Abrasive flow machining device capable of cleaning sharp edges and burrs at annular grooves in deep holes

A processing device and abrasive flow technology, which is used in abrasive feeding devices, metal processing equipment, abrasives, etc., can solve the problem of inability to clean burrs in deep hole ring grooves, avoid deformation, improve processing quality, and eliminate difficulties. dead zone effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

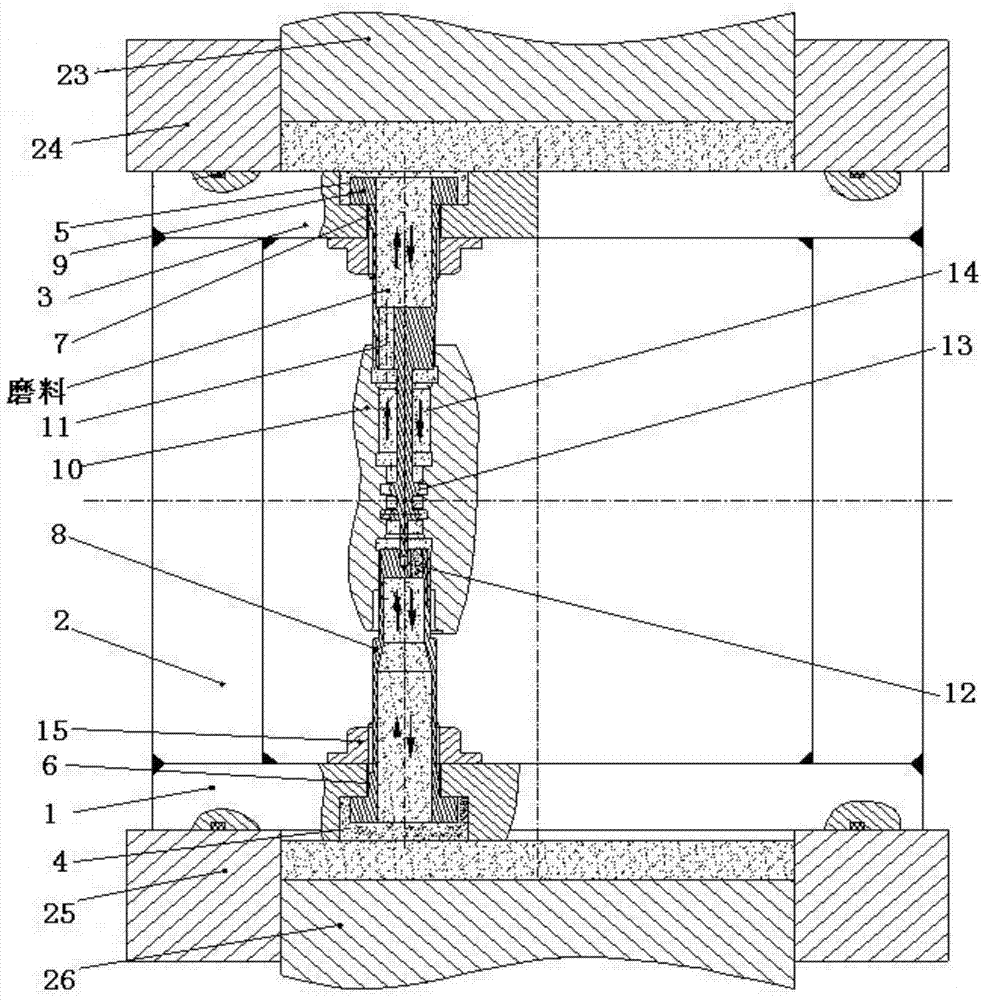

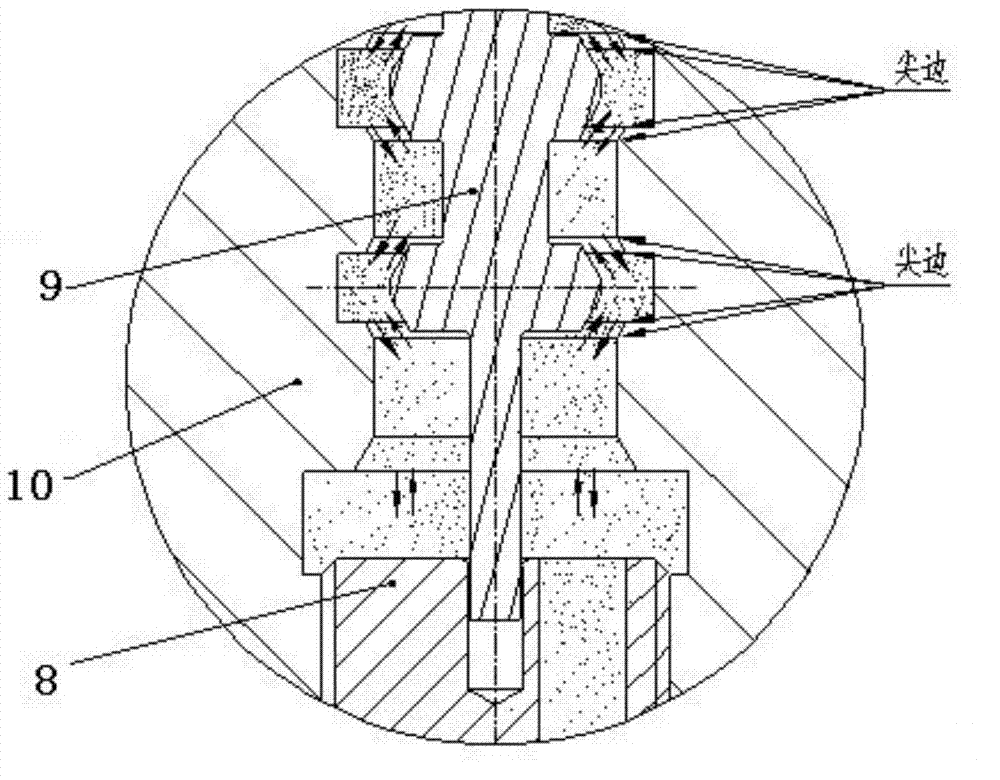

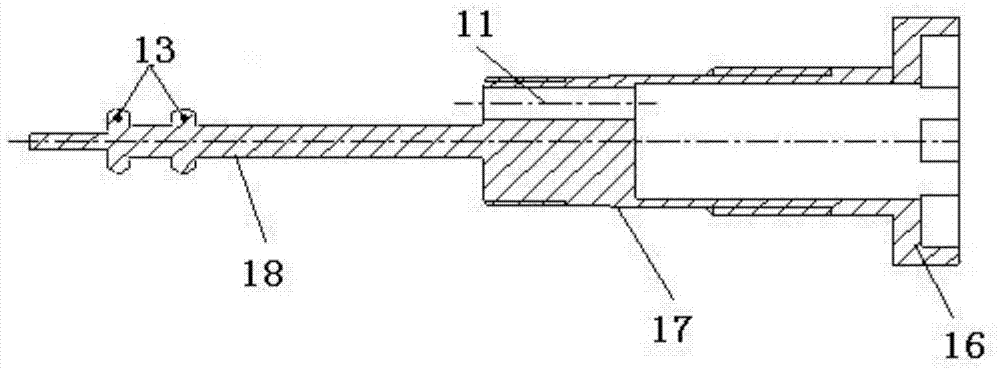

[0021] Example. A abrasive particle flow processing device for cleaning sharp edges and burrs at ring grooves of deep holes, which consists of Figure 1-4 As shown, it includes a frame support structure composed of a base plate 1, a support plate 2 and a cover plate 3. The base plate 1 and the cover plate 3 are respectively provided with a base plate counterbore 4 and a cover plate counterbore 5 arranged outwardly, and the base plate sinks The center of the hole 4 and the cover plate sink hole 5 is respectively provided with a base plate through hole 6 and a cover plate through hole 7, and the bottom plate sink hole 4 is reversed with a pipe joint 8 passing through the base plate through hole 6, and the cover plate sinks In the hole 5, there is a guide rod 9 that passes through the through hole 7 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com