Method for eliminating bottom through-hole burr of processed deep cylindrical work pieces and dedicated male die therefor

A technology of deep cylindrical parts and punches, applied in the field of stamping processing, to achieve the effects of reducing the deburring process after machining, low manufacturing cost and easy implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

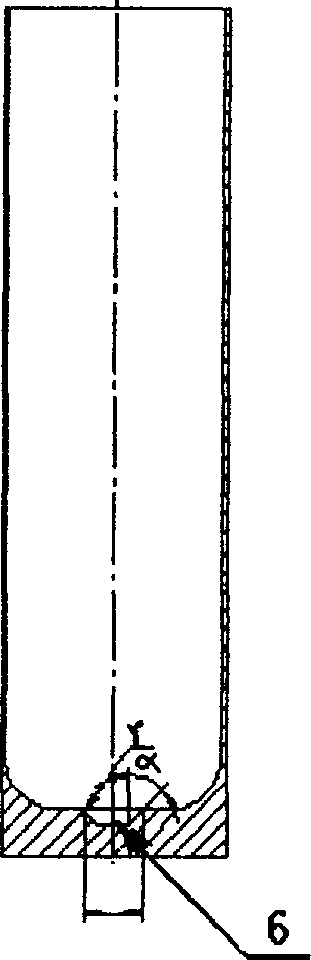

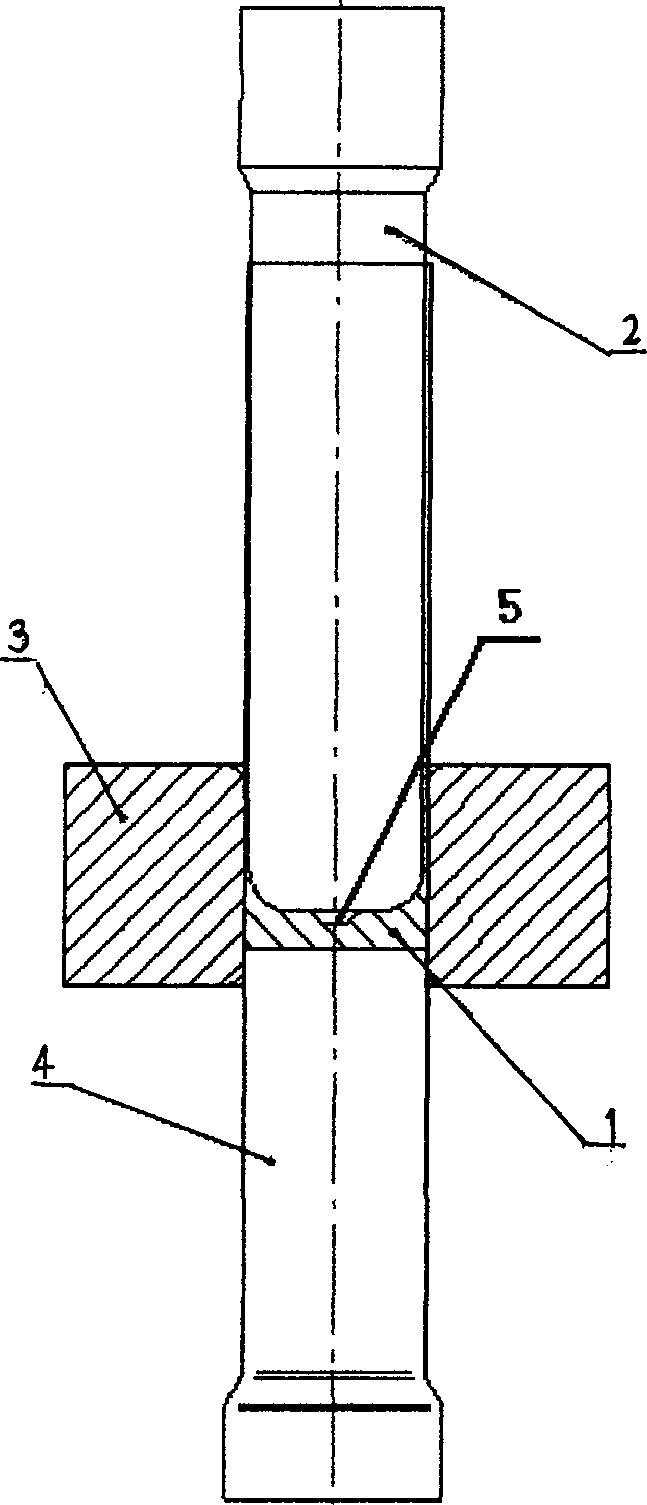

[0017] see figure 2 . Take the extrusion die. The extrusion die is composed of a special punch 2, a die 3 and a bottom punch 4 for eliminating the burrs of the bottom through hole of the deep cylindrical workpiece. The working part of the punch 2 is provided with a circular protrusion 5 with a taper, and its taper is α = 5° ~ 60°; the upper end of the protrusion and the inner wall are arc surface transitions, and the radius of the arc surface is r = R0 .5 ~ R2. The shape of the protrusion corresponds to the shape of the groove at the bottom of the cavity of the deep cylindrical workpiece.

[0018] see figure 1 and figure 2 . First use the extrusion die to extrude the deep cylindrical workpiece. When extruding, the extrusion punch 2 is driven by the slider on the press, and the die 3 and the bottom punch 4 act together on the extrusion 1. The punch 2 extrudes a tapered circular groove 6 at the bottom of the cavity of the deep cylindrical part, the diameter of the groov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com