Patents

Literature

173results about How to "No fading" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for production of preserved flower, and processing solution for use in the method

InactiveCN101861092AKeep natural colorReduce processDead plant preservationNatural resinVegetable oil

Disclosed is a method for producing a preserved flower, which enables to keep the original color of a real flower, particularly the subtle gradation in color of the real flower. Also disclosed is a processing solution for use in the method. Specifically disclosed is a method for producing a preserved flower, which comprises immersing a real flower in a processing solution and drying the flower, wherein the processing solution comprises a solution or dispersion containing at least one component selected from a natural oil material oil, a natural resin material, a siloxane, a synthetic resin, a water-addition-reaction-type urethane, a fatty acid ester and a surfactant, wherein the natural oil material is terpin oil, stand oil, whale oil, boiled oil, linseed oil, camellia oil, olive oil, rapeseed oil, a salad oil (a purified plant oil), sesame oil, camphor oil or the like, wherein the natural resin material is rosin, glue, wax, bees wax, rubber, rhus lacquer or the like, and wherein the fatty acid ester is an ester of a saturated or unsaturated fatty acid such as lauric acid, palmitic acid, stearic acid and myristic acid and a lower or polyhydric alcohol.

Owner:坂本好央

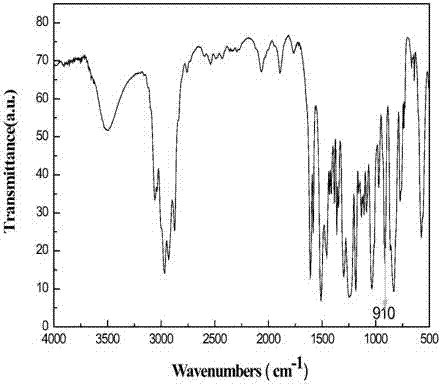

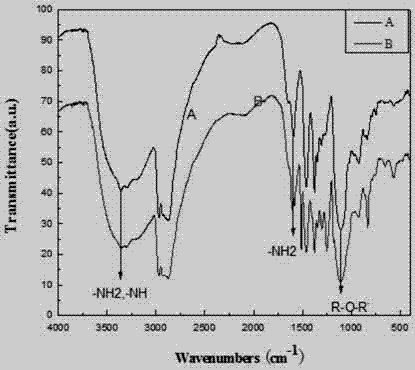

Polyether amine modified waterborne epoxy floor hardener and preparation method thereof

InactiveCN104231232AGood water dispersibilitySimple processEpoxy resin coatingsReaction temperatureEpoxy amine

The invention relates to a polyether amine modified waterborne epoxy floor hardener and a preparation method thereof. The polyether amine modified waterborne epoxy floor hardener is prepared through modification of polyether amine, synthesis of epoxy-amine and dispersion of deionized water; the molar ration of the polyether amine, epoxy-terminated glycidyl ether and epoxy resin is 2-6:0.5-4.5:0.5-4.5; during reaction, the polyether amine is firstly added into a reactor, then the epoxy-terminated glycidyl ether is added, the epoxy resin is added in drops, and lastly, the reactants are dispersed through the deionized water to obtain the polyether amine modified waterborne epoxy floor hardener. The preparation method of the polyether amine modified waterborne epoxy floor hardener is simple in process; the reaction temperature is easy to control; waterborne epoxy floor paints produced with the polyether amine modified waterborne epoxy floor hardener are high in hardness and glossiness, reach level-1 impact resistance and obtain high acid and alkali resistance.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY AND SCIENCE

Wear-resistant leather and preparation method thereof

InactiveCN106702753AImprove embossing effectImprove wear resistanceTextiles and paperWater basedWear resistant

The invention discloses wear-resistant leather and a preparation method thereof. The wear-resistant leather comprises a base fabric, an adhesive layer, a foaming layer, a surface layer and a surface treatment layer, wherein the surface layer comprises the following raw materials in parts by weight: 100 parts of polyvinyl chloride paste resin powder having a polymerization degree of 1600-2000, 60-80 parts of a plasticizer, 1-3 parts of a heat stabilizer and 3-5 parts of color paste; the surface treatment layer comprises the following raw materials in parts by weight: 80-90 parts of water-based polycarbon type PU resin, 15-20 parts of aliphatic polyurethane, 4-6 parts of an aziridine crosslinking agent, 3-5 parts of an isocyanate-based crosslinking agent, 15-20 parts of water-based silicone hand feeling agent, 6-8 parts of an acrylic thickening agent and 2-3 parts of a pH adjusting agent. The wear resistance and the mechanical fatigue resistance of the wear-resistant leather provided by the invention are improved by mainly improving the surface layer, the surface treatment layer, the foaming layer and the preparation method of the original polyvinyl chloride artificial leather.

Owner:广西鑫深科技有限公司

Continuous adjustment screen printing process of water-based gloss oil

The invention belongs to the technical field of printing and particularly relates to a continuous adjustment screen printing process of water-based gloss oil. The continuous adjustment screen printing process comprises the following steps of: 1) manufacture of continuous adjustment image files; 2) manufacture of films; 3) cleaning of the films; 4) stretching of a screen; 5) gluing; 6) positioning of the films; 7) exposure; 8) development; 9) drying; and 10) screen printing. The continuous adjustment screen printing process has the advantages that 1) the wear resistance is strong, the scratching is resisted, the screen-printed surface is wear-resistant, water-repellent and oil-repellent, and no color-fading phenomenon occurs on the surface of a printed product; 2) the film forming speed is fast, and the drying is rapid; 3) the high temperature resistance and the hot-sealing performance are good; 4) the degree of planeness is good, and the winding force resistance is strong; 5) the used water-based gloss oil has better leveling property, can realize fast leveling before a coating layer is dried to form a smooth surface, so that the coating layer can have high glossiness; and 6) the water-based gloss oil adopts water as a solvent without toxicity and smell. Compared with the water-based gloss oil used for local glossing, the continuous adjustment screen printing has the advantage that the image layering can be reproduced.

Owner:浙江华人数码科技有限公司

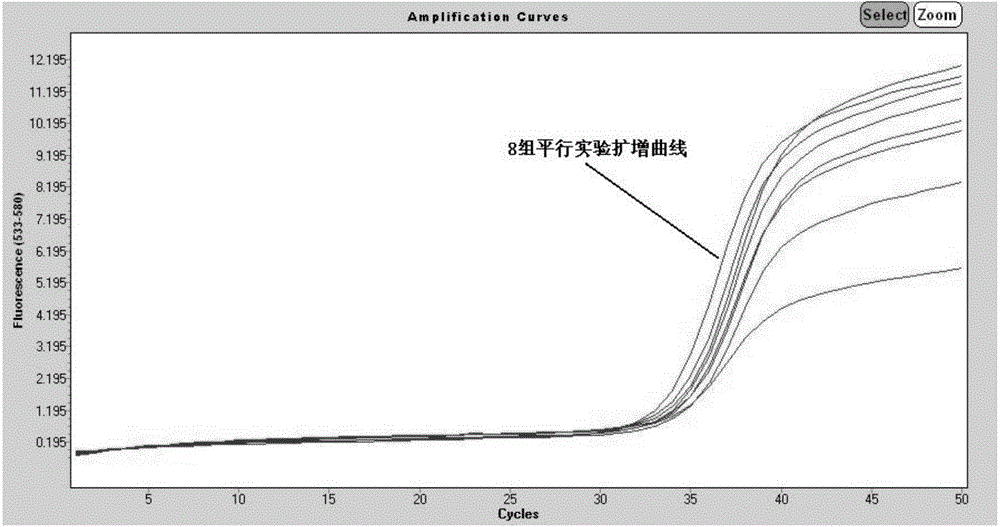

Method for storing biological samples and kit

ActiveCN104651524AImprove transfer efficiencySave fast, safe and effectiveMicrobiological testing/measurementBiotechnologyAntioxidant

The invention belongs to the technical field of biology and in particular discloses a method for storing biological samples and a kit. The method for storing the biological samples comprises the following steps: fully mixing a collection tool with adsorption of the biological samples with a functional solution, and transferring the mixed biological samples to a filter paper card for storage, wherein the functional solution comprises a buffering solution, a complexing agent, an antibacterial agent, a color indicator and an antioxidant. The method for storing the biological samples is simple and convenient to operate and high in sample transferring efficiency, and is capable of better killing bacteria and viruses. The collected biological samples are further mixed and subsequently transferred to the ordinary filter paper card; the purpose of quickly, safely and effectively storing the genetic materials in the biological samples can be achieved; meanwhile, the phenomenon of fading in long-term storage can be avoided.

Owner:SUZHOU NUHIGH BIOTECH

Rubber tire tread and milling process thereof

The invention discloses a rubber tire tread and a milling process thereof. The rubber tire tread comprises the following components in parts by weight: 70-110 parts of natural rubber, 0-15 parts of styrene-butadiene rubber, 5-20 parts of tread rubber powder, 1.5-2.5 parts of stearic acid, 1-2 parts of sulfur powder, 2-18 parts of white carbon black, 12-15 parts of carbon block, 2-30 parts of aromatic oil, 1-8 parts of zinc oxide, 4-7 parts of an anti-aging agent, 1-4 parts of pine tar, 1-4 parts of an accelerating agent, 0.2-1 part of an anti-reversion agent and 2-5 parts of a binding agent. A three-section milling process is adopted, and the milling process can improve the abrasive resistance, tear resistance and chunking and chipping resistance of the tire tread.

Owner:SHANDONG YONGTAI CHEM GROUP

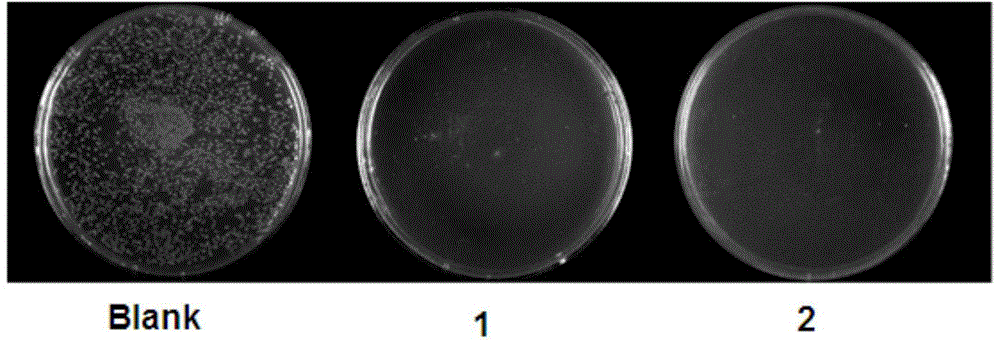

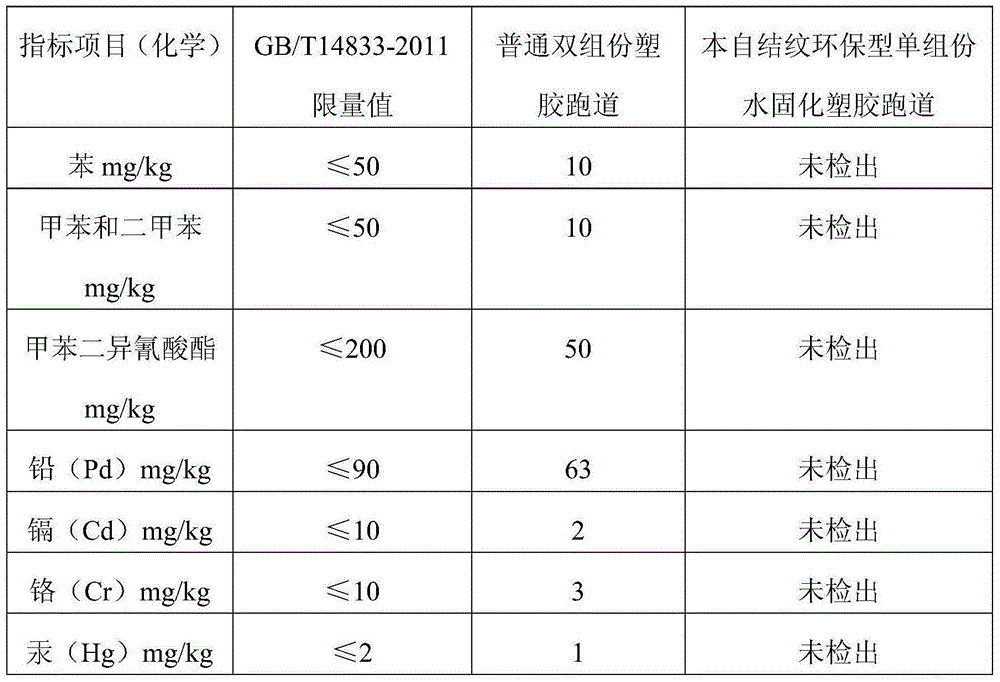

Environment-friendly type one-component water-cured lines-self-forming plastic track material and preparation method thereof

The invention relates to an environment-friendly type one-component water-cured lines-self-forming plastic track material and its preparation method. The track material contains the following raw materials, by weight, 30-50 parts of bifunctional polyether polyol, 30-50 parts of tri-functional polyether polyol, 30-50 parts of diethylene glycol dibenzoate, 30-40 parts of epoxidized soybean oil, 20-30 parts of methyl diphenylene diisocyanate, 1-5 parts of pigment, 60-80 parts of powdered steatile, 10-20 parts of a stabilizer, 1-5 parts of a rheological agent, 0.5-3 parts of calcium oxide and 1-3 parts of white carbon black. The track material is environmentally friendly, can be prepared in advance, is stored in a barrel after being prepared and is directly used at a construction site. According to the invention, the problem that bi-component materials need to be weighed and blended on site and must be uniformly stirred is minimized; three links which are most likely to get wrong during the construction process are avoided; construction process is simplified; and construction efficiency is enhanced.

Owner:蔡晓明

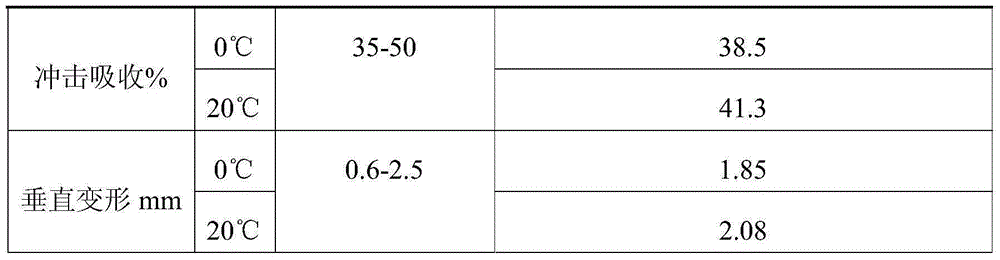

Physical dyeing method for lumber

InactiveCN101367222AWill not cause pollutionNo consumptionWood treatment detailsWater vaporWood machining

The invention provides a method for physically dyeing wood, which belongs to the technical field of wood processing. The method for physically dyeing the wood is to heat the wood and control temperature and time for heating to dye the wood. The method for physically dyeing the wood has the characteristics of small equipment investment, small production field, simple process and short treatment period; moreover, no pollution is generated during dyeing treatment, with safe production and high production efficiency; besides, the dyeing process does not require water vapor, so that the method has the advantages of no water consumption, small heat energy consumption, energy conservation, low production cost and the like during the process of dyeing treatment. Furthermore, the thickness of dyed wood is not restricted, and the method overcomes the defects of deformation, cracking, color difference and the like for the wood during production process, and has high product quality; and dyed wood has dimension stability, improved noncorrosibility and wide application range.

Owner:广西贺州恒达板业股份有限公司

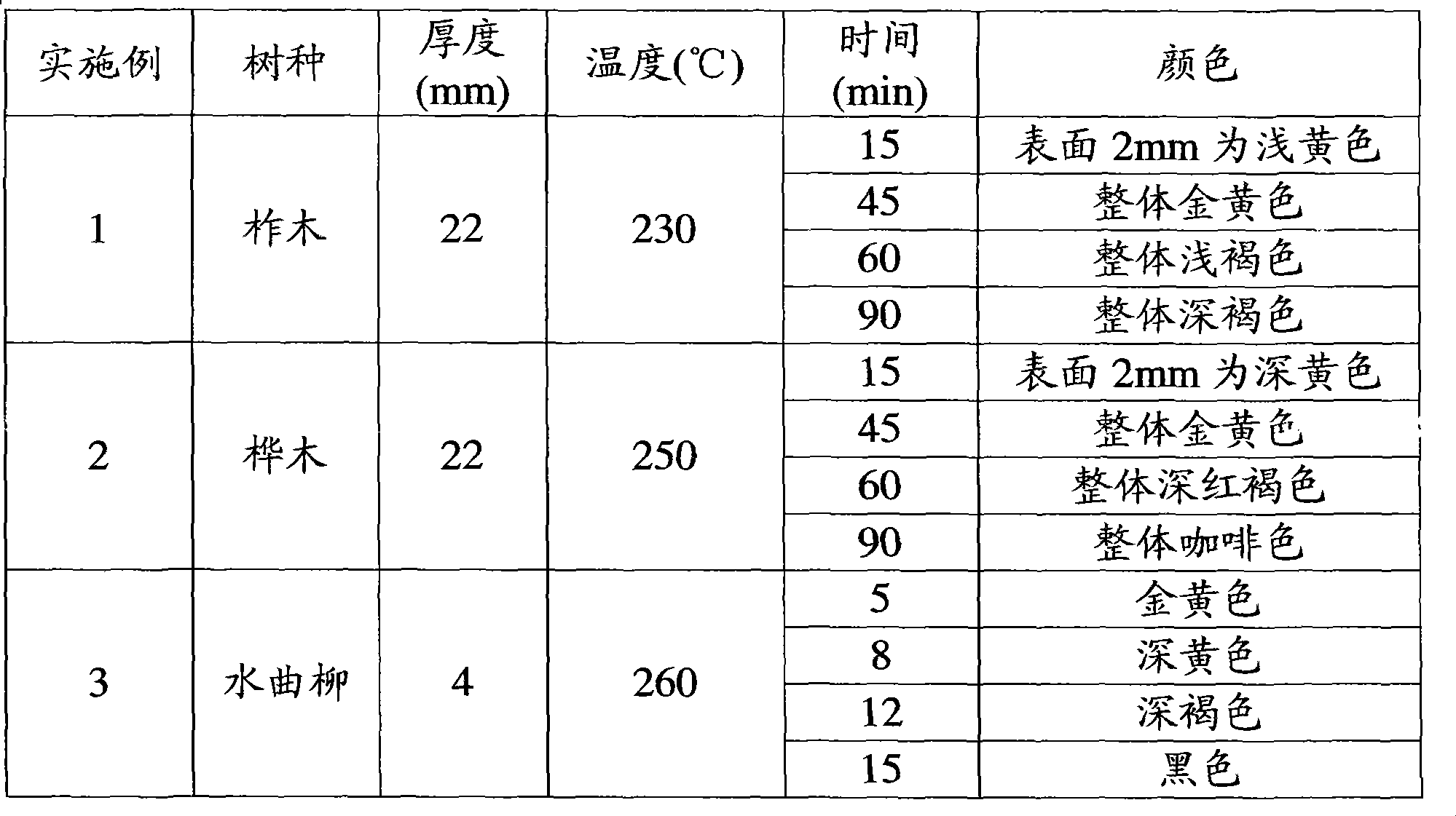

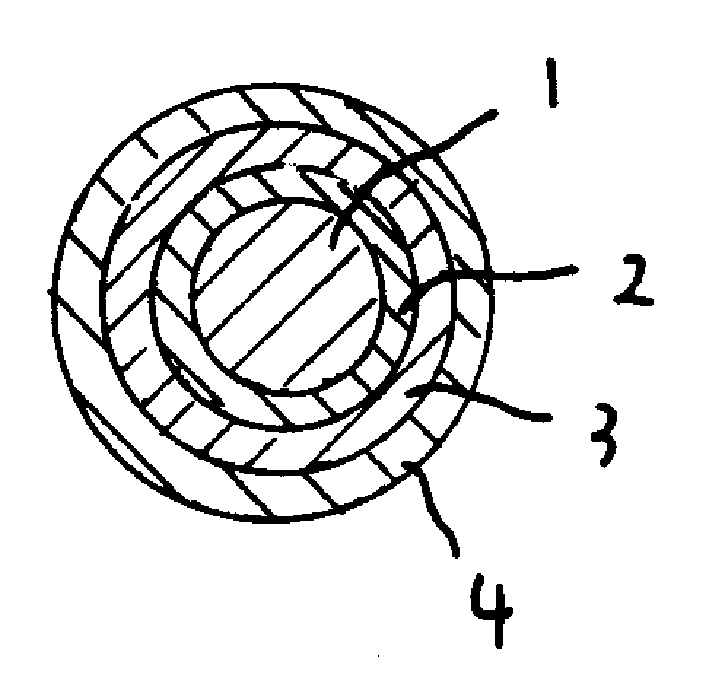

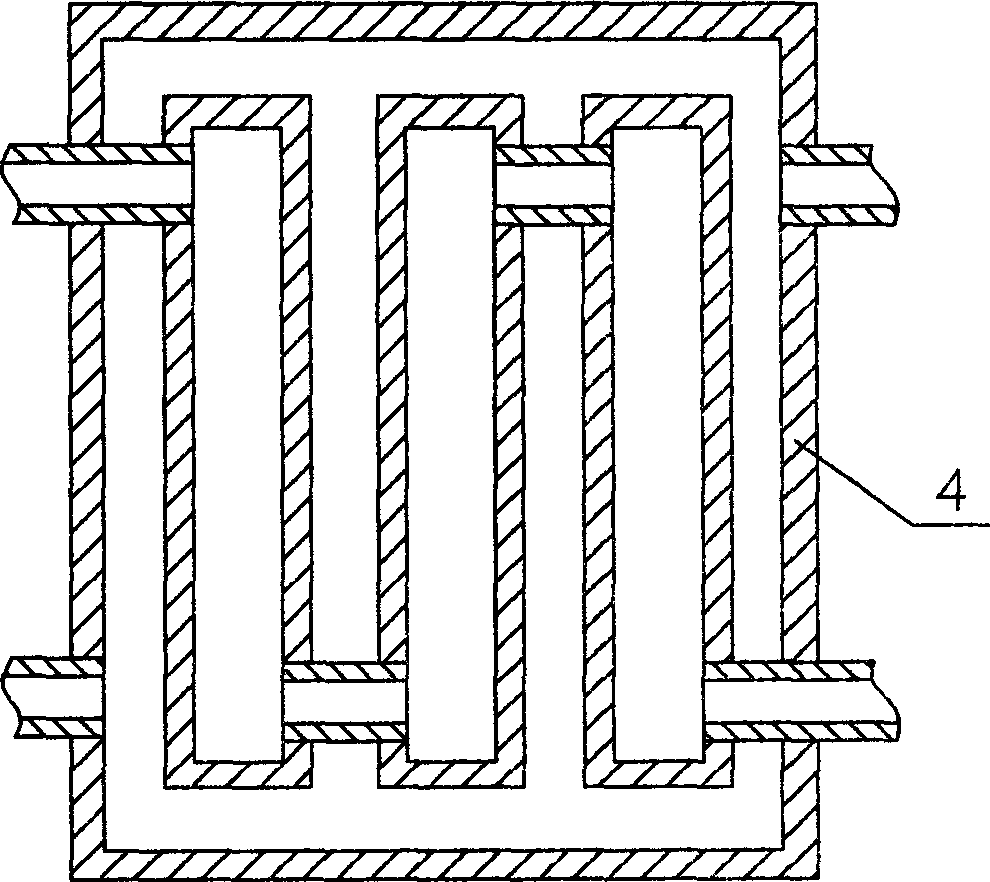

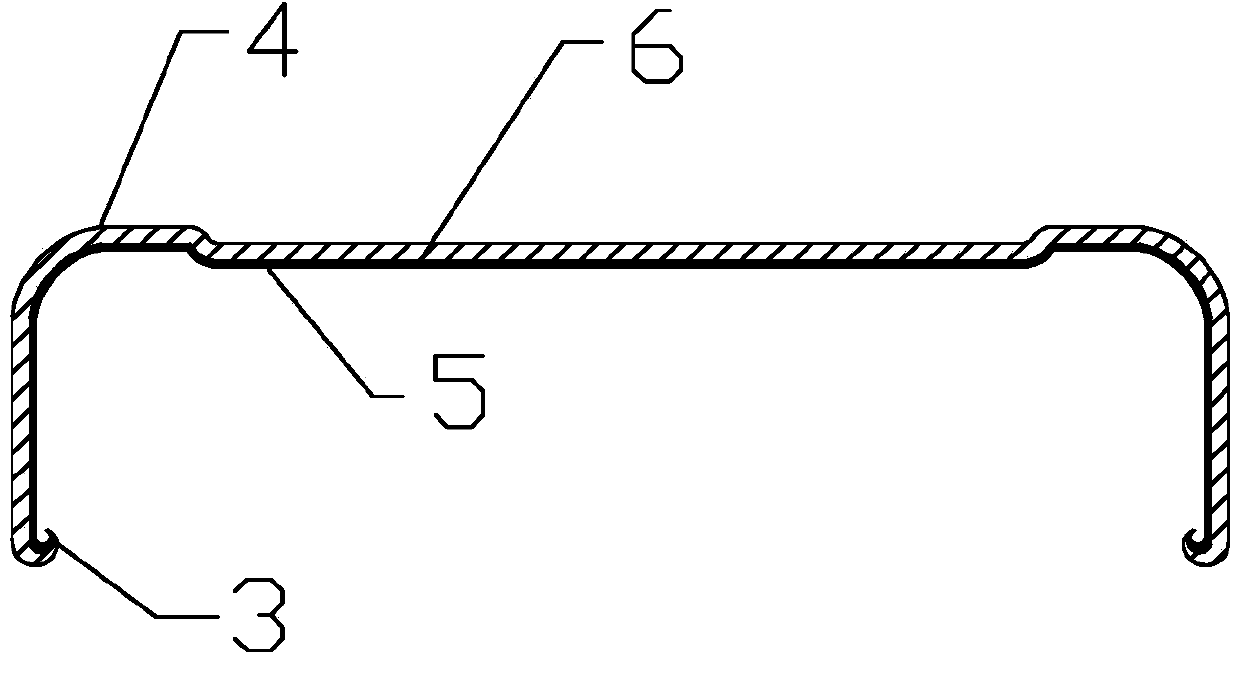

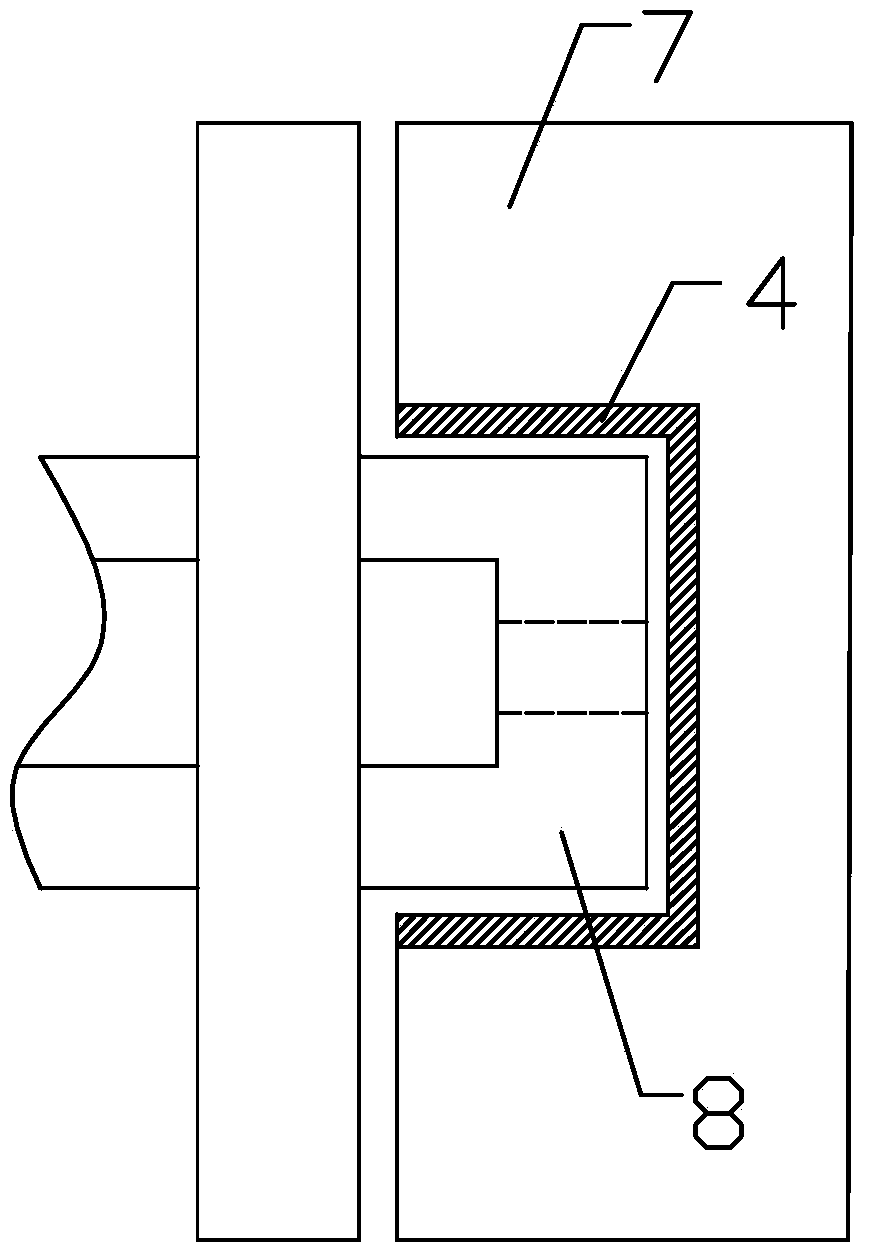

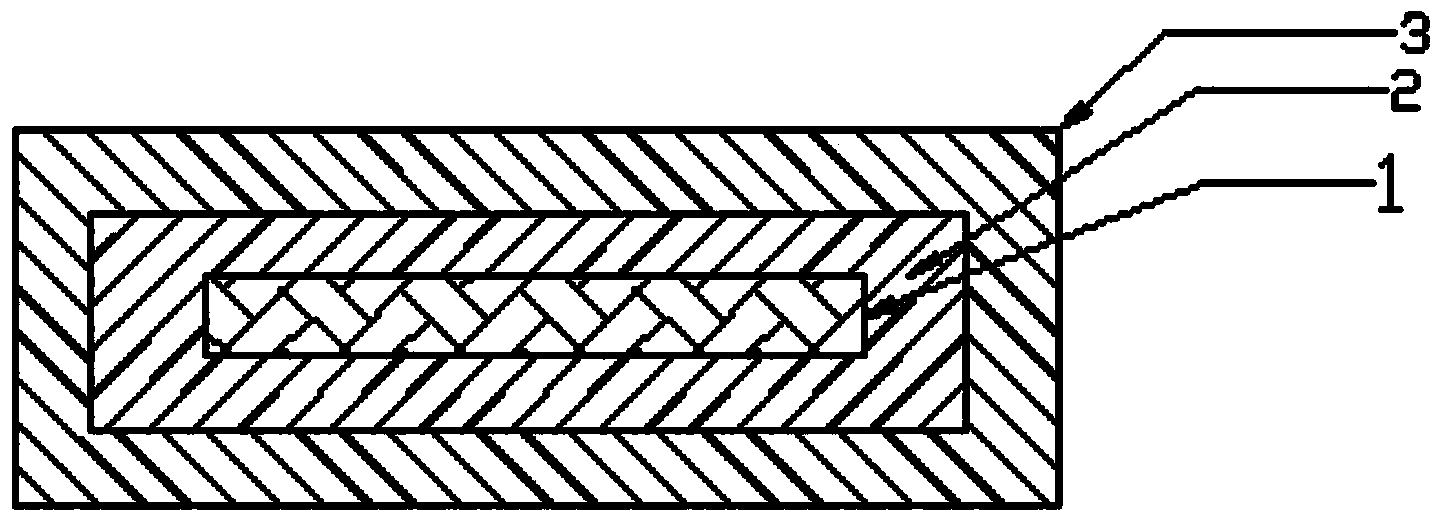

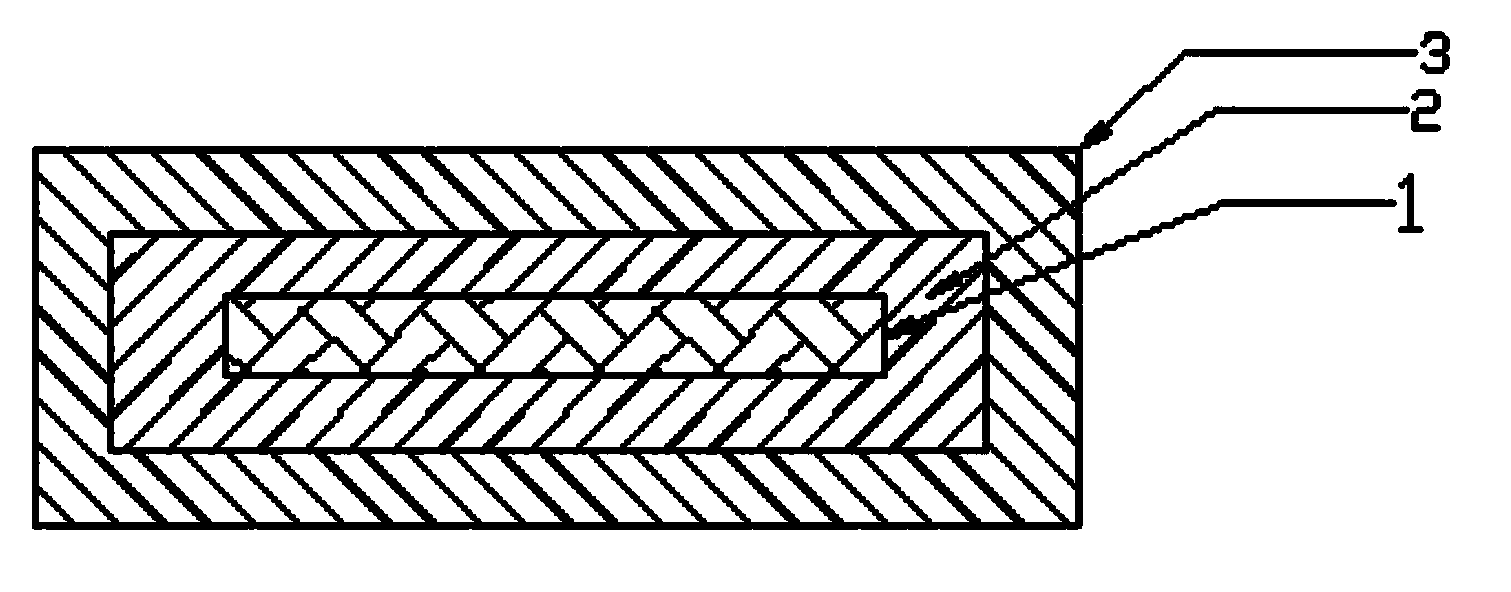

Silicon rubber heat resistant wire for heating coil

InactiveCN1490824AHigh strengthGood environmental protectionTransformers/inductances coils/windings/connectionsInsulated cablesLeading lineWear resistance

The present invention relates to a heat-resistant wire coated with silicone rubber which is used for the heating coil, the wire being mainly suitable to the coil winding and the leading line of microwave oven. It includes from the inner to outer portion a core 1 made of nickel plated copper wires, an insulating layer 2 made of silicone rubber, a weaving layer 3 made of Dacron and an outer heat-resistant coating 4. The weaving layer of the invention has high strength, good wear-resistance, long operating life and good firmness of color attachment.

Owner:马仕兴

Urush modulating method

InactiveCN101525521AImprove finishing performanceShorten drying timeNatural resin coatingsChemical/physical/physico-chemical stationary reactorsLacquerAcid value

The invention belongs to the filed of chemical modification processing of paint, in particular relates to a urush modulating method, and provides a high-quality raw lacquer modulating method. The modulating process comprises the following steps: filtering raw lacquer by 300-mesh grass cloth to remove impurities; pouring settled tung oil into a polyreaction pot, and adding bismuth nitrate into the polyreaction pot; regulating the acid value of the tung oil to make the acid value reach between 6.7 and 6.9; keeping the temperature of the tung oil after acid value regulation between 35 and 45 DEG C and adding the raw lacquer and a coloring material for mixing; and grinding the mixture of the raw lacquer, the tung oil and the coloring material, and packaging the mixture to obtain a finished product. The urush modulating method improves the labor production efficiency by adopting a novel process to shorten the drying time, improves the coating performance and physicochemical performance of urush, and makes products have high purity and good quality.

Owner:洪克俭 +1

Sectional material manufacturing technique for regenerative plastic doors and windows

The invention relates to a sectional material manufacturing technique for regenerative plastic doors and windows, which has the innovative points that the sectional material manufacturing technique adopts the technical steps as follows: regenerative plastics that adopt polyolefin thermoplastic plastics as main components are taken as main material; a sectional material is prepared through the procedures such as cleaning crushing, granulation, injection mold extrusion formation, stress elimination, planing milling processing, surface coating, and co-extrusion sealing; and the sectional material can be used for manufacturing high-quality doors and windows. The sectional material mainly takes the regenerative plastics made of recovered plastic garbage as the main material, so that the utilization ratio of resources is improved, and environmental protection can be achieved; the sectional material adopts a solid structure that is processed through extrusion moulding, and no shedding, no fracture and no deformation are caused in a cool drop hammer impact test; in addition, aluminum foil layers are arranged on the surface of the sectional material, so that ultraviolet ray resistance, ageing resistance, no fading, no shedding and strong weatherability can be achieved. A non-decorative surface of the sectional material is coated with a high density polyethylene layer, and decorative surfaces of the sectional material are coated with the aluminum foil layers through bonding agents, so that the high density polyethylene layer is formed between the aluminum foil layers of a front decorative surface and a rear decorative surface and is used as a heat blocking layer, and the thermal conductivity coefficient is low.

Owner:南通美特美节能门窗有限公司

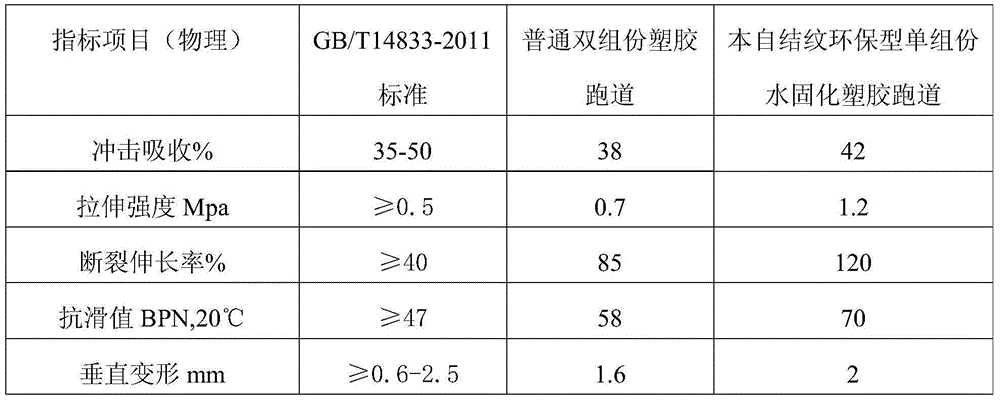

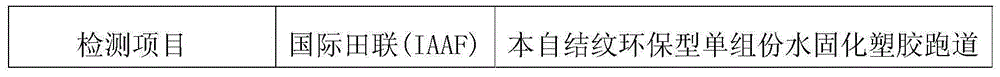

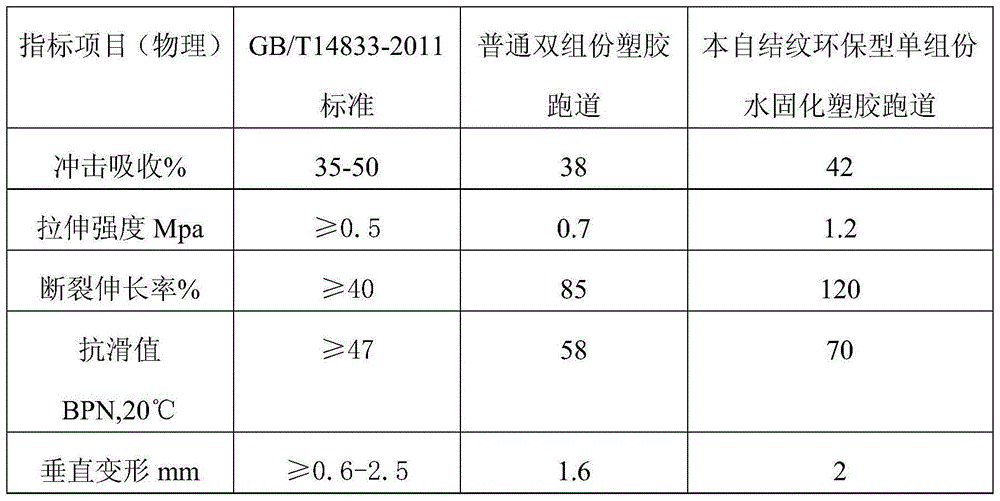

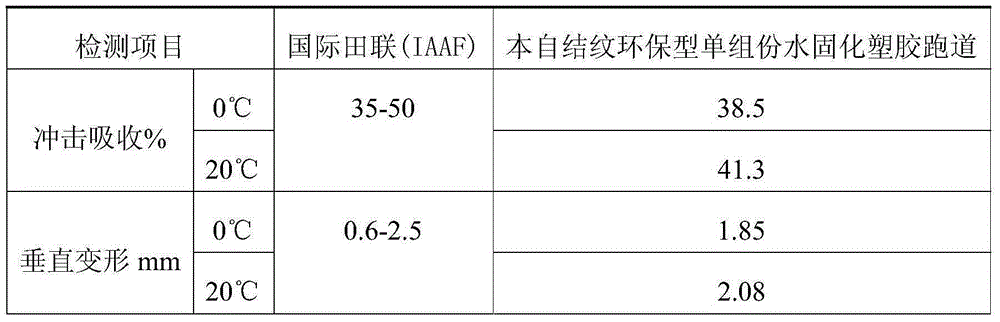

Laying method of automatic texture formation particle-free environmentally-friendly plastic track

The invention discloses a laying method of an automatic texture formation particle-free environmentally-friendly plastic track. The method comprises the following steps: S21, laying a substrate layer: mixing an environmentally-friendly single-component water solidified plastic track material with black micelles according to a weight ratio of 1:4-6, and laying the substrate layer on a dry and solidified cement base or asphalt base; S22, laying a reinforcing layer: spreading a layer of the black micelles on the dry and solid base layer, and lying the environmentally-friendly single-component water solidified plastic track material to cover the substrate layer; and S23, laying an automatic texture formation layer: uniformly mixing 10-12 parts of an automatic texture formation finish, 1-3 parts of EPDM particle rubber powder and 3-6 parts of quartz sand to form an automatic texture formation layer material, fully stirring, and spraying the obtained material on the dry and solidified reinforcing layer. The track has the advantages of environmentally friendly material, no shedding of particles, good durability, plump and uniform surface textures, high tensile strength and long service life, and all performance indexes of the track accord with technical requirements of International Association of Athletics Federations and GB / T14833-2011.

Owner:广州帝森康体设备有限公司

Nano fluorocarbon exterior wall heat-insulating paint

The invention relates to nanometer fluorocarbon exterior wall heat insulation paint, which is prepared from ingredients according to the following weight proportion: the ratio of acrylics to fluorocarbon resin to nanometer SiO2 to titanium pigment to silicon acrylate latex to calcium carbonate to foam suppressor is 100-220 to 100-200 to 20-50 to 10-18 to 80-150 to 20-50 to 10-20. The invention makes the structure and the chemical composition part of transparent paint regulated to the most scientific and most reasonable state, and adds a few nanometer grade materials, so that the exterior wall paint is non-toxic and odorless, and accords with the requirement of environmental protection; a paint film resists water, has quite strong performances of acid and alkali resistance and mildew resistance; and the paint film can cover fine cracks. The nanometer fluorocarbon exterior wall heat insulation paint has the advantages of strong adhesive force, good heat insulation performance and low cost.

Owner:孙恒玉

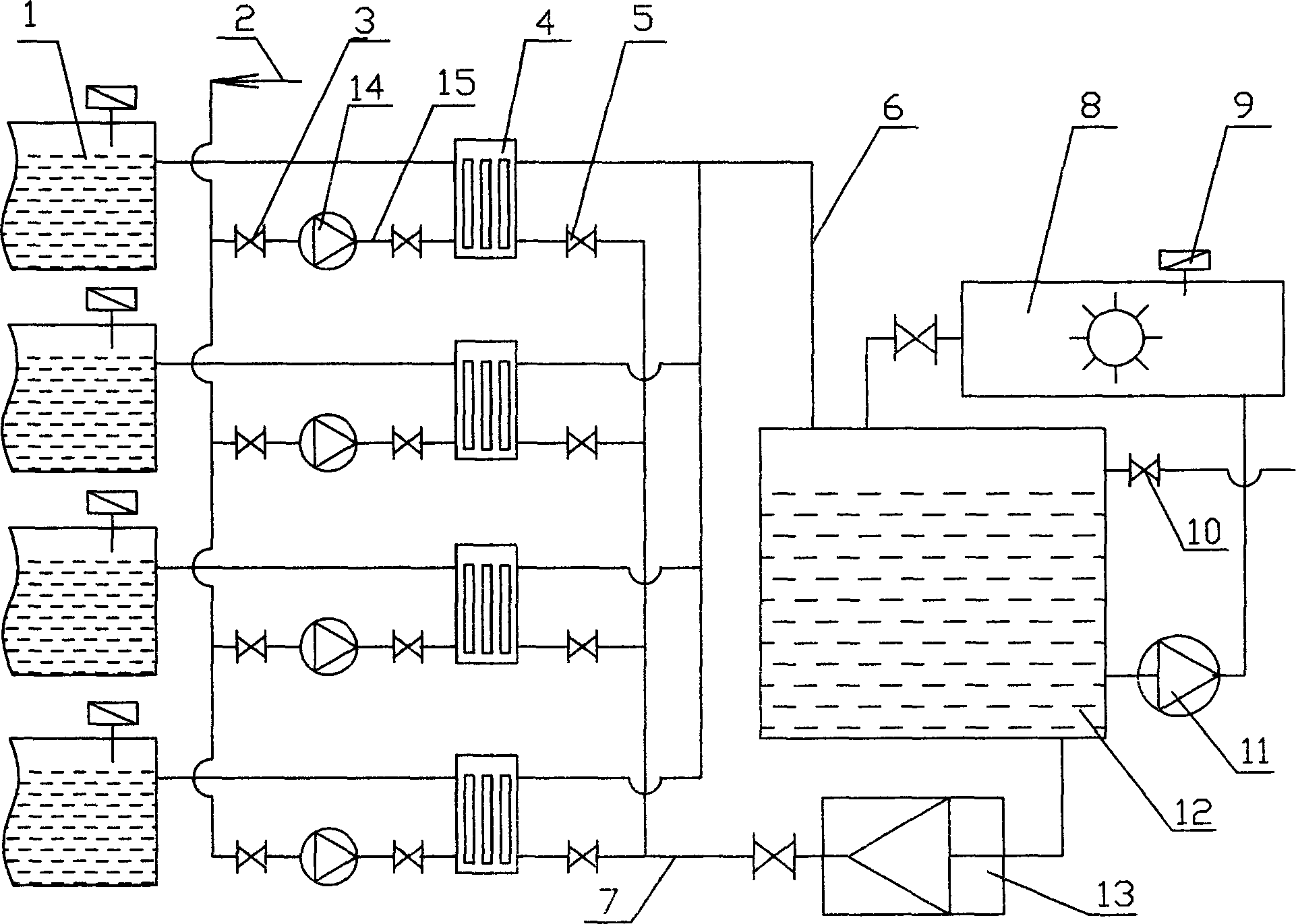

Temperature control device in seawater breeding pond water reflow treatment

The invention provides a temperature control device in seawater breeding pond water reflow treatment. The temperature control device comprises a reflow water tank, a breeding pond and a heat exchange pump; the temperature control device is characterized in that a heat storage water tank and a plurality of heat exchangers are additionally arranged; one water outlet of the heat exchange water tank is communicated with a solar water heater through a water pump; the water outlet of the solar water heater is communicated with a water inlet of the heat storage water tank; another water outlet of the heat storage water tank is communicated with a heat source main pipe through a water source heat pump; the heat source main pipe is communicated with a plurality of heat source branched solenoid valve pipelines; each reflow branch pipe is communicated with the liquid inlet of the corresponding heat exchanger; the liquid discharge port of each heat exchanger is communicated with a reflow port of the breeding pond; each heat source branched solenoid valve is communicated with the water inlet of the corresponding heat exchanger through a heat source branch pipe; the water outlet of each heat exchanger is communicated with a reflow main pipe through a reflow branch pipe; and the reflow main pipe is communicated with the reflow port of the heat storage water tank. The temperature control device provided by the invention has the advantages that no seawater desalination phenomenon exists in reflow water indirect heat exchanging, and the seawater breeding effect is ensured, and moreover, the solar energy and the water source heat pump are complementary.

Owner:宁德市海洋技术开发有限公司

Diacetylene-class thermochromic ink and method for preparing same

ActiveCN103497574AWith temperature-sensitive irreversible discolorationImprove stabilityInksPolymer scienceFood grade

The invention provides diacetylene-class thermochromic ink and a method for preparing the diacetylene-class thermochromic ink. The diacetylene-class thermochromic ink is formed by the raw materials of, by mass, 8-15 parts of diacetylene-class thermochromic materials, 40-50 parts of vegetable oil type varnish, 20-25 parts of calcium carbonate and 10-15 parts of barium sulfate. The diacetylene-class thermochromic ink is even in color component dispersion, strong in viscosity with print and fadeless, equipment used in the preparing process is simple, the ink can be transformed into mass production and is easy to popularize, productivity is formed, food grade materials are selected and used as raw and auxiliary materials according to rules, and the ink can be used for food package printing.

Owner:THE 724TH RES INST OF CHINA SHIPBUILDING IND +1

Boiling-resistant aqueous composite ink and preparation method thereof

InactiveCN102532997AGood resolubilityExcellent retort resistanceInksPolymer sciencePigment dispersion

The invention discloses boiling-resistant aqueous composite ink and a preparation method thereof. The boiling-resistant aqueous composite ink mainly comprises raw materials including aqueous polyurethane resin, a pigment and water, and a surface wetting agent, a wetting dispersing agent and a defoaming agent are additionally added. The preparation method of the boiling-resistant aqueous composite ink comprises the following steps of: firstly, adding partial aqueous polyurethane resin into a stirring reaction kettle; secondly, slowly adding the surface wetting agent, the wetting dispersing agent and partial defoaming agent, and adding the pigment after stirring and dispersing; thirdly, stirring and dispersing at high speed, and grinding after dispersing; fourthly, adding the residual aqueous polyurethane resin and defoaming agent and stirring and dispersing, and adding the water until the required viscosity is obtained through regulation; and at last, stirring, dispersing, filtering and packaging. The boiling-resistant aqueous composite ink, provided by the invention, is prepared by taking the high-performance aqueous polyurethane resin as a connecting material, and has the advantages of good pigment dispersibility, wide use range, lower film forming temperature, better mechanical property of formed film, more uniform particle size distribution and the like, and can be used for soft retort packages.

Owner:ZHENGZHOU LETONG NEW MATERIAL TECH

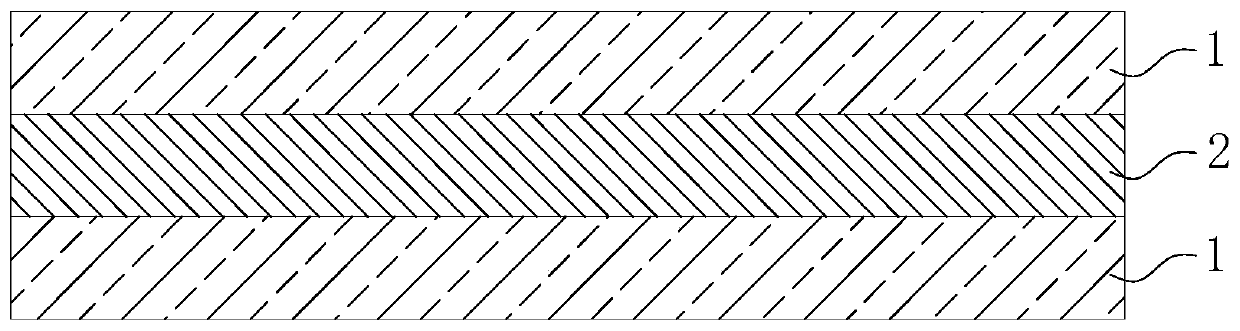

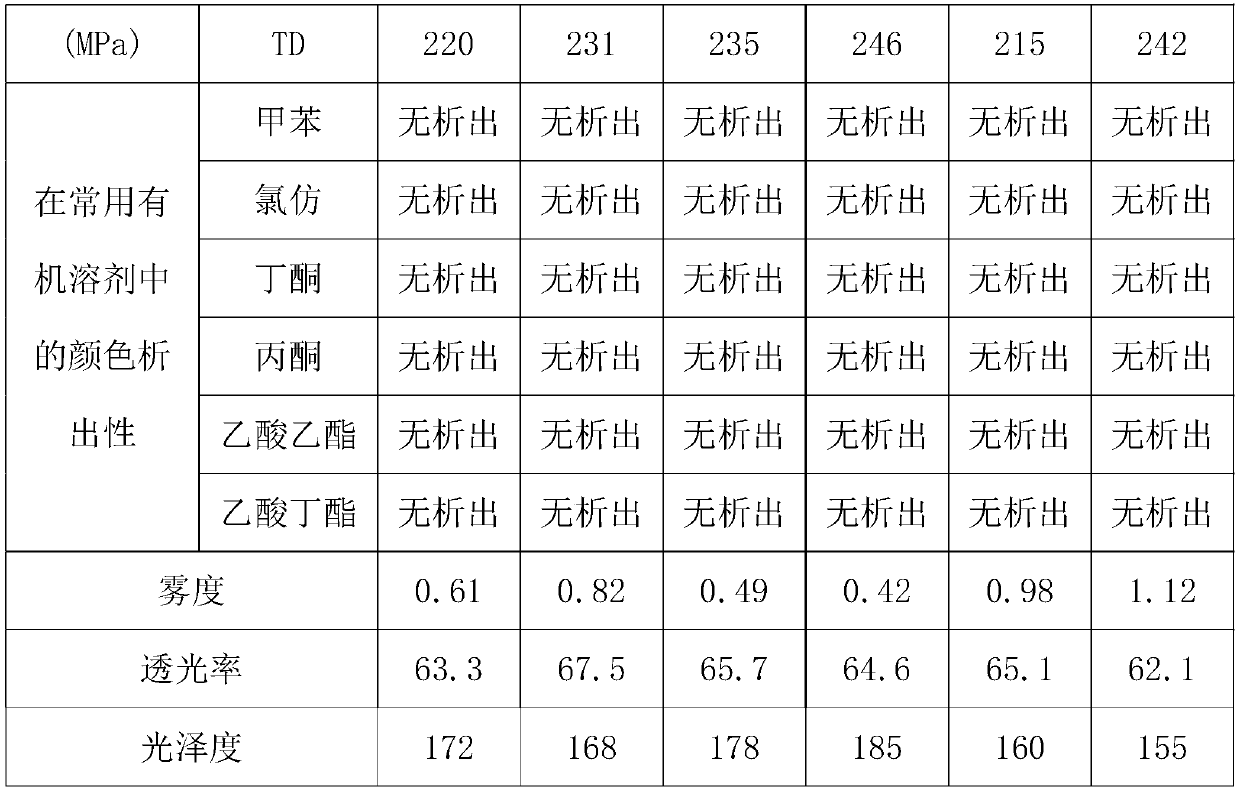

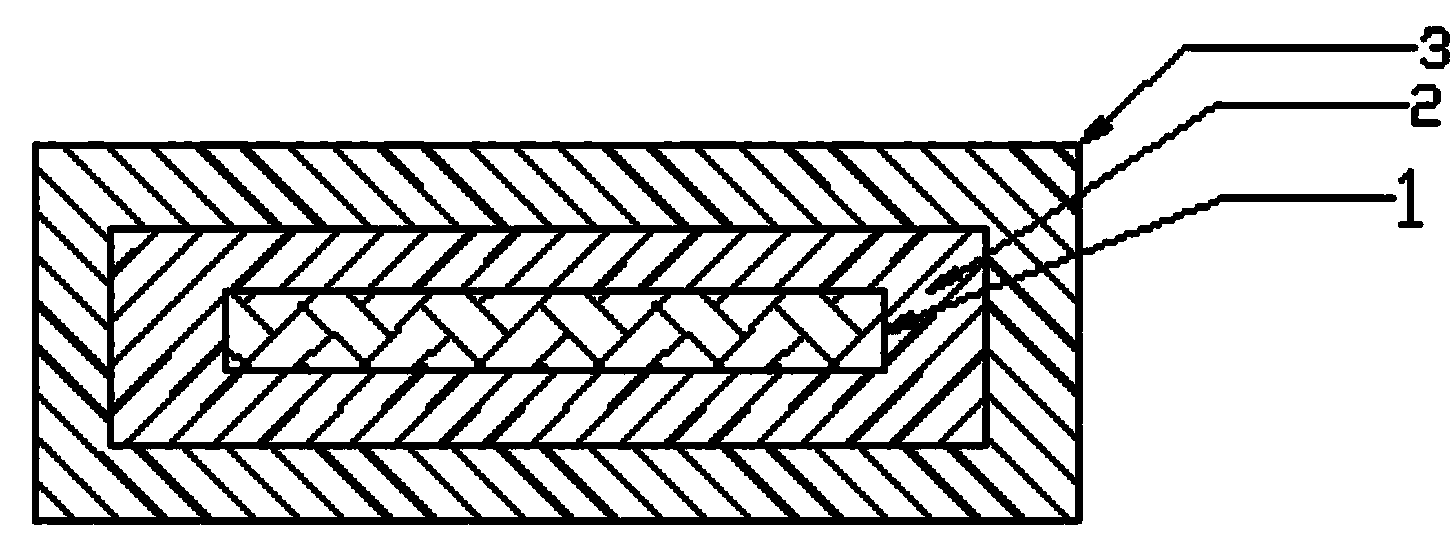

Purple biaxial-stretching polyester film and preparation method thereof

The invention provides a purple biaxial-stretching polyester film. The purple biaxial-stretching polyester film is of an ABA-type three-layer structure, wherein an A layer is a transparent layer, a Blayer is a colored layer, and a C layer includes purple masterbatch and optical-grade PET slice; and the A layer includes open-end masterbatch and optical-grade PET slice. When the preparation methodis compared with the prior art, the purple biaxial-stretching polyester film has the advantages of no color migration, no color fading, low haze and high gloss through selection of reasonable composition matching and a reasonable structure, and the performance of the purple biaxial-stretching polyester film is optimized. According to a preparation method of the purple biaxial-stretching polyesterfilm, related temperature parameters and mixing time are controlled reasonably, so that the performance of the purple biaxial-stretching polyester film is optimized, and the manufacture cost the purple biaxial-stretching polyester film is reduced.

Owner:ZHEJIANG HESHUN NEW MATERIAL CO LTD +1

Sand-in-water type granite-imitating coating and preparation method thereof

The invention provides a sand-in-water type granite-imitating coating and a preparation method thereof, and relates to the field of architectural coating; the sand-in-water type granite-imitating coating comprises the following raw materials in parts by weight: 1400-1600 parts of water, 8-15 parts of a preservative, 10-15 parts of hydroxyethyl cellulose, 2-5 parts of ethylene glycol, 1-3 parts ofa pH regulator, 3-5 parts of a defoaming agent, 2-5 parts of an anionic wetting agent, 2-5 parts of a dispersant, 10-20 parts of 2,2,4-trimethyl-1,3-pentanediol monoisobutyrate, 5-10 parts of rutile titanium dioxide, 70-80 parts of kaolin, 300-350 parts of an acrylic emulsion, 180-220 parts of lithium magnesium silicate, 5-10 parts of snow white sand, 5-10 parts of a color paste, and 4-12 parts ofother auxiliary agents. The sand-in-water type granite-imitating coating has the advantages of rich and full patterns, strong stereoscopic texture, high simulation degree, good decorative effect andthe like, and a coating film has high strength and good weather resistance.

Owner:江苏科创建筑节能科技有限公司

High-temperature-resistant colorful aluminium pigment

InactiveCN103849179ACharming effectImprove stabilityInorganic pigment treatmentMetallic aluminumPhysical chemistry

A disclosed high-temperature-resistant colorful aluminium pigment is characterized in that the pigment comprises a sheet-shaped substrate material, the external of the substrate material is coated with a silicon dioxide layer, and also the external of the silicon dioxide layer is coated with a layer of a coloring agent for forming a metal oxide composite coating. The coloring agent is ferric oxide. The sheet-shaped substrate material is sheet-shaped aluminium sheets. The beneficial effects comprise that on the premise of not reducing the brightness of a conventional aluminium pigment slurry, the colorful aluminium pigment with diversified colors and high chroma is prepared, the colorful aluminium pigment is substantially improved in both brightness and chroma, and the quality stability of the product is relatively good. Through coating of the inorganic metal oxide ferric oxide, the pigment is relatively high in stability and resistant to high temperature.

Owner:陈永煌

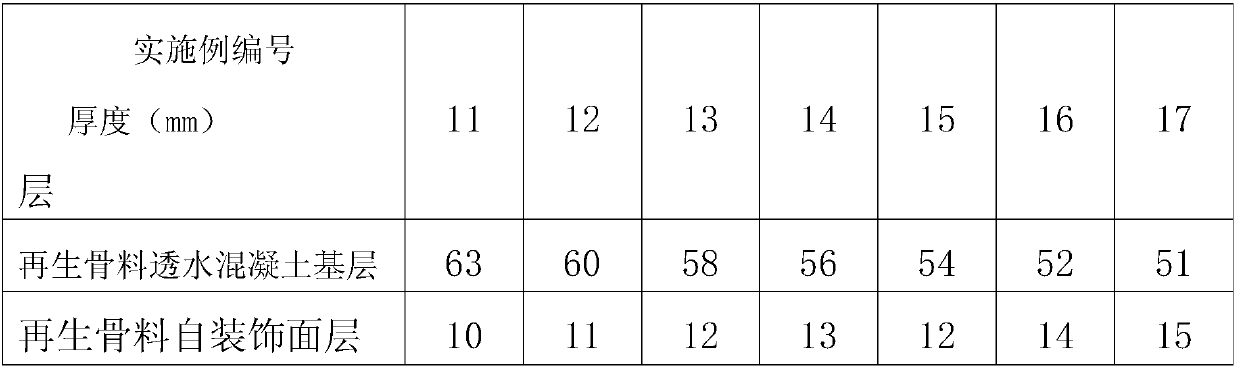

Self-decorating recycled aggregate permeable concrete product and preparation method thereof

ActiveCN107640943AAvoid destructionDecorative natureSingle unit pavingsPaving gutters/kerbsCompound aBrick

The invention discloses a self-decorating recycled aggregate permeable concrete product and a preparation method thereof. The self-decorating recycled aggregate permeable concrete product is characterized by being prepared by compounding a recycled aggregate permeable concrete base layer and a recycled aggregate self-decorating surface layer, wherein the base layer is prepared by mixing common Portland cement, concrete or / and mortar-type building waste recycled aggregate of which the particle size is 2.36 to 9.5mm, concrete or / and mortar-type building waste recycled aggregate of which the particle size is less than or equal to 2.36mm, and water; the surface layer is prepared by mixing white cement, building waste recycled decorating aggregate being a mixture of one or two or more of sintered bricks and tiles, glass and ceramic and having a particle size of less than or equal to 2.36mm, and water. The preparation method comprises the following steps: mixing the base layer and surface layer raw materials respectively; then paving in a layered way, pressing and molding into blanks, demolding and naturally curing. The product disclosed the invention has a high mechanical property, highwater permeability, a good decoration effect and high practicability.

Owner:SOUTHWEAT UNIV OF SCI & TECH

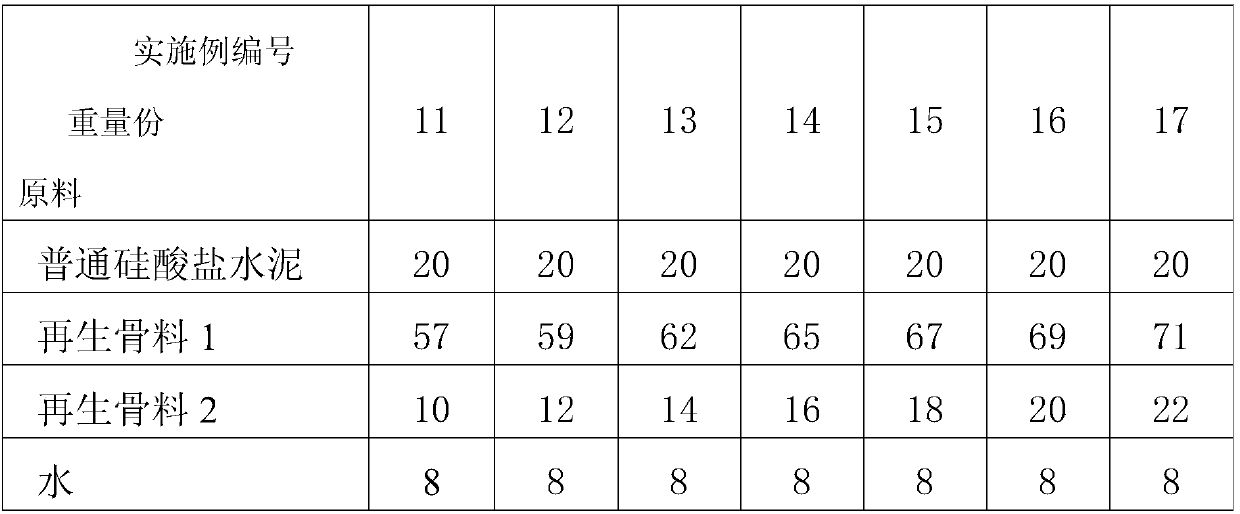

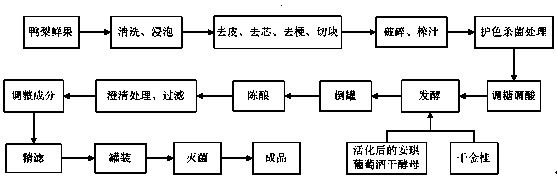

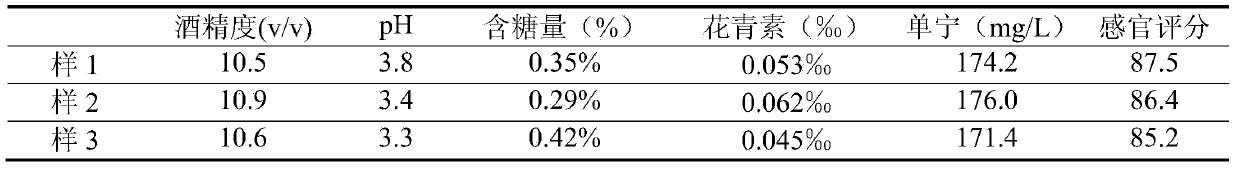

Process for producing osmanthus fragrans Chinese pear fruit wine

The invention discloses a process for producing osmanthus fragrans Chinese pear fruit wine, which belongs to the field of agriculture product machining. The wine is made by fermenting Chinese pear and osmanthus fragrans as main materials, the sour and sweet fruit taste of the Chinese pear, the sweet fragrance of the osmanthus fragrans, and the healthcare effects of the two materials are retained. The invention mainly focuses on research on novel fruit wine which is made by mixing and fermenting the Chinese pear and the osmanthus fragrans. The process comprises the following steps: juicing fresh Chinese pear as a raw material, wherein the ratio of juice to water is 1:(0.5-1.5), adding 3-5g of dried golden osmanthus fragrans into each liter of the fermentation liquid, subsequently inoculating activated grape wine high-activity yeast to brew the osmanthus fragrans Chinese pear fruit wine, wherein the fermentation condition is that the fermentation period is 6-8 days, the main fermentation temperature is 18-22 DEG C, the initial adjusted sugar degree is 20-22%, the initial pH value is 4.0-4.5, and the yeast inoculation amount is 6-10%, and the alcoholic strength of a fruit wine finished product brewed under such conditions is about 10-11% (v / v), and the wine is pure and gentle in taste, transparent and clear in color, thick and long-lasting in fragrance, thick in fruit fragrance and soft and tender in wine fragrance.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING

True flower embossed picture and method for preserving dried true flower

InactiveCN101407153AImprove qualityWill not oxidizeDecorative surface effectsSpecial ornamental structuresAdhesiveCompound (substance)

The invention relates to a method for storing and processing a real flower embossing picture and dried real flowers, which is characterized in that the embossing picture which is manufactured by real flowers and grass is placed on an aluminum-plated composite membrane; a transparent acryl board or transparent glass of which the area is the same as that of the aluminum-plated composite membrane is placed above the embossing picture; the aluminum-plated composite membrane and the high-precision transparent acryl board or the high-precision transparent glass are glued by glass cement; a small hole is reserved for inserting a suction pipe and tightly sealed by the hermetical glass cement after air in the picture is completely pumped by an air compressor; dried real flower and grass raw materials are placed into a plastic sealing bag; and air in the sealing bag is completely pumped by the air compressor, and the sealing bag is instantly sealed by a hot press. The method uses the vacuum technology to process the embossing picture, and can make the raw materials in the embossing picture be capable of being naturally adhered to a background board of the picture without use of a chemical adhesive. The dried flowers and grass are not exposed in the air and can not be oxidized, and have the advantages of no obvious fading, no mouldness, no worm damage, easy carrying, easy storage and so on.

Owner:李咏梅

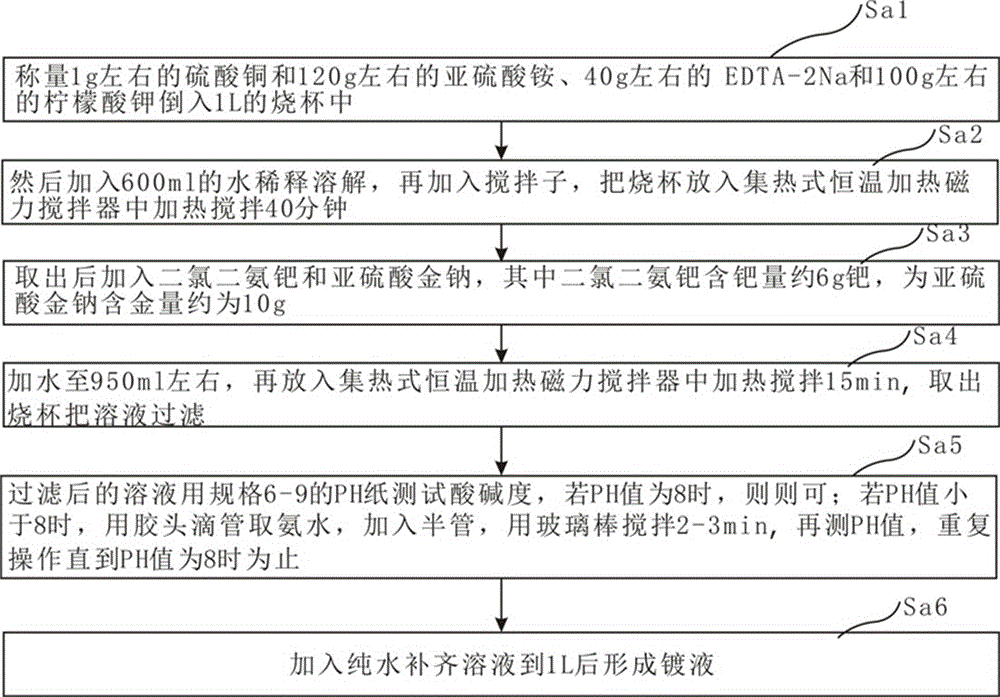

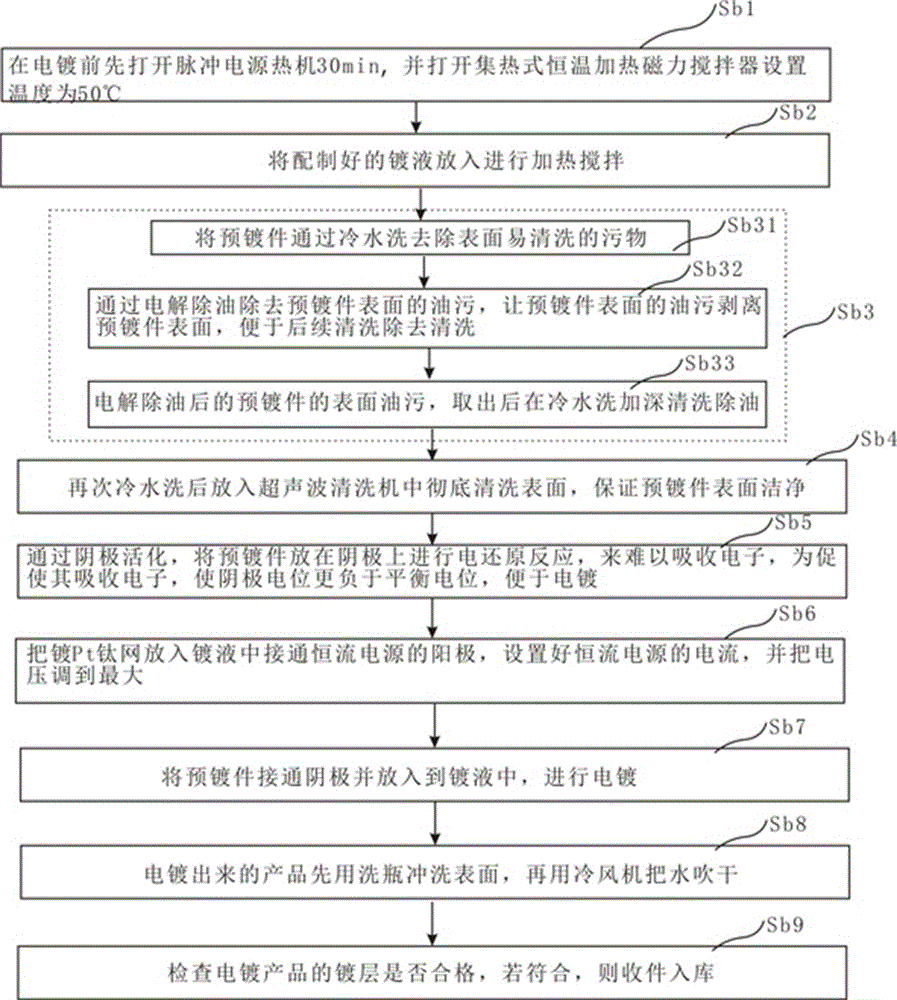

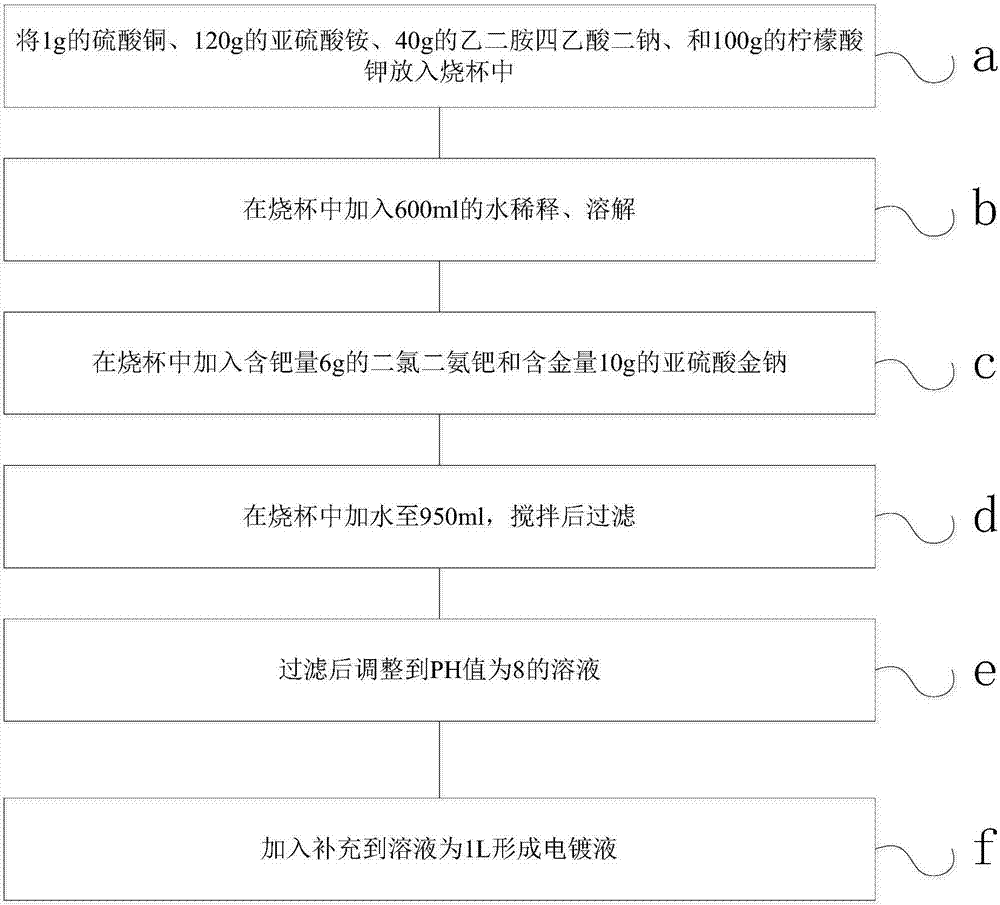

Jewellery rose gold surface treatment plating solution, preparation method and electroplating method thereof

The invention discloses a jewellery rose gold surface treatment plating solution, a preparation method and an electroplating method thereof. The preparation method comprises the following steps: weighing and pouring about 1 g of copper sulphate, about 120 g of ammonium sulphite, about 40 g of EDTA-2Na and about 100 g of potassium citrate into a beaker of 1L; then, adding 600 ml of water for diluting and dissolving, adding a stirring bar, placing the beaker in a heat collection type constant temperature heating magnetic stirrer, and heating and stirring the beaker for 40 minutes; taking out the beaker, and adding diamminedichloropalladium and sodium gold sulphite, wherein the palladium content of the diamminedichloropalladium is about 6 g, and the gold content of the sodium gold sulphite is about 10 g; adding water to about 950 ml, placing the beaker into the heat collection type constant temperature heating magnetic stirrer again, heating and stirring for 15 minutes, taking out the beaker, and filtering the solution; testing the acidity and alkalinity of the filtered solution by using PH paper with the specification of 6 to 9, wherein when the PH value is 8, the solution is the plating solution; if the PH value is less than 8, taking ammonia water by using a plastic cap dropper, adding half of the plastic cap dropper of the ammonia water, stirring for 2 to 3 minutes by using a glass rod, and testing the PH value again until the obtained PH value is 8; adding pure water to complement the solution to 1L to obtain the plating solution.

Owner:江捷新 +1

Claw-type unscrew cap with PE (poly-ethylene) or PP (poly-propylene) cushion layer, and production technology of claw-type unscrew cap

The invention provides a claw-type unscrew cap with a PE (poly-ethylene) or PP (poly-propylene) cushion layer, and a production technology of the claw-type unscrew cap. The cap body of the unscrew cap comprises a tin plate cap with no inner film coating and the poly-ethylene or poly-propylene cushion layer covering the inner surface of the tin plate cap, wherein the cushion layer is a 0.5 to 2.0 mm sealing gasket layer formed by conducting injection molding or dripping molding of poly-ethylene particles or poly-propylene particles on the inner surface of the tin plate cap; a curled edge and a rotating claw are formed by conducting punch forming on the edge of the opening of the tin plate cap with the poly-ethylene or poly-propylene cushion layer. The claw-type unscrew cap and the production technology have the advantages that the structure is simple; the production technology is relatively simple; the sanitary quality of each prepared bottle cap can reach the standard of food and drug safety; the sealing effect is high; the phenomena of fading and poisonous substance volatilization are avoided under a high-temperature condition; a preservative is not required to be added into a food or drug in a bottle sealed with the bottle cap, and can be preserved for a long time only through high-temperature sterilization.

Owner:王海鹏

Pearlescent pigment applied as car spray paint and preparation method thereof

InactiveCN103849168AIncrease brightnessImprove satisfactionInorganic pigment treatmentCoatingsOxide compositeTitanium oxide

The invention discloses a pearlescent pigment applied as car spray paint and a preparation method thereof. The pearlescent pigment is characterized in that the pigment is a pearlescent pigment coated with rutile TiO2, the external of an employed substrate material is coated with a layer of a titanium dioxide film, and also the external of the titanium dioxide film is coated with a coloring agent for forming a metal oxide composite coating; the coloring agent is ferric oxide; and the pearlescent pigment coated with rutile TiO2 employs granular mica as the substrate material. The pearlescent pigment coated with rutile TiO2 is directly prepared according to the following step: preparing a mica suspension by employing deionized water, controlling the pH value, adding a TiCl4 solution with the concentration of 20-25%, at the temperature of 80 DEG C, heating with stirring for reacting, filtering, washing, drying and calcining at 700 DEG C, and performing surface modification processing. The beneficial effects comprise that the pearlescent pigment provided by the invention has the effect of changing color along with angle variation, is relatively good in product brightness and color saturation, is substantially improved in brightness and chroma, is relatively high in stability, does not fade at a relatively high temperature, and is especially applicable as automobile spray paint.

Owner:陈浠

Treating agent for facilitating dyeing of wicker weaving products

InactiveCN106217564AKeep for a long timeExtension of timeWood treatment detailsReed/straw treatmentPentaerythritolSodium ascorbate

The invention discloses a treating agent for facilitating dyeing of wicker weaving products. The treating agent comprises the following components of furfuryl alcohol, corn stigma boiling liquid, borax, urea, pink soak liquid, sodium ascorbate, pentaerythritol, water and an additive. Compared with a current wicker weaving product treating agent, the treating agent provided by the invention is simple in preparation method; a treatment method after preparation is simple; the dyeing ability of treated wicker weaving products is greatly improved, so that surface permeability and colourability of dye for wicker are greatly improved, and the dye can uniformly and rapidly enter the surface of the wicker; the average time for coloring and color fixing is shortened by 20% compared with that of untreated wicker products; the color fastness is good after dyeing; color is uniform; stability is high; and color fading cannot occur.

Owner:安徽阜南县万家和工艺品有限公司

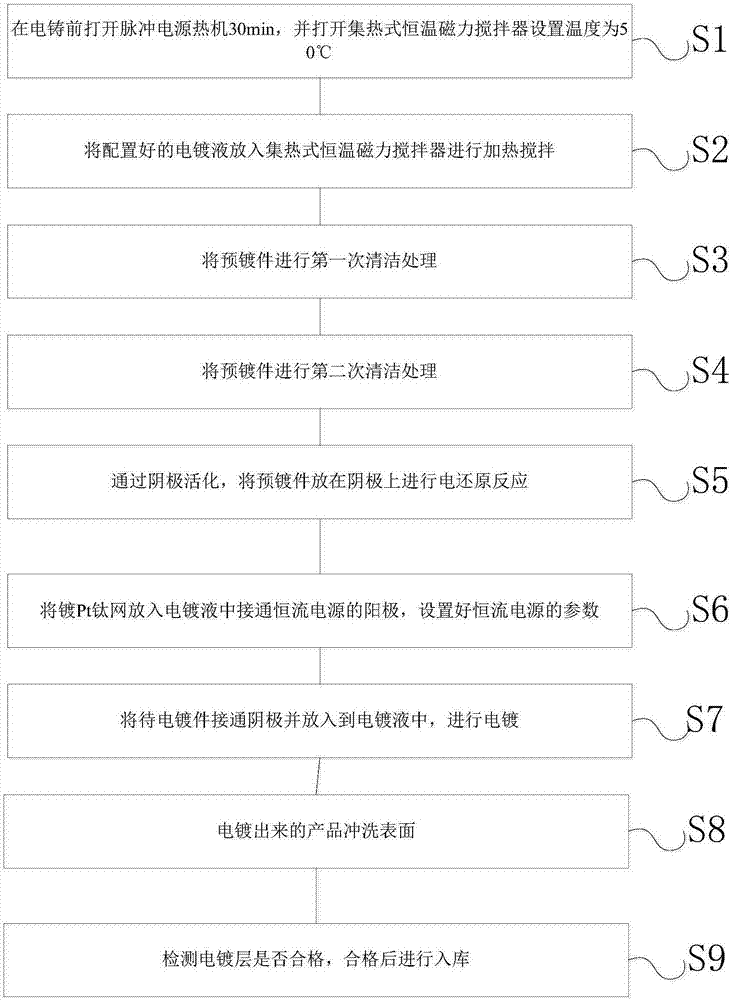

Rose gold electroplating liquid, preparation method and electric casting method

The invention provides rose gold electroplating liquid, a preparation method and an electric casting method. The rose gold electroplating liquid comprises 0.5-2 g of copper sulfate, 100-125 g of ammonium sulfite, 25-55 g of ethylene diamine tetraacetic acid, 85-115 g of potassium citrate, dichlorodiamminepalladium with a palladium content of 4-7 g, and sodium gold sulfide with a gold content of 5-15 g. In the rose gold electroplating liquid, the preparation method and the electric casting method, the rose gold electroplating liquid is excellent in electroplating effect, high in electroplating brightness and incapable of fading after long-time use.

Owner:深圳百泰新贵科技有限公司

Epoxy anticorrosive paint for circuit board as well as preparation method thereof

InactiveCN103589288AEvenly dispersedGuaranteed stabilityAnti-corrosive paintsEpoxy resin coatingsEpoxyShock resistance

The invention discloses epoxy anticorrosive paint for a circuit board. The epoxy anticorrosive paint is characterized by being prepared from the following raw materials in parts by weight: 80-85 parts of E-12 epoxy resin, 3-4 parts of aluminum powder, 1.4-1.6 parts of hexamethylene tetramine, 2-3 parts of triethyl acetyl citrate, 5-7 parts of talcum powder, 1-2 parts of an antioxidant DSTP (disteaxylthiodipropionate), 3-4 parts of vinyl tri(beta-methoxyl ethyoxyl) silane, 2-3 parts of isopropanol, 15-20 parts of ethyl acetate, 1-2 parts of zinc cyanurate, 3-4 parts of zinc oxide, 12-15 parts of bauxite, 2-3 parts of isocyanate and 3-4 parts of a dispersing auxiliary. The dispersing auxiliary improves the optical property, so that the paint is uniformly dispersed, and the stability of the paint is maintained. The gasoline and machine oil wiping resistant epoxy anticorrosive paint is mainly applied to metal surfaces and advertising boards, has excellent anticorrosive property, adhesive force, hardness, shock resistance and covering power, and is free from color fading.

Owner:ANHUI LANRUN AUTOMATION INSTR

Composite nano-paint for exterior wall

InactiveCN101440240AExcellent weather resistance and aging resistanceExtended service lifeCoatingsNanometreEmulsion

The invention relates to outer wall composite nano paint. The outer wall composite nano paint consists of the following raw materials: nano composite material II, plasticizing agent, pure water, dispersant, antifreeze, defoaming agent, nano titanium dioxide, flatting agent, styrene-acrylic emulsion, fine particle calcium carbonate and coarse whiting, thickening agent and film forming additive, wherein based on the total weight of inner wall nano paint, the outer wall composite nano paint comprises 7.2 percent of the nano composite material II, 2.8 percent of the intensifier, 0.3 percent of the dispersant, 2.6 percent of the antifreeze, 0.3 percent of the defoaming agent, 26 percent of the nano titanium dioxide, 0.6 percent of the flatting agent, 33 percent of the styrene-acrylic emulsion, 8 percent of the fine particle calcium carbonate and coarse whiting, 1 percent of the thickening agent, 2.2 percent of the film forming additive, and the balance being pure water. The outer wall composite nano paint integrates the functions of heat insulation, fire retardation, heat preservation, environment protection, high elasticity and impact resistance.

Owner:陈莹

Special luminous pearlescent pigment for ceramic firing

The invention discloses a special luminous pearlescent pigment for ceramic firing. The pigment is characterized in that the pigment comprises a sheet substrate, the substrate is coated with a high-refractive-index coat, and the high-refractive-index coat is coated with a layer of a coloring agent to form a metal oxide composite coat. The coloring agent is ferric oxide. The sheet substrate is synthetic mica composed of a long-afterglow luminous material and a base flux. The special luminous pearlescent pigment is optically variable, and has the advantages of good brightness and color saturation, high brightness, intelligible pattern, color variety, excellent glaze quality, strong mechanical performances, and high chemical stability; and the coating of the inorganic metal oxide-ferric oxide makes the pigment have a high stability and not fade under high temperature firing conditions.

Owner:许志永

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com