Patents

Literature

91results about How to "Ensure hygienic quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

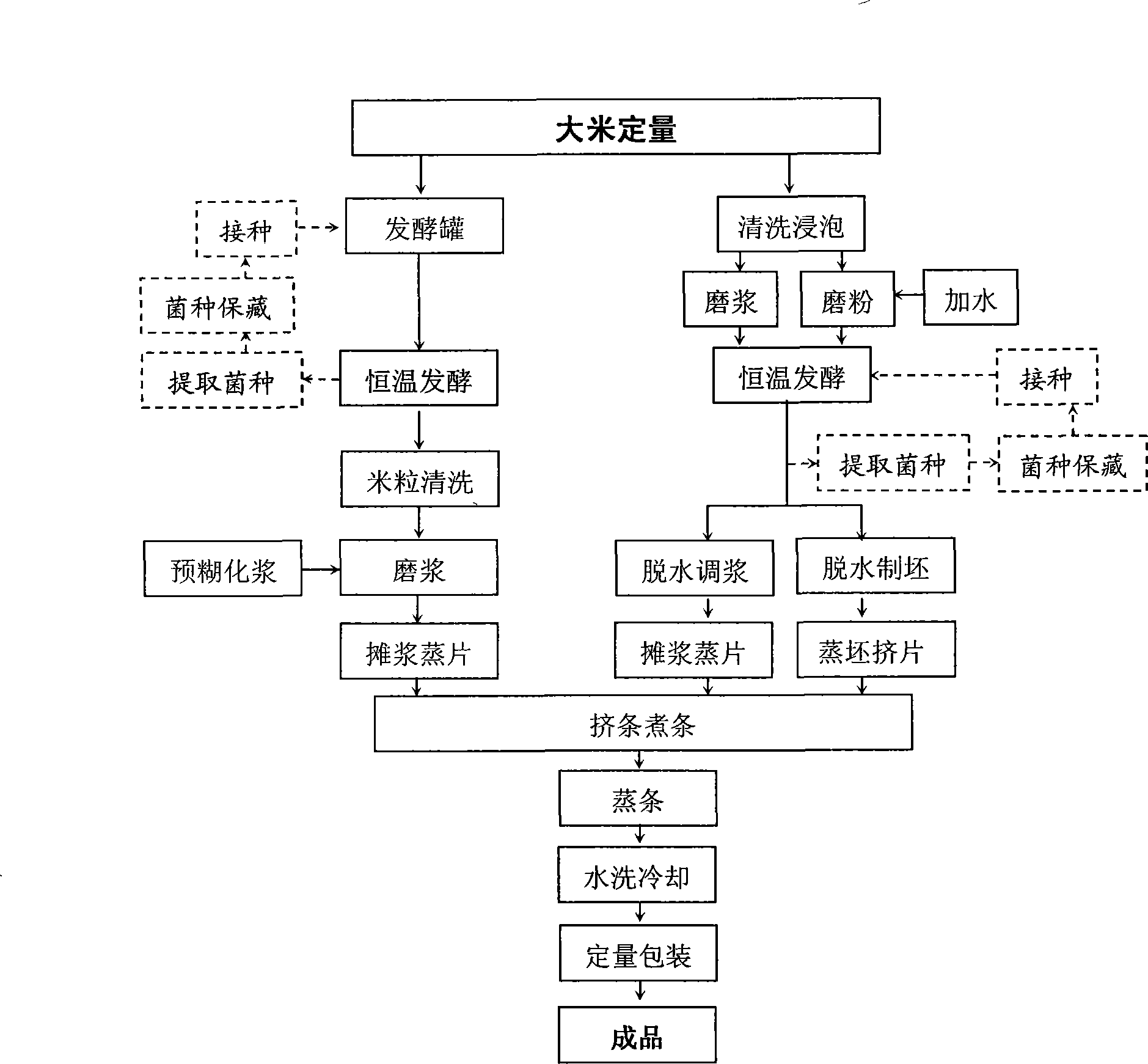

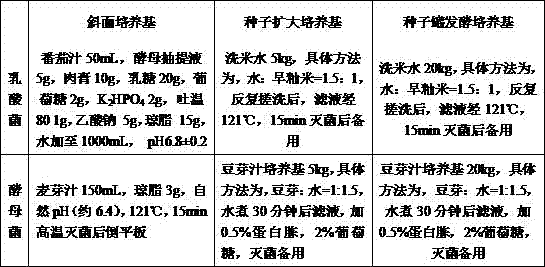

Method for processing lactic acid bacteria fermentation rice-flour noodles

InactiveCN101248852AShorten the production cycleReduce manufacturing costFood preparationBiotechnologyBroken rice

The invention discloses a processing method for fermenting rice flour by lactobacillus, namely using the lactobacillus to ferment and produce rice flour food with high quality, belonging to the technology field of food process. The technical proposal comprises the following steps of grinding the rice flour to thick liquid, spreading the thick liquid to steam a sheet, extruding and cooking rice bars, steaming the rice bars, and washing and cooling the rice bars. The processing method is characterized in that the selected material is rice or broken rice with amylose starch content more than 20%, the lactobacillus is added into the rice flour for fermentation at a constant temperature before or after grinding the rice flour to thick liquid, the number of the lactobacillus is 10<6> - 10<11>cfu / ml, the fermentation temperature is 30-50 DEG C, and the fermentation time is 8-18 hours. The processing method avoids the danger of latent miscellaneous bacteria by adopting pure strain enrichment fermentation, improves the flexibility and ensures the cleanness and the quality of the rice flour by utilizing pre-pasting rice milk instead of reserved rice sheet and fermented glutinous rice, and saves production cost due to the short production period.

Owner:CHINA AGRI UNIV

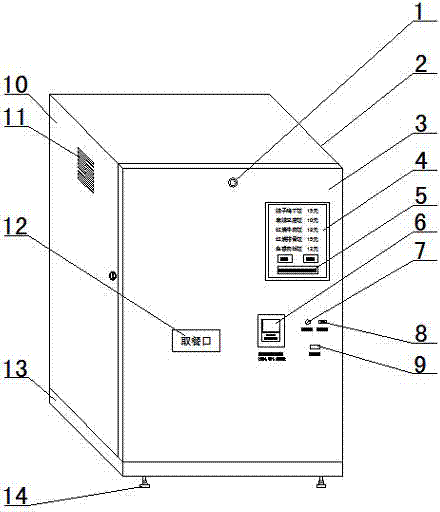

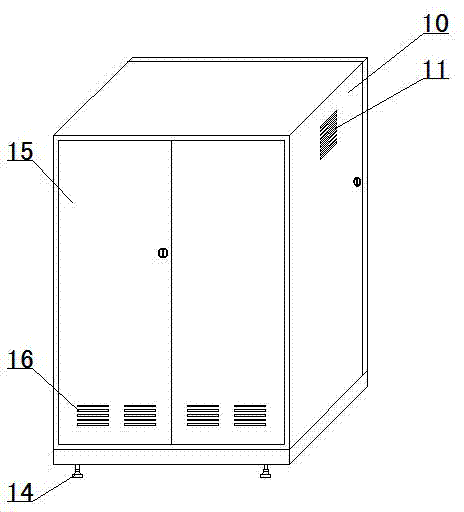

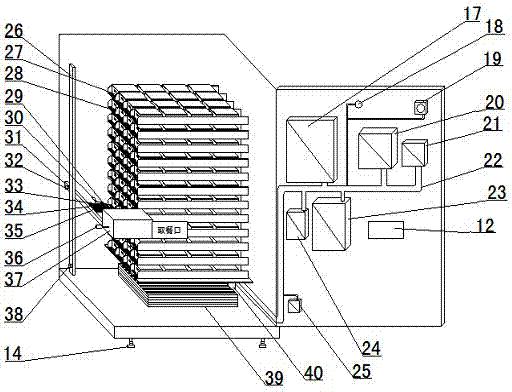

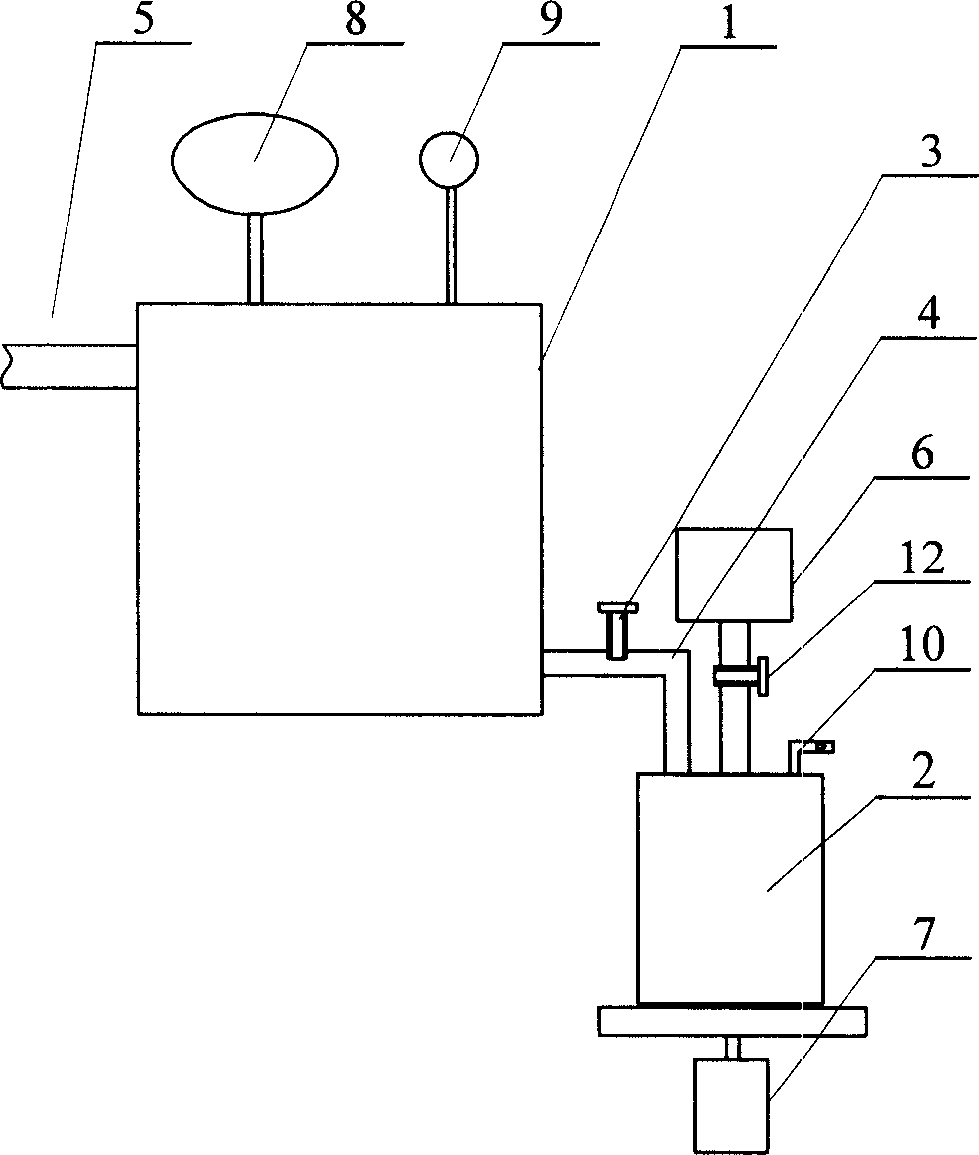

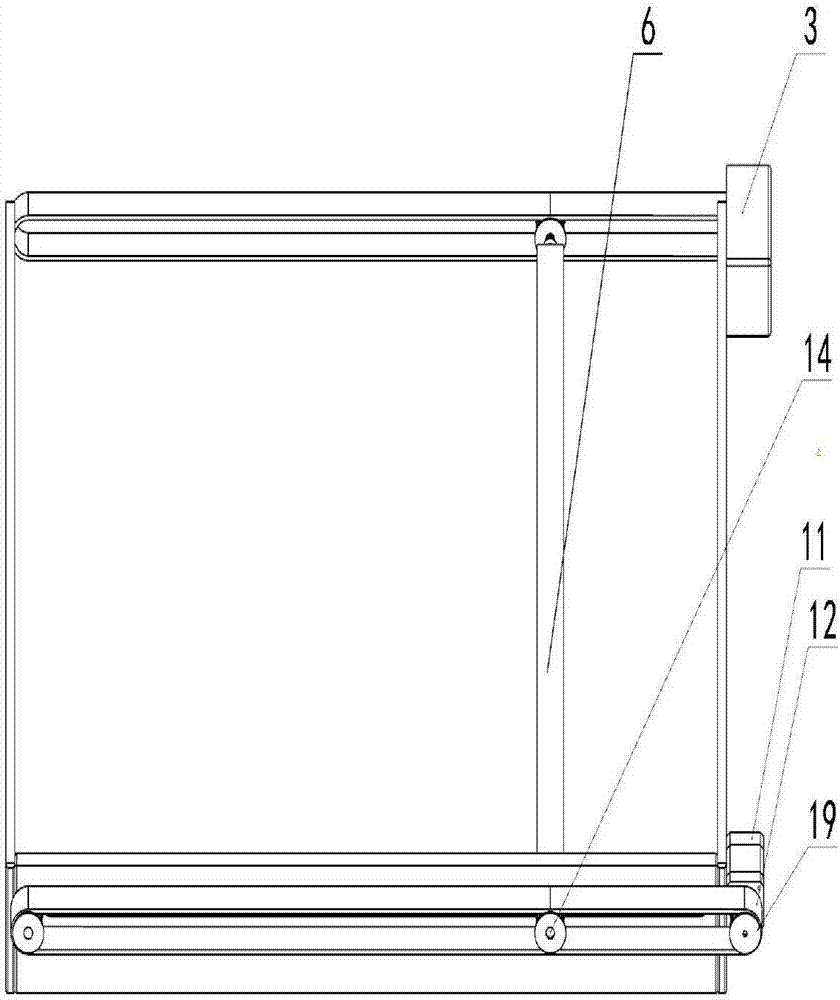

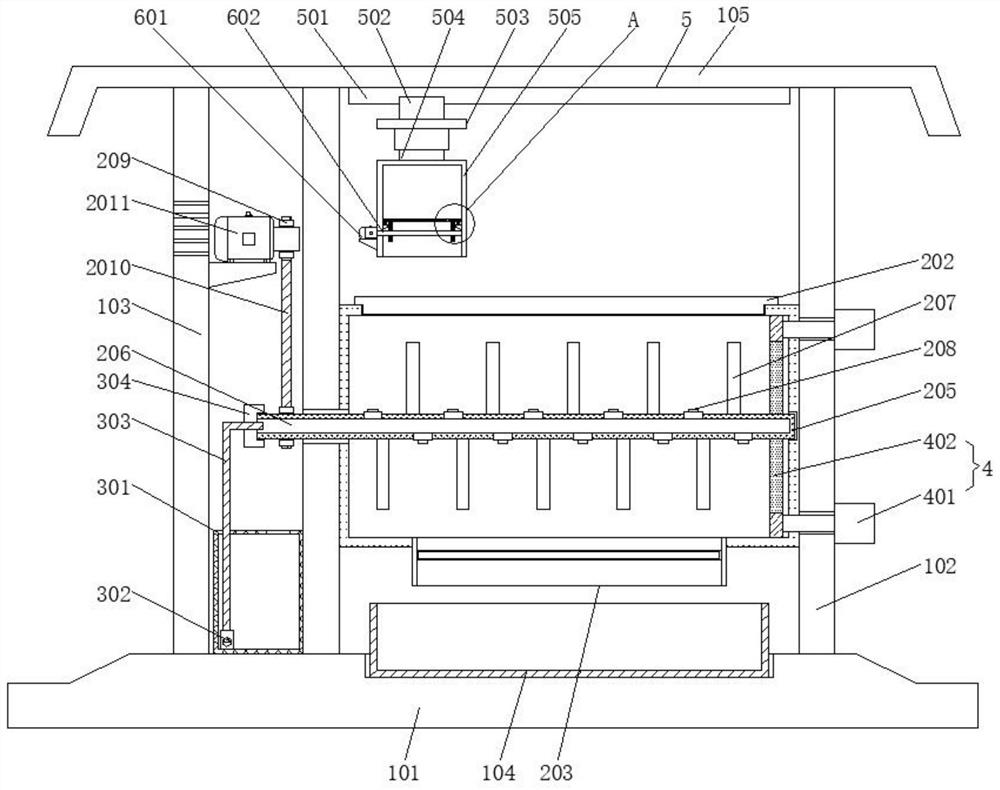

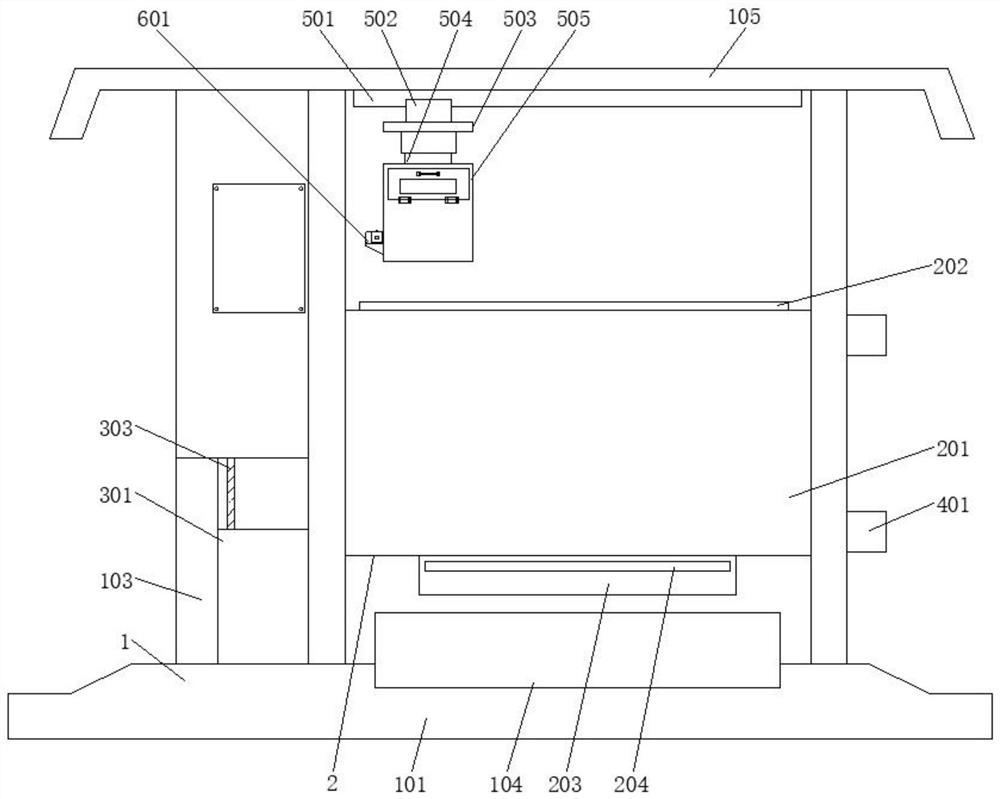

Cloud-control automatic meal-selling machine

InactiveCN104778784AEnsure hygienic qualityExtended shelf lifeCoin-freed apparatus detailsApparatus for dispensing discrete articlesMicrowaveRemote control

The invention discloses a cloud-control automatic meal-selling machine, which comprises a case, a control system, a meal-ordering system, a meal conveying system, a heating system, a constant-temperature refrigeration system, a monitoring system, a sterilization and deodorization device and a cloud control system, wherein the case is provided with a front door, a side door and a rear door, and the front door, the side door and the rear door are hinged to the machine body of the case; the control system, the meal conveying system, the heating system, the constant-temperature refrigeration system, the monitoring system and the sterilization and deodorization device are all arranged in the case; the meal-ordering system is arranged on the front door. According to the cloud-control automatic meal-selling machine, remote control and 24h automatic selling can be realized, thereby being convenient and quick; food in the automatic meal-selling machine is stored in the refrigeration environment, the system automatically sends the refrigerated food to a built-in big-power microwave heating device to be heated and then sends the heated food to a meal taking hole when a consumer purchases the food, expiration date is greatly prolonged, the sanitary quality of box lunches can be guaranteed to a large extent, all-weather selling is realized, and conversion from selling by people to self-service selling can be realized.

Owner:马放

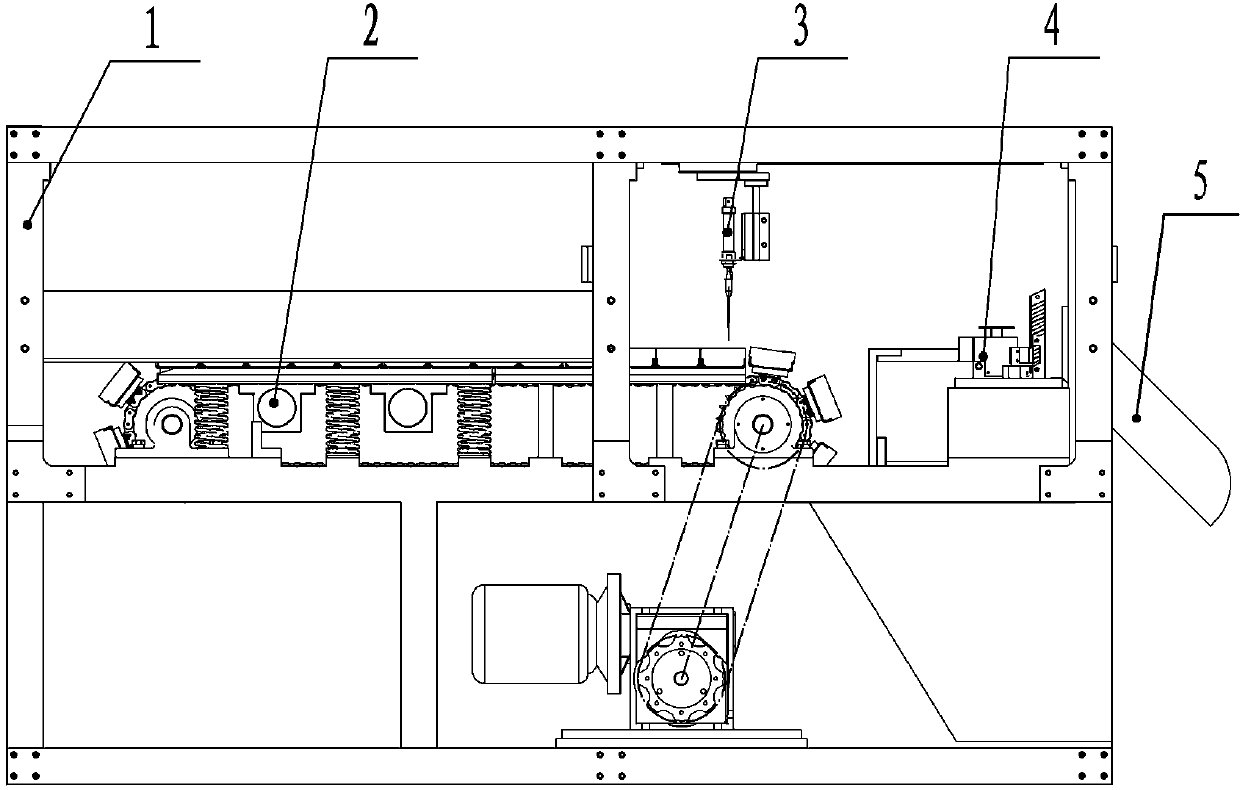

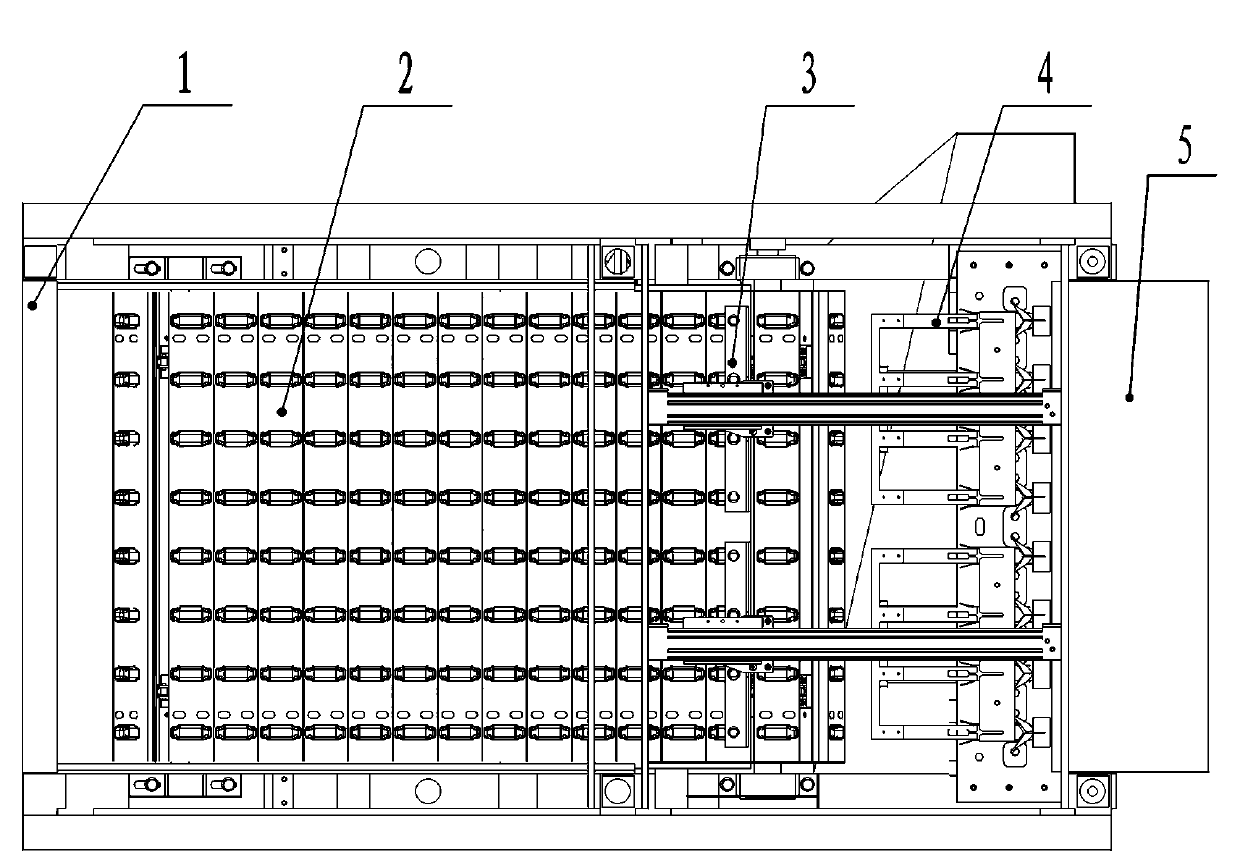

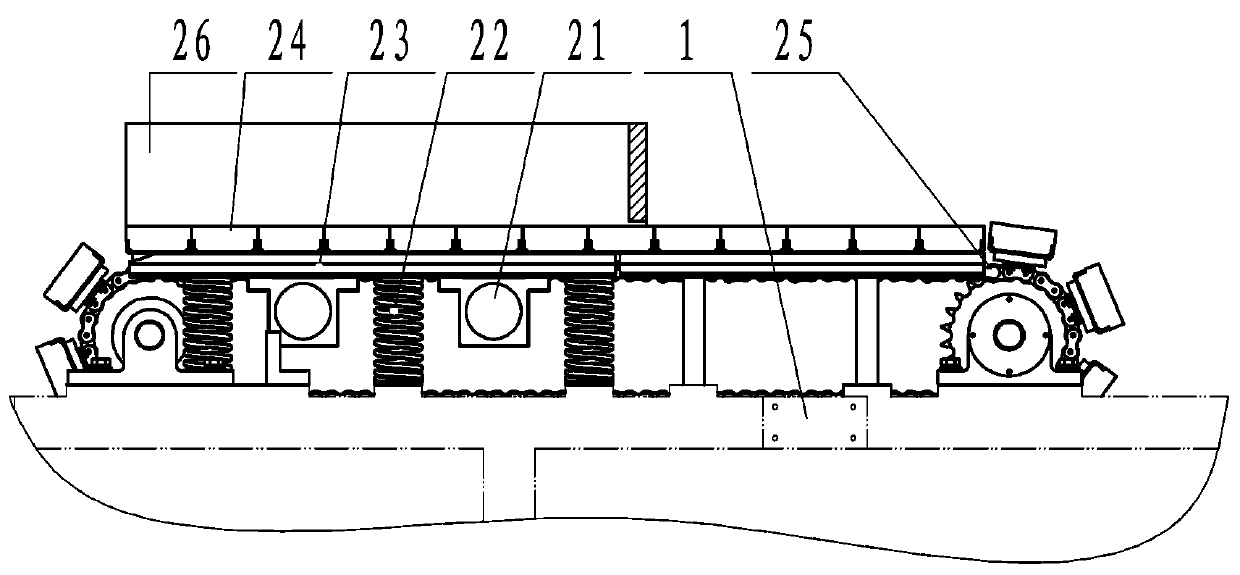

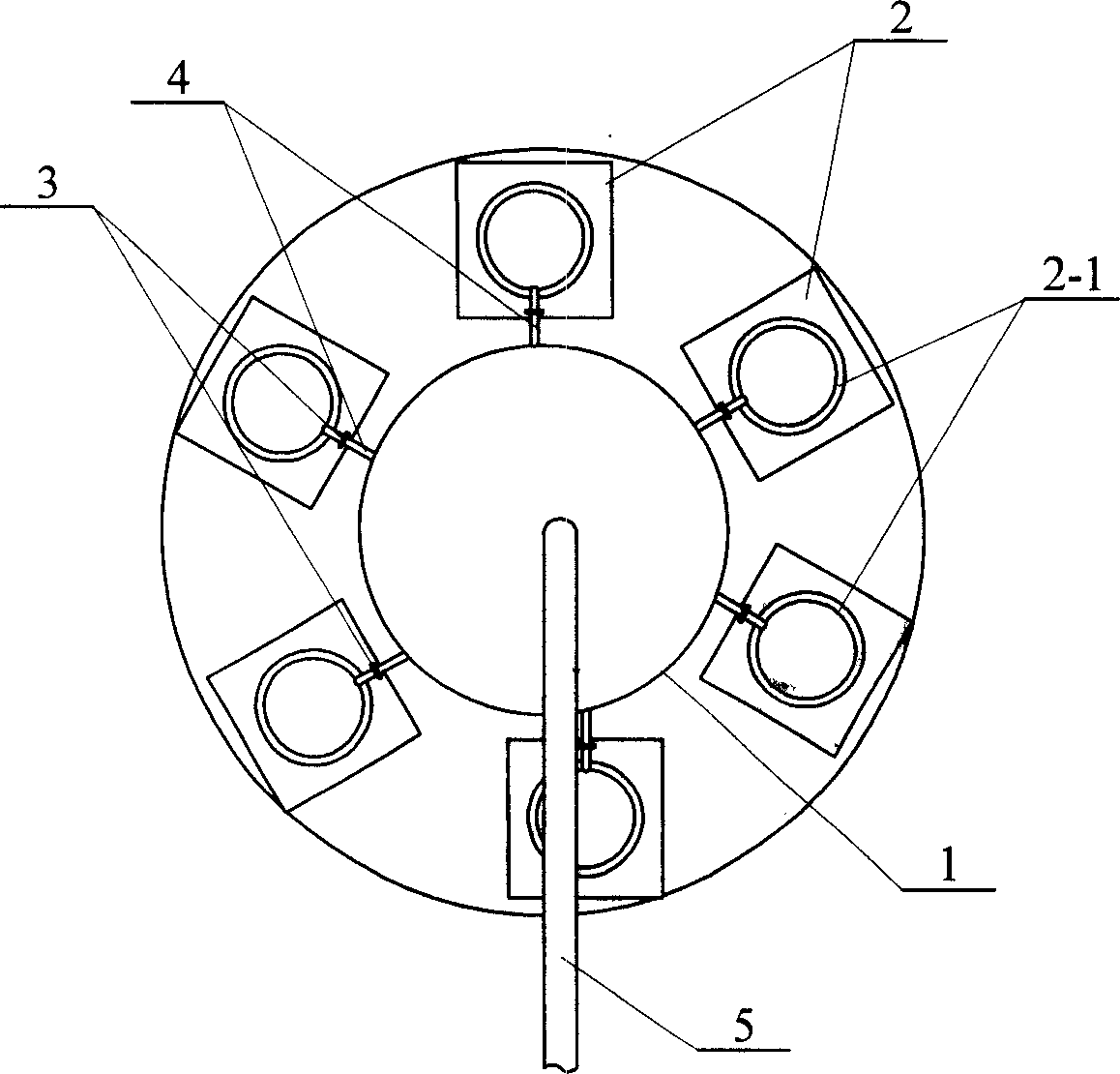

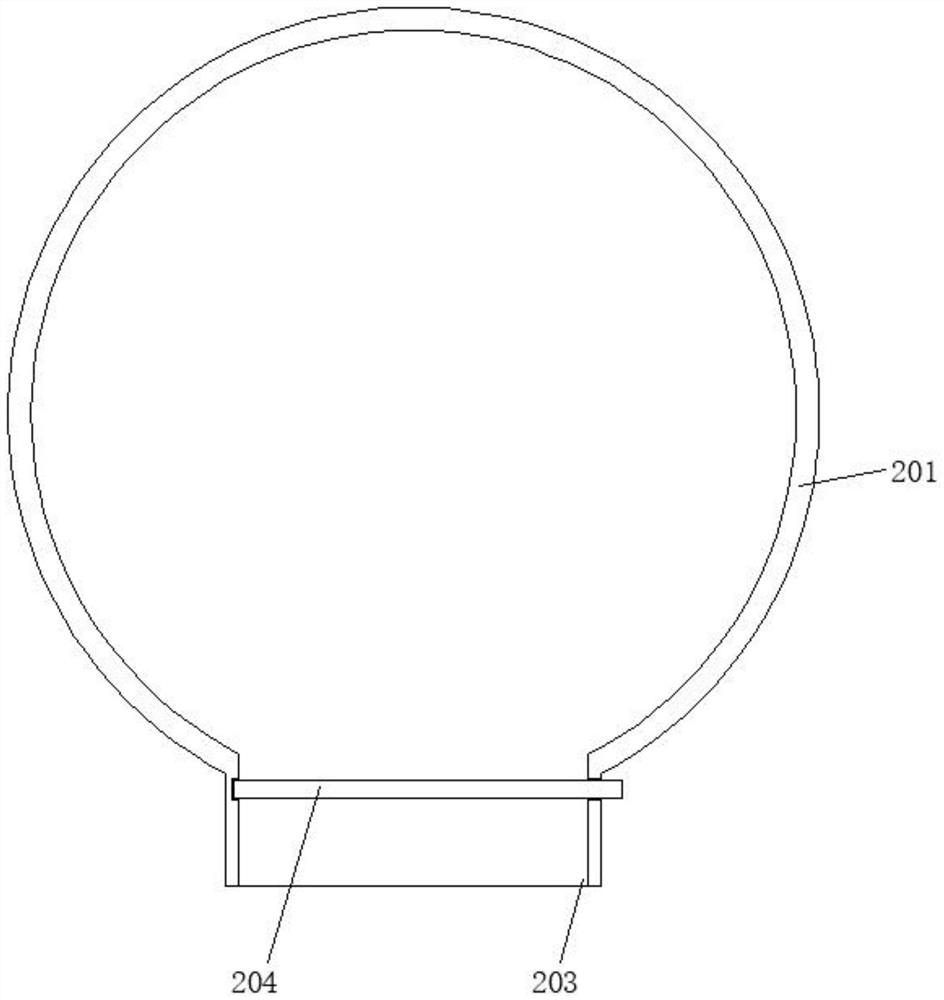

Full-automatic areca nut slicing machine

InactiveCN103273517AImprove slicing efficiencyEnsure personal safetyMetal working apparatusEngineeringMechanical engineering

A full-automatic areca nut slicing machine is characterized in that the full-automatic areca nut slicing machine is mainly composed of a machine frame assembly, a vibration assembly, a shifting assembly and a slicing assembly, the vibration assembly, the shifting assembly and the slicing assembly are sequentially connected to the machine frame assembly, the vibration assembly is mainly composed of a vibration source, a supporting spring, a die supporting plate, a transmission chain and a material arrangement die in a connected mode, a plurality of areca nut grooves are regularly arranged in the material arrangement die, the shifting assembly is mainly composed of an inserting pin, a lifting air cylinder, an air cylinder installation plate, an inserting pin air cylinder and a horizontally moving assembly, the slicing assembly is installed at one end of the shifting assembly through an installation support, and the slicing assembly is mainly composed of a seed removal assembly and a slicing knife, an areca nut upper baffle with an opening groove and a center positioning device. The full-automatic areca nut slicing machine is relatively simple in structure and low in manufacturing cost, liberates a large amount of workforce after the full-automatic areca nut slicing machine is used in the areca nut slicing process, greatly improves areca nut slicing processing efficiency, ensures sanitary quality of products, reduces production cost, and fundamentally ensures personal safety of operators.

Owner:HUNAN KOUWEIWANG GRP

Method for processing lactic acid bacteria-fermented rice-flour noodles

The invention discloses a method for processing lactic acid bacteria-fermented rice-flour noodles, and belongs to the technical field of food processing. The method comprises the following steps: jordaning, spreading pulp and steaming, extruding and boiling, steaming, washing and cooling, wherein the selected raw material is rice or broken rice of which the straight-chain starch content is greater than 20%; compound lactobacillus is added before or after a pulping process to carry out constant-temperature fermentation; the quantity of the compound lactobacillus is10*<6> to 10*<11>cfu / ml; the fermentation temperature is 35-45 DEG C; the fermentation time is 10-20 hours. The harm of latent mixed bacteria is eliminated by using pure enrichment fermentation, the toughness effect is better, the sanitation and the health of the rice-flour noodles are ensured, and the quality and the flavor of the product are improved.

Owner:QINGDAO ANBEIKANG BIOLOGICAL MEDICINE TECH CO LTD

Protein powder for fodder, and preparing method and use thereof

InactiveCN1507790AReduce energy consumptionLow costEgg immunoglobulinsProtein composition from eggsEscherichia coliAnimal science

The present invention relates to a preparation method of feed protein powder containing colibacillus yolk antibody whose active valence is greater than or equal to 1:64 and its application. Its preparation method includes the following steps: preparing serotype colibacillus immunogen, using said immunogen to immunize health egg-laying hen, immunogen injection dose is 0.5-3.0 ml / every hen, collecting the egg laid by hen after which is immunized for 7-10 days, remaining the egg containing colibacillus yolk antibody whose active valence is greater than 1:64 for stand-by, using whole egg liquor to make pasteurization and spray-drying.

Owner:北京同力兴科农业科技有限公司

Automatic stick-inserting mechanism for meat string

InactiveCN1775045AEnsure hygienic qualityAvoid affecting the plugging phenomenonMeat processing devicesEngineeringMechanical engineering

Owner:HARBIN UNIV OF COMMERCE

Process for dehydrating fruits, vegetables and traditional Chinese herbs through low-pressure penetration of gas

InactiveCN102349687AQuality improvementEnsure hygienic qualityDrying using combination processesDrying gas arrangementsNutritionSpinach

The invention discloses a process for dehydrating fruits, vegetables and traditional Chinese herbs through low-pressure penetration of gas, which is mainly used for the fruits, vegetables and Chinese herbs such as strawberry, tomato, spinach, Chinese cabbage, celery leaves, medlar and the like, and comprises the following steps that: 1) pretreatment of raw materials->2) gas penetration procedure->3) hot drying. The process has beneficial effect that: the raw materials are dried and dehydrated under low temperature and at a vacuum state, so the loss of nutrients and flavor of the fruits, vegetables and Chinese herbs during the high-temperature drying process can be avoided, and original nutrition, active substances, active ingredients, color and fragrance of the materials can be maximally maintained. The investment of equipment is small, the process cost is low, the equipment is convenient to install and maintain, and the technique method is easy to control.

Owner:JIANGSUCHINA PALARICH

Novel independent temperature and humidity control method and system

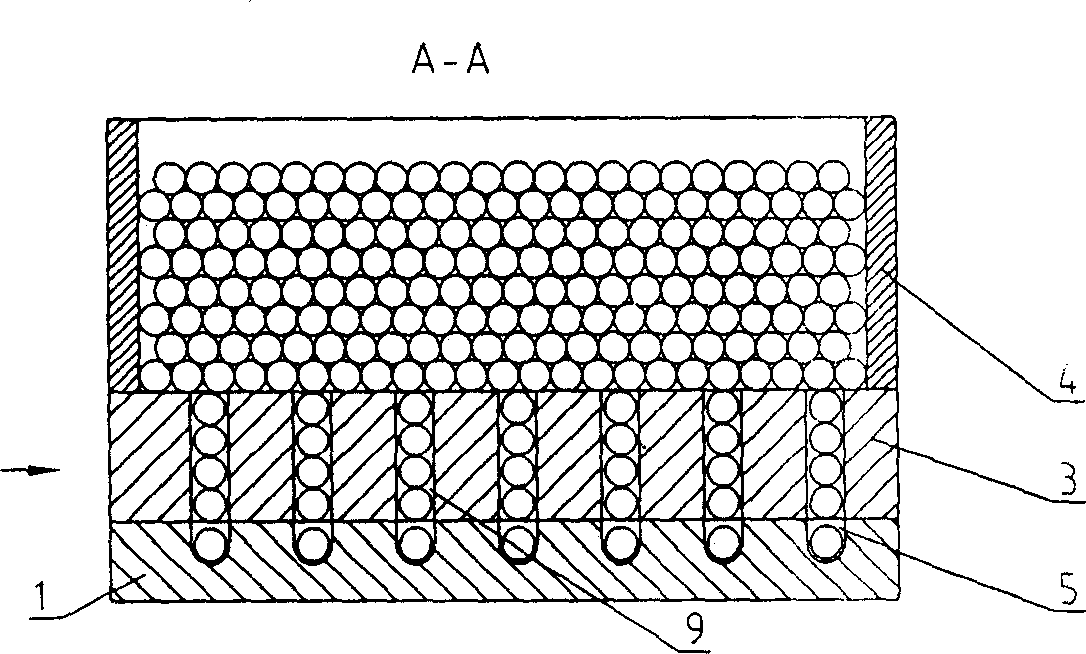

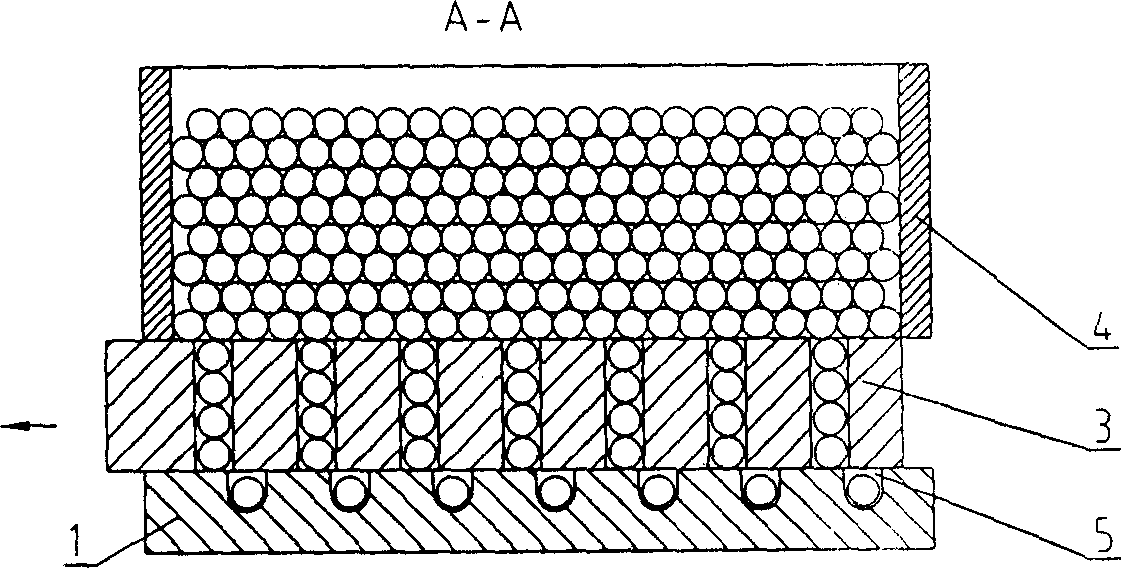

InactiveCN106369769AReduce humidityNo precipitationMechanical apparatusSpace heating and ventilation safety systemsControl systemEngineering

The invention discloses a novel independent temperature and humidity control method and system. According to the novel independent temperature and humidity control method, in summer, when the indoor temperature exceeds the first preset temperature, a dehumidification fresh air ventilator is started firstly, a sensible heat multigang machine is started when the dew point temperature of indoor air is lowered to the preset dew point temperature, the evaporating temperature of the sensible heat multigang machine is set as a preset evaporating temperature, and the preset dew point temperature is lower than the preset evaporating temperature; and in winter, when the indoor temperature is lower than the second preset temperature, the dehumidification fresh air ventilator is started to carry out heating and dehumidification on outdoor air and then feeds the outdoor air into a room, and the sensible heat multigang machine is started simultaneously to heat the indoor air. The number of steps of the novel independent temperature and humidity control method is small, the control system is simple in structure, indoor sensible heat loads and latent heat loads can be processed separately, energy consumption is low, and the method and system can well adapt to the change of a dampness-heat ratio.

Owner:SHANGHAI LANDLEAF BUILDING TECH CO LTD

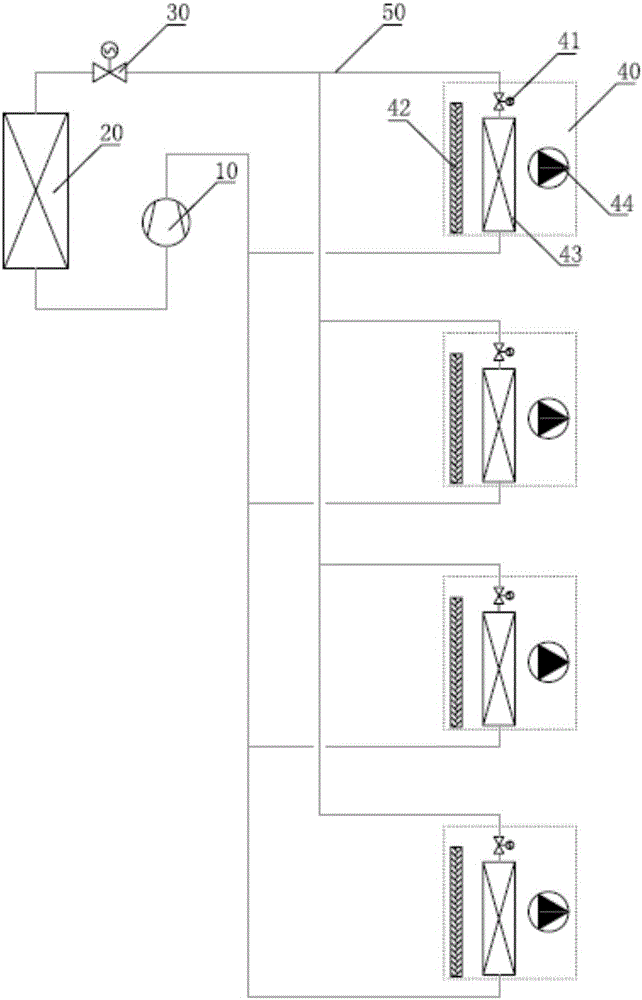

Production method of cooking wine

InactiveCN101396107AEnsure safetyGuaranteed yieldAlcoholic beverage preparationFood preparationCritical control pointGenetically engineered

The invention discloses a method for manufacturing a cooking wine product, belonging to the field of seasonings. The invention is characterized in that: spice is added; different dishes correspond to different alcoholic degree; key control points are optimized. The invention comprised the production course of mixing of raw material, filtering, sterilizing, bulking, cap screwing, lamp testing, labeling and code spraying followed by thermal shrinkage of plastic caps, incasing, and random inspection of the prepared cooking wines. In the invention, non-GM and green food is adopted as raw materials; 2Kg of diatomite is added to the filter recycling barrel with a pressure of 0.3Mpa and the sterilization temperature of 115-120 DEG C; the device is firstly rinsed with 2% alkali lye at 80 DEG C for 20 minutes, secondly rinsed with 2% acid liquor at 80 DEG C for 20 minutes and thirdly rinsed for 30 minutes, and then filled with water for later use; the finished product contains amino-acid nitrogen which is equal to or more than 0.2g / L, total acid which is 3-30g / L, salt which is equal to or more than 10.0g / L, and total sugar which is 0-80g / L, with alcoholic degree being 5-23V / V and color number being 40-50. The invention is characterized in that a spice is added to the raw material for manufacturing the cooking wine, the method is scientific and the obtained product is of top quality.

Owner:北京首农味业集团有限公司

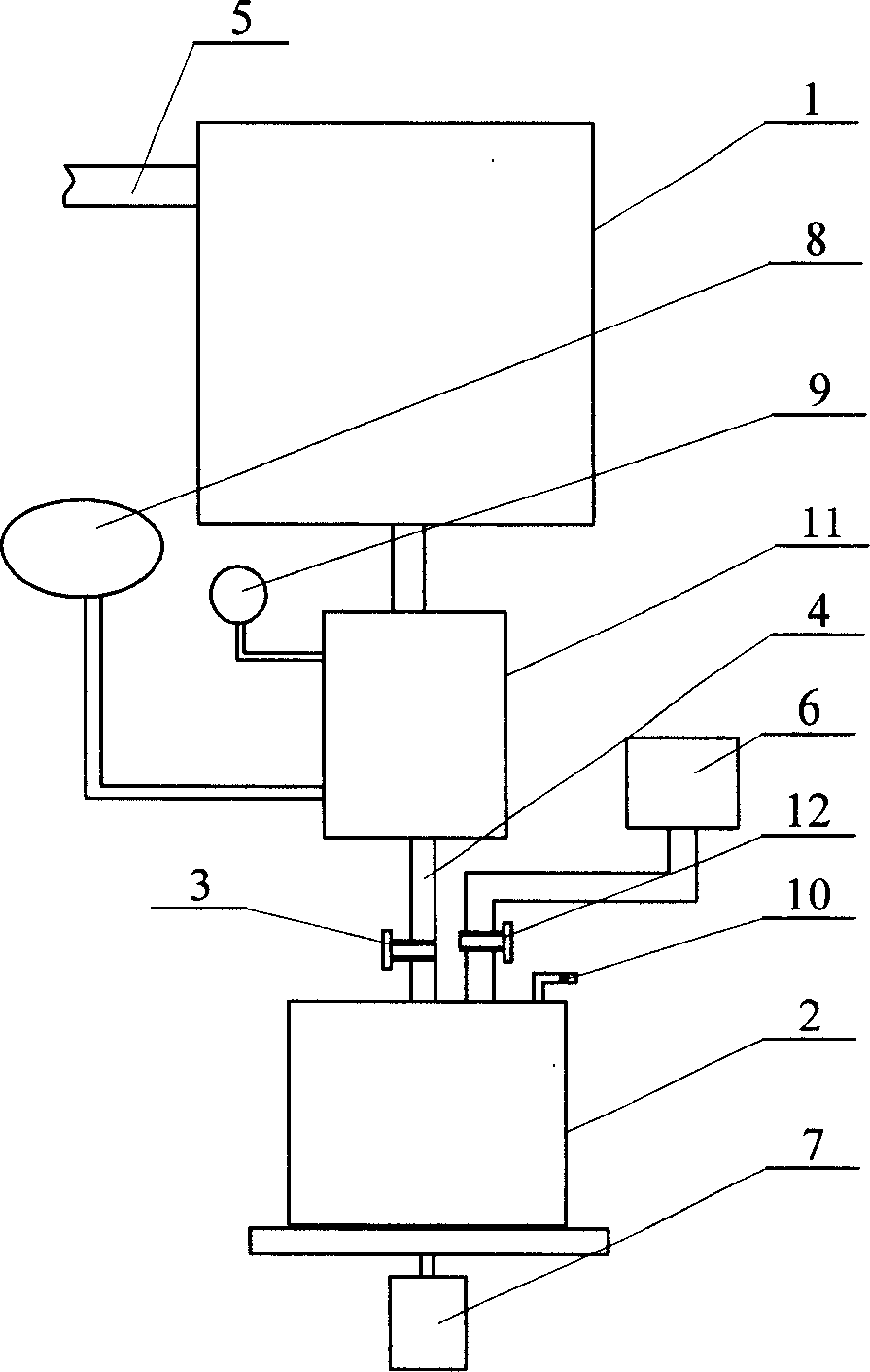

Automatic coagulating agent adding method in soybean curd production process and used automatic coagulating agent adding device

InactiveCN1823619AIncrease productivityUniform product qualityFood preparationEngineeringStorage tank

An automatic coagulating machine for producing bean curd is composed of a bean milk storage tank with milk inlet tube, a bean milk coagulating tank and a pipeline with valve for communicating both tanks with each other. Its method features that the procedure of making the bean milk flow in the coagulating tank is controlled.

Owner:HARBIN UNIV OF COMMERCE

Comprehensive treatment method of wastes in slaughtering process of meat duck

InactiveCN101748155AAvoid pollutionIncrease hydraulic loadWaste based fuelWater/sewage treatment by ion-exchangeConstructed wetlandEngineering

The invention discloses a comprehensive treatment method of wastes in the slaughtering process of a meat duck, which comprises the following steps: firstly, fermenting the discharged solid wastes to generate methane; and secondly, using discharged sewage to purify artificial wetlands. By adopting the method, matters and resources among industries are utilized in a cascade manner, a biomass industry chain is lengthened, and the pollution of pollutants to meat products and the damage to human health are efficiently controlled, so that the standardization production is achieved, and the food hygienic quality is ensured. The comprehensive treatment method forms a coexisting and interdependent industrial ecological chain, so that biological resources are optimally configured, and the economic and ecological multiplication effect is converted, thereby having good social benefit and economic benefit.

Owner:高顺兴

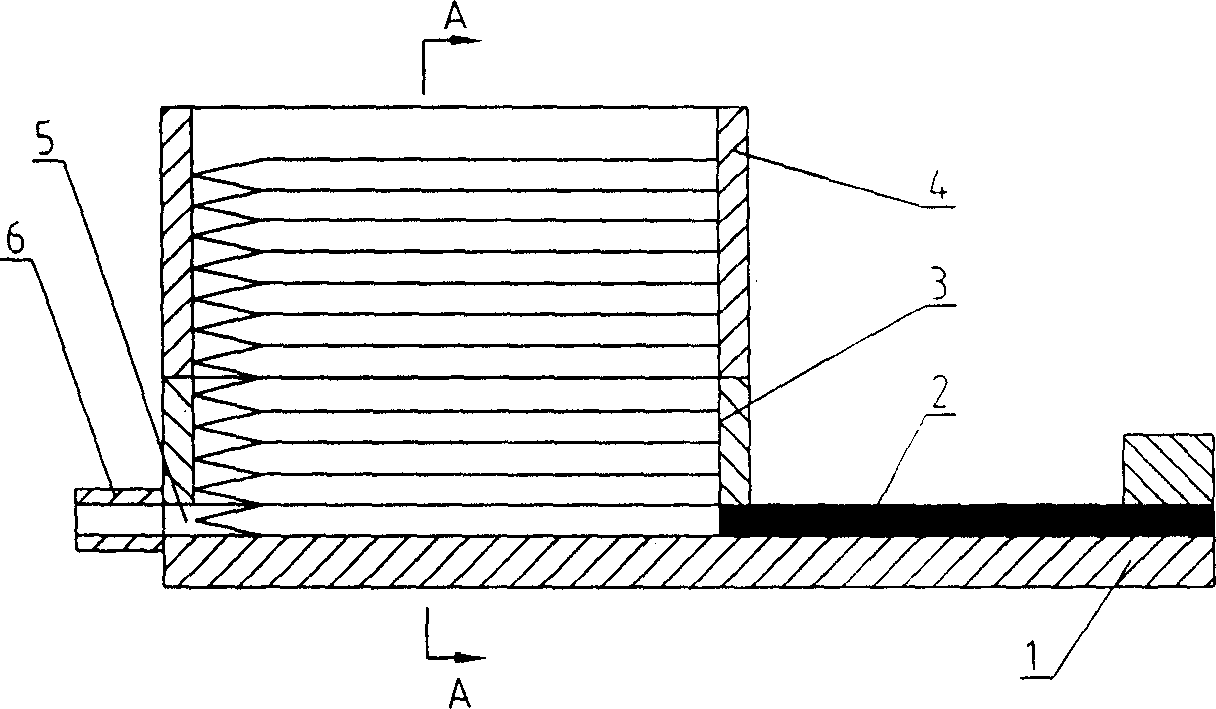

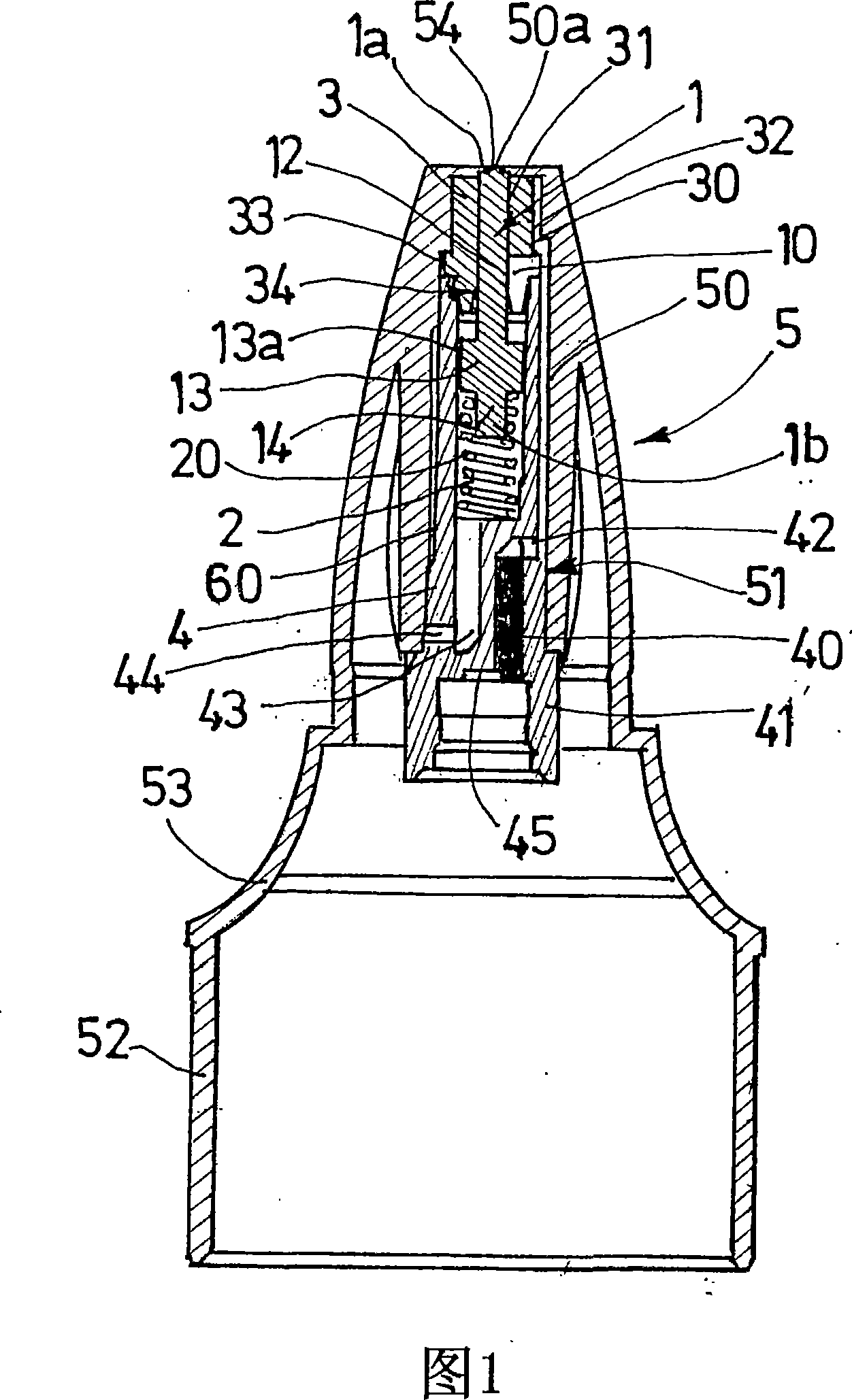

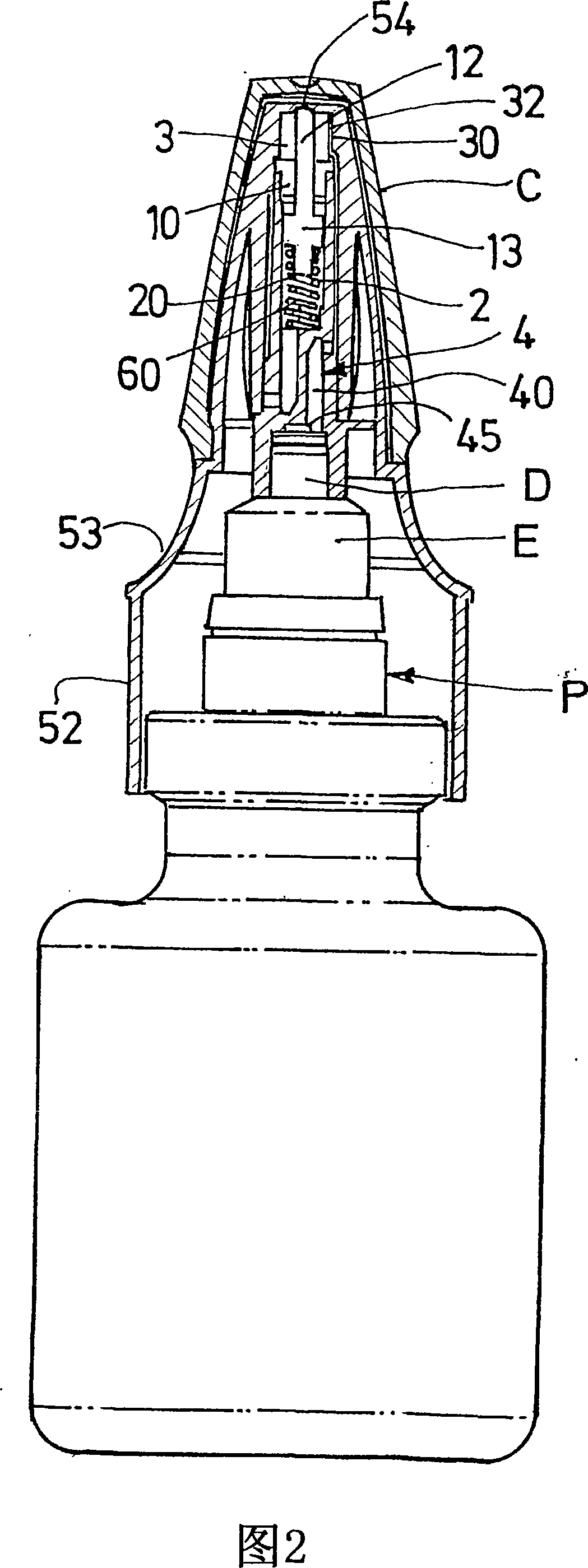

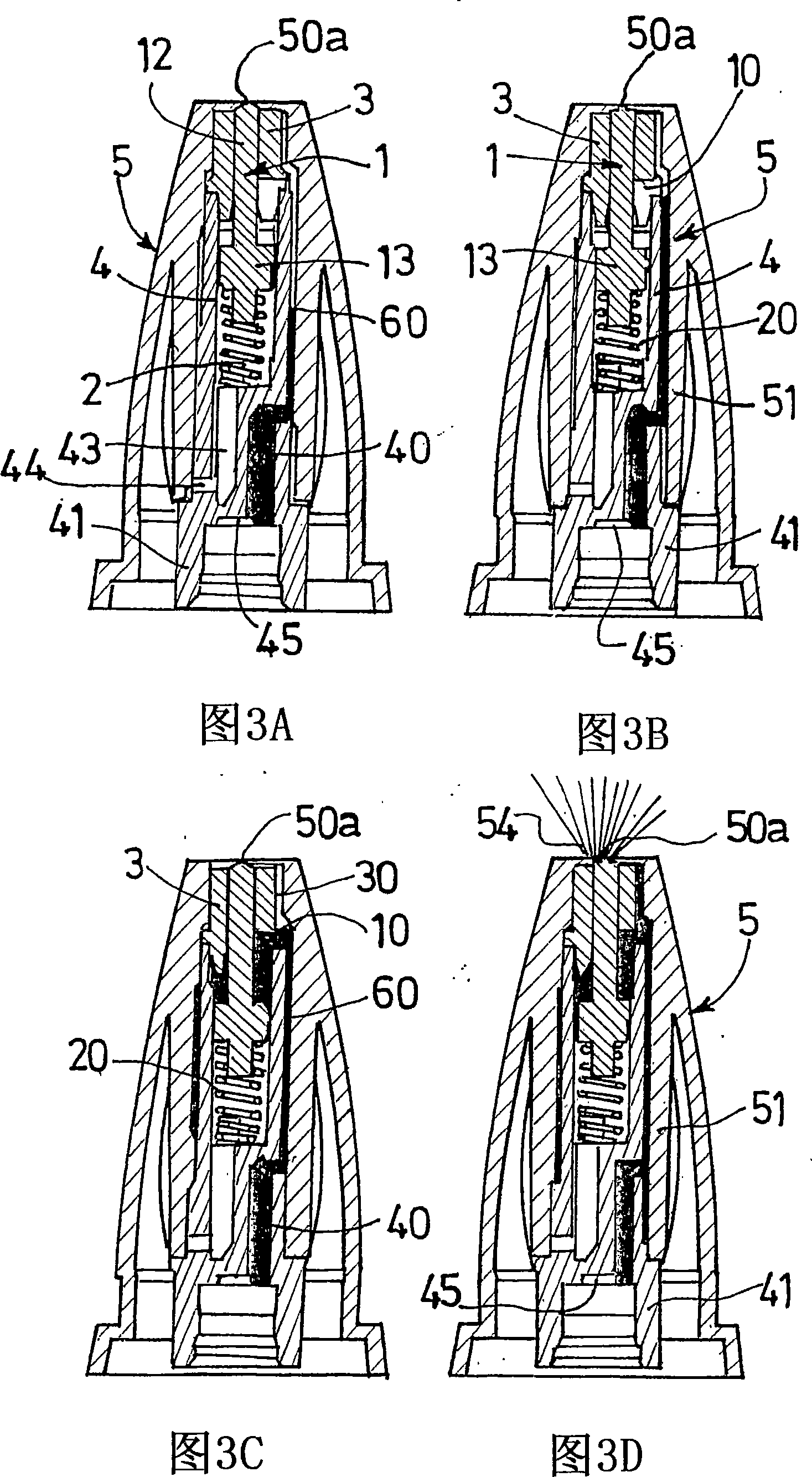

Push-button nozzle for liquid product dispenser

InactiveCN101203320AGuaranteed physical and chemical performanceEnsure hygienic qualityClosuresSpray nozzlesLiquid productEngineering

The invention concerns a push-button nozzle for liquid or semi-liquid product dispenser, said dispenser comprising means (P) for delivering the product under pressure which are mounted on the product container bottle and which comprise an ejection tube (E) projecting outside. The invention is characterized in that said nozzle comprises a needle valve (1) tightly closing the spraying orifice (50a) provided at the end of said nozzle, means for being fixed on the ejection tube and means for supplying products to a turbulence chamber located proximate said orifice.

Owner:NEMERA LE TREPORT

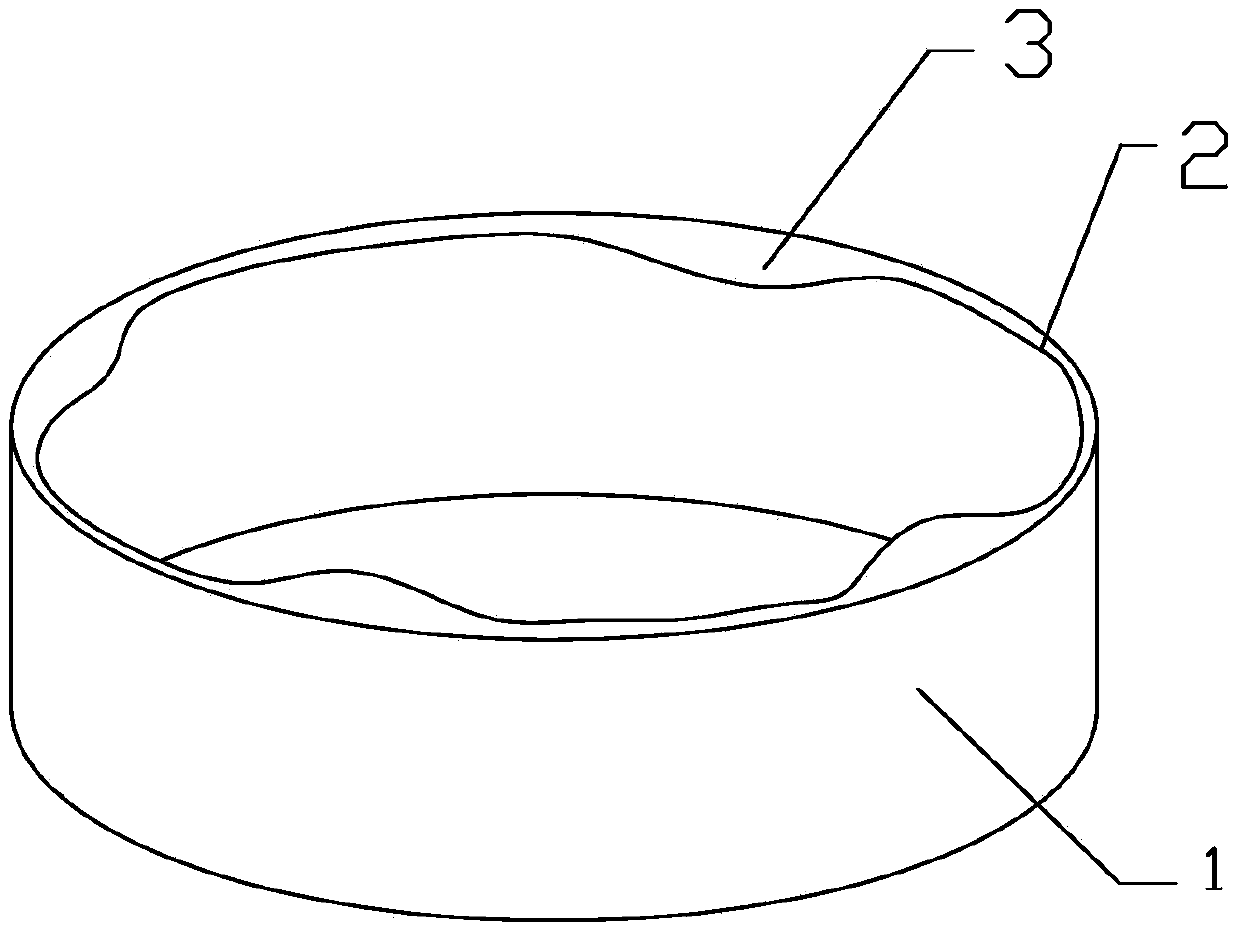

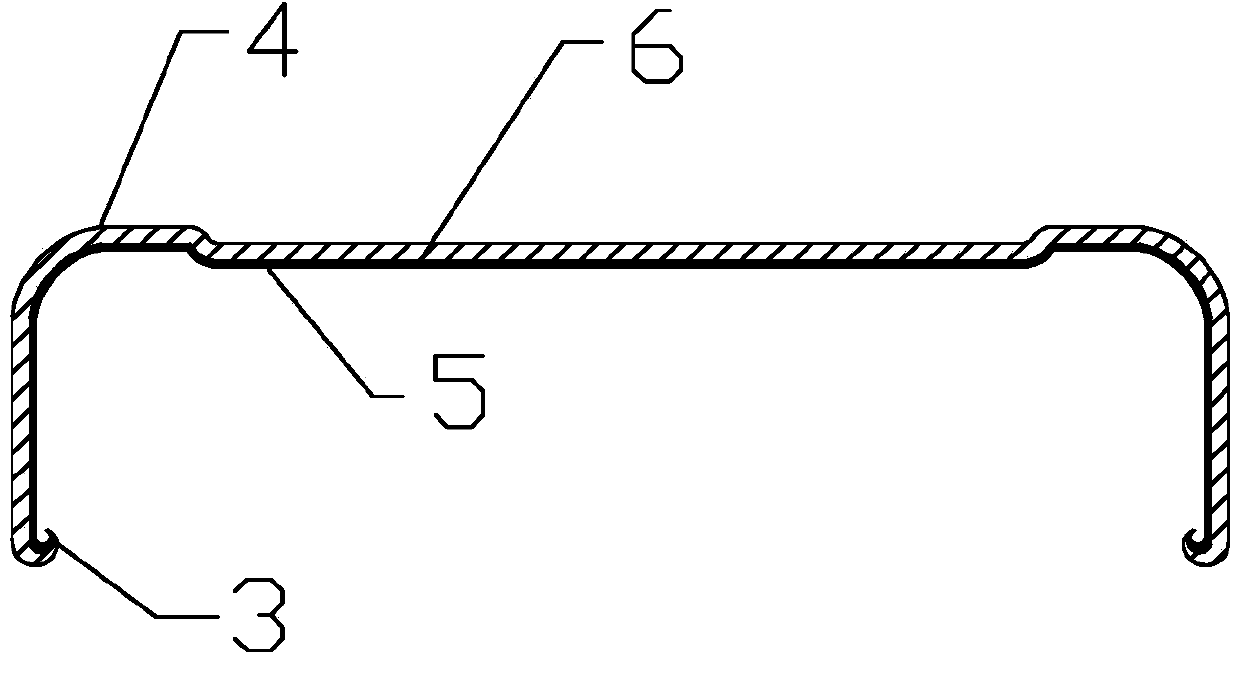

Claw-type unscrew cap with PE (poly-ethylene) or PP (poly-propylene) cushion layer, and production technology of claw-type unscrew cap

The invention provides a claw-type unscrew cap with a PE (poly-ethylene) or PP (poly-propylene) cushion layer, and a production technology of the claw-type unscrew cap. The cap body of the unscrew cap comprises a tin plate cap with no inner film coating and the poly-ethylene or poly-propylene cushion layer covering the inner surface of the tin plate cap, wherein the cushion layer is a 0.5 to 2.0 mm sealing gasket layer formed by conducting injection molding or dripping molding of poly-ethylene particles or poly-propylene particles on the inner surface of the tin plate cap; a curled edge and a rotating claw are formed by conducting punch forming on the edge of the opening of the tin plate cap with the poly-ethylene or poly-propylene cushion layer. The claw-type unscrew cap and the production technology have the advantages that the structure is simple; the production technology is relatively simple; the sanitary quality of each prepared bottle cap can reach the standard of food and drug safety; the sealing effect is high; the phenomena of fading and poisonous substance volatilization are avoided under a high-temperature condition; a preservative is not required to be added into a food or drug in a bottle sealed with the bottle cap, and can be preserved for a long time only through high-temperature sterilization.

Owner:王海鹏

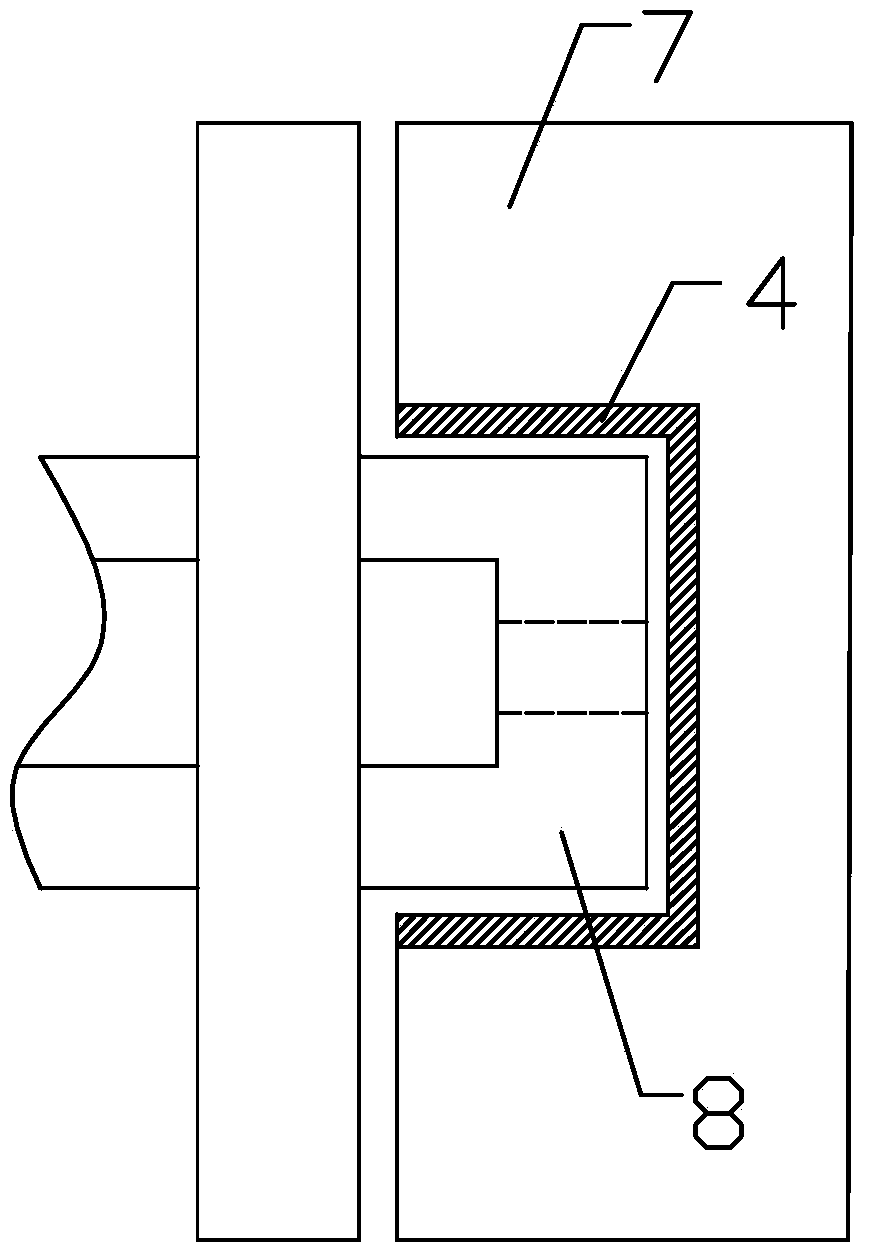

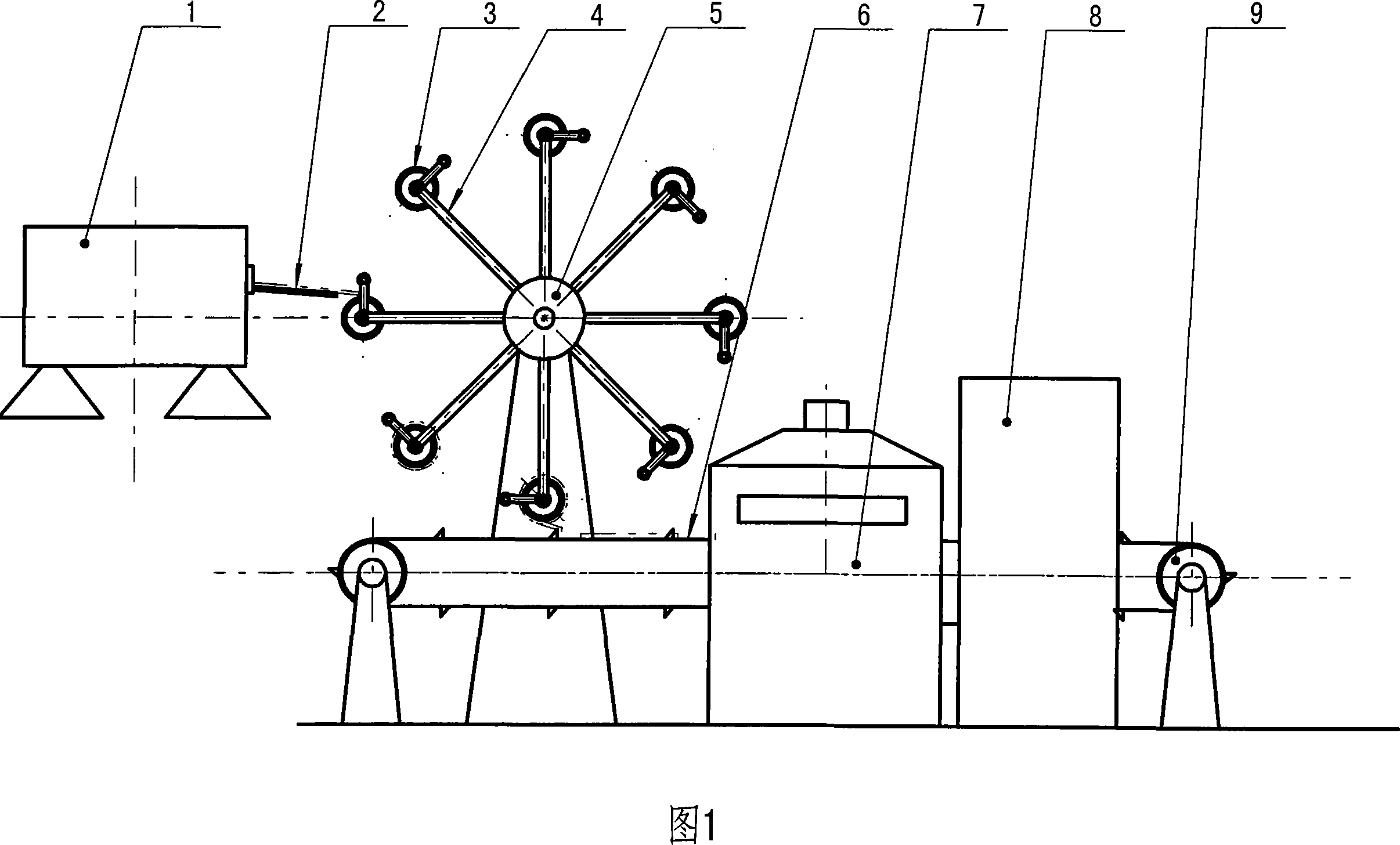

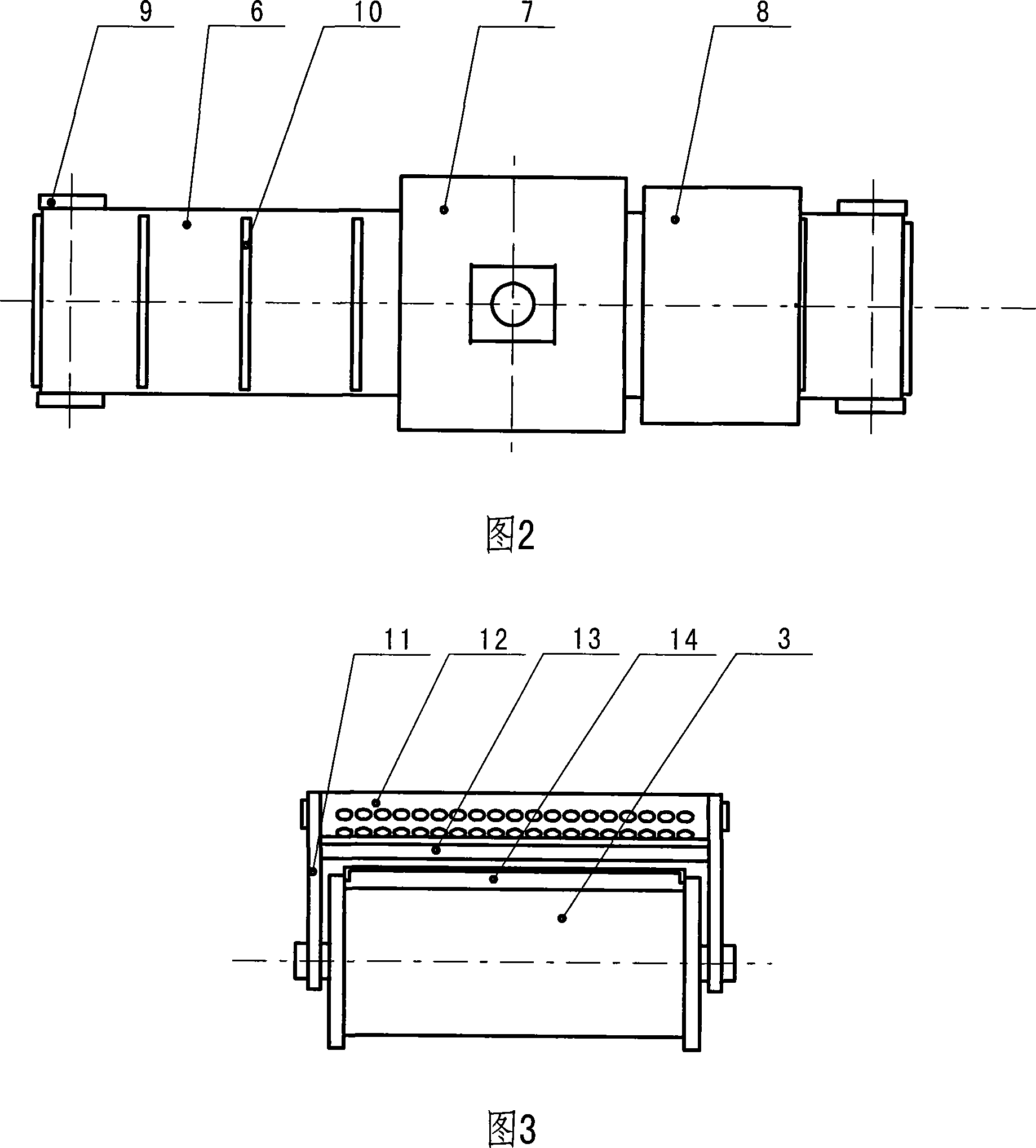

Mechanized full-automatic integrated equipment for making milk sector

The invention relates to a mechanized automatic integration equipment for dairy fan manufacture, which consists of a clot extruder, a maneuvering shaft roller draw machine and a processing combination machine, wherein, the maneuvering shaft roller draw machine consists of a shaft, a rotating arm fixedly arranged and uniformly distributed on the shaft along radial direction and a roller arranged on the end of the rotating arm, the roller is an electrical roller and is arranged along the same axial direction as the shaft, each roller is provided with an automatic clamping board, an automatic cutter and a cold wind pipe along radial direction, the automatic clamping port board is coaxially arranged on a column-shaped external edge of the roller, and the cold wind pipe and the automatic cutter are fixedly arranged on the roller through a bracket on the two sides of the roller; the processing combination machine consists of a transmission belt, a spraying forming machine and a cold wind drying machine, the two ends of the transmission belt are driven by a driving device, and the transmission belt gets through the spraying forming machine and the cold wind drying machine to form a cycle. The integration equipment has mechanized integration operation with higher level of quality, meanwhile realizing large-scale production and greatly improving productivity.

Owner:TIANJIN UNIV OF SCI & TECH

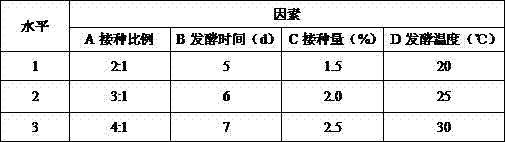

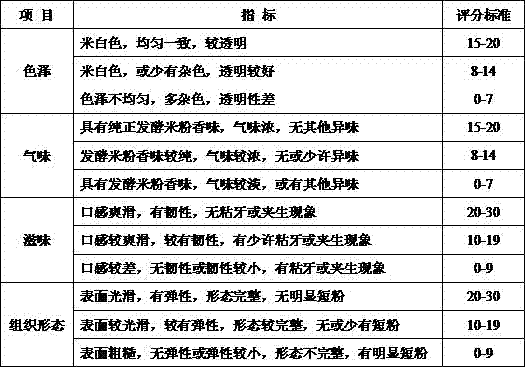

Method for making fermented straight rice noodles

The invention aims to provide a method for making fermented straight rice noodles. The straight rice noodles take milled early long-grain non-glutinous rice as a raw material and are produced by adopting a fermentation process. The method comprises the following steps: soaking the cleaned milled early long-grain non-glutinous rice, fermenting, draining, pulping, squeezing, dehydrating, milling, extruding and boiling dough, pressing and boiling powder, and drying. The step of fermenting comprises the following sub-steps: fermenting the washed milled early long-grain non-glutinous rice and fermentation strain liquid in a fermentation device, controlling a mass ratio of the milled early long-grain non-glutinous rice to water to be 1:(1.4-1.6), and controlling the addition amount of the fermentation strain liquid to be 1.5-2.5Wt% of the mass of the milled early long-grain non-glutinous rice, wherein the fermentation time is 130-160 hours, the fermentation temperature is 23-28 DEG C, and the fermentation strain liquid is a mixture of lactic acid bacterial liquid and / or saccharomycetes liquid. By controlling the fermentation strain liquid and adopting a basket drying method, industrialized production of the fermented straight rice noodles can be realized. The production efficiency of the rice noodles is greatly increased, the labor intensity is reduced, and income and yield of peasant households and enterprises are increased.

Owner:江西省食品发酵研究所

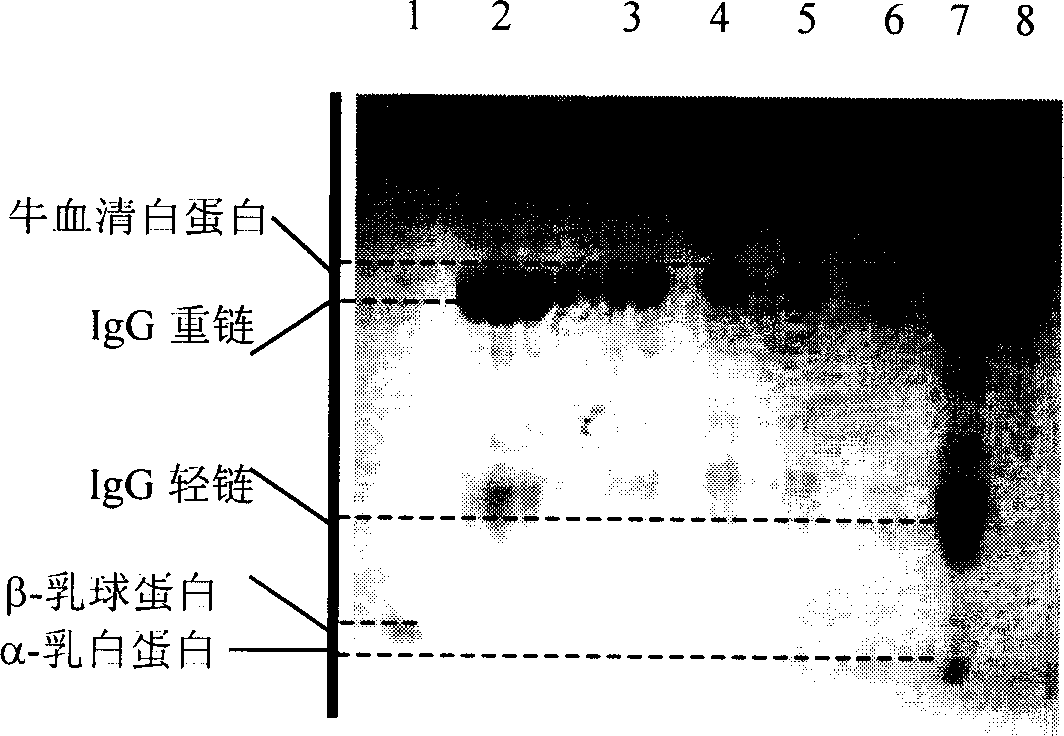

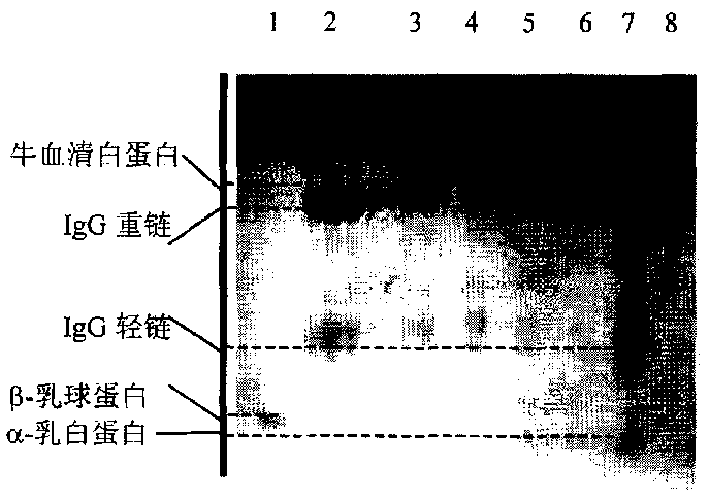

Production process for cow primary milk whey with natural immunocompetence and low irritability

InactiveCN1484964AEnsure hygienic qualityRetain activityWhey manufactureNative immunityImmunocompetence

It relates to a technique of processing oxen colostrum whey with native immunity active and low sensitization. It comprises, first, the Oxen colostrum should be centrifuged, then casein of Oxen colostrum is removed through a precipitation method, and the pellucid whey liquid is obtained; adding FeCl3 for selectively precipitating ª‰ - lactoglobulin, then adding NaOH, adjusting pH; precipitating, removing excessive Fe3+ in the system; removing bacteria by microfiltering, mixing with the ""matrix"" which has been processed thermally and disinfected at sterile conditions, then obtaining final whey products.

Owner:上海伟浩生物科技有限公司

Manufacturing method of dried persimmons

The invention discloses a manufacturing method of dried persimmons, and the manufacturing method of the dried persimmon comprises the following seven steps: harvesting and selecting materials, cleaning peeling, sunning pressing kneading, fumigating with sulfur and deastringenting, kneading sunning shaping, stacking covering frosting, and chilling and drying in air. By processes of manual peeling and manual shaping, and the like, loss of proteins, sugar, trace elements and other vitamins and the like of the dried persimmons can be prevented, original flavor and nutrients of the dried persimmons can be effectively preserved, the appearance of the dried persimmons cannot be easily damaged by manual operation, the manual operation is uniform in force, color is good; through the processes of fumigating with the sulfur and deastringenting, and subsequent chilling and drying in the air, tannin-induced astringent taste can be effectively removed, the anti-astringent phenomenon in the later drying process can be prevented, so that good taste of the dried persimmons can be ensured. The dried persimmons have dry cores, keep the flavor of persimmon fruits, have even appearance and better color, ensure the good taste without damaging the medical value, can be used as edible food, can also be used as a medicine and can be eaten directly.

Owner:贾巧娟

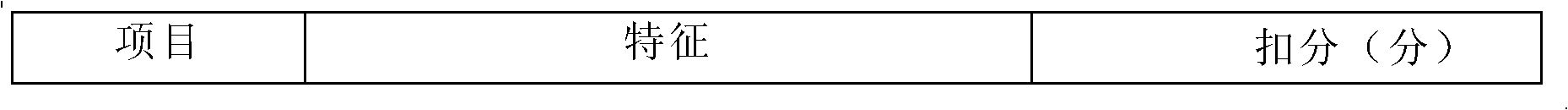

Preparation method of milk film

InactiveCN102422901AProduct quality is stableProcess parameters are clearOther dairy technologyChemistryMilk products

The invention relates to the field of traditional milk product processing, and particularly, relates to a preparation method of a milk film. The preparation method of a milk film of the invention comprises the following steps: 1) filtering raw material milk by filter cloth with 2-3 layers, putting the filtered milk liquid in a cheese groove, heating and stirring, adding white sugar with a concentration of 50-100g per kilogram of milk liquid after boiling, continuously stirring; 2) after a lot of bubbles are generated on the milk liquid surface, stopping stirring, performing heat preservation without boiling at 60-70 DEG C for 4-6 hours; 3) after heat preservation, stopping heating, naturally cooling at room temperature with cooling time of 5-7 hours; 4) after cooling, when a thick and hard film is formed on the milk liquid surface, taking out the film on the milk surface, naturally drying and performing vacuum packaging to obtain the milk film product. With the preparation method of the milk film of the invention, the obtained milk film has stable quality, low cost, no any additives, and wide market prospects.

Owner:INNER MONGOLIA YILI INDUSTRIAL GROUP CO LTD

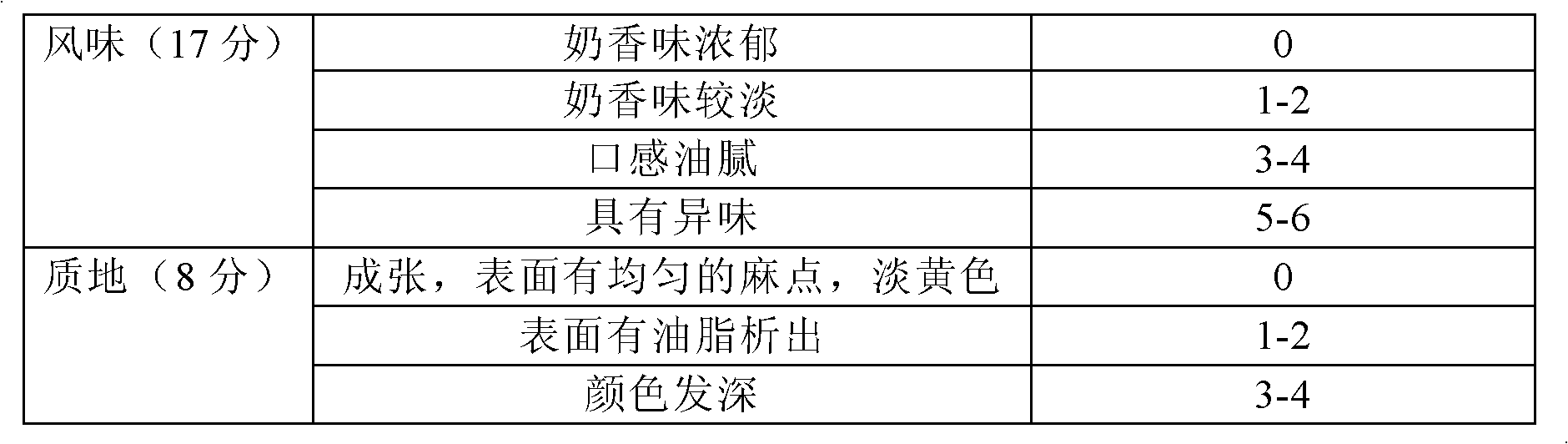

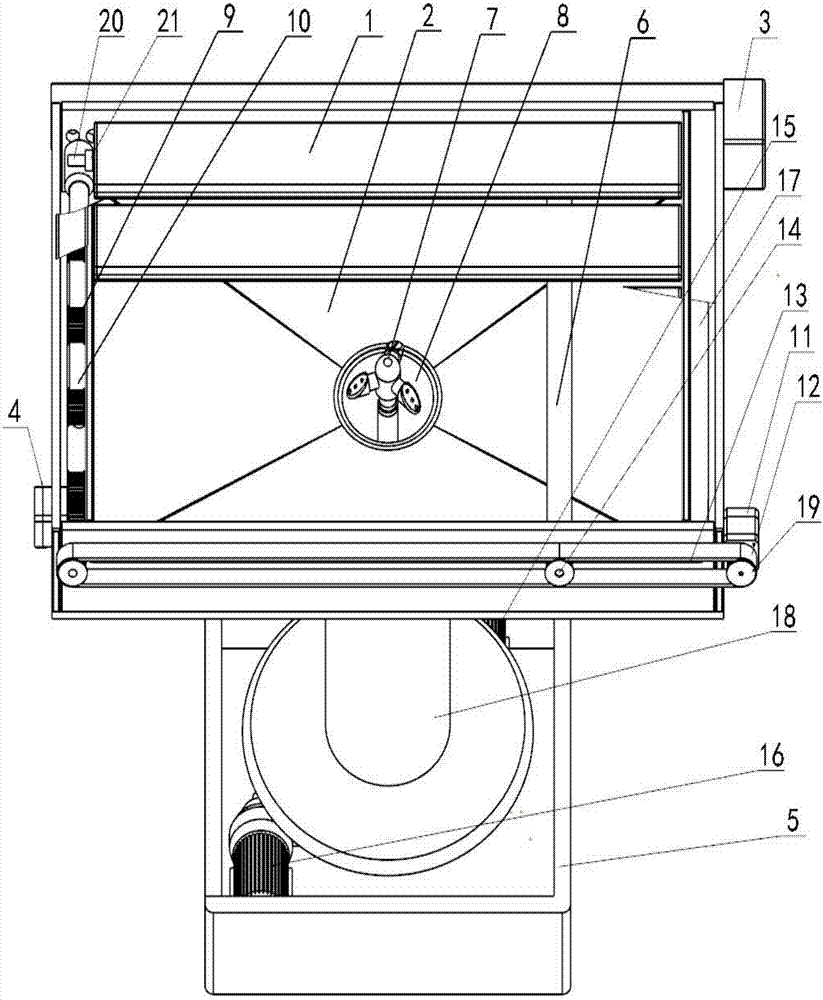

Dining table capable of achieving automatic cleaning

The invention relates to a dining table that can be cleaned automatically, comprising a table body, a support column and a water tank; the support column is vertically placed on the water tank, and the table body is horizontally arranged on the top of the support column; the table The body is a square structure, and the upper surface of the table body is made up of a plurality of reversible panels. A clean room is provided in the table body, and a clean room is provided in the clean room by pumping the clean water in the water tank. And a cleaning device for automatically cleaning the bottom surface of the flipped panel. The beneficial effect of the invention is that the desktop with oil stains after eating can be automatically cleaned, the cleaning quality can be greatly improved, and manpower can be saved.

Owner:GUILIN UNIV OF ELECTRONIC TECH

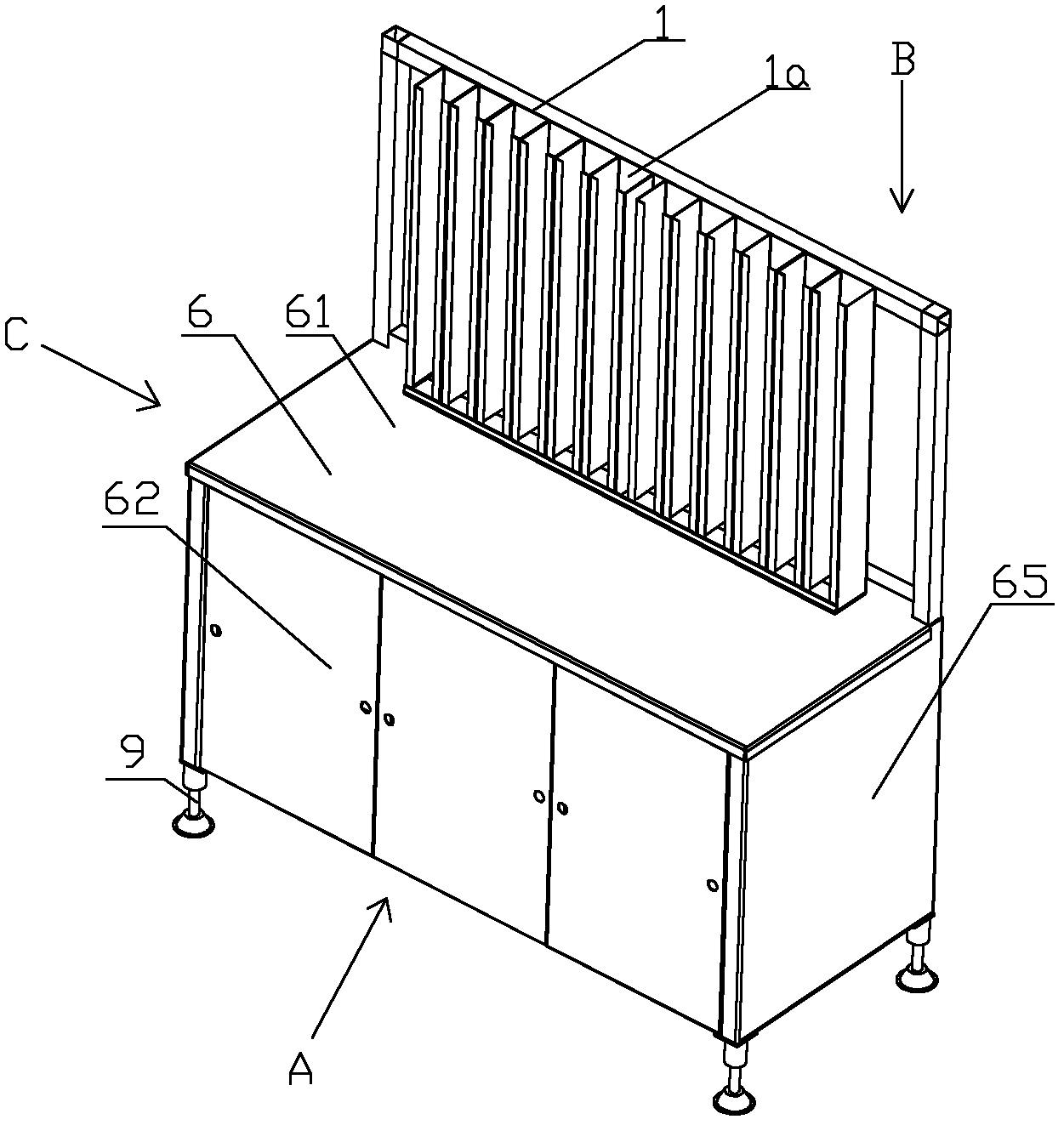

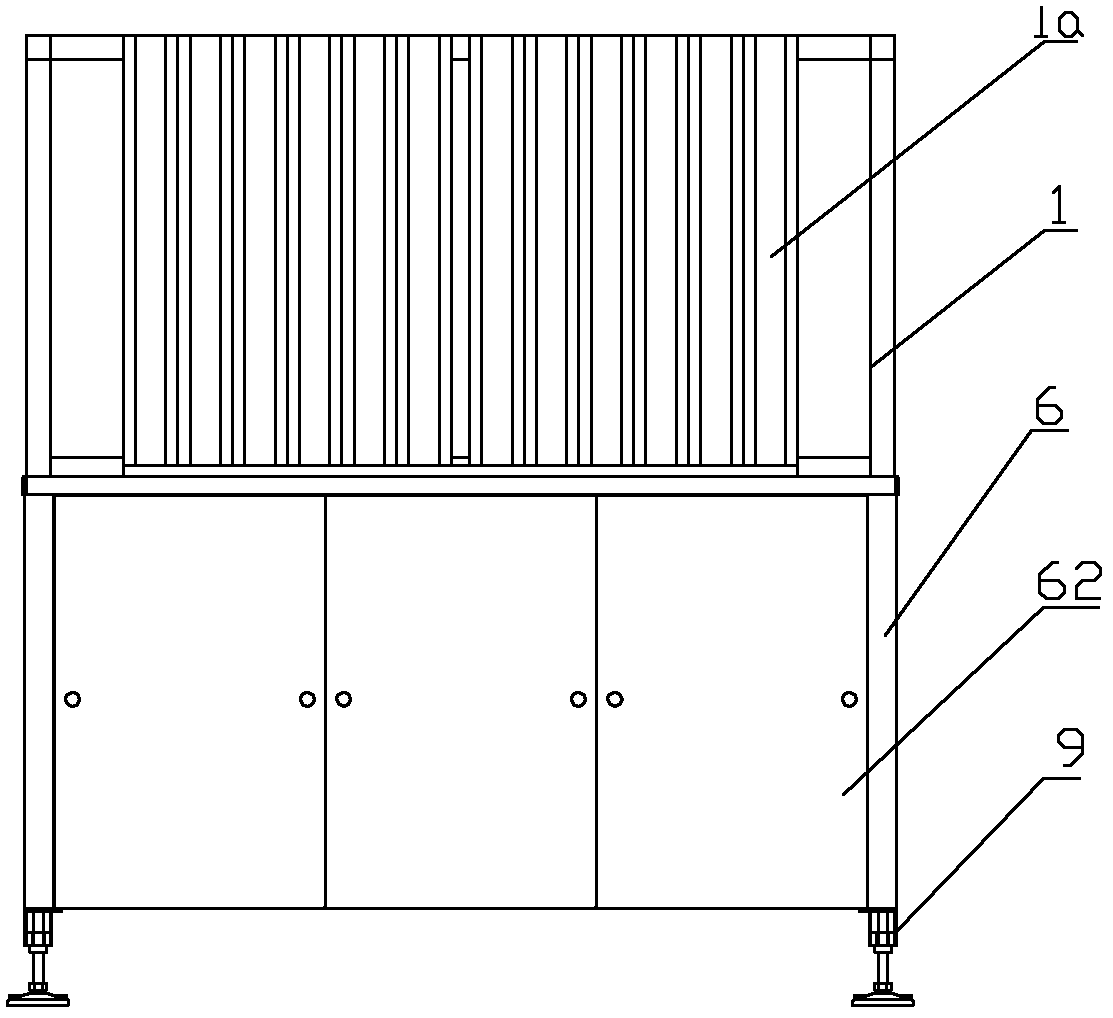

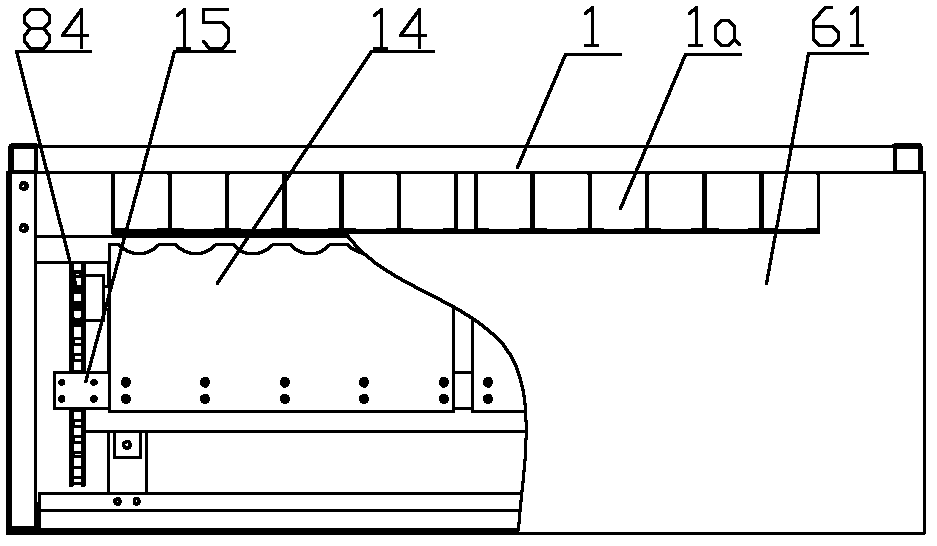

Automatic sorting machine for bread slices

ActiveCN102293226ARealize automatic arrangementAvoid human contactDough processingElectric machineryStructural engineering

The invention discloses an automatic bread slice arranging machine, which comprises a blanking hopper, a cutting device and a feeding device, wherein the cutting device is arranged below the blanking hopper; the feeding device comprises a motor of which the free end in transmission connection with an eccentric wheel, a rocking handle component of which one end is in transmission connection with an eccentric shaft of the eccentric wheel through a connecting rod pin component and the other end is in transmission connection with a transverse rotating shaft, a right chain wheel component which isin transmission connection with the right end of the rotating shaft, a left chain wheel component which is in transmission connection with the left end of the rotating shaft, and a feeding plate component which is arranged below the cutting device and of which the left and right ends are in transmission connection with the left chain wheel component and the right chain wheel component respectively along the vertical direction. The automatic bread slice arranging machine has high production efficiency, is clean and sanitary and meets the using requirements of the conventional bread processing industry.

Owner:广州浩胜食品机械有限公司

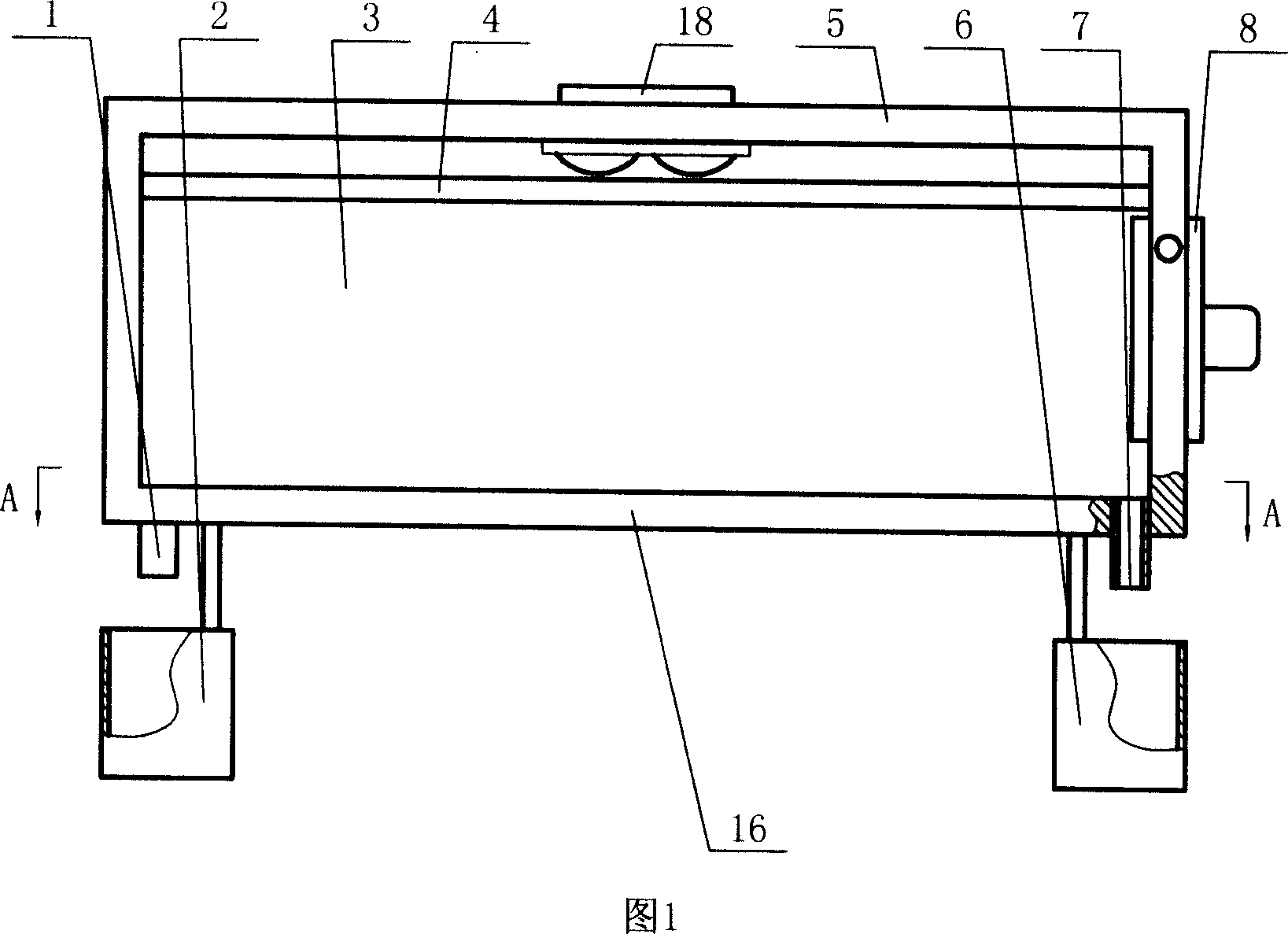

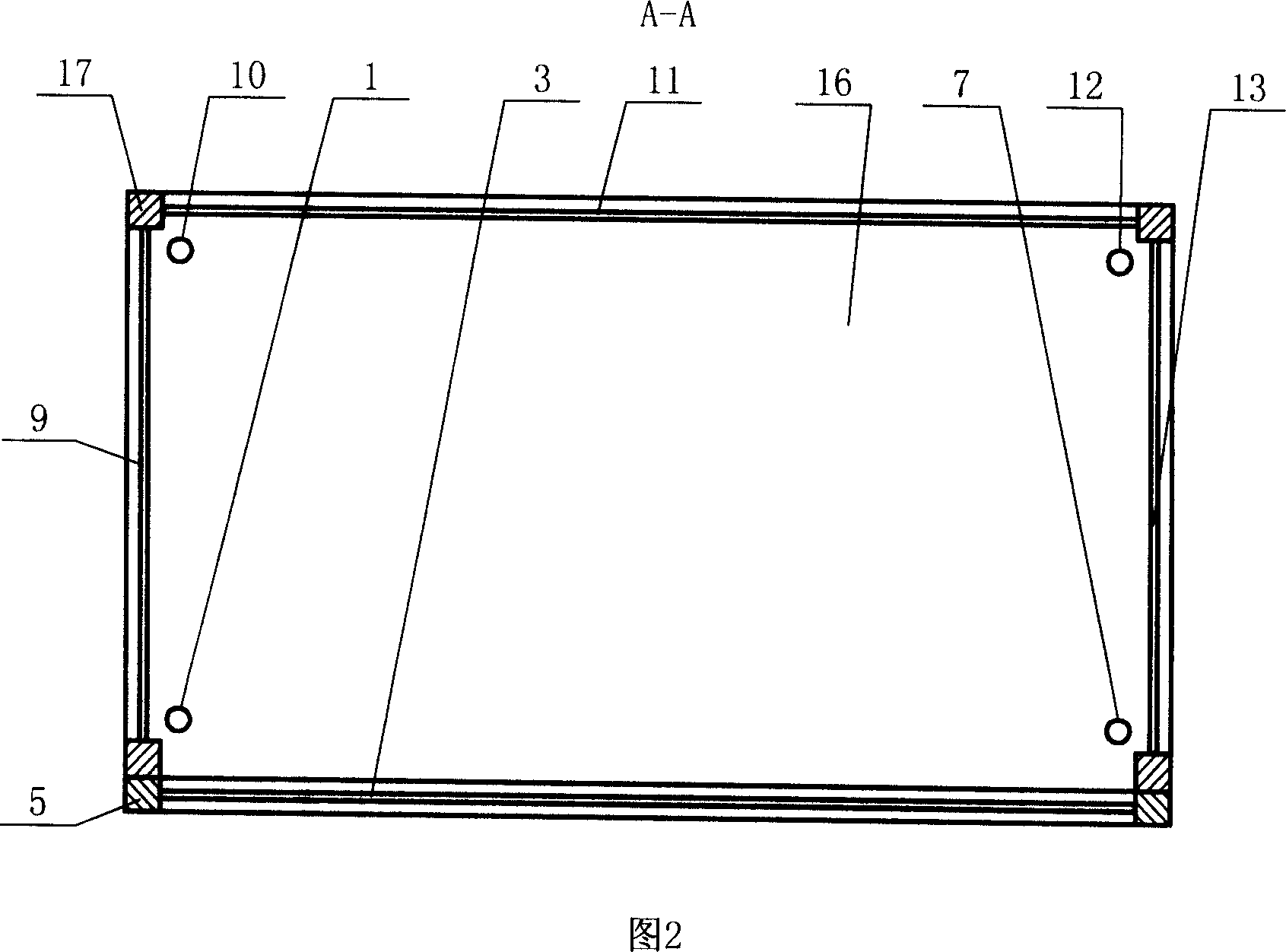

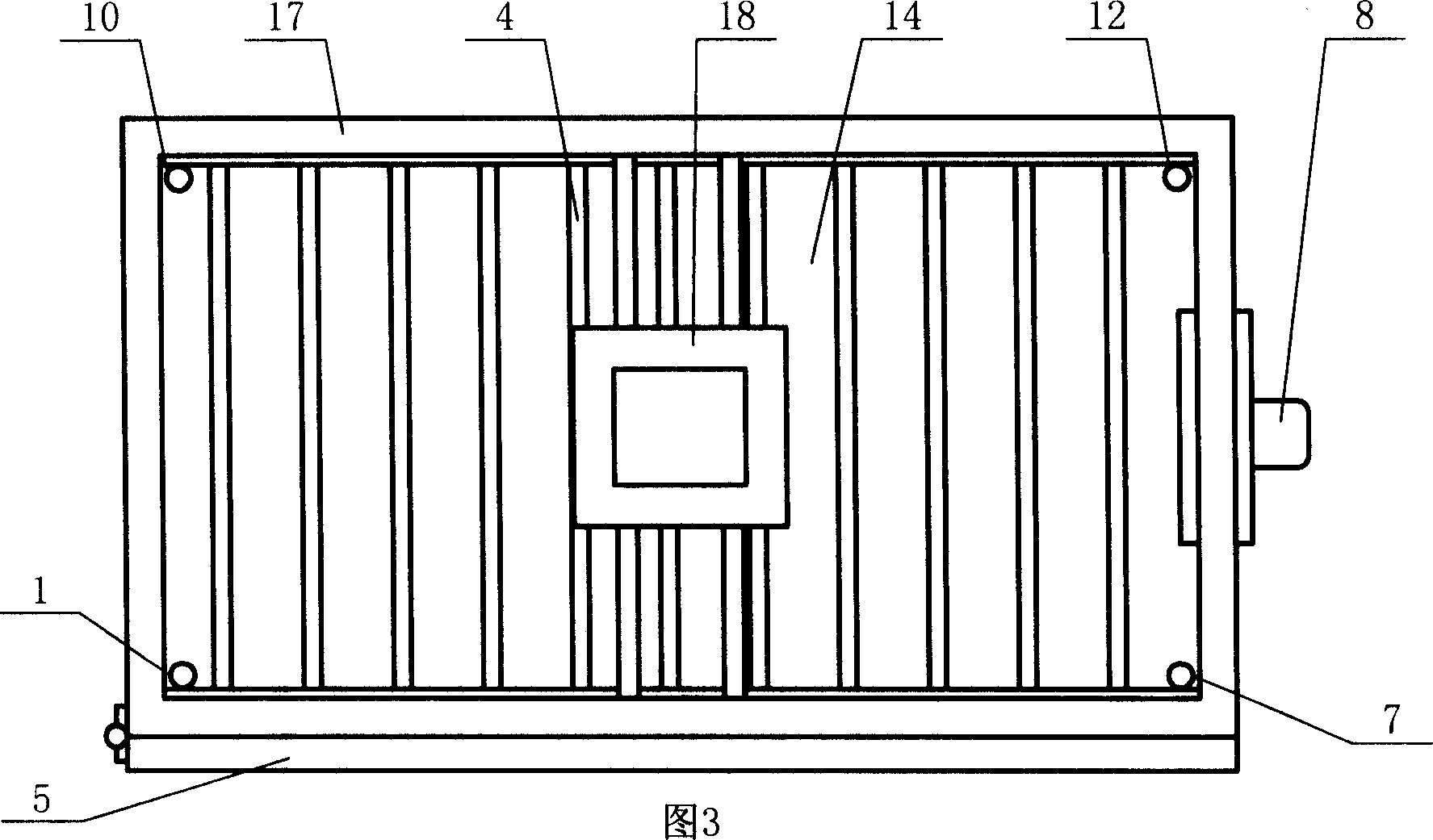

Food air drying apparatus

InactiveCN1973640ASpeed up dryingEnsure hygienic qualityEggs preservation by dryingDrying machines with local agitationDried foodFood sanitation

The food air drying apparatus includes one frame with bottom plate, ventilating ports in the sides and top, door hinged to the front and gauzes to avoid air contamination and fly, one shelf inside the frame for hanging the matter to be dried, and one electric fan on the frame to force airflow. It may also be provided with high temperature lamp or other heater to speed the air drying. It is set indoor to dry food and can ensure high quality of the dried food.

Owner:黑伟钰

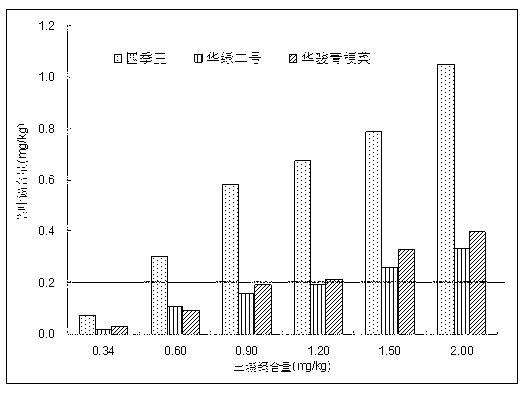

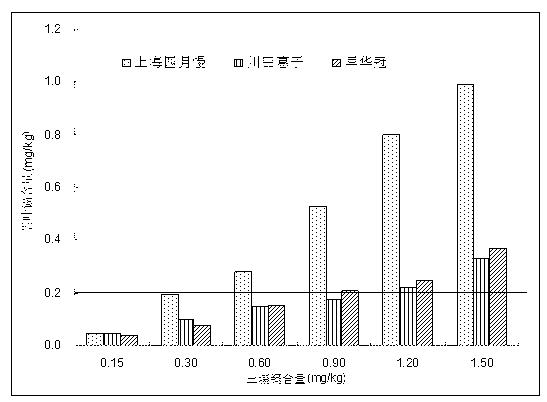

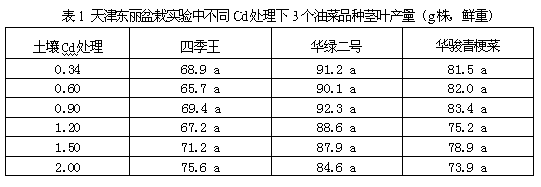

Method for screening cadmium rejection varieties of leaf-edible rapes

ActiveCN103238439AReduce the content of heavy metal cadmiumGuarantee quality and safetyHorticultureDry weightScreening method

The invention relates to a method for screening cadmium rejection varieties of leaf-edible rapes. The method comprises the steps of 1) performing outdoor open-air cultivation in a potting mode; 2) selecting a plurality of varieties of leaf-edible rapes; 3) selecting uncontaminated soil to add a cadmium salt solution to enable the soil cadmium content to be 0.3mg / kg, 0.6mg / kg, 0.9mg / kg, 1.2mg / kg and 1.5mg / kg when the pH is lower than 7.5 and the soil cadmium content to be 0.6mg / kg, 0.9mg / kg, 1.2mg / kg, 1.5mg / kg and 2.0mg / kg when the pH is higher than 7.5; 4) sowing the rapes and managing growth; 5) harvesting stem leaf portions and analyzing the fresh weight, the dry weight and the cadmium content; and 6) analyzing the stem leaf yield and the cadmium content of different varieties successively from 0.3mg / kg processing to maximum concentration processing, and selecting the cadmium rejection rape varieties under the pollution level, wherein the stem leaf cadmium (Cd) content of the cadmium rejection rape varieties is lower than a food hygienic standard of 0.2mg / kg and the stem leaf yield ratio is not reduced obviously under the pollution processing. According to the method, safe and high-yield cadmium rejection varieties of leaf-edible rapes can be screened, the application range can be obtained, and the method can be effectively used in safety agriculture production.

Owner:AGRO ENVIRONMENTAL PROTECTION INST OF MIN OF AGRI

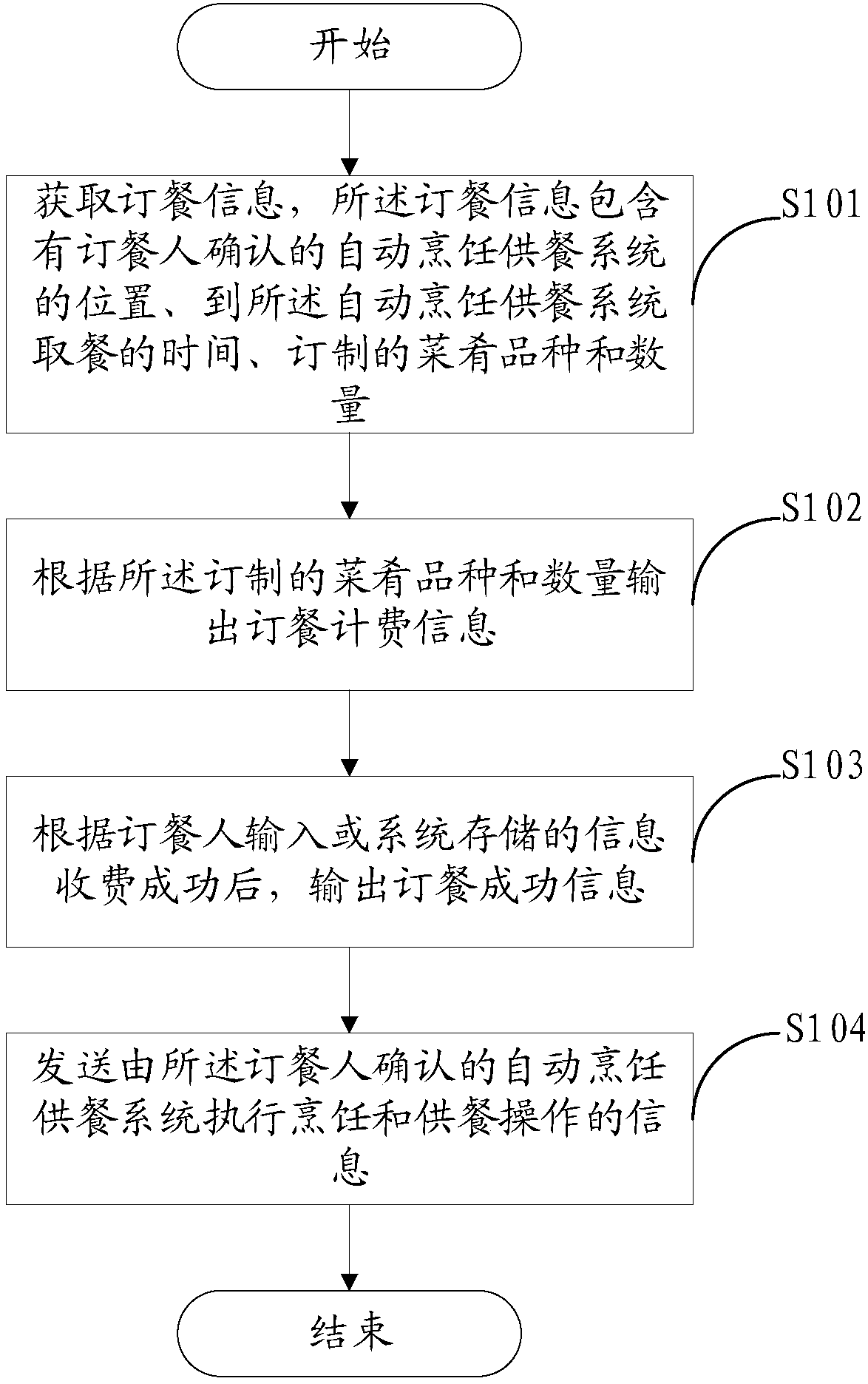

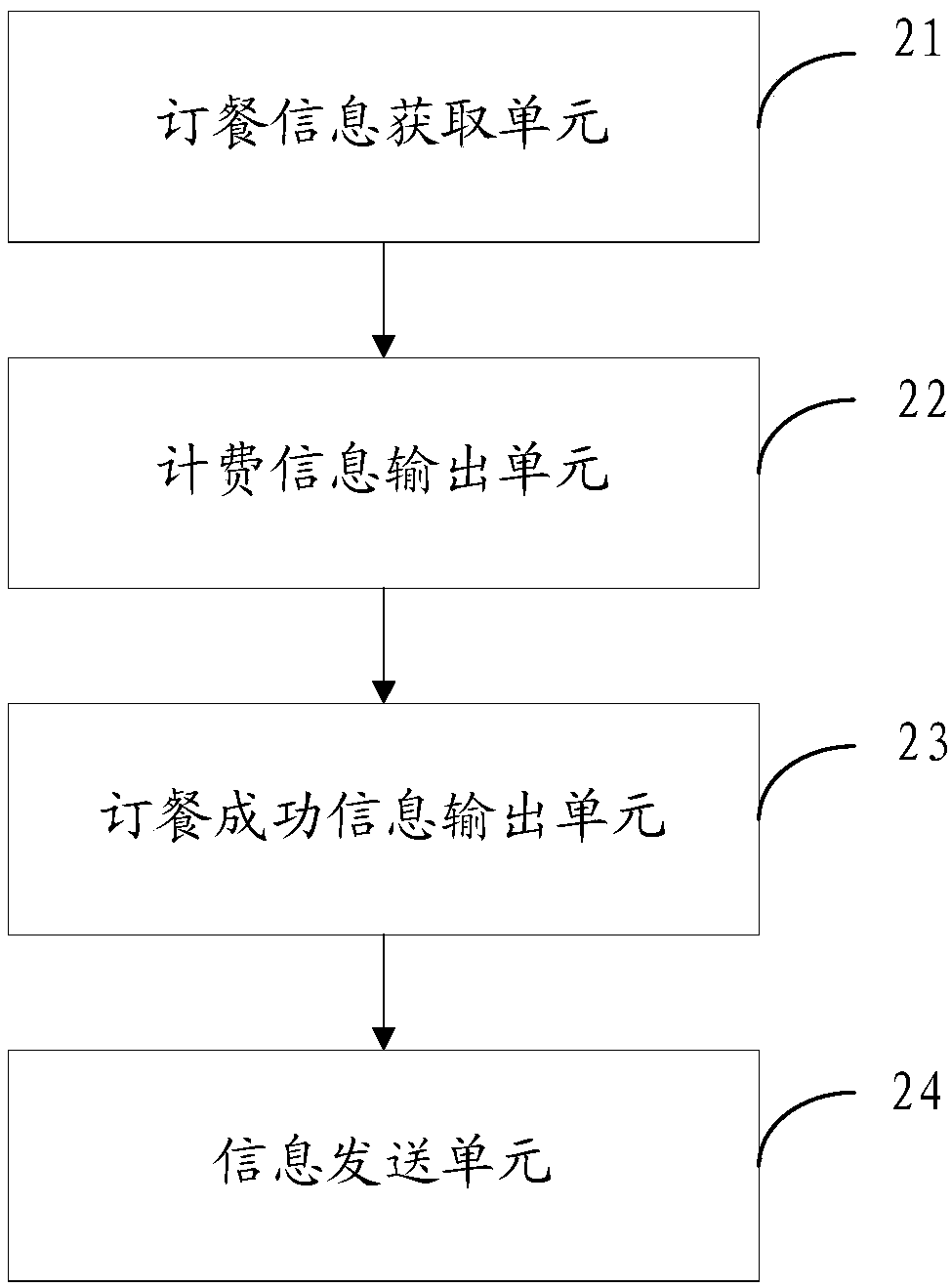

Online meal ordering method and device

InactiveCN110135926AGreat tasteEnsure hygienic qualityBuying/selling/leasing transactionsEngineeringSanitation

The invention is applicable to the technical field of catering, and provides an online meal ordering method and device. The online meal ordering method comprises the following steps: obtaining meal ordering information which comprises the position of an automatic cooking meal supply system confirmed by a meal ordering person, the meal taking time of the automatic cooking meal supply system, and the variety and quantity of ordered dishes; according to the variety and quantity of the ordered dishes, outputting meal ordering charging information; outputting meal ordering success information afterthe information input by the meal ordering person or stored by the system is successfully charged; and sending information that the automatic cooking meal supply system confirmed by the meal orderingperson executes cooking and meal supply operation. According to the invention, the meal ordering information of the user is acquired, and the cooking information is sent to the automatic cooking mealsupply system according to the meal ordering information, so that the meal delivery speed is greatly guaranteed while the sanitation quality of dishes is ensured, and a large amount of manpower is saved, and the user experience is extremely high.

Owner:深圳卡帕智能系统有限公司

Method for preparing dried medlar after secondary cleaning

ActiveCN104012901ASolve the problem of drying after secondary cleaningImprove qualityGranular material dryingDrying gas arrangementsChemistryEngineering

The invention provides a method for preparing dried medlar after secondary cleaning, which is implemented by using a belt dryer through a specific multi-stage drying process. According to the method for preparing the dried medlar after the secondary cleaning, the problem about preparing the dried medlar after the secondary cleaning is effectively solved by adopting the multi-stage drying process; the obtained product has bright color and loose particles, and is clean, sanitary and safe; the quality of the dried medlar is improved; a novel way is developed for preparing the high-quality dried medlar.

Owner:青海新泰行生物科技有限公司

Feed formula for growth period of fur animals and preparation method thereof

InactiveCN105815552ARealize partial self-productionImprove digestion utilizationFood processingAnimal feeding stuffChicken LiverBran

The invention relates to the technical field of fur animal breeding, and specifically relates to a feed formula for the growth period of fur animals and a preparation method thereof. The feed formula is composed of the following components in parts by weight: 25 to 35 parts of fish and byproducts of fish, 8 to 15 parts of chicken frame, 10 to 25 parts of chicken intestine, 7 to 10 parts of chicken liver, 10 to 16 parts of puffed corn and wheat, 1 to 2 parts of puffed bran, 1 to 2 parts of probiotics, 3 to 10 parts of soybean oil, 2 to 5 parts of fermented soybean meal, 0.2 part of acidifying agent, and 1 part of growth period premix (1%). The feed formula can provide comprehensive nutrients and can be well absorbed by animals. The growth speed of animals is quick, the fur is bright, and the fur animal will not get sick easily.

Owner:SHANDONG ZHUBANG FEED TECH CO LTD

Pepper vinegar

ActiveCN102876557AIncrease Aromatherapy HumidityEnsure hygienic qualityVinegar preparationBiotechnologyWheat Brans

The invention relates to a pepper vinegar which takes rice, wheat bran, pepper, water and sweet wormwood as raw materials and is brewed by processing the raw materials, making drug, making acidic blank and fermenting for a plurality of times; the pepper vinegar is prepared by the processing method comprising the steps of: (1) processing the rice, taking the water and the rice according to the weight ratio of 4-7: 1, and cooking thin gruel; (2) evenly mixing wheat and water according to the ratio of 3: 1, covering the fresh sweet wormwood on the mixture, and fermenting for at least 20 days at the room temperature of 12-20 DEG C to obtain the drug; (3) mixing the thin gruel and the drug and fermenting for 20-30 day at the room temperature not higher than 20 DEG C, wherein the dosage ratio between the drug and the thin gruel is 1:(60-100); (4) evenly stirring the wheat bran in the fermented rice thin gruel according to the ratio of 1:1.5 between the fermented rice thin gruel and the wheat bran, fermenting for at least 7 days to obtain the blank, adding drinking water into the blank, and stirring for precipitation to obtain vinegar which is the liquid arranged at the upper part; and (5) adding pepper, frying the pepper with the weight being 2-5% of the wheat bran until the rice pepper smell is sent out, putting the fried pepper into the vinegar, soaking for at least 30 days, and filtering the pepper to obtain the pepper vinegar with the fragrance of sweet wormwood and pepper.

Owner:HUIZE RONGPU VINEGAR IND CO LTD

Material scattering device with turnover mechanism for dried meat floss processing

InactiveCN113598320ARich functionalityImprove uniformityRotary stirring mixersMixer accessoriesPhysicsElectric machinery

The invention discloses a material scattering device with a turnover mechanism for dried meat floss processing. The material scattering device comprises a supporting mechanism, the turnover mechanism and a cleaning mechanism, wherein an auxiliary supporting rod is arranged at the top of a base; a material storage box is connected to the base in a sliding mode; the turnover mechanism comprises a material mixing box, a top cover, a discharging box, a baffle, a rotating shaft, a cavity, a turnover rod, a spray head, a belt shaft, a transmission belt and a first motor; an adjusting mechanism is arranged above the material mixing box; the left end and the right end of the material mixing box are connected with supporting columns; the rotating shaft is arranged inside the material mixing box; the cavity is formed inside the rotating shaft; and the first motor is arranged on a supporting seat on the right side of the auxiliary supporting rod. According to the material scattering device with the turnover mechanism for dried meat floss processing, an electric sliding block is arranged, the electric sliding block can drive a material scattering box to move left and right, so that the material scattering position of the material scattering box can be conveniently adjusted, then the material scattering box can conveniently scatter dried meat floss at different positions in the material mixing box, and meanwhile, the material scattering uniformity can be conveniently improved.

Owner:盐城市崧味食品有限公司

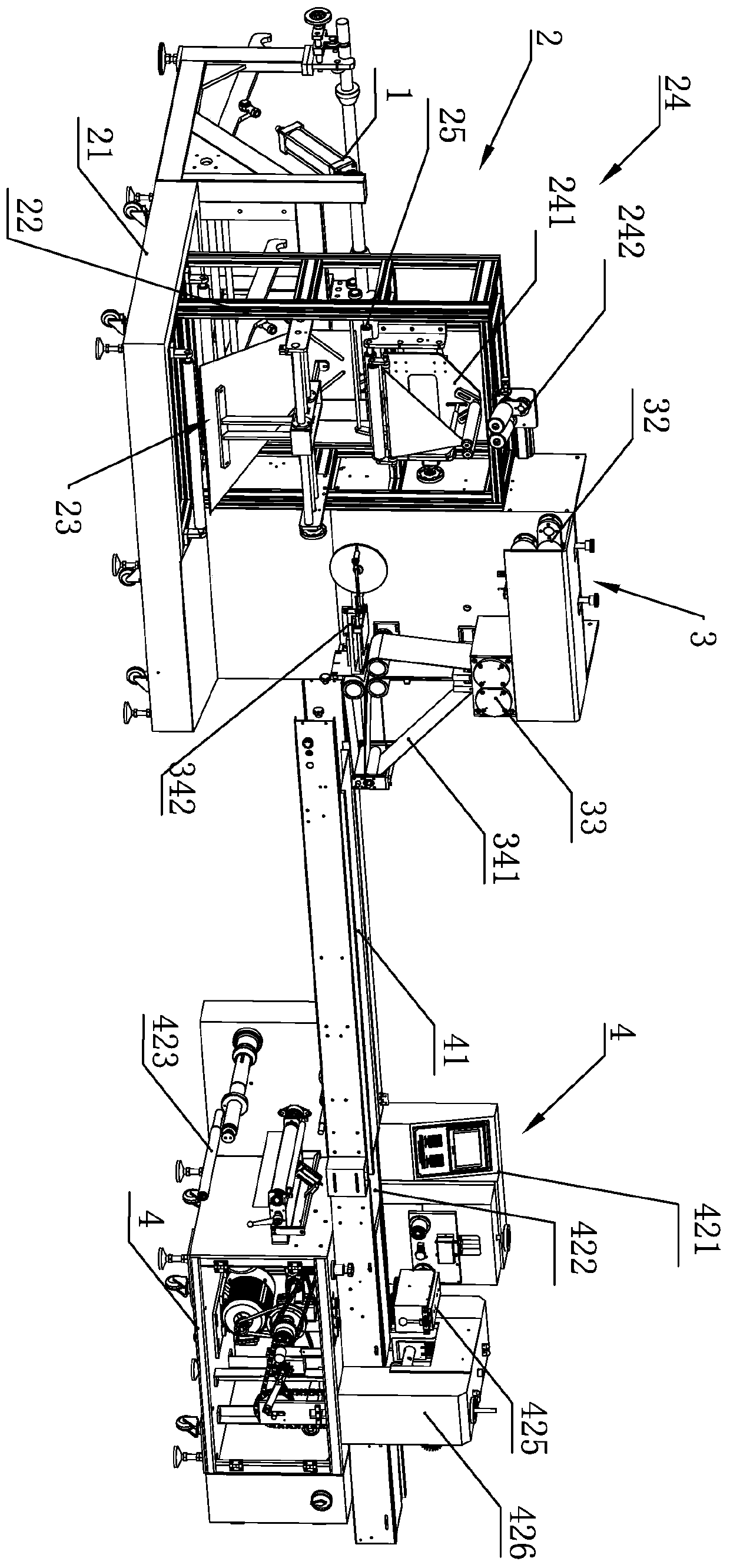

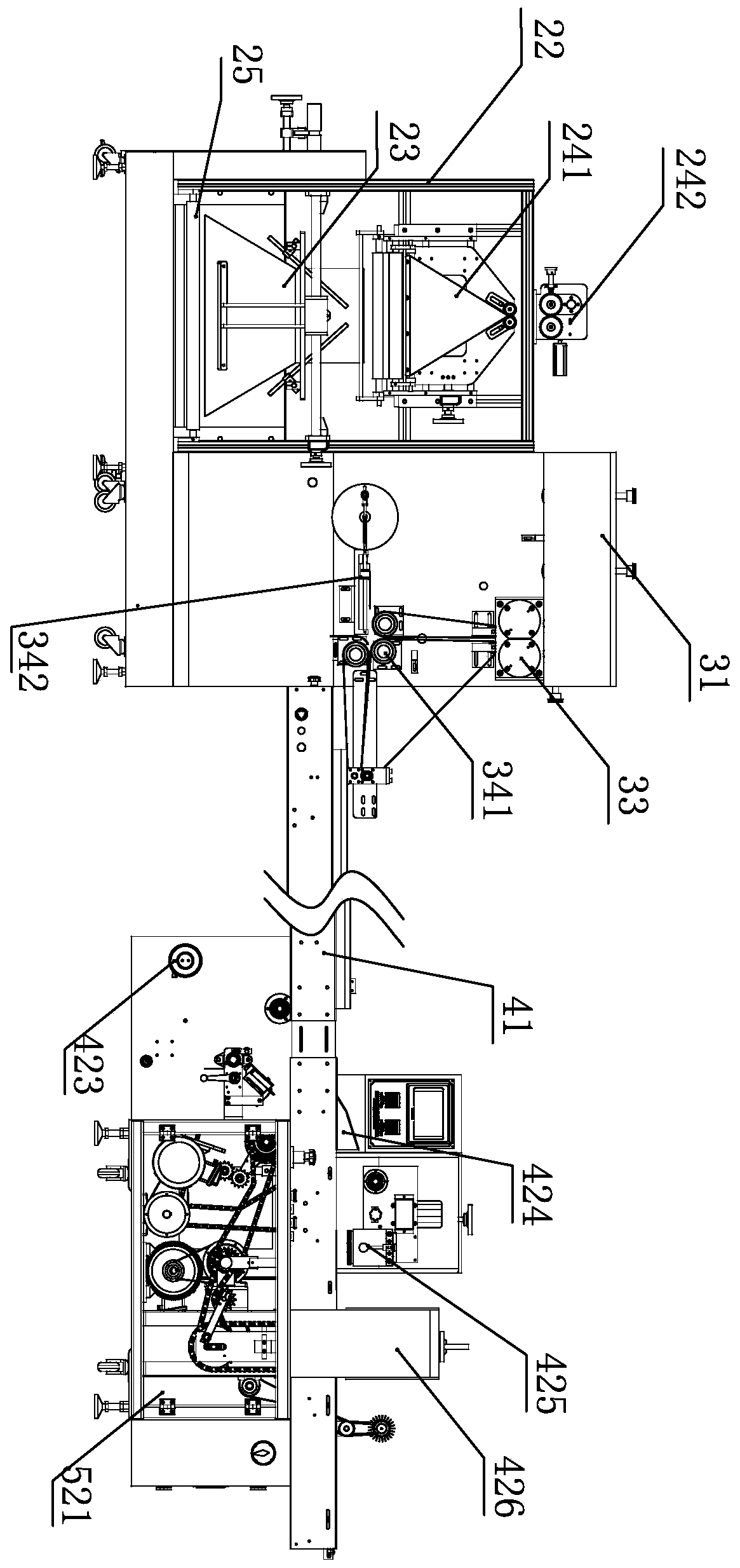

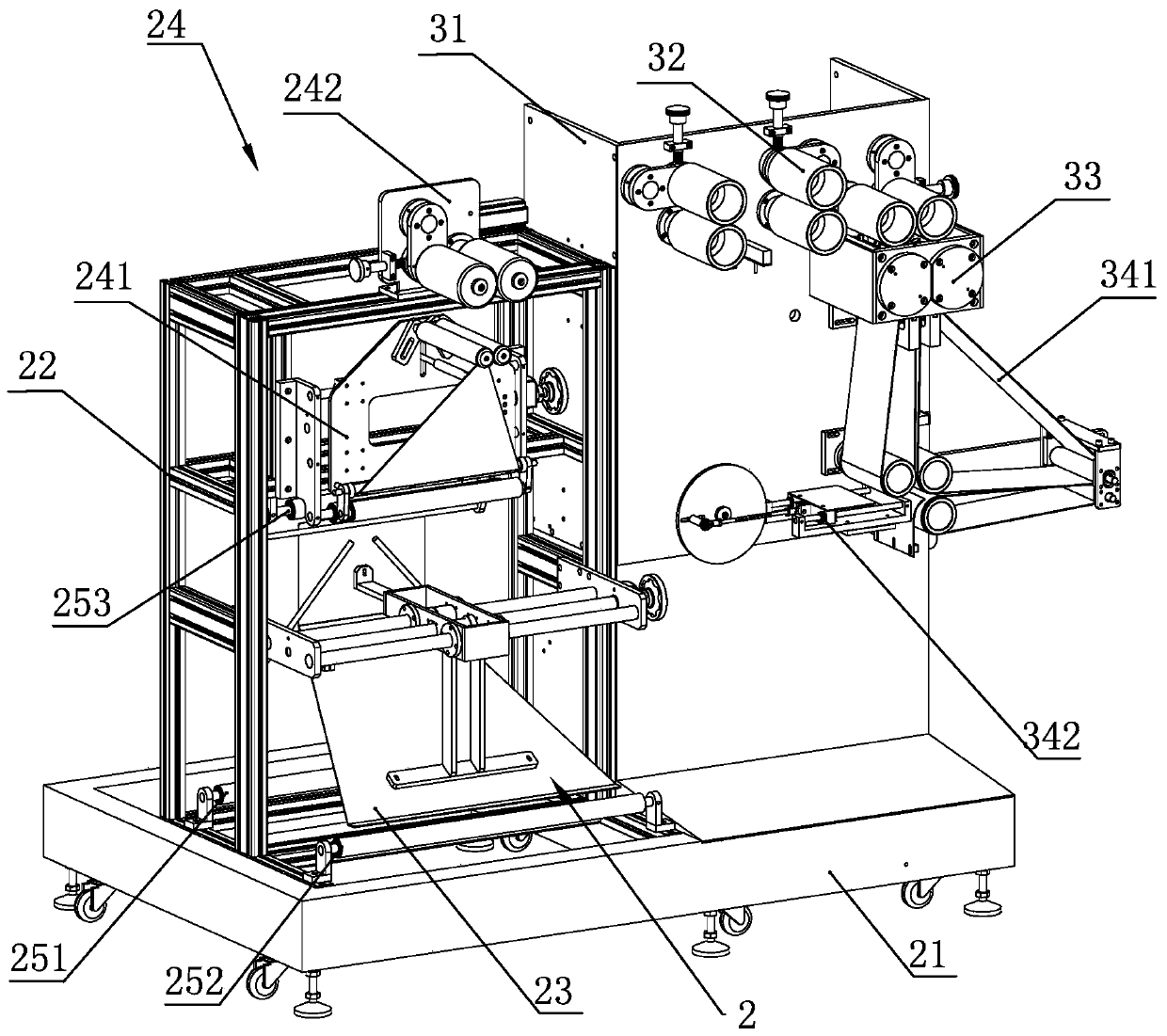

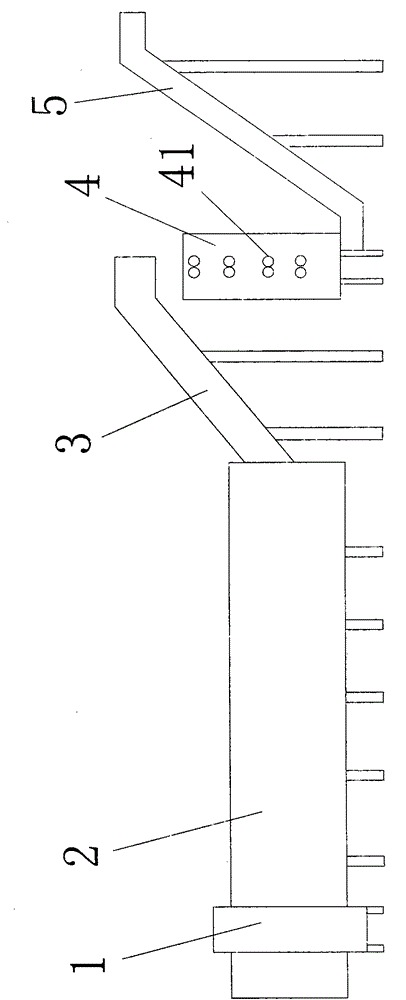

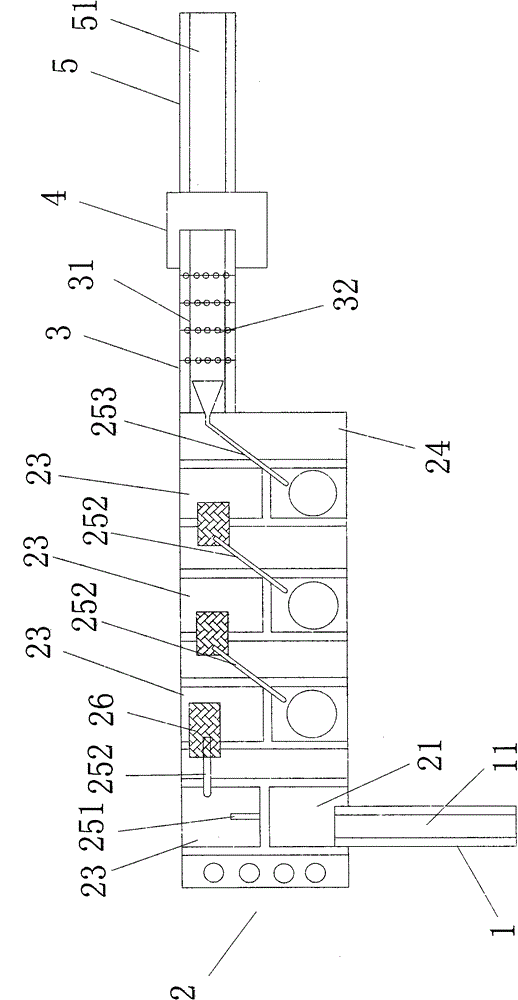

Full-automatic non-woven fabric packaging machine

PendingCN110435994AHigh speedIncrease productivityWrapper twisting/gatheringFolding thin materialsEngineeringNonwoven fabric

The invention relates to a full-automatic non-woven fabric packaging machine. The packaging machine comprises a material frame, a folding mechanism, a slitting mechanism, and a packaging mechanism, wherein the material frame is used for placing a non-woven fabric coiled material, the folding mechanism is used for folding non-woven fabric, the slitting mechanism is used for slitting the folded non-woven fabric, and the packaging mechanism is used for packaging the slit non-woven fabric; and the material frame is arranged on one side of the folding mechanism, the non-woven fabric on the materialframe is dragged and conveyed to the folding mechanism for folding, the folding mechanism folds the non-woven fabric, then the folded non-woven fabric is conveyed to the slitting mechanism for slitting, and the slit non-woven fabric is conveyed to the packaging mechanism for packaging. The manual operation is replaced through adopting the cooperation among the mechanical mechanisms, so that the labor intensity of workers is reduced, the slitting and folding speed and the production efficiency of the non-woven fabric are improved, and the sanitary quality of the non-woven fabric during packaging is ensured.

Owner:PINGYANG HAIHANG MACHINERY

Process for dehydrating fruits and vegetables and Chinese herbal medicine plants with liquid carbon dioxide

InactiveCN102232410AFast dehydrationEnergy savingFruit and vegetables preservationPlant ingredientsChinese herbsFruits and vegetables

The invention discloses a process for dehydrating fruits and vegetables and Chinese herbal medicine plants with liquid carbon dioxide and relates to a fruit and vegetable and Chinese herbal medicine processing process. The process comprises the following flows: (1) putting the sliced fruits and vegetables, Chinese herbal medicines or semifinished products from which the free water is removed in advanced into a dehydration tank, closing the bin gate of the dehydration tank and sealing and vacuumizing the dehydration tank; (2) opening a liquid carbon dioxide tank bleeder valve, gasifying the liquid carbon dioxide, then pressurizing the gaseous carbon dioxide by virtue of a compressor, entering into a gas-distributing tank, entering into the dehydration tank, maintaining the pressure for a period of time after the pressure in the dehydration tank reaches a certain pressure value, entering into a high-pressure recovery tank, entering into a low-pressure recovery tank, pumping and pressurizing the gases in the dehydration tank and the recovery tanks by virtue of a gas recovery compressor, flowing back to the gas-distributing tank, ensuring the recovery compressor to stop working when the pressure in the dehydration tank is approximate to the atmospheric pressure and closing the intake valve of the high-pressure recovery tank and opening the blowoff valve of the dehydration tank to discharge the residual carbon dioxide in the dehydration tank to the atmosphere; (3) taking out the materials in the tank; (4) carrying out inspection; and (5) packaging and warehousing.

Owner:JIANGSUCHINA PALARICH

A method for secondary cleaning and drying of dried wolfberry fruit

InactiveCN104013079BNot prone to breakageGood for secondary dryingFood treatmentLycium barbarum fruitWater flow

The invention provides a dried lycium barbarum secondary washing and drying method. After lycium barbarum is washed in a washing production line, and drying is then achieved. By means of the dried lycium barbarum secondary washing and drying method, impurities on the surfaces of the lycium barbarum are removed in the washing process according to the physical effect of water flow and the flotation performance of the dried lycium barbarum and the impurities, the lycium barbarum is not prone to being damaged, most of moisture on the surface of the washed dried lycium barbarum can be easily removed through a flexible water absorption rubber roller, secondary drying after dried lycium barbarum washing is easily carried out, and the dried lycium barbarum secondary washing and drying method is suitable for automatic industrial large-scale production. In addition, the multi-section type belt drying method is adopted, drying after secondary washing of the dried lycium barbarum is effectively achieved, the obtained product is bright in color, loose in particle, clean, sanitary and safe, the quality of the dried lycium barbarum is improved, and a new way is developed for making high-quality dried lycium barbarum.

Owner:CHINA ACAD OF SCI NORTHWEST HIGHLAND BIOLOGY INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com