Pump

A high-pressure pump and piston technology, applied in the field of high-pressure pumps, can solve problems such as noise and reduced service life of high-pressure pumps, and achieve the effects of reducing impact, simplifying configuration, and reducing adverse consequences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

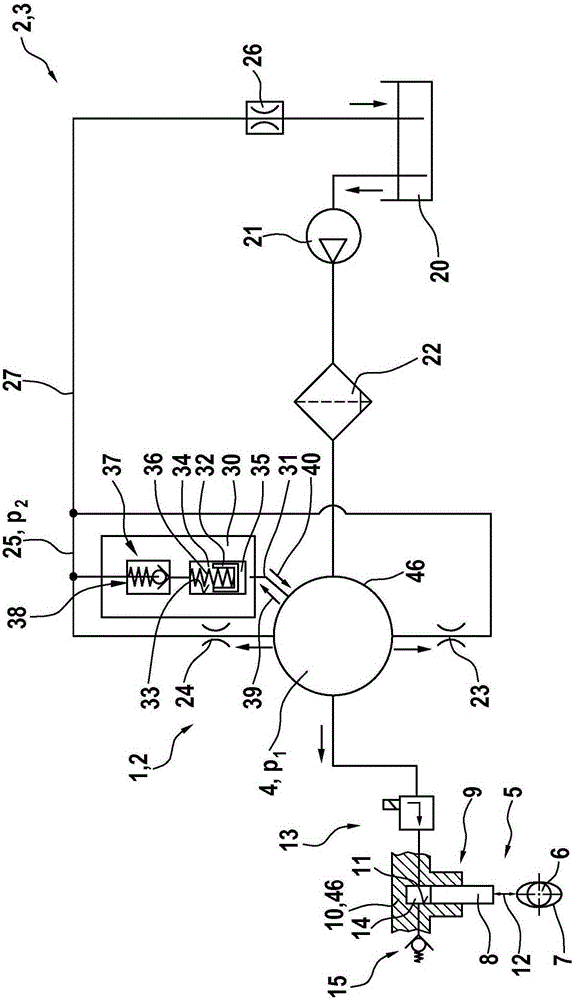

[0026] figure 1 According to a first exemplary embodiment, a high-pressure pump 1 of a fuel injection system 2 with a low-pressure circuit 3 is shown in a schematic illustration. The high-pressure pump 1 can be used in particular for air-compressed self-igniting internal combustion engines or hybrid-compression externally ignited internal combustion engines. Furthermore, the high-pressure pump 1 can also be configured as a hydraulic pump for other hydraulic applications.

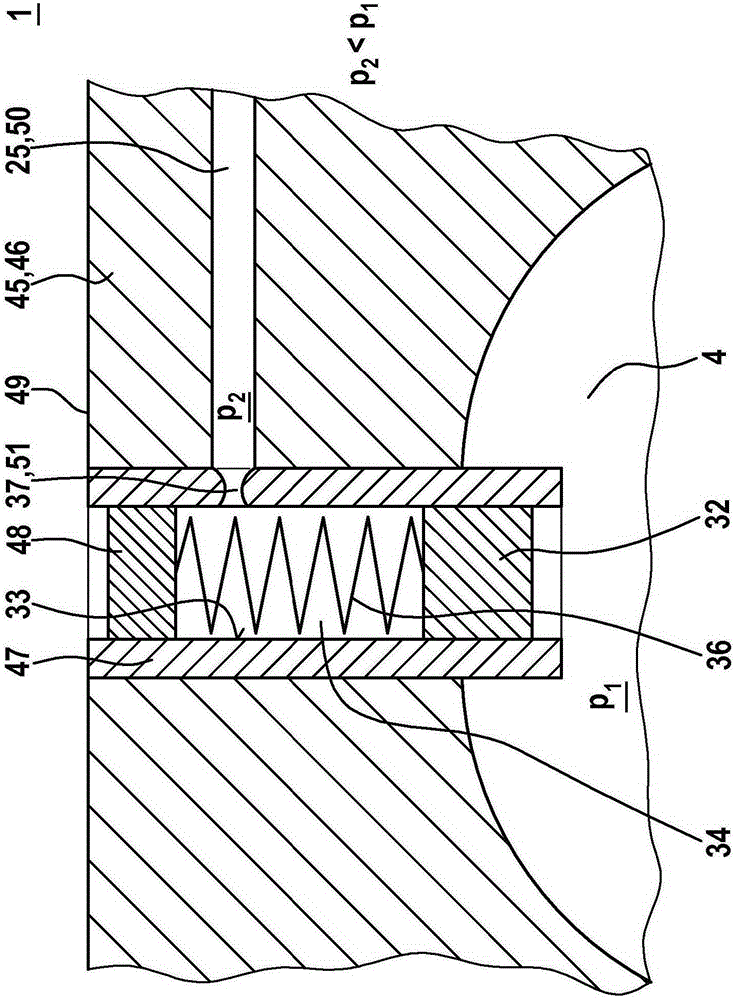

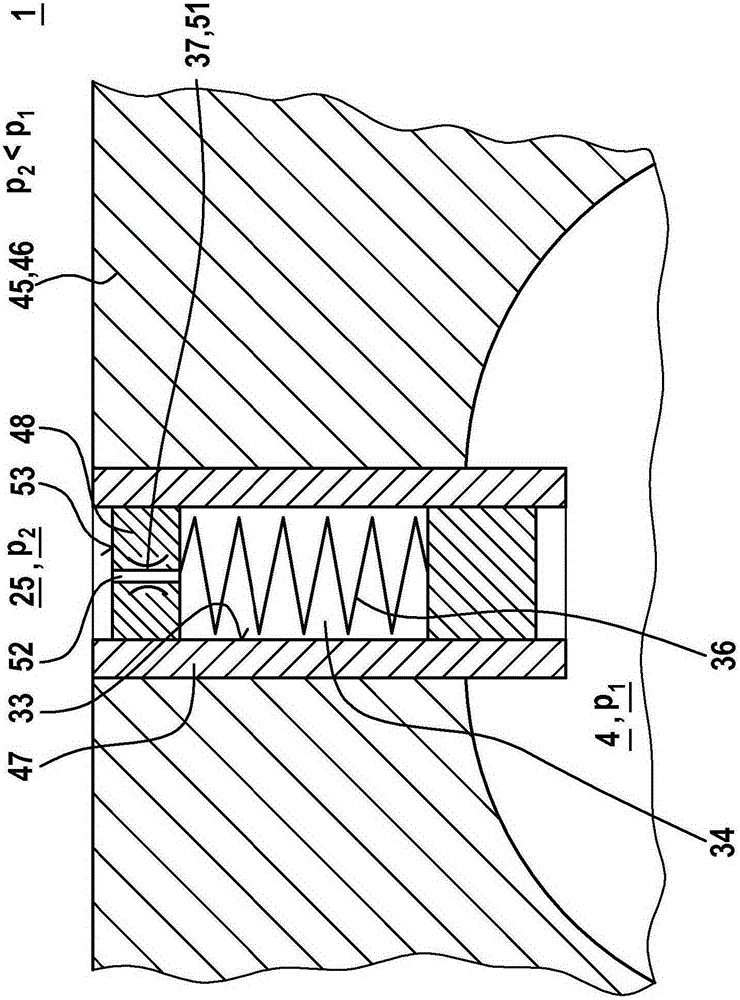

[0027] The high-pressure pump 1 has a low-pressure chamber 4 and a drive 5 . During operation, pressure pulses are generated in the low-pressure chamber 4 by the drive 5 . In this exemplary embodiment, the low-pressure chamber 4 is formed by a drive mechanism chamber in which the shaft 6 with a plurality of cams 7 is at least partially arranged. A plurality of cams 7 of the shaft 6 serve to drive a pump piston 8 of a pump assembly 9 of the high-pressure pump 1 . Here, a section of a cylinder head 10 is s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com