Manufacturing method of LED aluminum substrate V-shaped groove

A technology of an LED aluminum substrate and a manufacturing method, applied in the field of PCB manufacturing, can solve problems such as inability to repair quality defects, inability to make V-shaped grooves, etc., achieving the effects of easy implementation, low cost, and solving burr problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] In order to facilitate the understanding of those skilled in the art, the present invention will be further described in detail below with reference to the drawings and embodiments.

[0010] The whole process of the method for processing the V-groove of the aluminum substrate disclosed by the present invention is as follows: surface treatment of the aluminum substrate→covering the blue glue→shaping→V-CUT cutting→removing the blue glue→cleaning and washing.

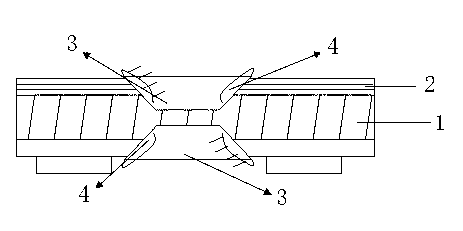

[0011] Before covering the blue glue, polish the aluminum surface of the aluminum substrate with a needle brush grinder to enhance the bonding force between the aluminum surface and the blue glue, and remove the debris on the aluminum surface, and then press on the surface of the aluminum substrate 1 blue gum 2, such as figure 1 shown. Pay attention to check the compaction of the blue glue after pressing, and there must be no air bubbles. The blue glue is a commonly used adhesive tape in the PCB industry. For exam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com