Processing method for improving drilling burrs

A processing method and burr technology, applied in the direction of electrical components, printed circuit manufacturing, printed circuits, etc., can solve the problems of high functional requirements of time-consuming equipment, reduce production efficiency, increase economic costs, etc., achieve high production efficiency, improve quality, The effect of removing burrs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

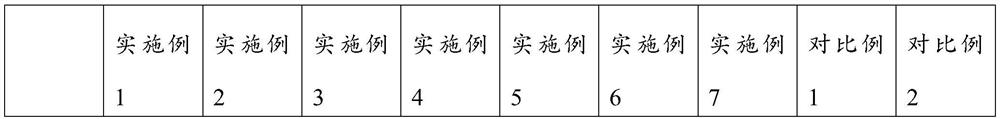

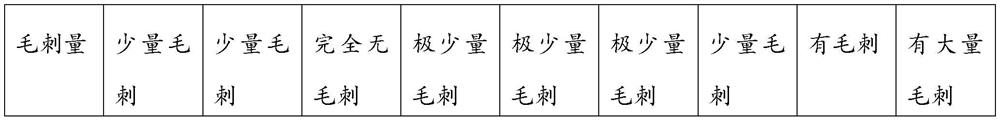

Embodiment 1

[0030] Embodiment 1: Improve the processing method of drilling burr

[0031] A processing method for improving drilling burrs, comprising the following steps:

[0032] Lay the PCB to be drilled flat, fix it, and then use a drill to drill the first hole and the second hole on the same position of the PCB; the diameter of the second drilled hole is 0.01mm larger than that of the first drilled hole ;The hole diameter of the first drilling is 1mm; keep the position of the PCB fixed during the first drilling and the second drilling.

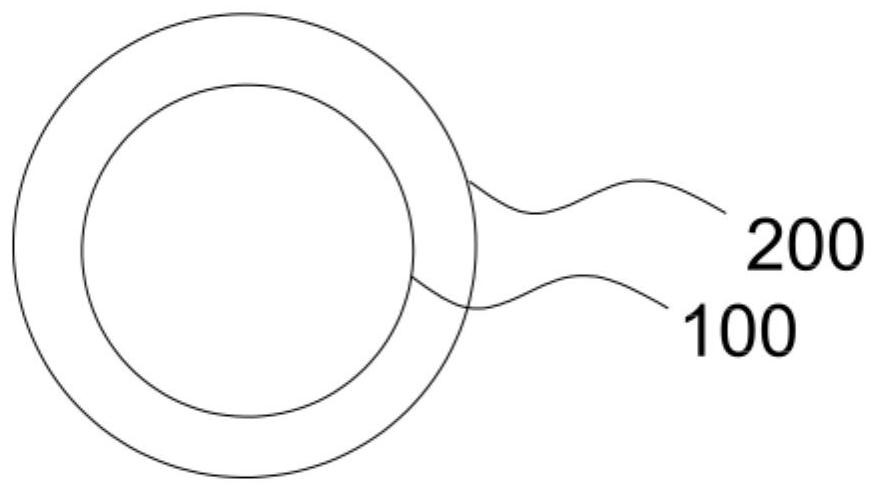

[0033] figure 1 It is the schematic diagram of the holes formed by drilling for the first time and drilling for the second time in embodiment 1, wherein, figure 1 100 in the figure represents the hole formed by the first drilling, and 200 represents the hole formed by the second drilling, and the diameter of the hole formed by the second drilling is larger than that of the hole formed by the first drilling.

Embodiment 2

[0034] Embodiment 2: Improve the processing method of drilling burr

[0035] A processing method for improving drilling burrs, comprising the following steps:

[0036] Lay the PCB to be drilled flat, fix it, and then use a drill to drill the first and second holes at the same position on the PCB; the diameter of the second drilled hole is 0.05mm larger than that of the first drilled hole ;The hole diameter of the first drilling is 2mm; keep the position of the PCB fixed during the first drilling and the second drilling.

Embodiment 3

[0037] Embodiment 3: the processing method of improving drilling burr

[0038] A processing method for improving drilling burrs, comprising the following steps:

[0039] Lay the PCB to be drilled flat, fix it, and then use a drill to drill the first hole and the second hole on the same position of the PCB; the diameter of the second drilled hole is 0.01mm larger than that of the first drilled hole ;The hole diameter of the first drilling is 1mm; keep the position of the PCB fixed during the first drilling and the second drilling.

[0040] During the second drilling process, the drilling fluid is coated on the surface of the drill bit; the composition of the drilling fluid includes: 12 parts of acrylic resin, 8 parts of fatty alcohol polyoxyethylene ether, 5 parts of sodium dodecylsulfonate, ten parts 10 parts of dialkyl sodium sulfate and 30 parts of alcohol; the preparation method of the drilling fluid is as follows: stirring and mixing the components; the stirring speed is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com