Bearing element having a roller rotatably mounted therein, in particular in the drive of a pump piston of a high-pressure fuel pump

A rotary ground, pump-piston technology, used in fuel injection pumps, engine components, components with teeth, etc., can solve the problems of fuel high-pressure pump failure, bearing component roller wear and other problems, and achieve the effect of small wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

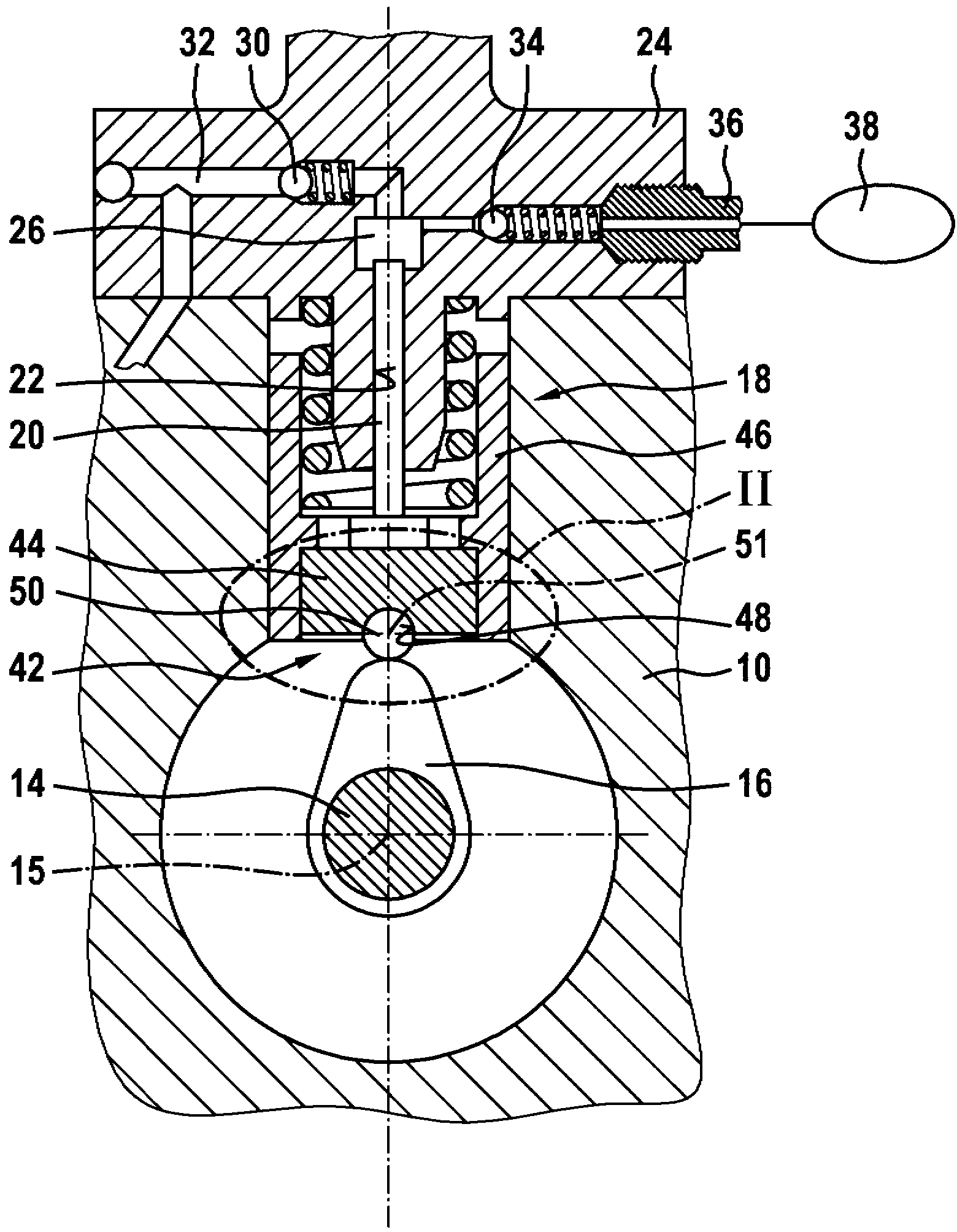

[0011] exist figure 1 shows a pump, which is in particular a high-pressure fuel pump for a fuel injection system of an internal combustion engine. The pump has a housing 10 which can be constructed in multiple parts and in which a rotatably driven drive shaft 14 is mounted rotatably about an axis of rotation 15 . The drive shaft 14 has at least one cam 16 , which can also be multiple cams. The pump has at least one or more pump elements 18 , each having a pump piston 20 , which is at least indirectly moved in a reciprocating linear motion by means of a cam 16 of the drive shaft 14 at least approximately radially with respect to the axis of rotation 15 of the drive shaft 14 . driven in the direction. It can also be provided that the pump does not have its own drive shaft 14 and that the pump piston 20 of the pump element 18 is driven via the shaft of the internal combustion engine with the cam 16 or the eccentric.

[0012] The pump piston 20 is tightly guided in a cylinder b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com