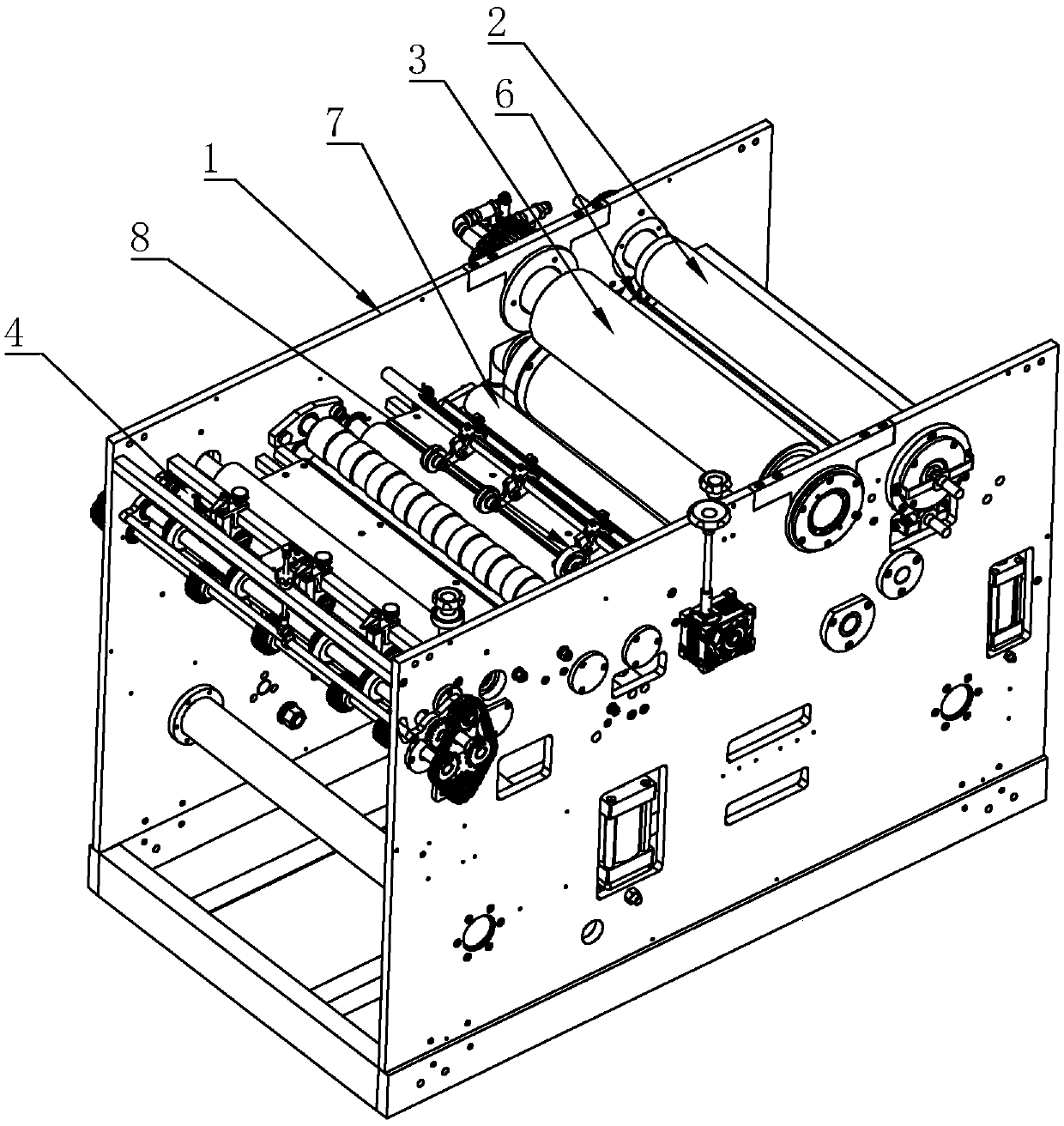

Embossing splitting machine

A slitting machine and embossing technology, which is applied in the directions of mechanical processing/deformation, sending objects, thin material processing, etc., can solve the problems of difficult to suppress lines, difficult deformation of films, and poor embossing effect, etc., to achieve good deformation and embossing Good texture effect, the effect of increasing the film temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

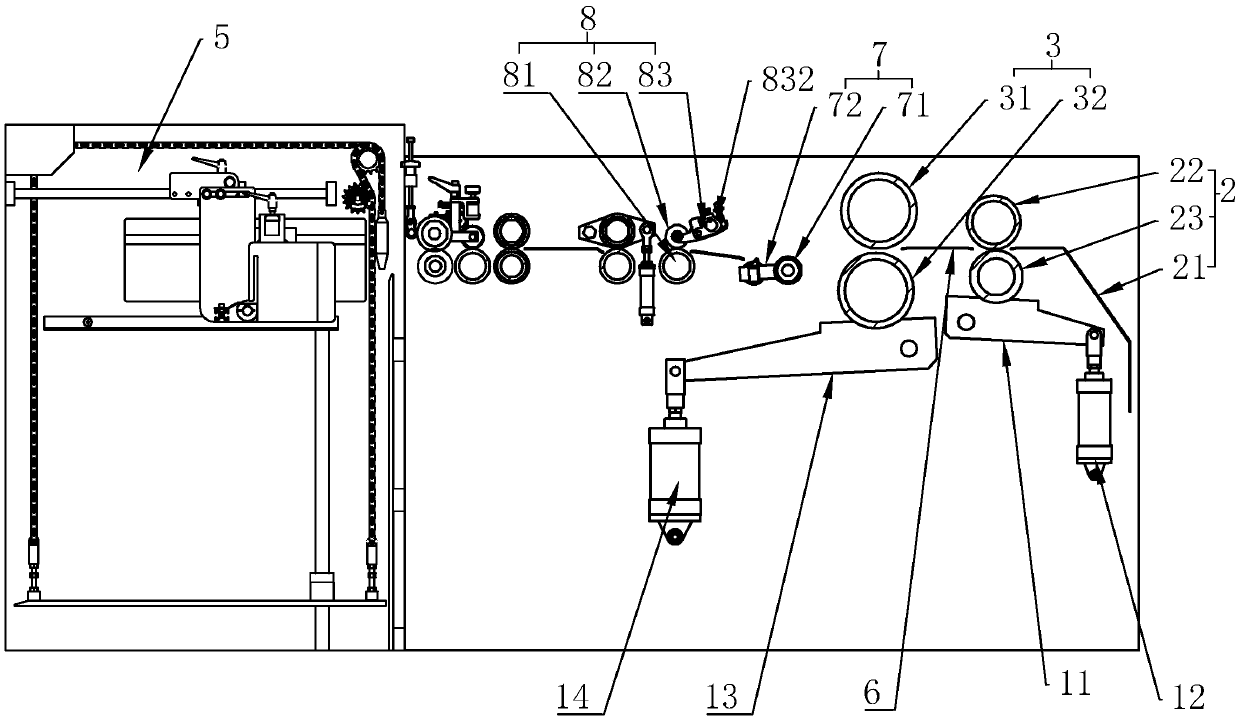

[0023] As an improved specific implementation, the preheating device 2 includes a cardboard 21 and an upper preheating roller 22 and a lower preheating roller 23 that are both rotatable and arranged on the frame 1. The upper preheating roller 22 and the lower preheating roller 23 are distributed up and down, forming a preheating space for the paper to pass through between them, and the paper input plate 21 is arranged on the preheating space of the upper preheating roller 22 and the lower preheating roller 23, facing away from the embossing device 3 On one side, the paper-feeding board 21 is arranged in a strip shape, and is bent toward the preheating space on the frame 1 to form a guide section and a feeding section, and the end of the feeding section extends to a position close to the preheating space, Through the setting of the cardboard 21, the film-coated paper can be effectively guided into the preheating space between the upper preheating roller 22 and the lower preheati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com