Manufacturing method of shielding case bracket

A manufacturing method and shielding cover technology are applied in the field of manufacturing shielding cover brackets, which can solve the problems of upward burrs on flange edges, top damage to PCB wiring layers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention is further illustrated below by means of examples, but the present invention is not limited thereto within the scope of examples.

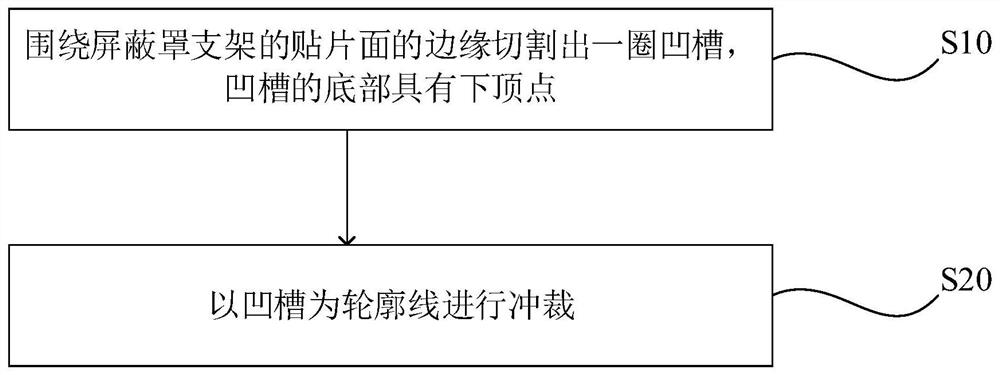

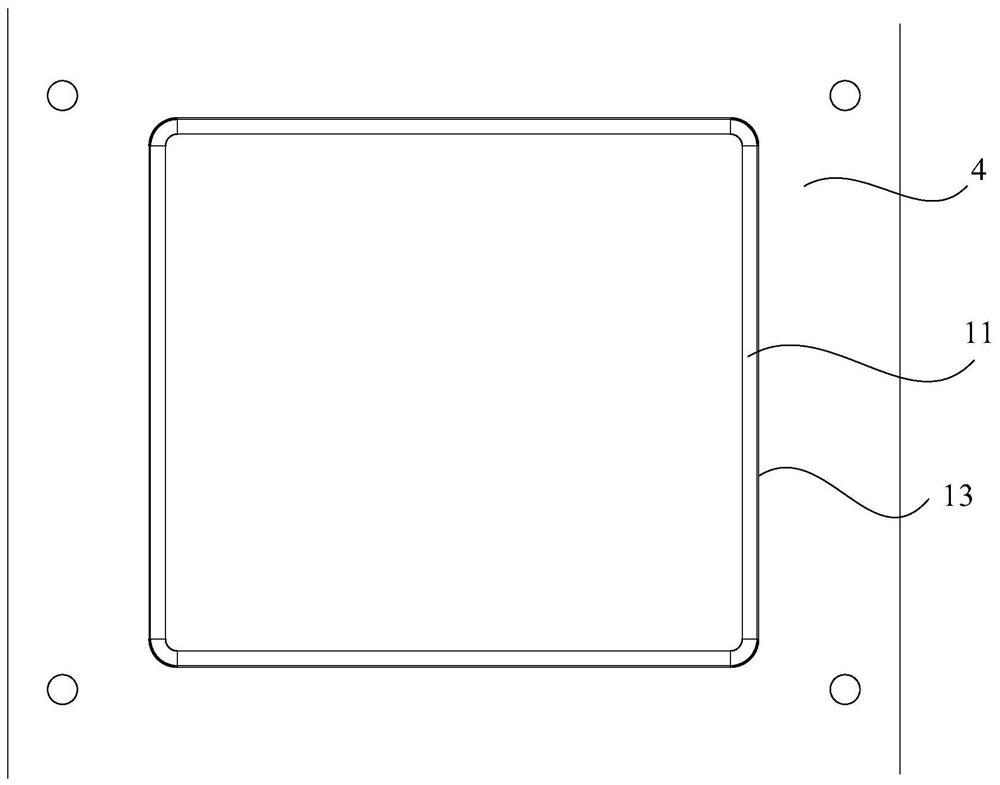

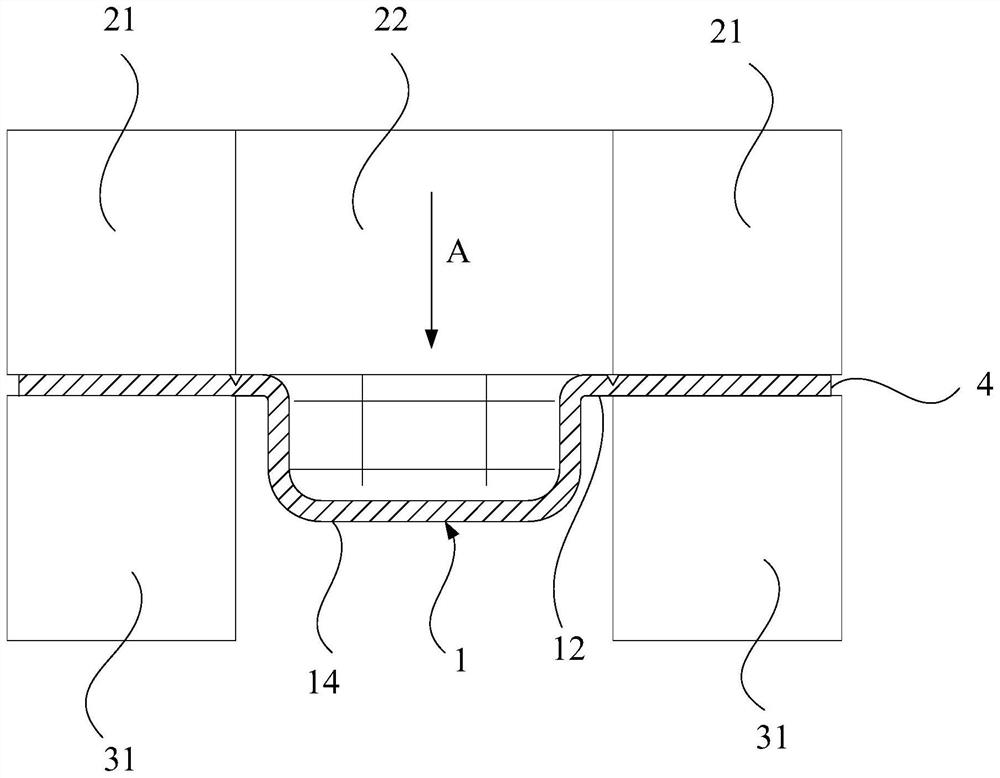

[0043] This embodiment discloses a manufacturing method of the shield bracket 1, such as Figure 1-4 As shown, the manufacturing method of the shield bracket 1 includes steps: S10, cutting a circle of grooves 13 around the edge of the patch surface 11 of the shield bracket 1, the bottom of the groove 13 has a lower apex 131; S20, using the groove 13 Punching for outline.

[0044] In this embodiment, since the groove 13 is added on the edge of the patch surface 11, when the upper die punch 22 punches down the raw material 4 of the shield bracket 1, the raw material 4 of the shield bracket 1 will not pass through the The three stages from elastic deformation to plastic deformation and then to fracture and separation, but the following apex 131 is the tear point directly fracture and separation, so as to avoid the burr p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com