Drilling method of manufacturing printed circuit board (PCB) and PCB

A drilling method and aperture technology, used in printed circuit manufacturing, electrical components, printed circuit components, etc., can solve problems such as easy formation of burrs, copper etching on hole walls, contact tips, etc., to improve quality and overcome burr problems. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

[0015] An embodiment of the present invention provides a drilling method for making PCBs, comprising: making a drilling 1 on a PCB manufacturing board; making a drilling 2 intersecting the drilling 1 on the PCB manufacturing board; Deburr the intersection of borehole 1 and borehole 2.

[0016] Because the method removes the burr at the intersection of the first drill hole and the second drill hole, the burr problem in the related art is overcome, and the quality of the PCB is improved.

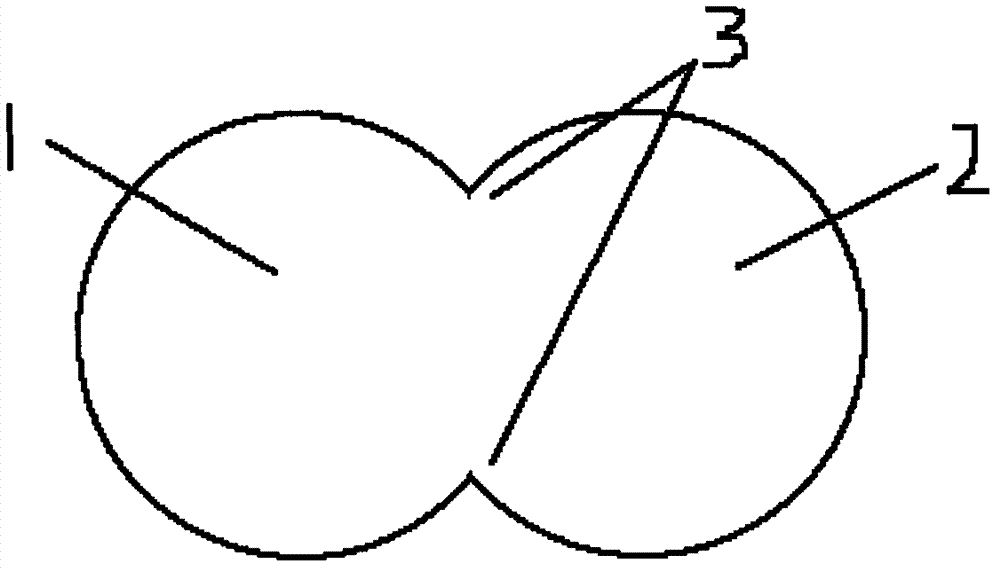

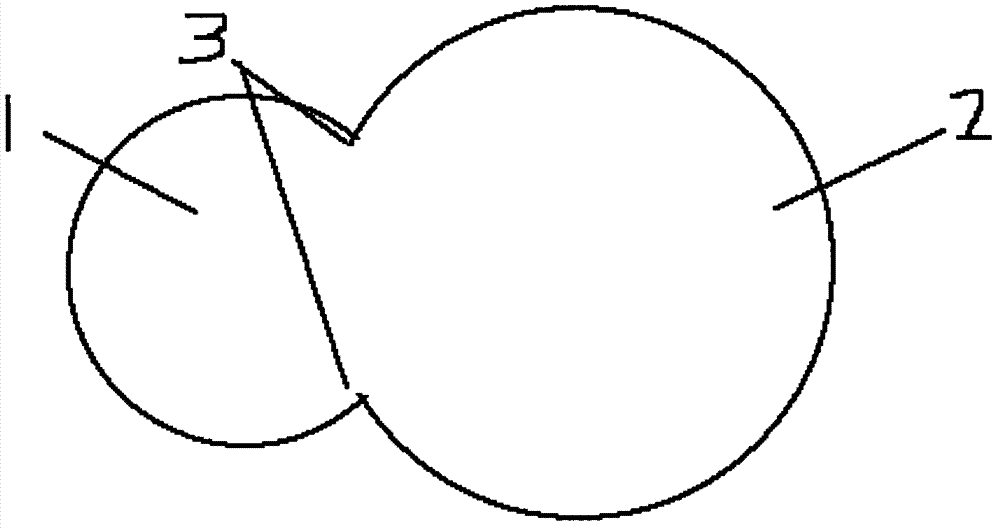

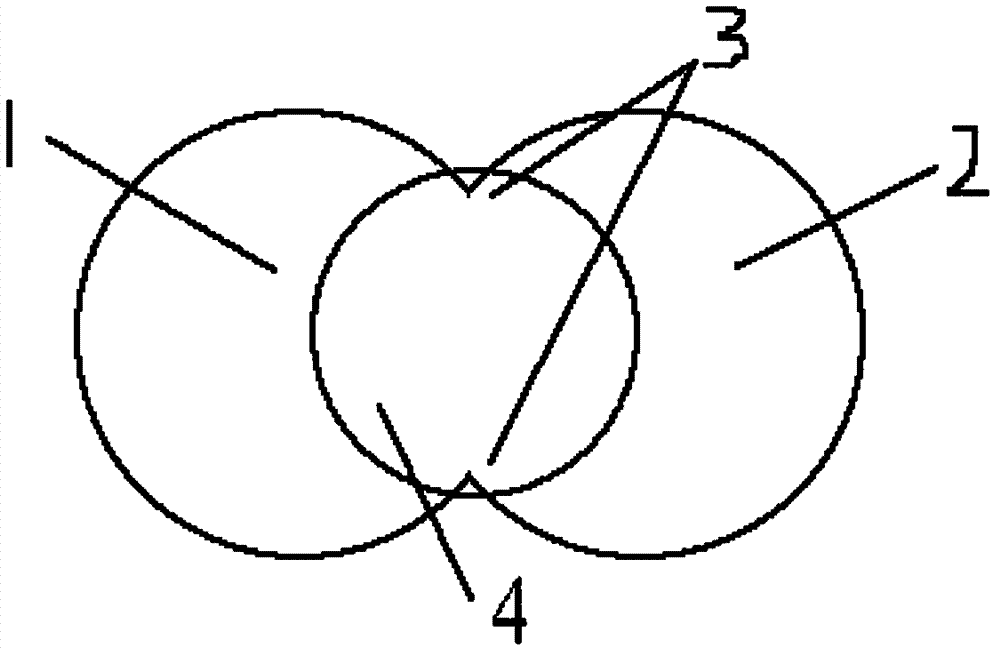

[0017] image 3 A schematic diagram of making a figure-eight hole according to an embodiment of the present invention is shown, Figure 4 A schematic diagram of making a gourd hole according to an embodiment of the present invention is shown. like image 3 and Figure 4 As shown, drill a hole at the intersection 3 (that is, the deburring hole 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com