Mounting structure of longitudinal cutter in sub longitudinal cutting die for fins of air conditioners

A technology for slitting sub-molds and air-conditioning fins is applied in the field of slitting knife-mounted tool holder structures, which can solve problems such as confusion and waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

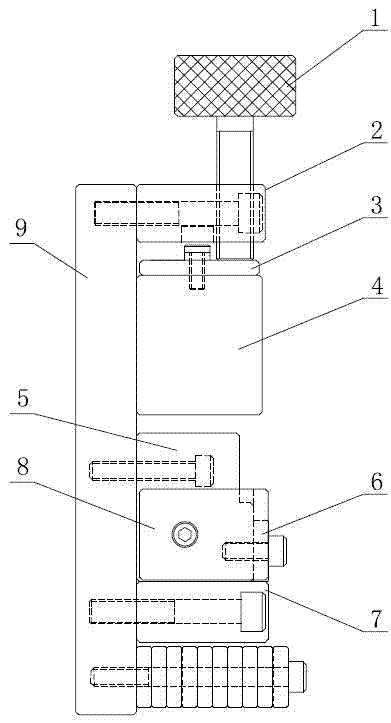

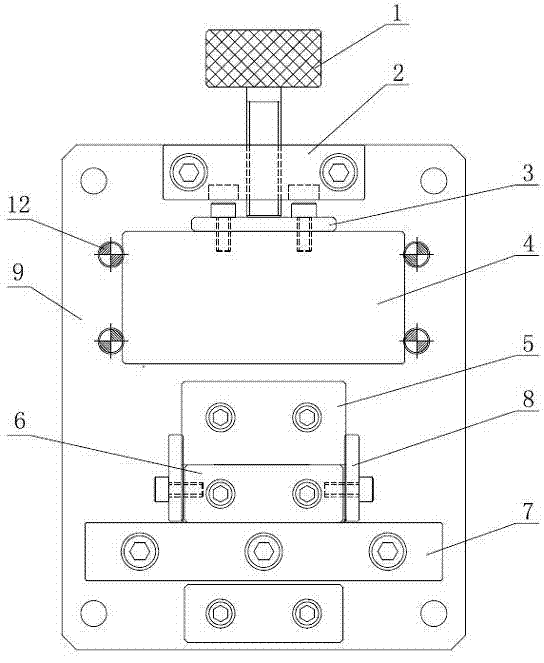

[0017] See figure 1 , figure 2 , the present invention includes a mold base 9 and a tool holder 5, and also includes a screw 1, the screw 1 passes through the connecting block 2, and the protruding end is located above the gasket 3, the connecting block 2 is fastened to the mold base 9; the gasket 3 is fastened Connect the slider 4, the mold base 9 is equipped with a pin 12 along the outer periphery of the slider 4, and the brim of the pin 12 is in contact with the slider 4; Tighten and connect the limit block 6, fasten and connect the mold base 9 on the other side, and fasten the front and rear end faces of the tool rest 5 to connect the side stoppers 8 respectively; just below the knife rest 5, a stopper 7 is arranged, and the stopper 7 is tight. Firmly connect the mold base 9.

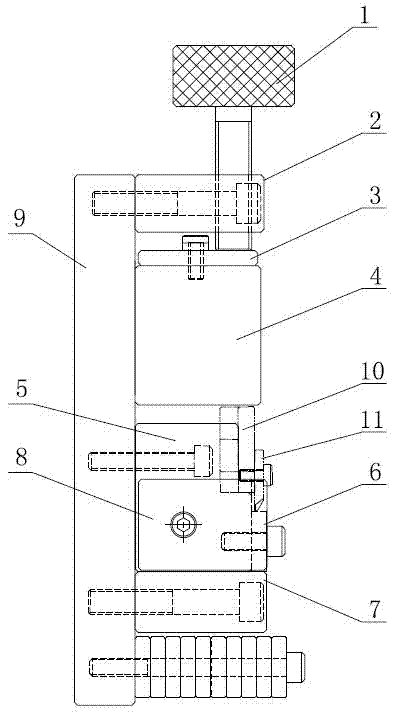

[0018] See image 3 , Figure 4 , taking the slittin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com