Plunger

A technology of push rod and shell, applied in the field of push rod, can solve problems such as change, and achieve the effect of simple modeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

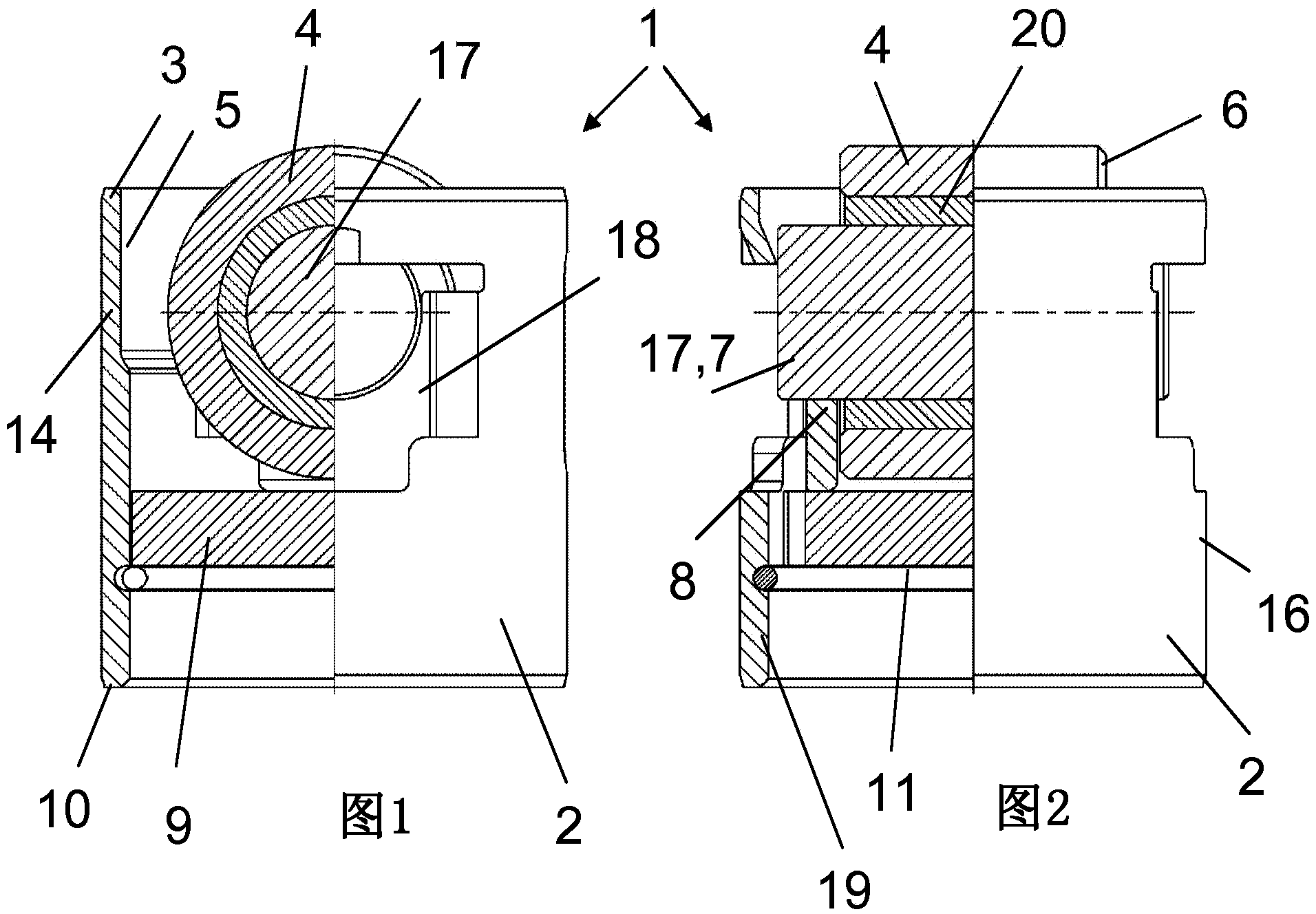

[0018] The shown pushrod 1 is used here for a high-pressure pump of diesel fuel for an internal combustion engine. The push rod 1 has a tube-like housing 2 which accommodates a roller 4 for actuating a lifting cam within an inner side 5 of the housing in the region of a first upper annular end edge 3 .

[0019] Axially below the rollers 4 , the housing 2 , here deep-drawn from sheet steel, is traversed by a separate bridge 9 . The bridge is a punched plate, the underside 11 of which faces the lower second annular end edge 10 of the housing 2 and serves as an abutment for the pump piston.

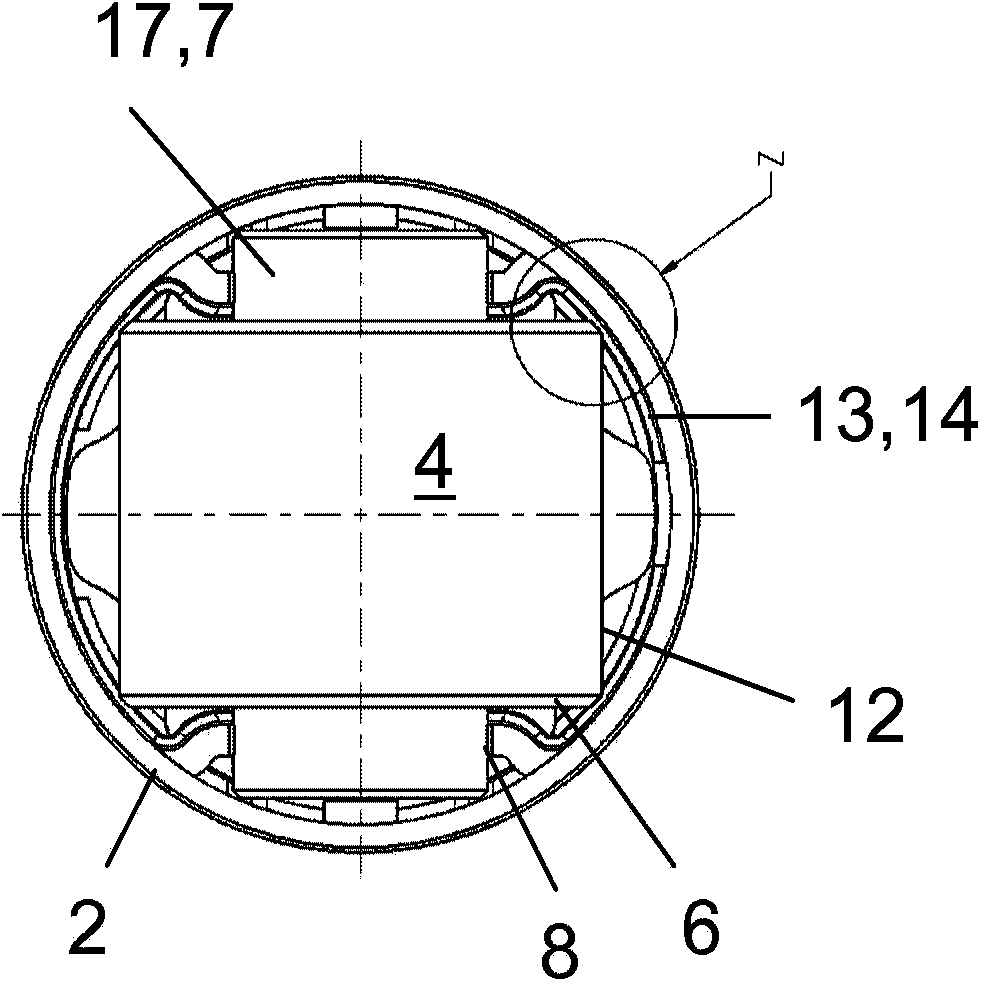

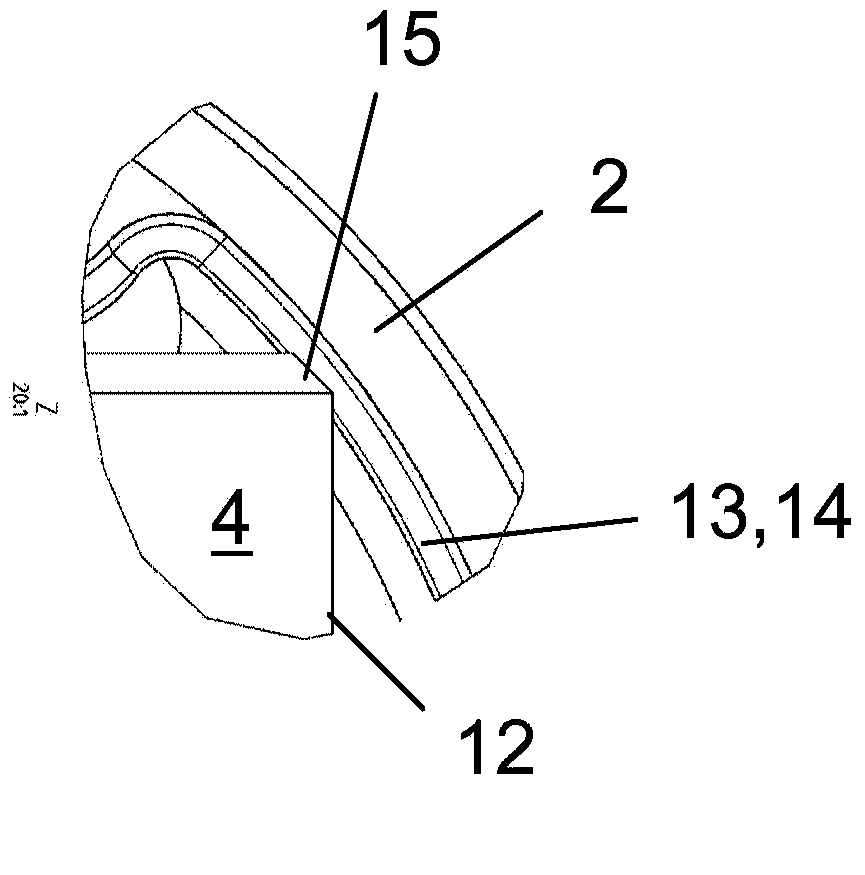

[0020] As shown, the rollers 4 run on pins 17 via rolling bearings 20 . The pins 17 are accommodated with each end (referred to here as the shaft end 7 ) in a part-cylindrical receptacle 8 of the respectively retracted region 18 of the housing 2 , which is designed as a flat part.

[0021] The inner side 5 of the housing 2 has a pocket-shaped material constriction. This material constrict...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com