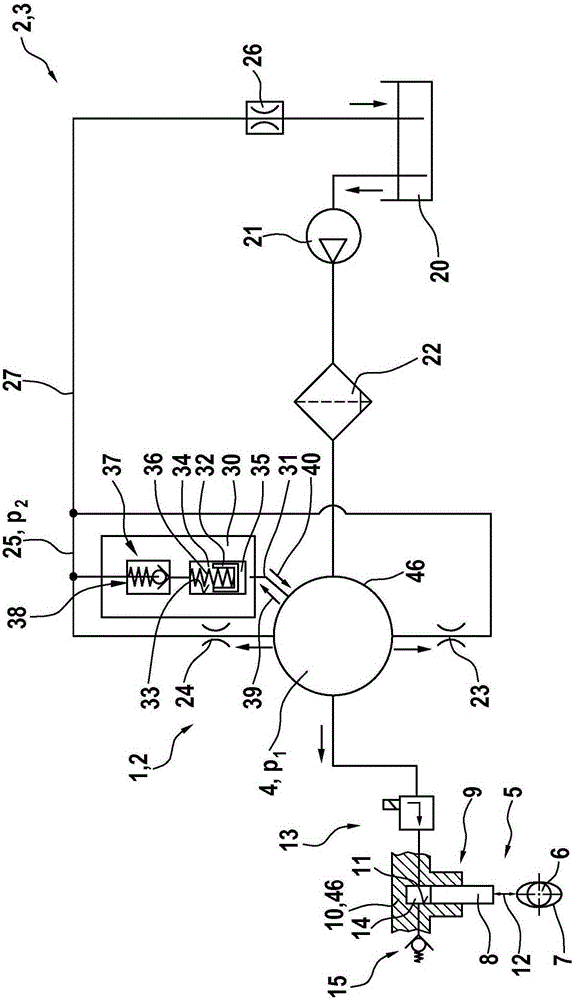

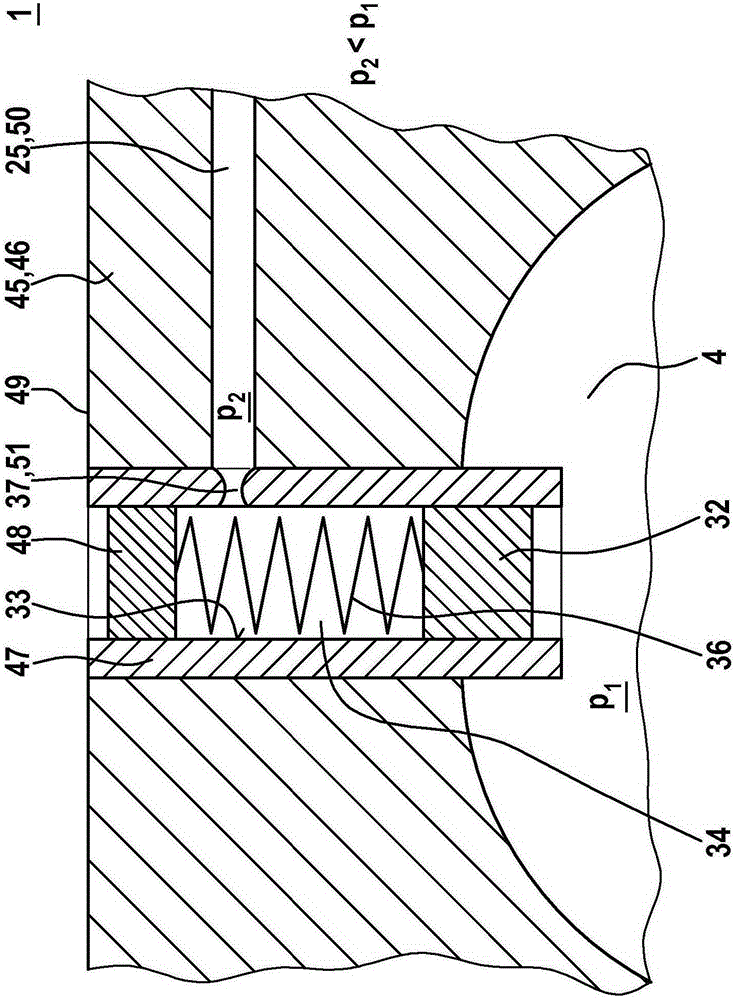

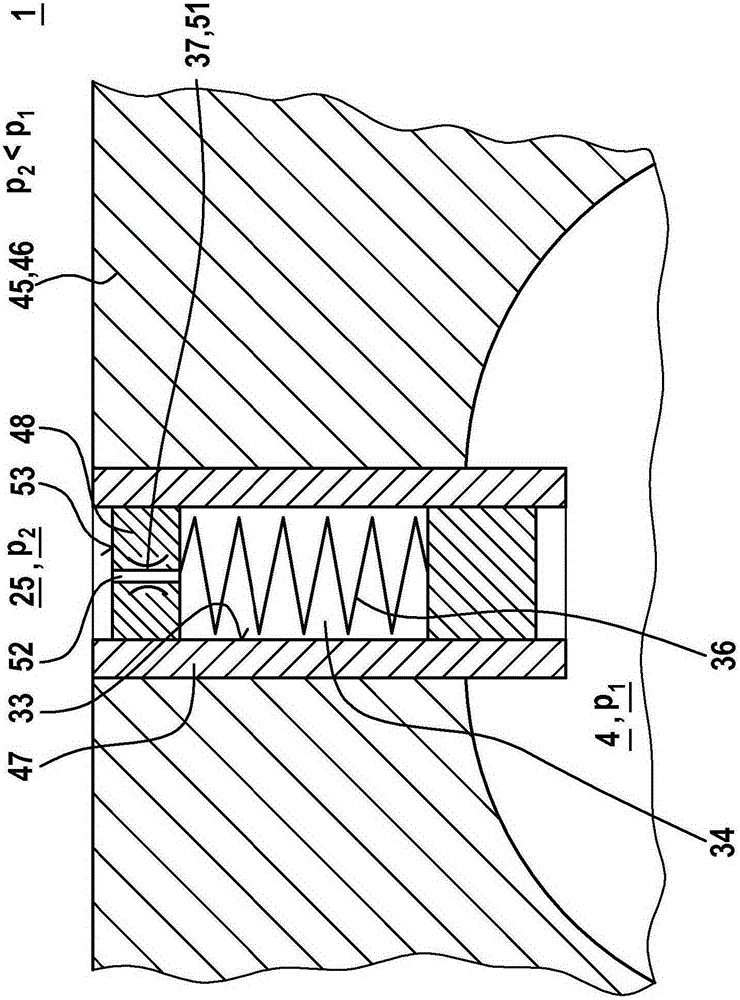

Pump

ActiveCN105339659ASimple configurationLarge steam volumePositive displacement pump componentsNoise reducing fuel injectionCombustionEngineering

The invention relates to a high-pressure pump (1) which serves in particular for fuel injection systems of internal combustion engines, comprising a low pressure chamber (4) configured as a power unit chamber (4) and a drive (5) which is disposed at least partially in the low pressure chamber (4). In operation pressure pulses are generated in the low pressure chamber (4) by the drive unit (5). A damping device (30) is provided which on the one hand is coupled to the low pressure chamber (4) and on the other hand is connected to a low pressure level (25) which in operation is located below a pressure (p1) in the low pressure chamber (4). The damping device (30) has a piston which is displaceable in a piston bore (33) and which not only is acted upon by the pressure (p1) in the low pressure chamber (4) against a spring force of a spring element (36) but also delimits a vapour chamber (34) in the piston bore (33). Furthermore the damping device (30) has a pressure relief means (37) which connects the vapour chamber (34) at least intermittently to the low pressure level (25).

Owner:ROBERT BOSCH GMBH

Direct injection fuel pump

ActiveUS9599082B2Reduce lubricationIncreased power consumptionWear reducing fuel injectionNoise reducing fuel injectionLubricationFuel pump

Owner:FORD GLOBAL TECH LLC

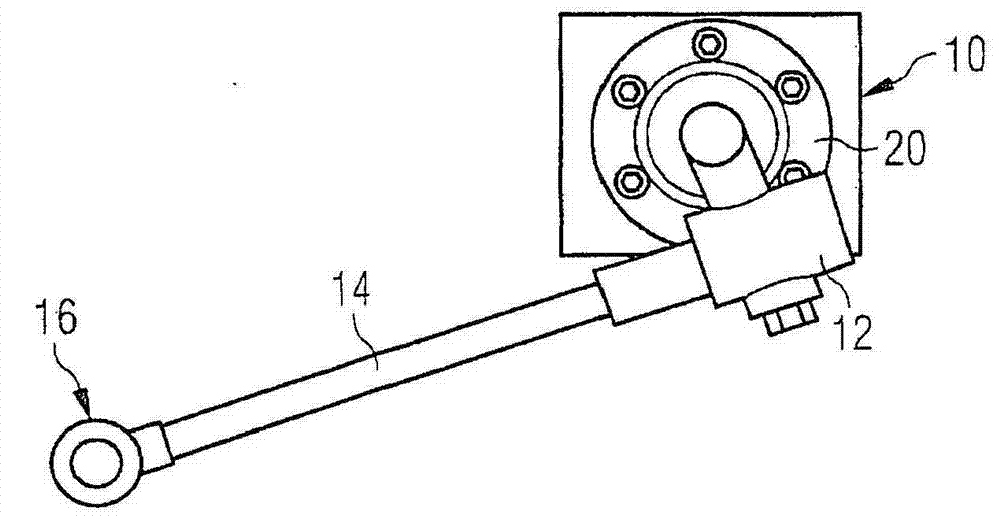

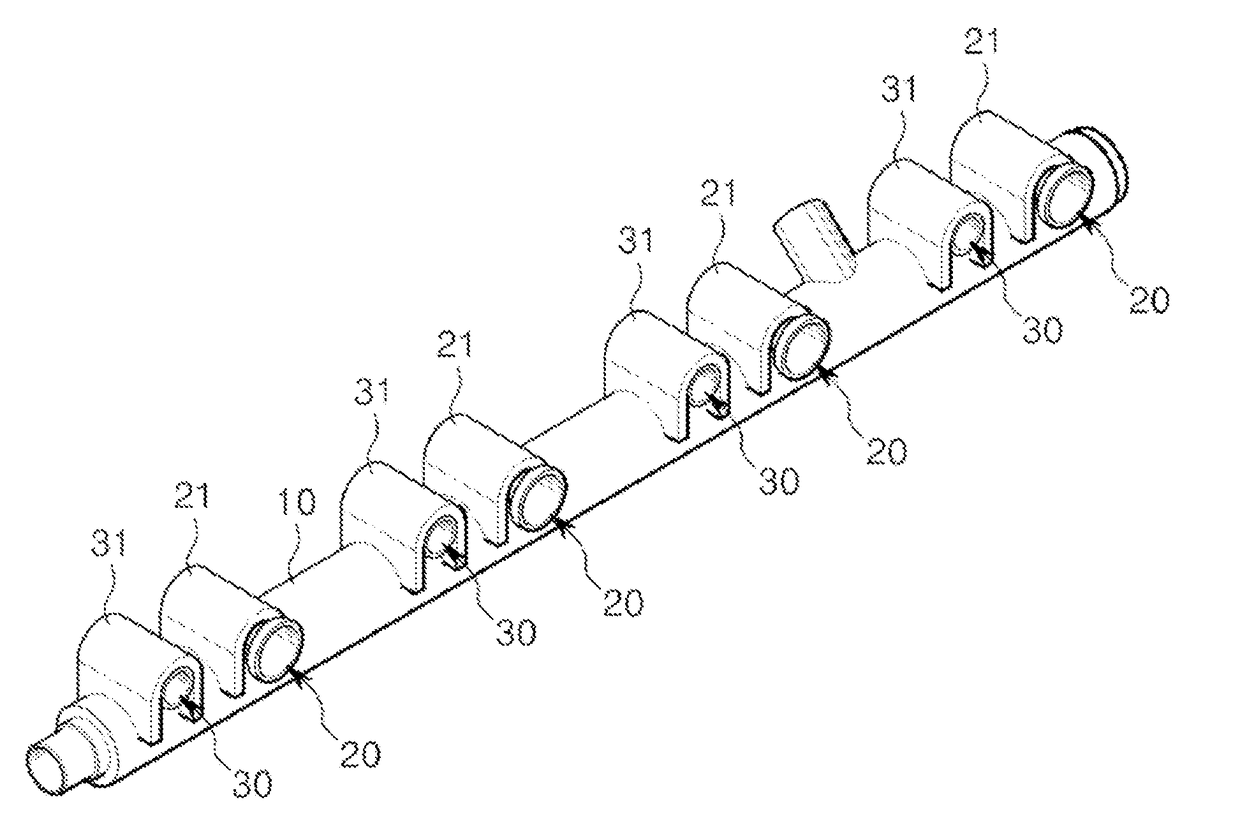

Holder and system having a fuel rail and multiple holders

ActiveUS20160195054A1Reduction in stress increaseReduce pointsMachines/enginesStress reducing fuel injectionEngineeringInternal combustion engine

A holder is used for fastening a fuel distributor to an internal combustion engine. The holder has a base element which is connected to the fuel distributor. A slotted sleeve is provided, which is connected to the base element, and the base element is braced on the internal combustion engine via the slotted sleeve. Furthermore, a system having the fuel distributor and a plurality of holders of this type is provided.

Owner:ROBERT BOSCH GMBH

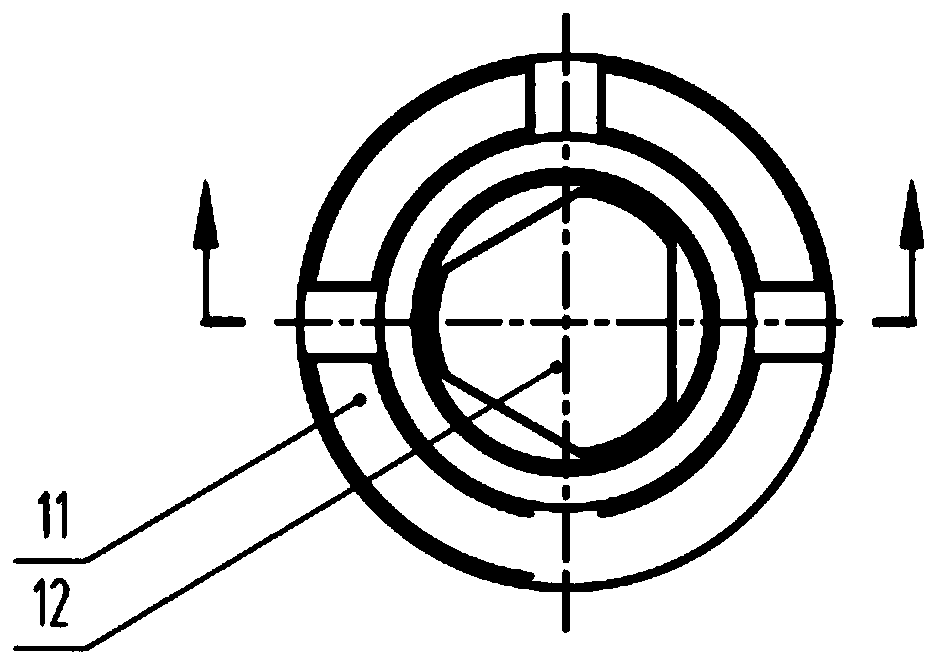

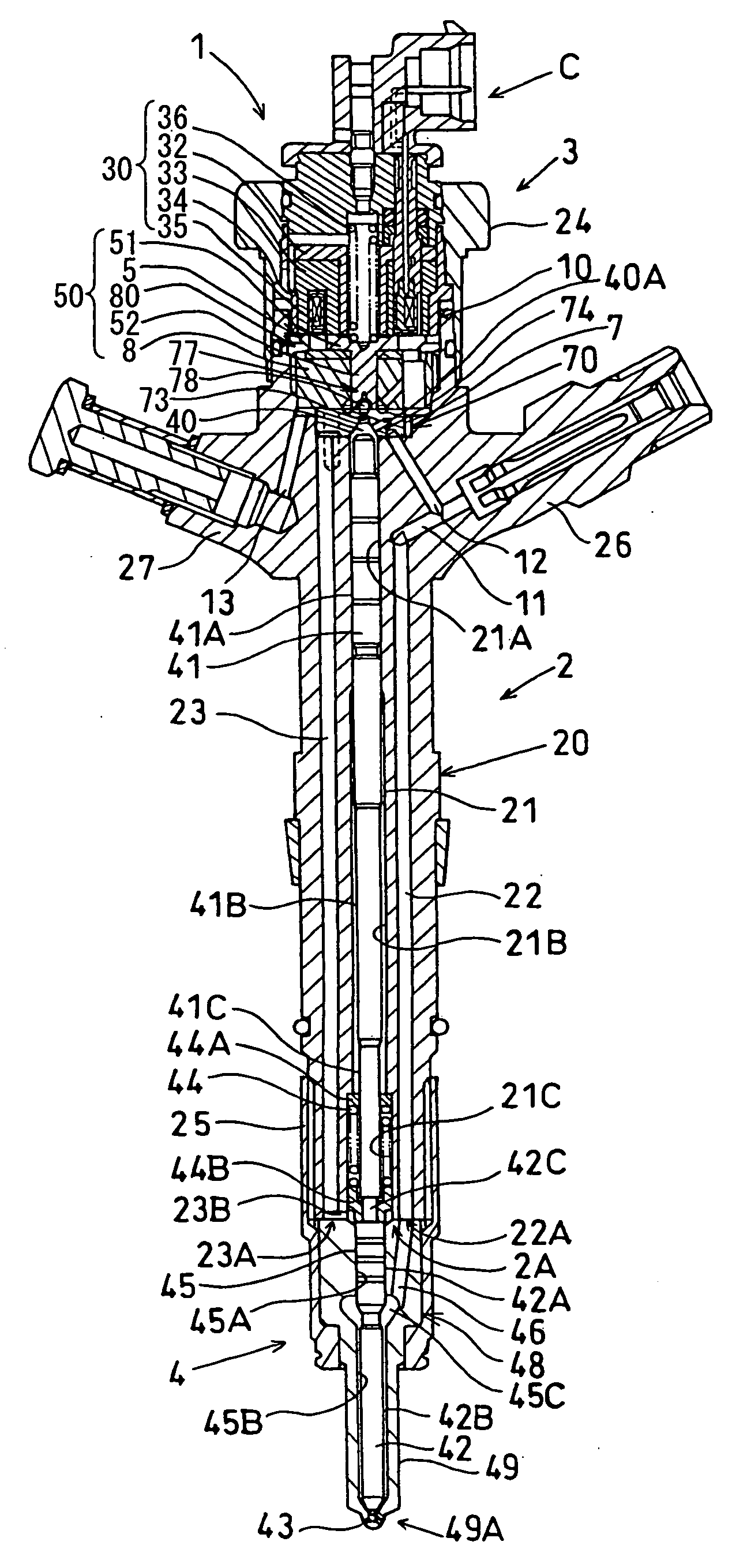

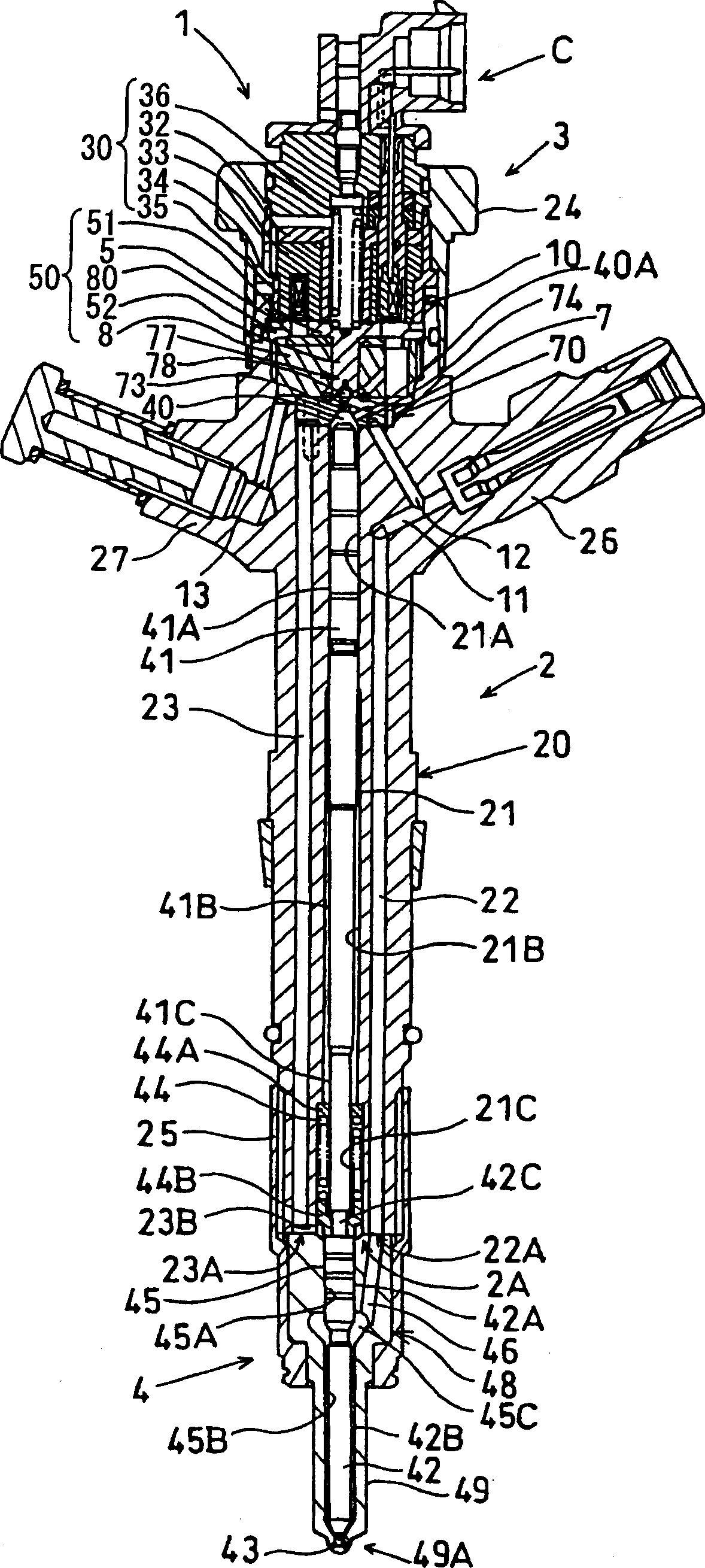

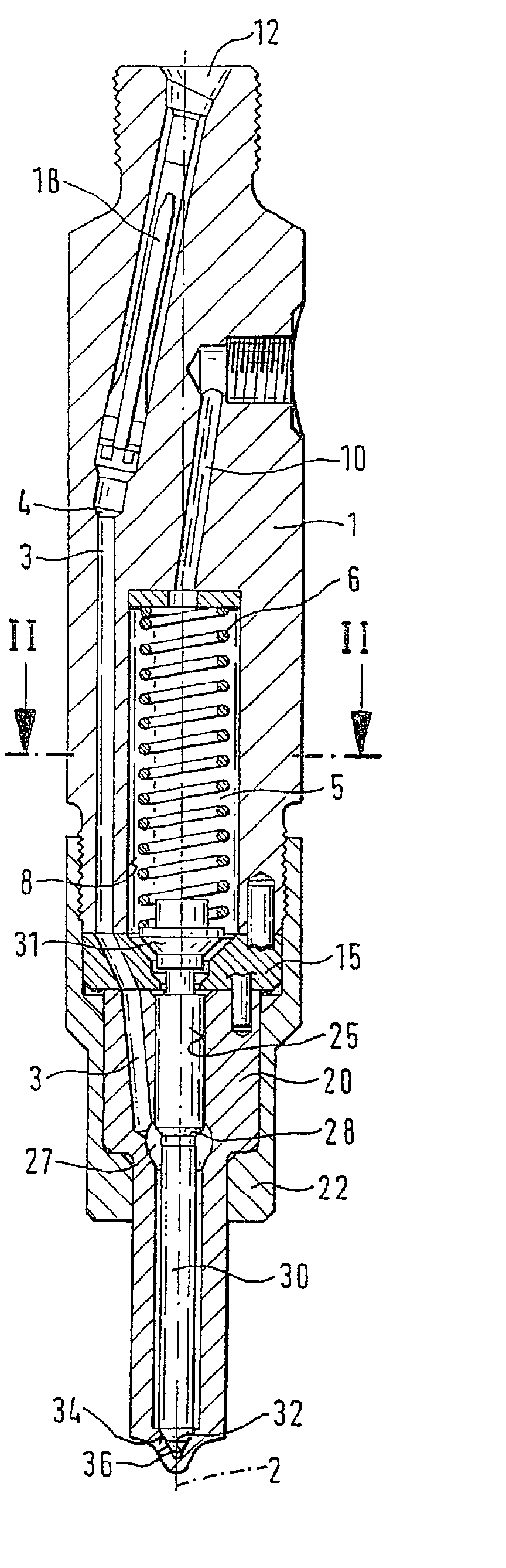

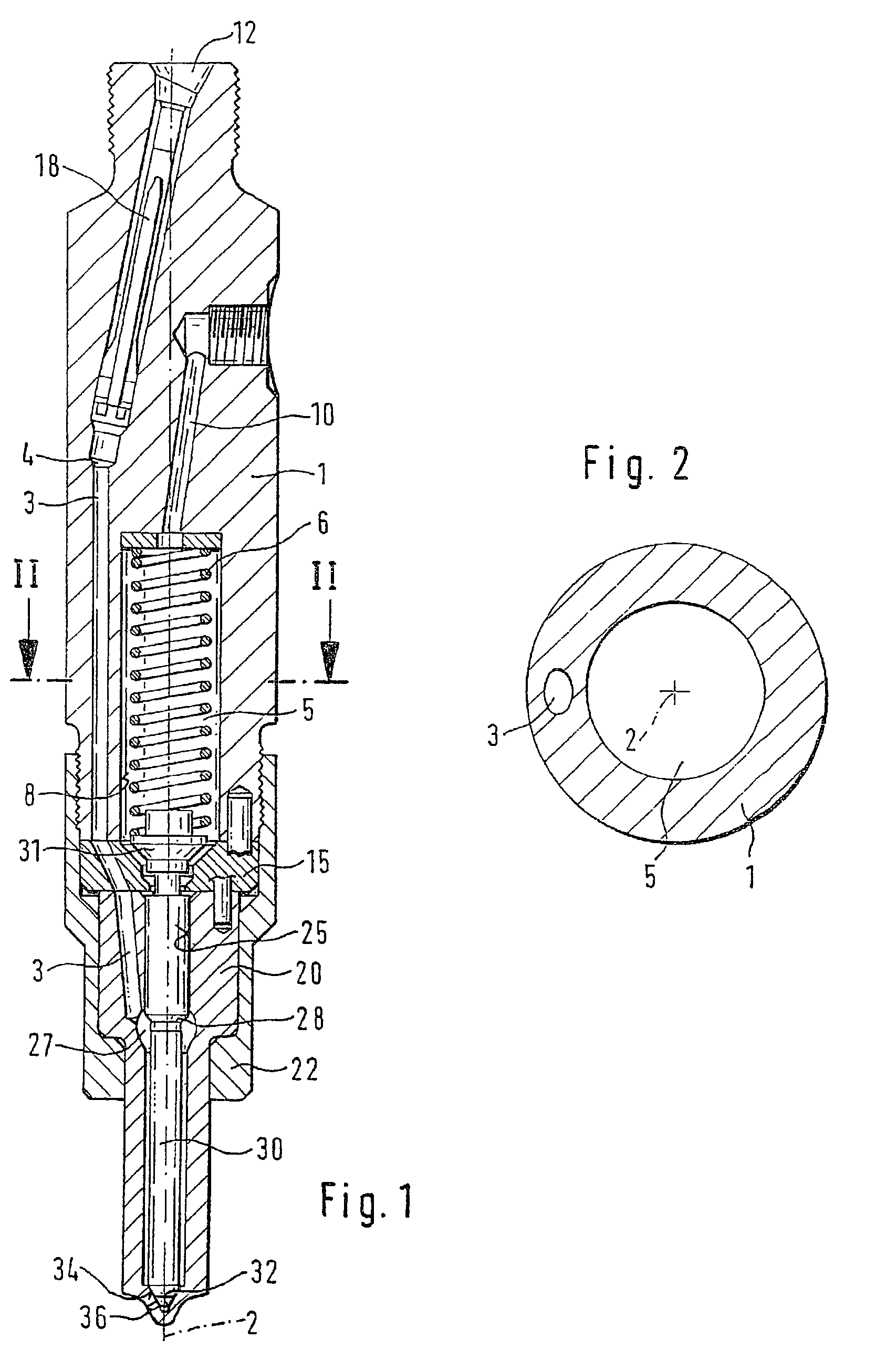

Fuel injection valve for internal combustion engines, and a method for producing same

InactiveUS20030071145A1Reduce the cross-sectional areaIncrease fuel pressureSpray nozzlesMachines/enginesCombustionInternal combustion engine

A fuel injection valve having a valve retaining body (1), which has a longitudinal axis (2) and in which a central spring chamber (5) is embodied. In this spring chamber (5), a closing spring (6) is disposed, which transmits a closing force to a valve member (30), which valve member (30) cooperates with a valve seat (32) for controlling at least one injection opening (36). In the wall of the spring chamber (5), an inlet conduit (3) extends parallel to the longitudinal axis (2) of the valve retaining body (1), and by way of this conduit, fuel at high pressure can be delivered to the at least one injection opening (36). The cross section of the inlet conduit (3) has a greater length in the circumferential direction than in the radial direction, so that the wall region between the inlet conduit (3) and the spring chamber (5), or the outer jacket face of the valve retaining body (1), is larger than in the case of an inlet conduit (3) with the same size of cross-sectional area and a circular cross-sectional contour (FIG. 1).

Owner:ROBERT BOSCH GMBH

Engine assembly including fuel system with fuel line connector

A fuel line may include a hollow elongate body having a first end and a second end. A first sealing member located on the first end of the hollow elongate body may have a monolithic construction and include a base region and a sealing region. The base region may have a first material hardness and the sealing region may have a second material hardness, the second material hardness being less than the first material hardness. A first connector may be coupled with the elongate body and the first connector and the first sealing member may be configured to sealingly connect to a fuel injector.

Owner:GM GLOBAL TECH OPERATIONS LLC

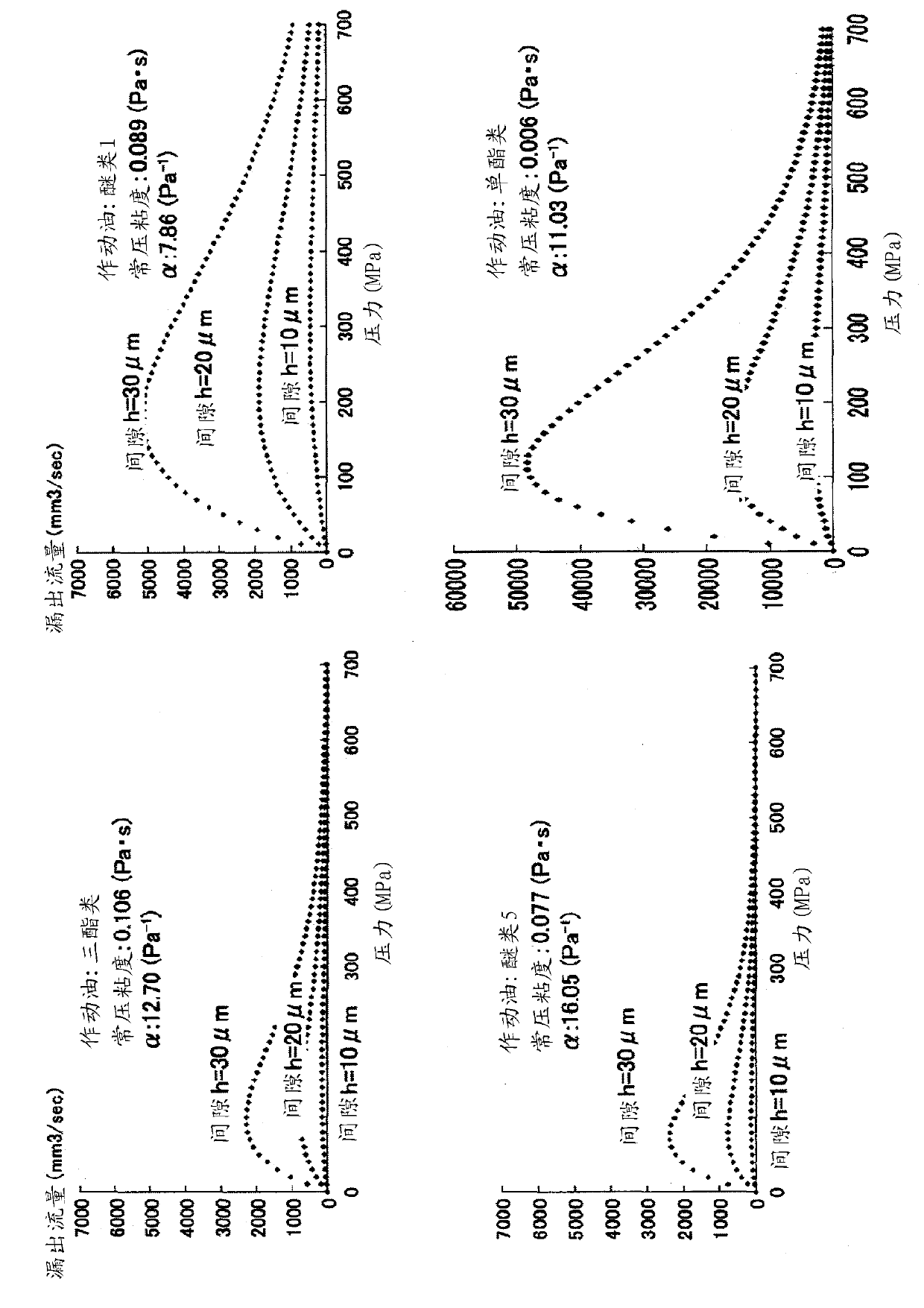

Autofrettage machining device

InactiveCN103958085AFast feedingMachines/enginesStress reducing fuel injectionCountermeasureEngineering

Provided is a solution to various limitations caused by product shape and the like. An autofrettage machining device characterized in comprising: a workpiece that is sealed off except for the workpiece end opening and in which a pressurized chamber is filled with a hydraulic oil via the workpiece end opening; a jig capable of being attached and detached from the workpiece, having an internal direct flow channel, and in which the direct flow channel is in communication without leakage with the workpiece end opening via a seal part; a piston for forming a gap having a predetermined average gap size with the inner wall of the direct flow channel provided inside the jig; and a pressurizing unit for driving the piston.

Owner:DENSO CORP

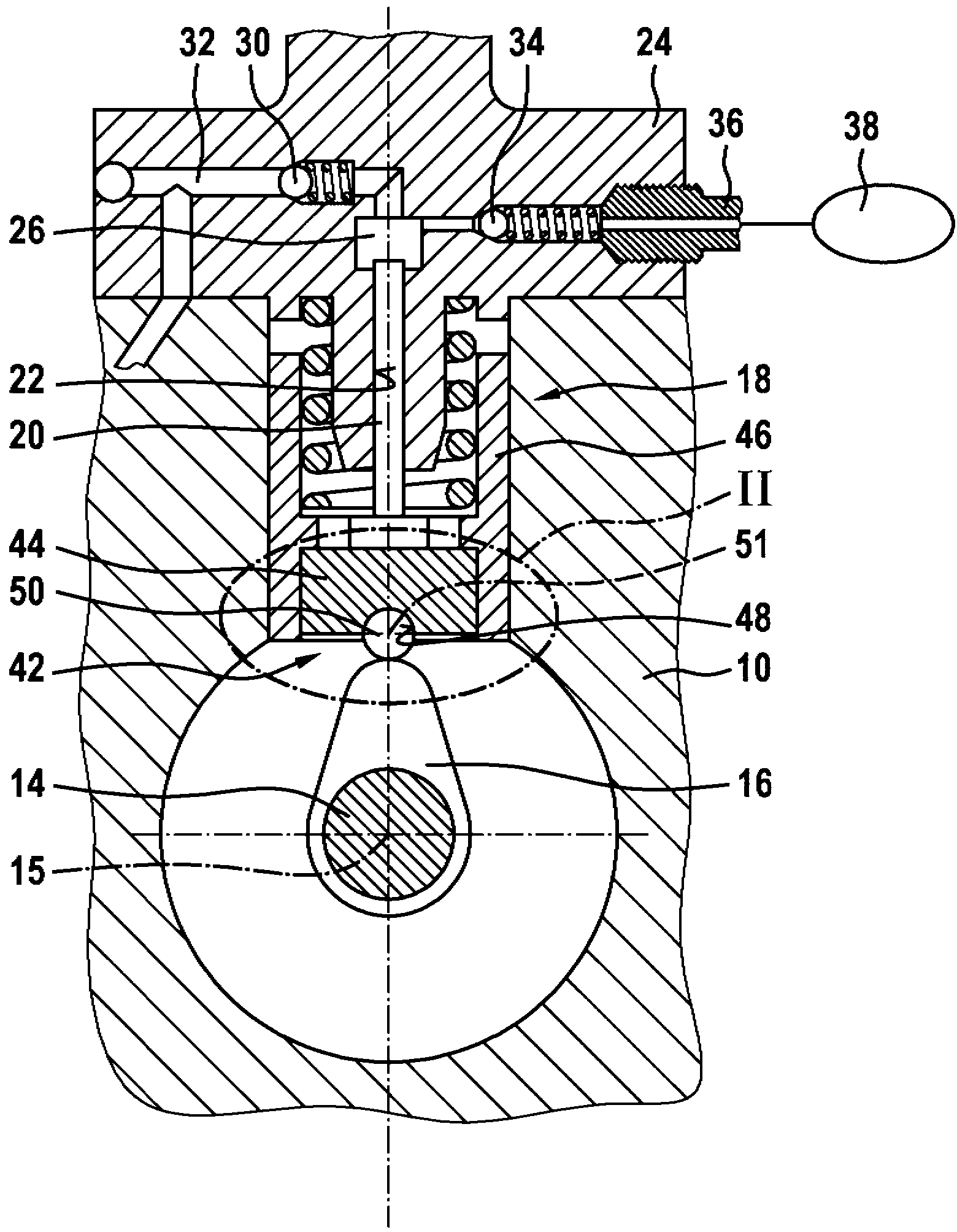

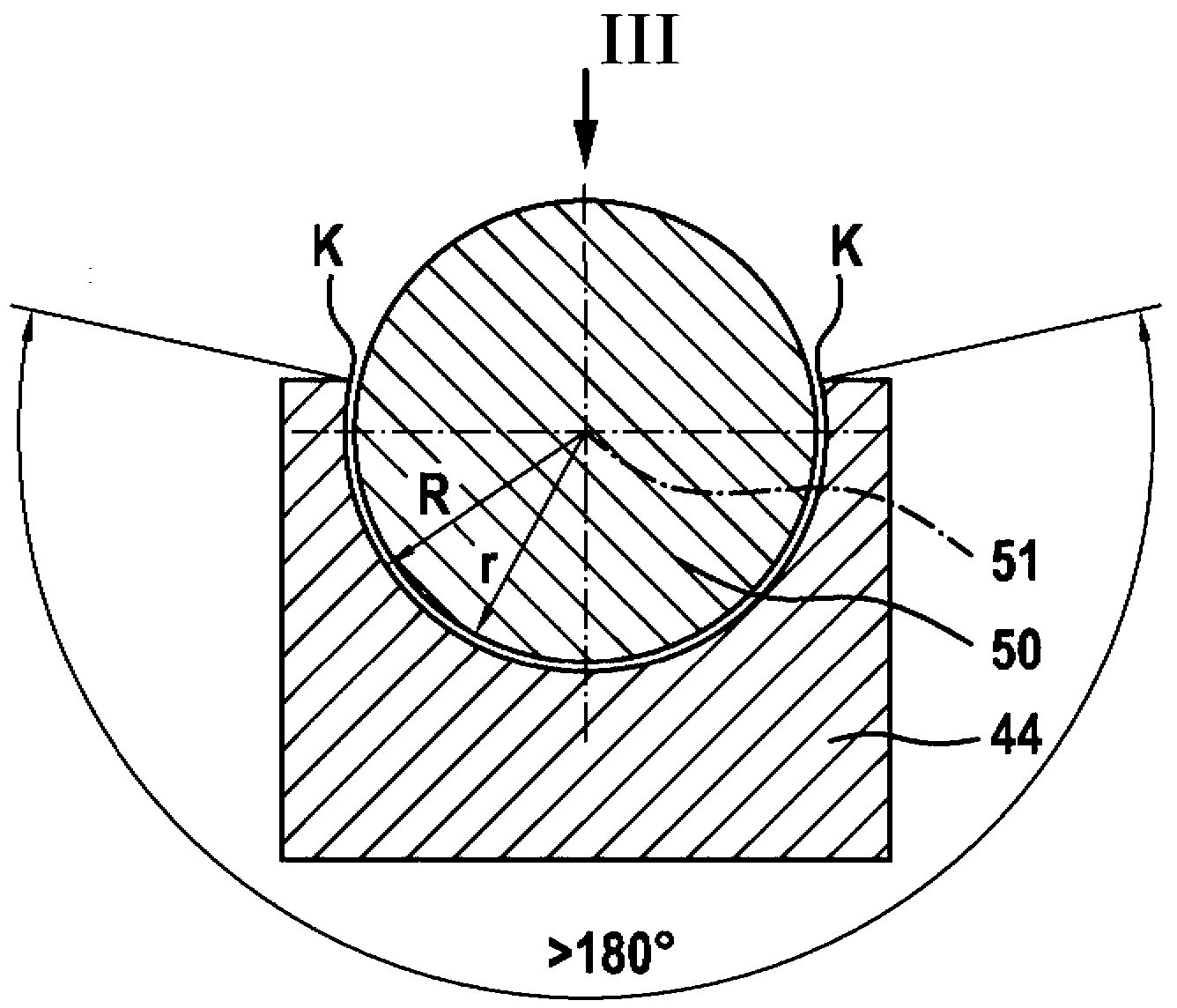

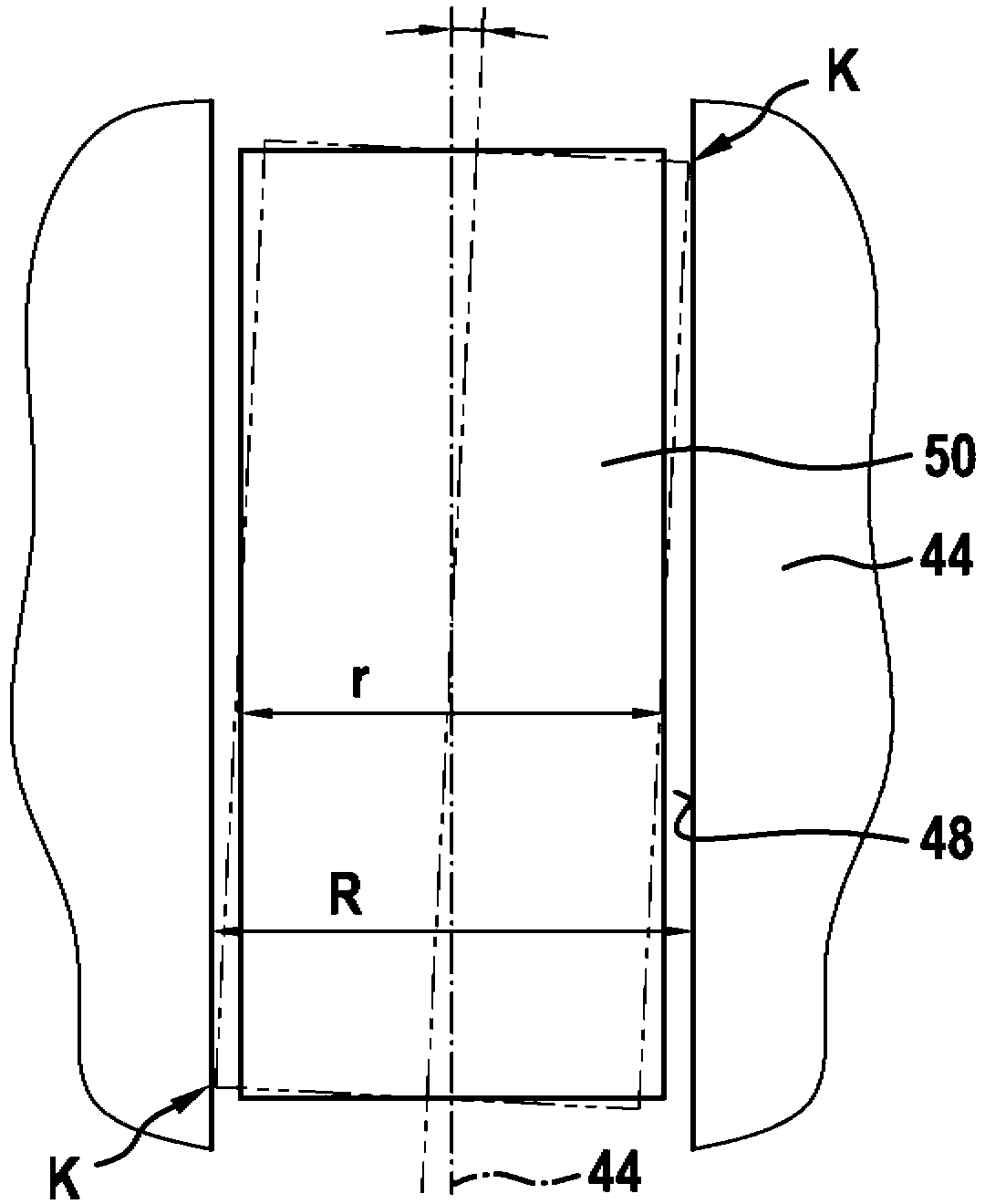

Bearing element having a roller rotatably mounted therein, in particular in the drive of a pump piston of a high-pressure fuel pump

ActiveCN103154495ANo risk of jammingEasy inflowValve arrangementsCam-followersEngineeringHigh pressure

The invention relates to a bearing element having a roller rotatably mounted therein, in particular in a drive of a pump piston of a high-pressure fuel pump, wherein the bearing element (44) comprises a concavely curved recess (48) in which the at least approximately circular cylindrical roller (50) is rotatably mounted. The recess (48) is curved at least in a central area (148) at least approximately as a circular segment in cross section perpendicular to the axis of rotation (51) of the roller (50), and the radius (R) thereof is equal to or only slightly greater than the radius (r) of the roller (50). The recess (48) extends over an angle range of more than 180 DEG around the circumference of the roller (50). The central area (148) of the recess (48) extends over an angle range of no greater than about 180 DEG about the circumference of the roller (50) and the recess (48) comprises edge areas (248, 348) adjacent to the central area (148) in the circumferential direction, in which the recess (48) runs, having a greater radial distance from the roller (50) than in the central area (148).

Owner:ROBERT BOSCH GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com