Wind generating set blade inner reinforcing preparation method and wind generating set blade

A technology in wind turbines and blades, used in household components, household appliances, other household appliances, etc., can solve the problems of low production efficiency, low production efficiency, inconvenient curing methods, etc., to improve product quality and production efficiency, Improve curing efficiency and curing effect, eliminate the effect of long mold time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

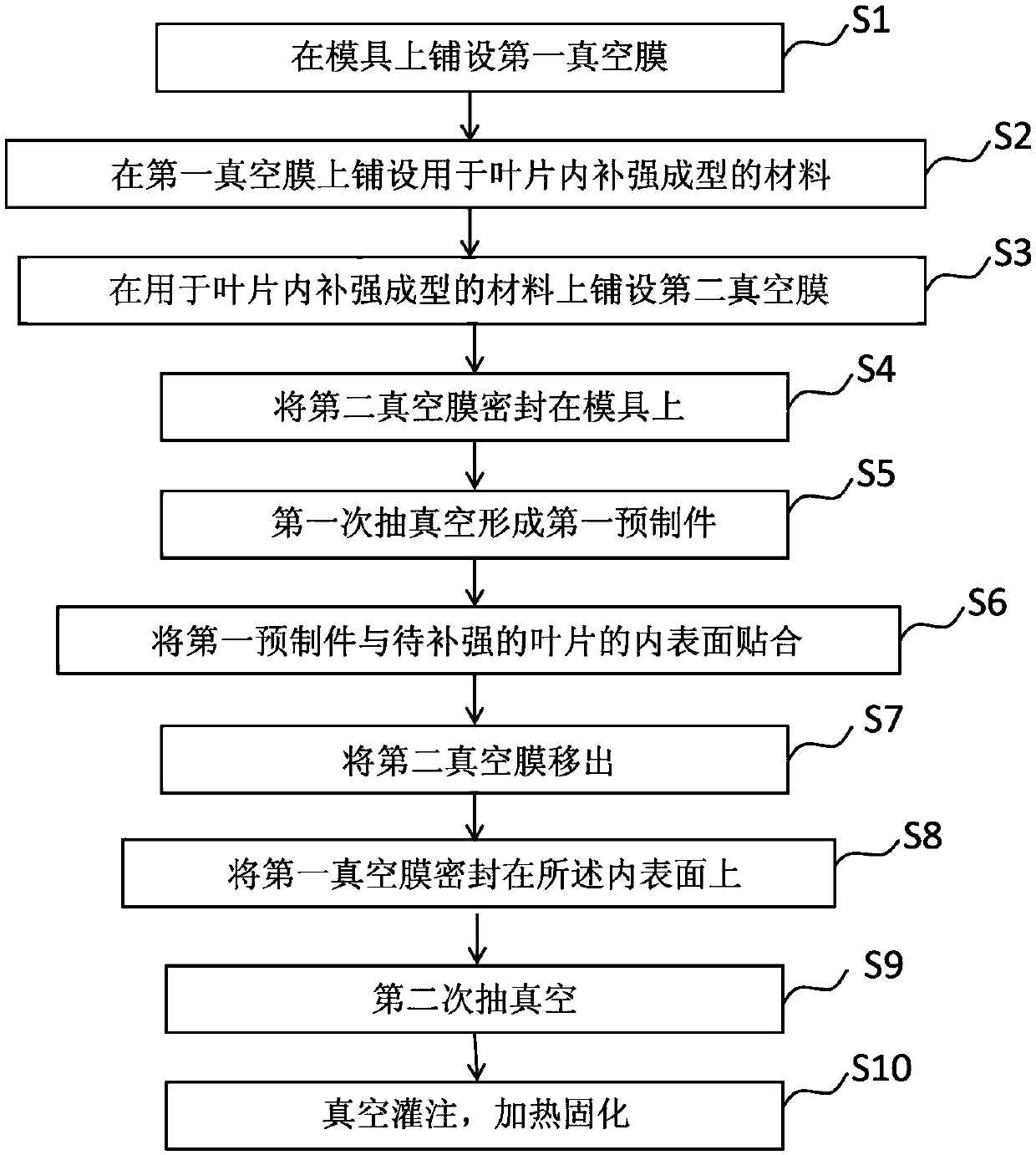

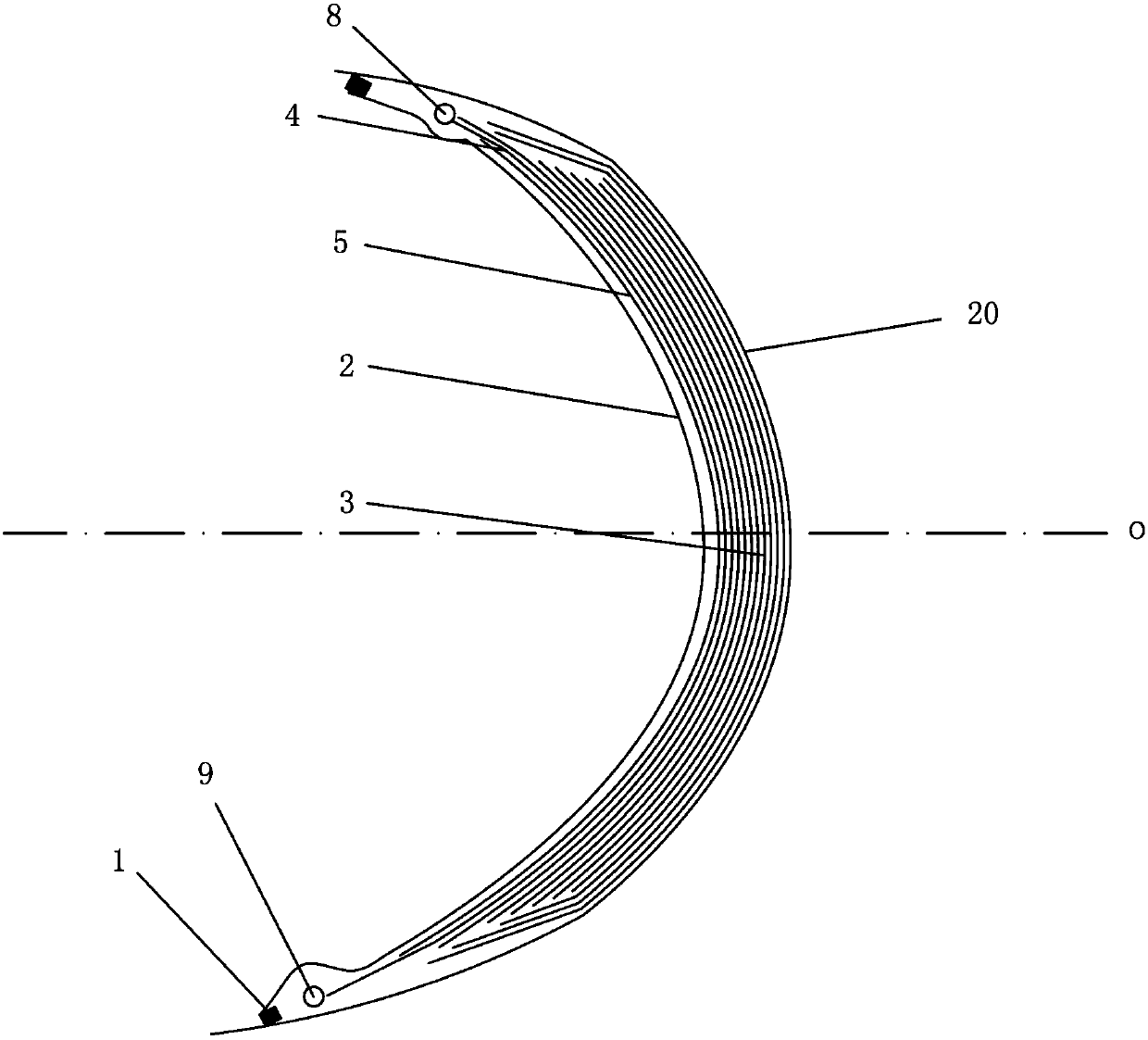

[0024] Embodiments of the present invention will now be described more fully with reference to the accompanying drawings, in which exemplary embodiments of the invention are shown. The following will combine Figure 1 to Figure 3 A method for preparing internal reinforcement of a blade of a wind power generating set according to an exemplary embodiment of the present invention is described in detail. The method for preparing internal reinforcement of a blade of a wind power generating set described in the present invention according to an exemplary embodiment of the present invention can be used to prepare internal reinforcement suitable for the leading edge and / or trailing edge of the blade.

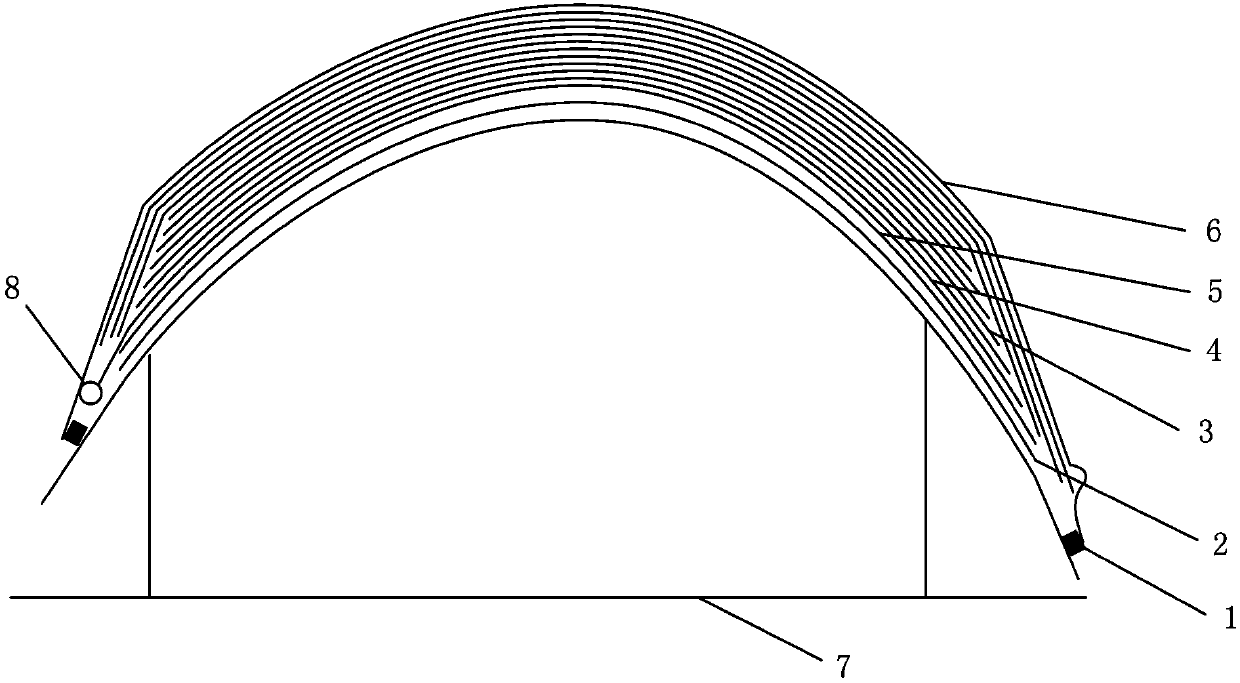

[0025] In step S1 , the first vacuum film 2 is laid on the mold 7 . Here, the mold 7 can be referred to as a pre-laid mold, and the mold 7 has a shape corresponding to the shape of the inner surface 20 of the blade to be reinforced, and has a smooth transition, so that the reinforced p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com