Claw-type unscrew cap with PE (poly-ethylene) or PP (poly-propylene) cushion layer, and production technology of claw-type unscrew cap

A technology for unscrewing caps and cushions, which is applied in capping, bottle/container caps, and capping containers with caps, etc. It can solve problems such as cumbersome processes, affecting quality and safety, and low production efficiency, so as to ensure hygienic quality, Good sealing effect, good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

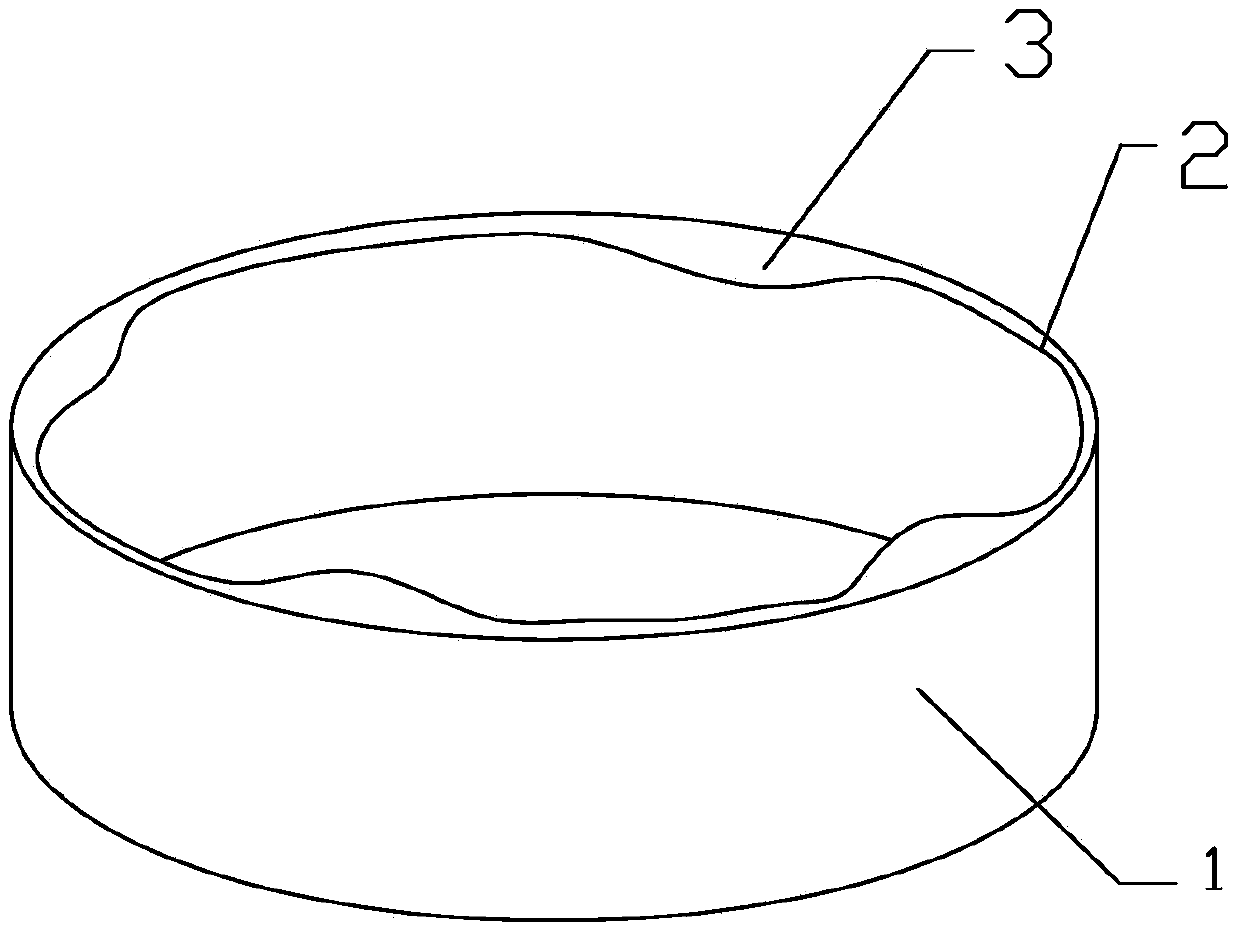

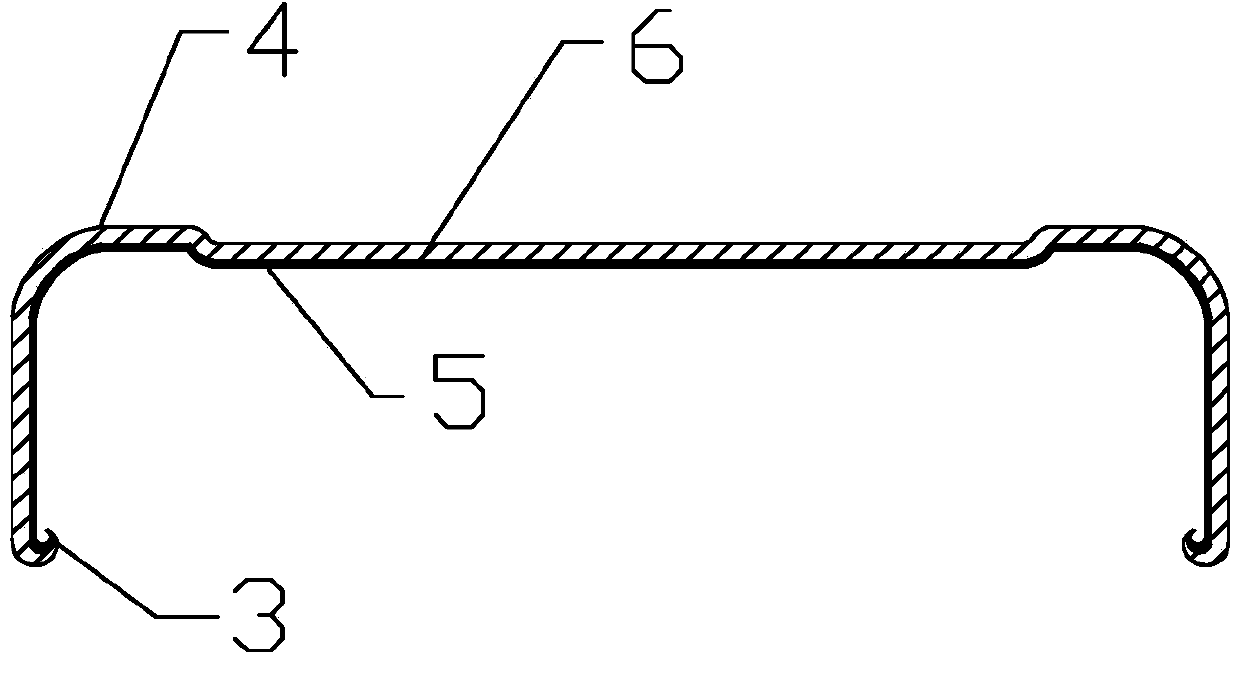

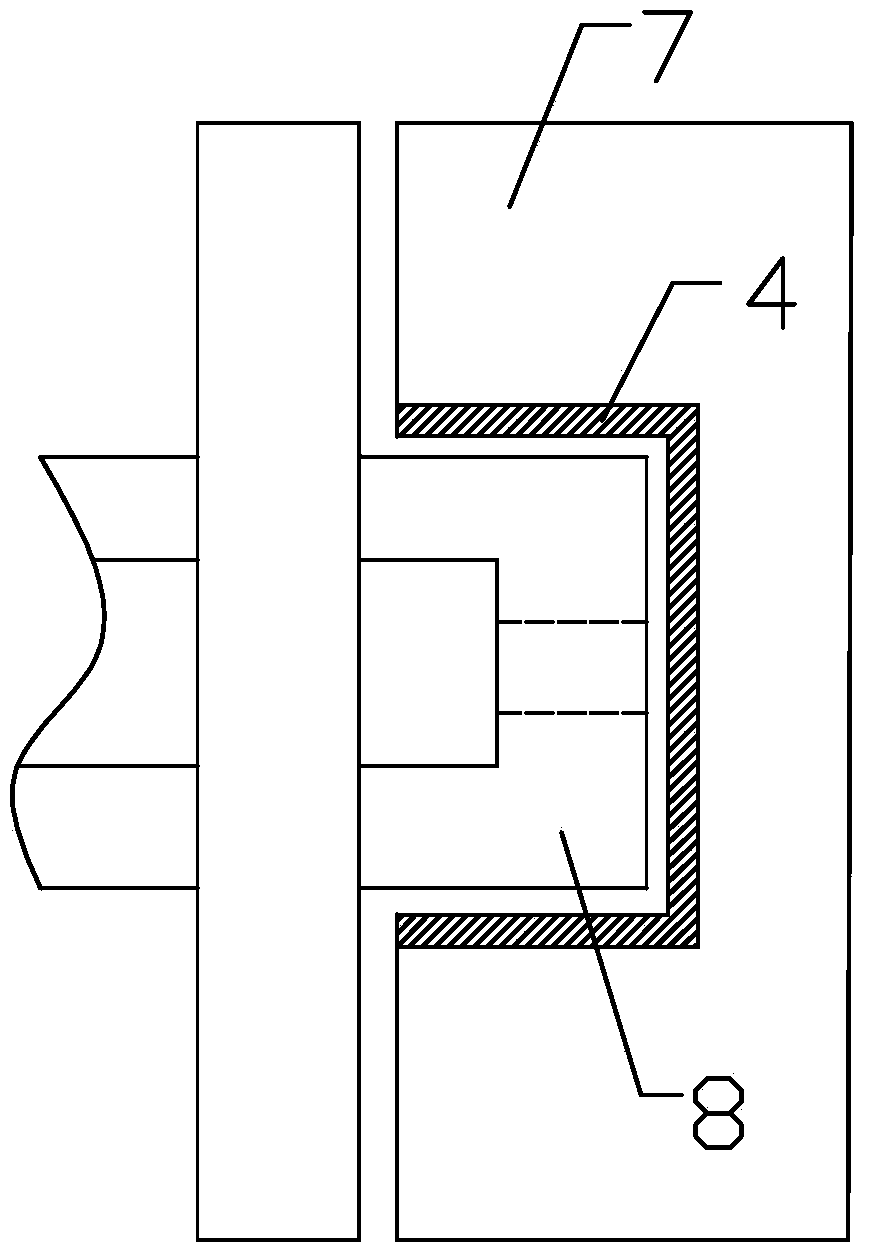

[0033] The present invention will be further described below in conjunction with accompanying drawing. Such as figure 1 , figure 2 As shown, the claw-type twist-off cap with a PE or PP cushion includes a cap body 1, and the top surface of the cap body 1 is recessed inwardly to form a circular boss 6 with a height of 0.5-1 mm. The edge of the circular boss 6 is arc-shaped, and the opening edge of the cover body 1 has a curling edge 2 and a rotary claw 3. It is characterized in that: the cover body 1 is made of a tinplate cover 4 without an inner film coating and a cover The polyethylene or polypropylene cushion layer 5 arranged on its inner surface is composed of polyethylene particles or polypropylene particles through injection molding or drop molding on the tinplate cover 4 without inner film coating. A gasket layer with a thickness of 0.5-2.0mm formed on the inner surface, the optimum thickness is 0.8-1.2mm, and completely covers the inner surface of the tinplate cover 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com