Fuel injector reducing stress concentration

A technology of fuel injectors and injectors, applied in the direction of fuel injection devices with stress-reducing measures, fuel injection devices, special fuel injection devices, etc., capable of solving problems such as high-pressure fuel leakage, separation of nozzle bodies, and complex structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

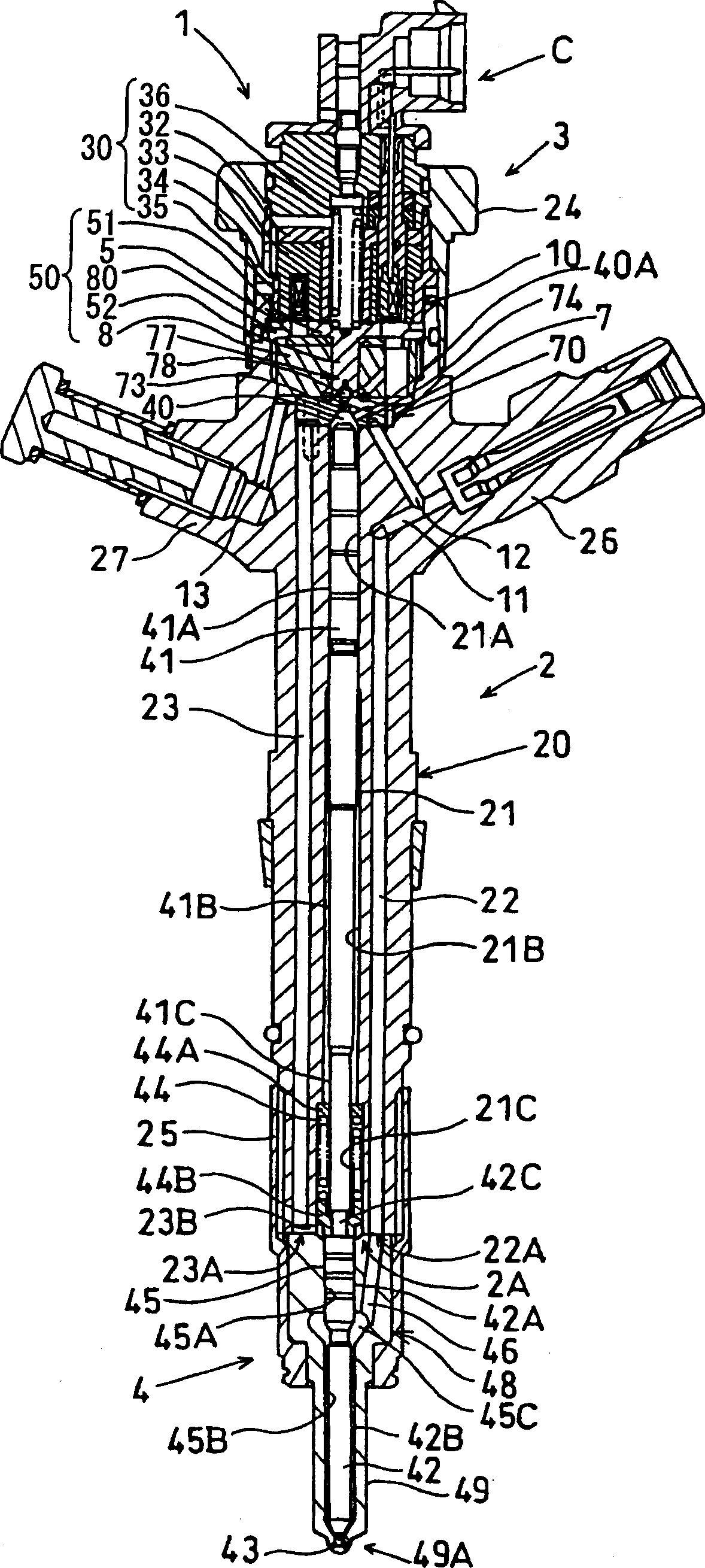

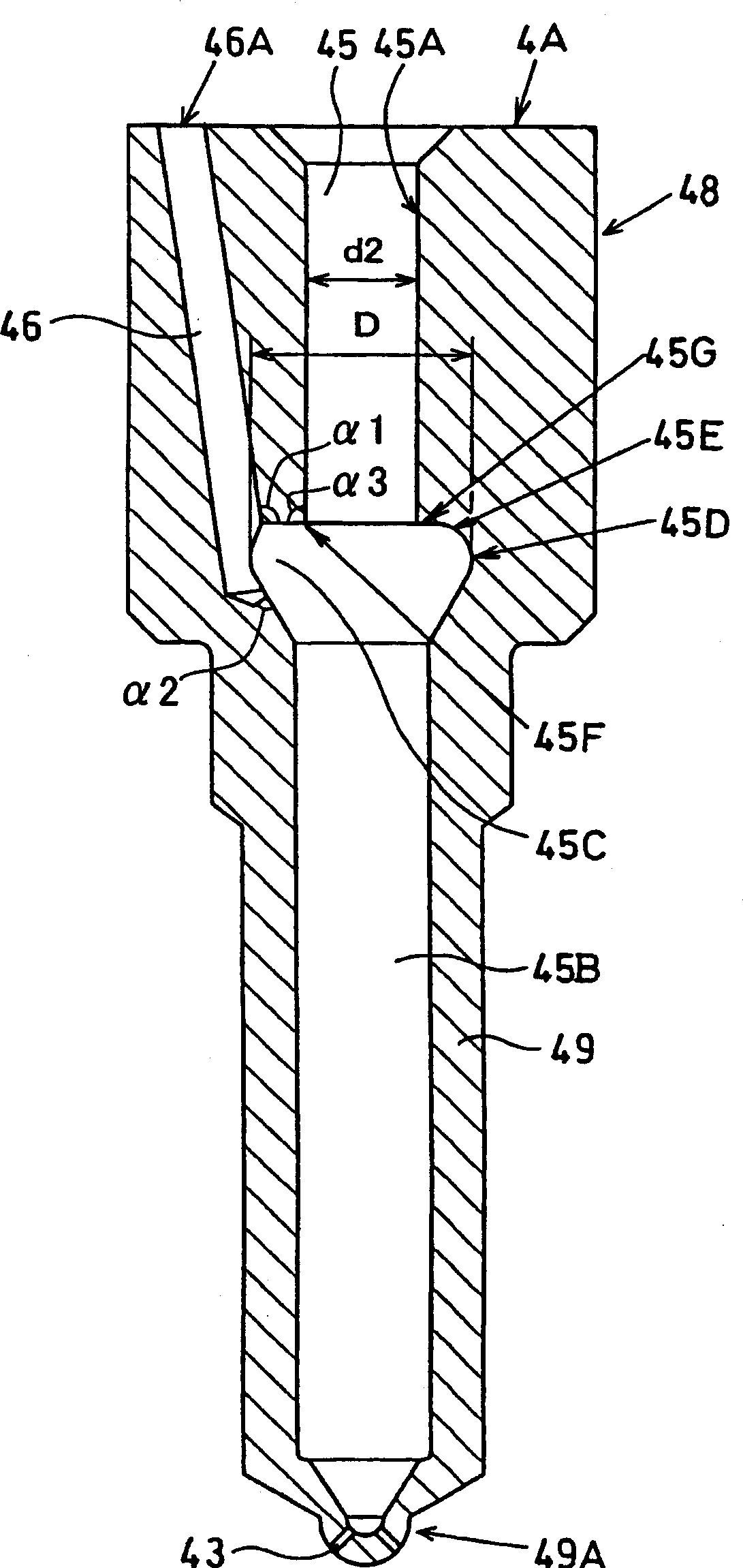

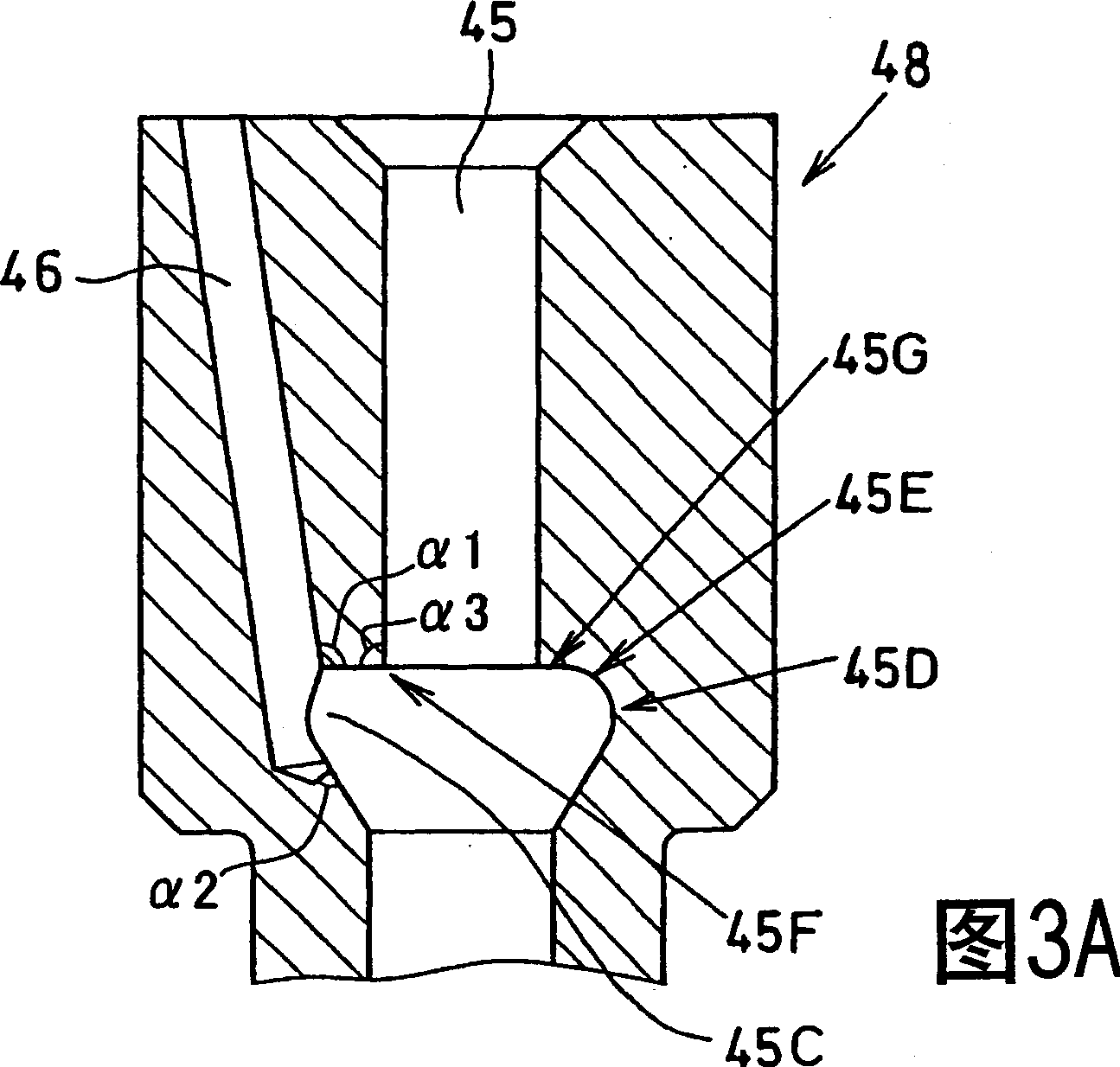

[0029] refer to figure 1 , which shows an electromagnetically controlled fuel injector (such as a piezoelectric fuel injector) 1 that intermittently injects fuel into the combustion chamber of the engine. The fuel injector 1 is used in an accumulator type (common rail type) fuel injection device of a diesel engine, and injects high-pressure fuel from a common rail (not shown) into a combustion chamber of the engine. The injector 1 has an injector body 2 , a solenoid valve 3 mounted on an upper end side of the injector body 2 , and a fuel injection nozzle 4 fixed to a lower end side of the injector body 2 .

[0030]The solenoid valve 3 has a connector C connected to a wire harness extending from an engine control unit (ECU) (not shown). The solenoid valve 3 is controlled by a control signal output from the ECU.

[0031] The injector body 2 has a valve body 20 formed in a rod shape. The valve body 20 is formed with a barrel 21 passing through the axial center, and a high-pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com