Burr processing jig

A technology of burrs and jigs, which is applied in the field of mechanical processing, can solve the problems of increased sliding resistance of pins, more residues, and affecting the feel of instruments, etc., and achieves the effect of solving burrs, simple use, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

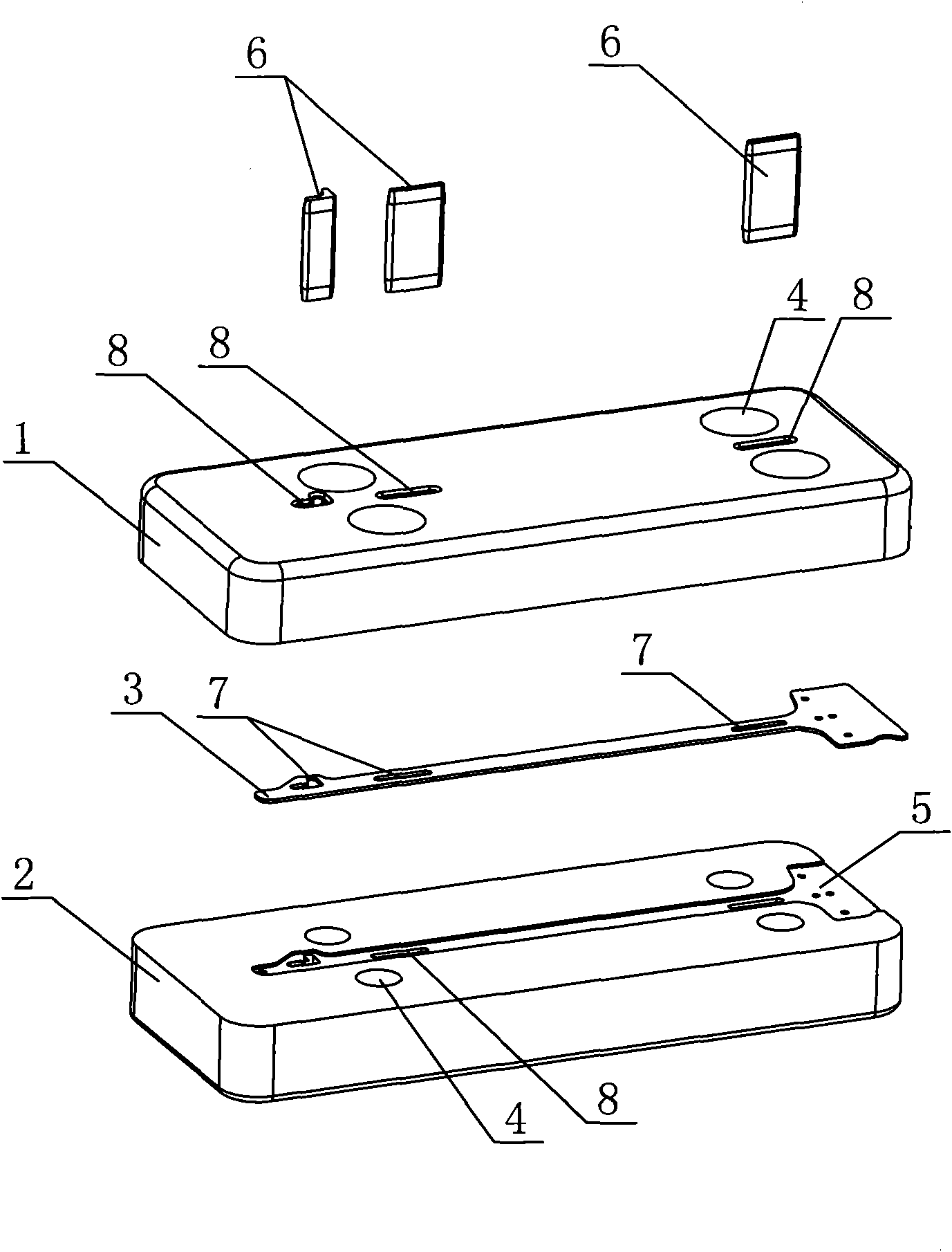

[0020] The invention discloses a burr treatment jig, such as figure 1 As shown, it includes an upper mold 1 and a lower mold 2 detachably connected by fasteners, the fasteners are bolts and nuts, and the upper and lower molds are correspondingly provided with passages for the bolts to pass through. Hole 4.

[0021] The surface of the lower mold 2 is provided with a notch 5 consistent with the outer contour of the workpiece 3 to be processed, and the workpiece 3 to be processed can be placed in the notch 5 .

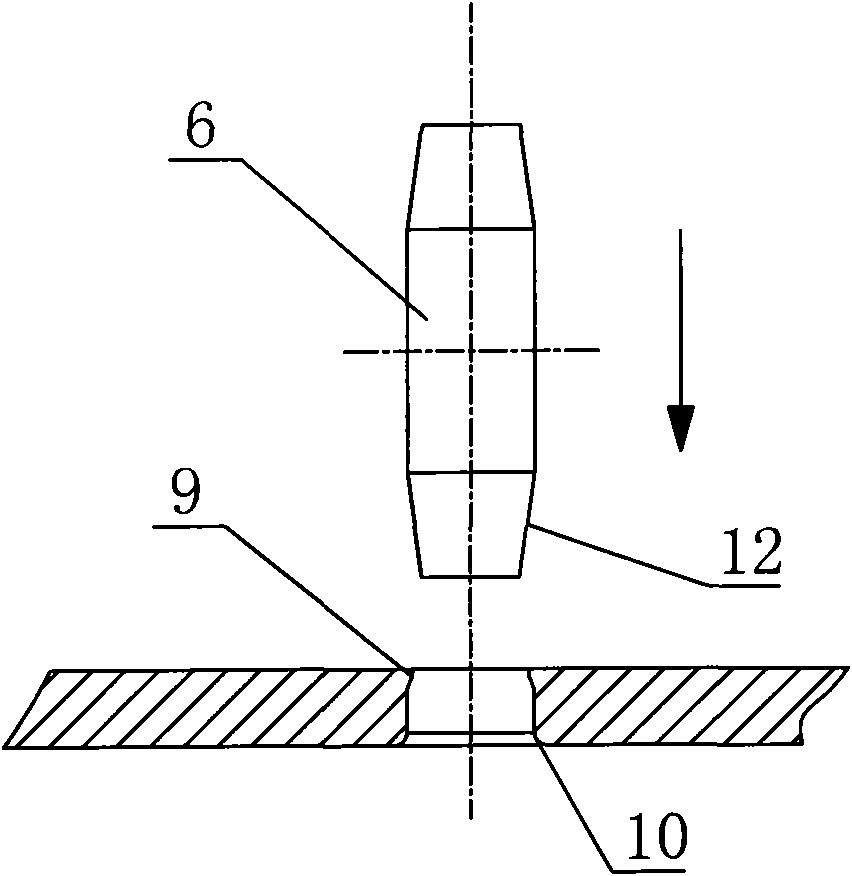

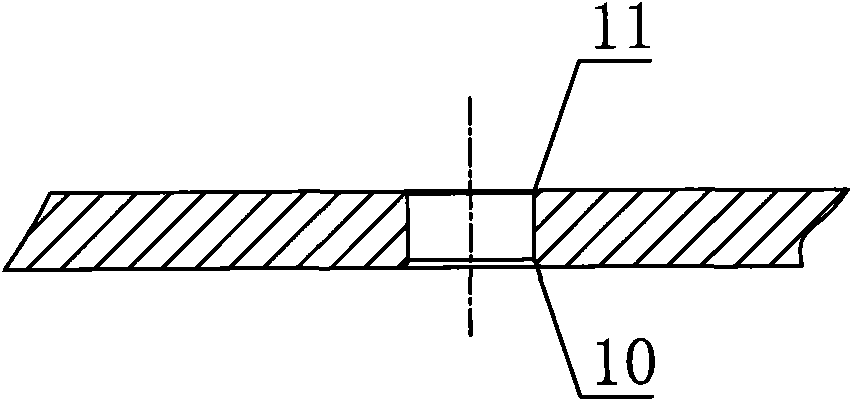

[0022] The deburring jig also includes a punch 6 that can reciprocate between the upper and lower molds, and the punch 6 can be driven by a cylinder or other reciprocating parts. The upper and lower molds 1 and 2 are provided with punching holes 8 for the punches to pass through, and the number and cross-sectional shape of the punches 6 are consistent with the burr holes 7 of the workpiece 3 to be processed. And the number and outline of the punching holes 8 of the uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com