Production process for cow primary milk whey with natural immunocompetence and low irritability

A technology of natural immunity and production technology, applied in the direction of whey, dairy products, applications, etc., can solve the problems of low heat treatment intensity and not too high heat treatment intensity, and achieve the effect of ensuring hygienic quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

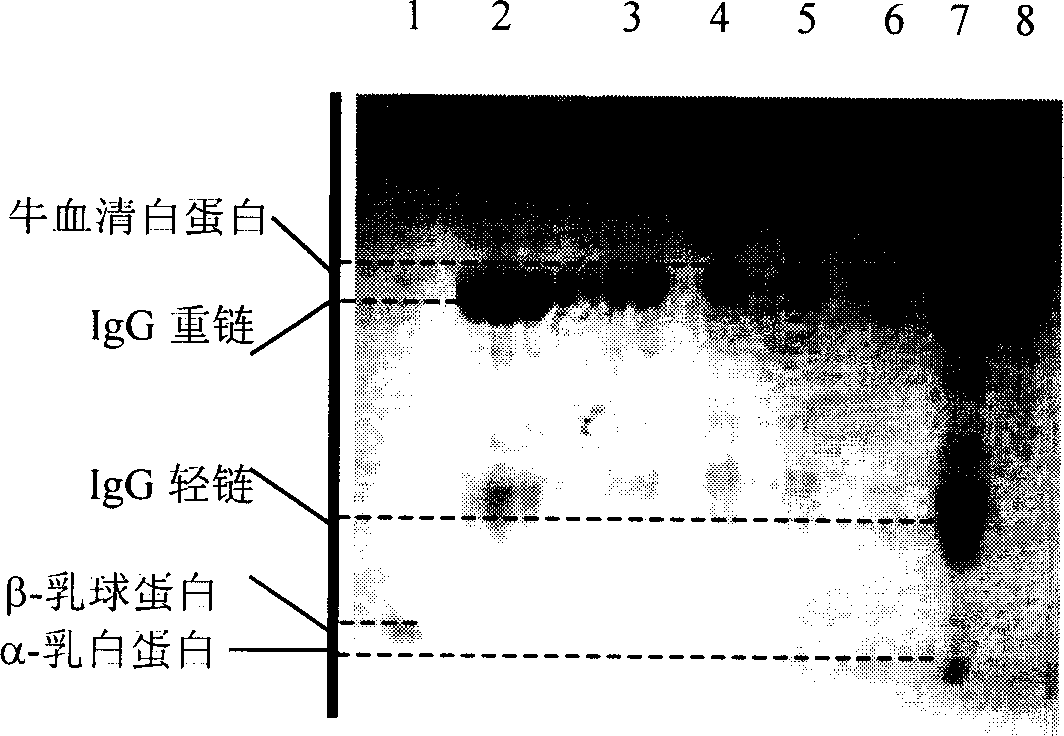

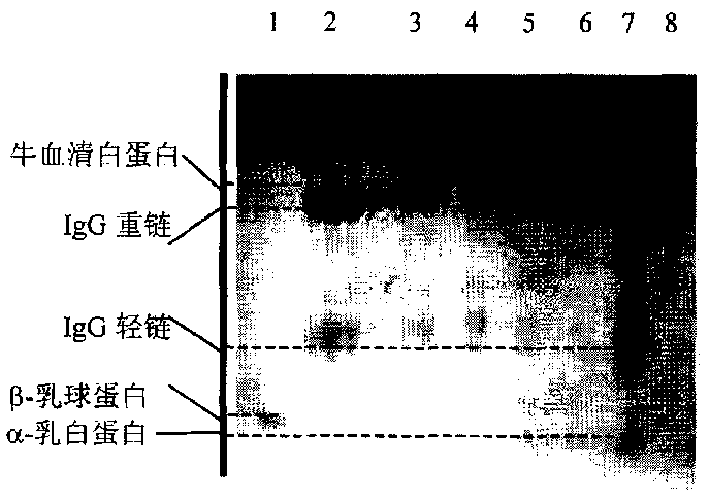

Image

Examples

Embodiment 1

[0014] Place 2.4L of bovine colostrum in a preparative centrifuge at 4000r / min for 20 minutes to remove the milk fat to obtain 2.18L of skimmed bovine early emulsion. Adjust the pH of the skimmed milk to 4.6 with 50% lactic acid. After standing for 20 minutes, place it in the centrifuge. Centrifuge at 4000r / min for 20-30min in the machine to precipitate casein and obtain 1.94L of clear whey liquid. Add 1.0mol / L FeCl 3 Solution, adjust the pH to 3.5~5.0, then continue to add FeCl 3 Solution, until system Fe 3+ The concentration reaches 3.0~8.9mmol / L. During this period, the pH of the system is kept constant between 3.5~5.0 by adding NaOH solution. Let it stand for 1.5h and centrifuge at 4000r / min to remove the precipitate (mainly β-lactoglobulin). Adjust the pH of the clear liquid to 8.0 with 3mol / L NaOH solution, and after standing for 2.5h, centrifuge again at 4000r / min to remove Fe(OH) 3 precipitation. After the supernatant is sterilized by microfiltration through a membrane wit...

Embodiment 2

[0016] Put 6.0L bovine colostrum in a preparative centrifuge at 4000r / min and centrifuge for 25min to remove milk fat to obtain 5.5L skimmed bovine first emulsion. Adjust the skim milk pH to 4.6 with 5%-10% hydrochloric acid, and let it stand for 15-30min Afterwards, place it in a centrifuge at 4000r / min and centrifuge for 20-30min to precipitate casein to obtain 4.95L of clear whey liquid, and then add FeCl to the above-mentioned whey liquid 3 Solution, adjust the pH to 3.5~5.0, then continue to add FeCl 3 Solution, until system Fe 3+ The concentration reached 8.5mmol / L. During the period, the pH of the system was maintained between 3.5 and 5.0 by adding NaOH solution. After standing for 1 to 3 hours, the precipitate of β-lactoglobulin-iron complex was removed by centrifugation at 4000r / min, and the supernatant Adjust the pH of the solution to 8.0~8.5 with 5%~10% NaOH solution. After standing for 2~3h, centrifuge again at 4000r / min to remove Fe(OH) 3 After precipitation, the resu...

Embodiment 3

[0018] Put 6.0L bovine colostrum in a preparative centrifuge at 4000r / min and centrifuge for 20-25min to remove milk fat to obtain skimmed bovine colostrum, then precipitate casein according to the method of Example 1 or 2, and centrifuge to separate whey. Then use hydrochloric acid or lactic acid to adjust the pH of skimmed milk to 4.5, and then add 0.5mol / L FeCl 3 Solution, while adding 10%-15% NaOH solution dropwise to maintain the pH of the system to about pH 4.5, then continue to add FeCl 3 Solution, until system Fe 3+ The concentration reached 8.0mmol / L, stand for 2.5h, centrifuge at 4000r / min to remove the precipitate (mainly β-lactoglobulin), and then use the method of Example 1 or 2, after microfiltration, and the matrix in the prior art Mixing according to a certain ratio, that is, the production process of the innate immune activity and hypoallergenic bovine colostrum whey described in the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com