Connector pin and production process thereof

A production process and connector technology, applied in the direction of vehicle connectors, connections, fixed connections, etc., can solve problems such as low production efficiency of pins, reduction of overall quality of pins, collapse angles and burrs, etc., to solve the problems of collapse angles and burrs Phenomena, elimination of serious defects, and the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention is further described below in conjunction with accompanying drawing and embodiment:

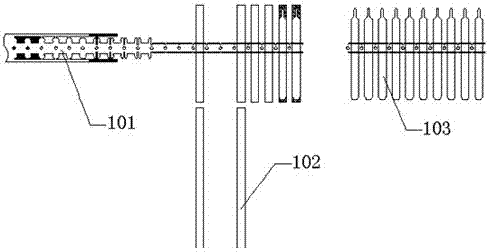

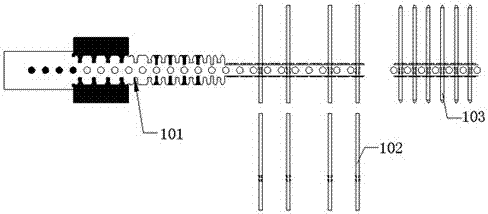

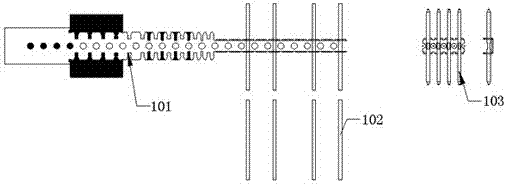

[0030] Such as Figure 1-3 As shown, a connector pin includes a strip 101 and a pin 102. The strip 101 includes a plate and a U-shaped clip formed on the plate. The U-shaped clip is formed by punching and cutting. The pin 102 is embedded in the clip to form a machine pin body 103 . The head of the pin 102 is chamfered in various shapes, and the chamfer connection makes the head form a pointed shape, and the tail of the pin 102 is provided with the required shape of the lower PCB board.

[0031] The pin 102 is a round pin with a circular cross section, or the pin 102 is a square pin with a square cross section, or the pin 102 is a flat pin with a rectangular cross section, and both the pin and the flat pin are extruded from a round pin.

[0032] Such as Figure 4-5 As shown, a production process of a connector pin is characterized in that it comprises the follow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com