Push-button nozzle for liquid product dispenser

一种分配器、产品的技术,应用在喷射装置、喷射装置、单个的手持设备等方向,能够解决有损用户使用舒适度、不能令人满意产品、不利产品吸收等问题,达到喷射平稳与均匀、精确剂量、易于装配的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

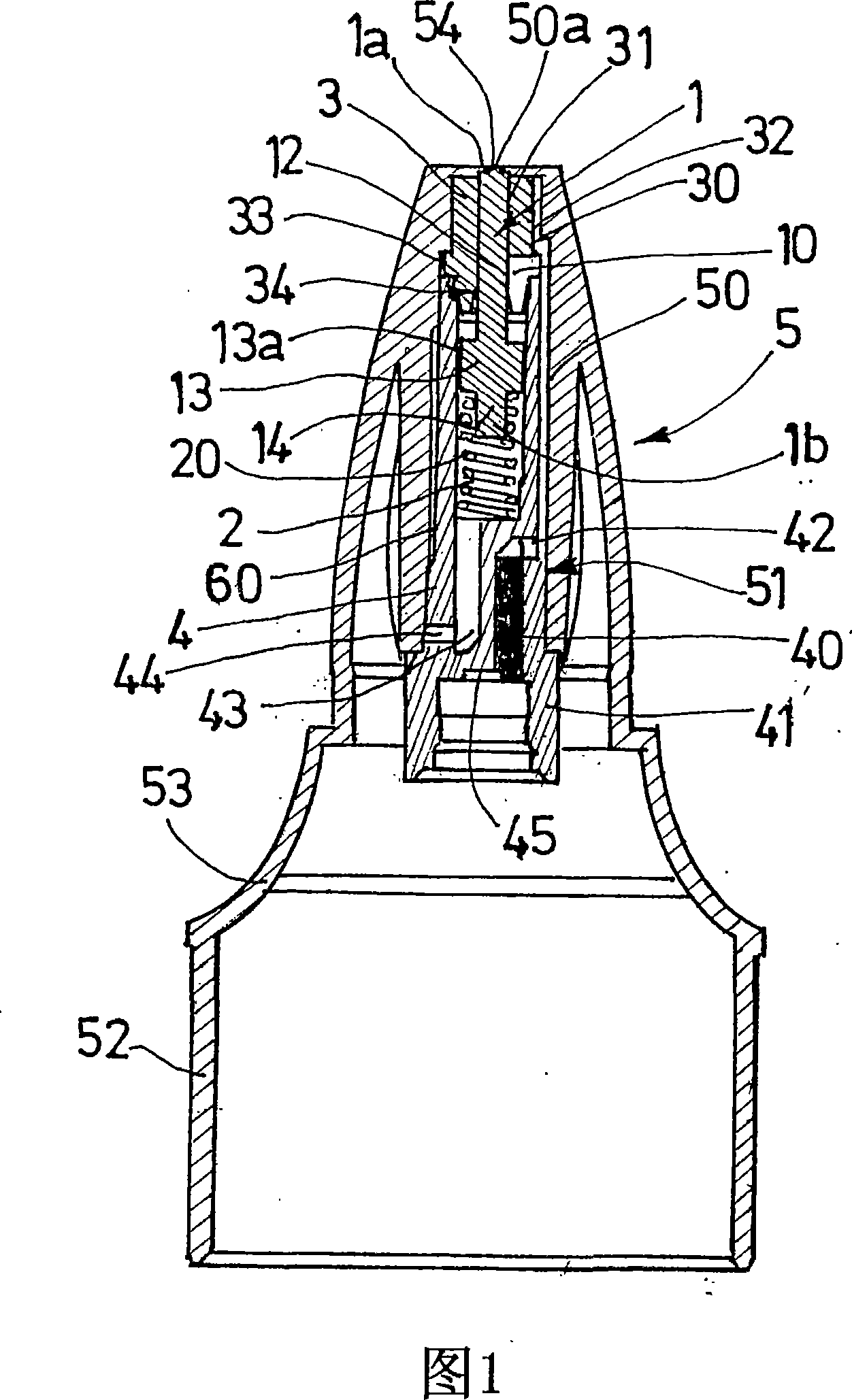

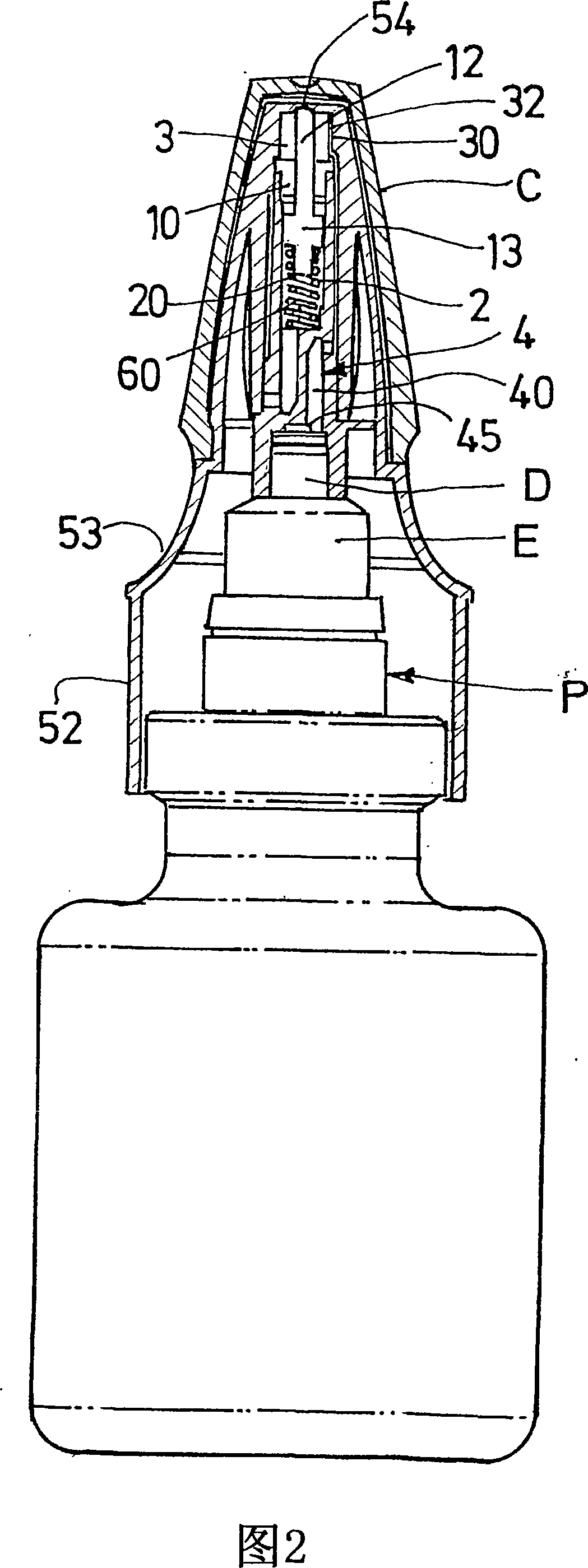

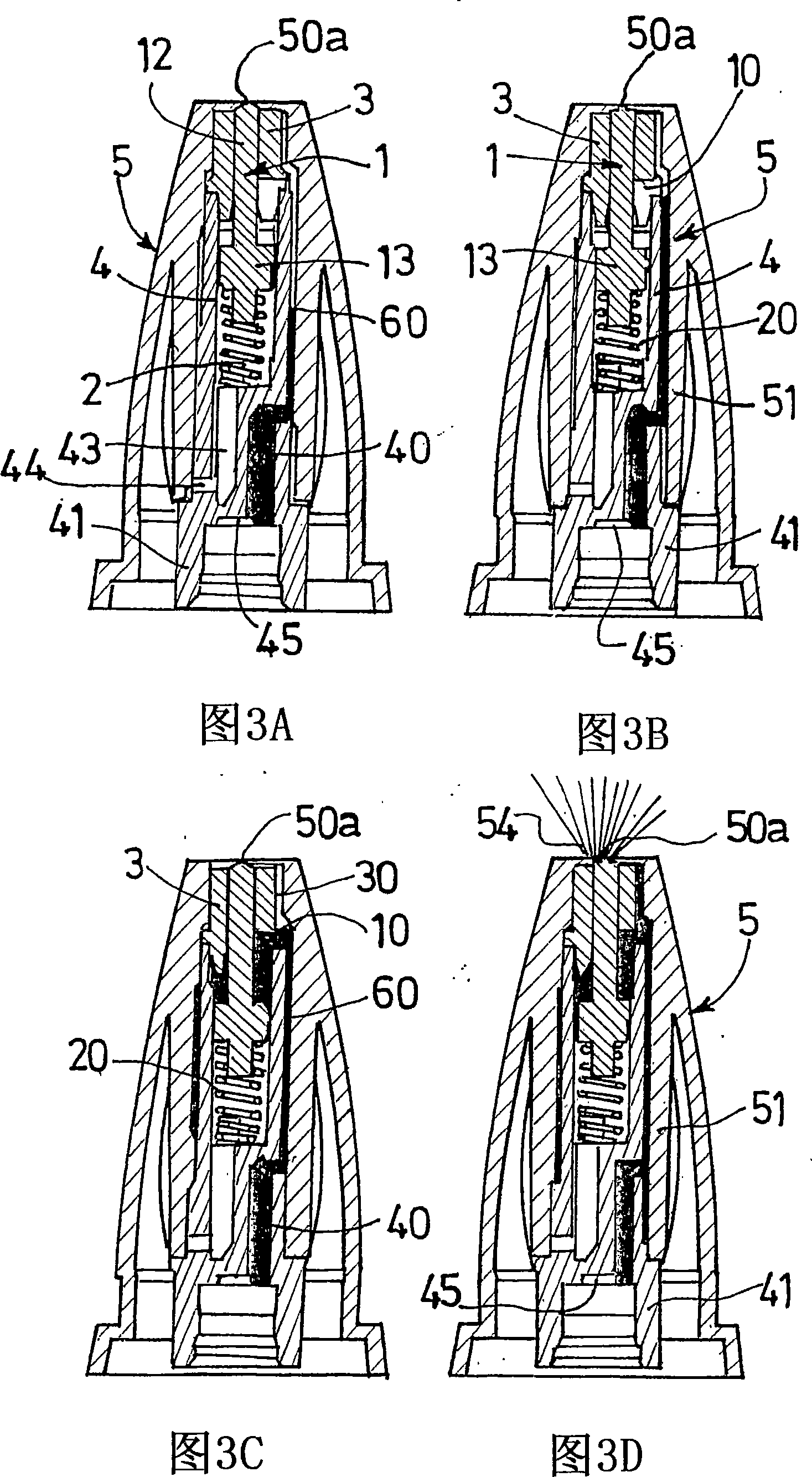

[0030] The nozzles shown in Figures 1 to 4 show a conical shell 5 with a central axis at least in its upper part defining a wall of an inner tube 50 upwards through a small diameter spray hole 50a. Opens outwards and extends downwards through the inner sleeve 51 .

[0031] As shown in Figure 2, the housing 5 has a lower outer skirt 52 covering the neck of the bottle.

[0032] As also shown in FIG. 2 , advantageously, a removable cover C can cover the upper part of the housing 5 .

[0033] The housing 5 of the nozzle has a recessed outer area 53 located close to its fixing means for fixing to the end of the spout tube E and enabling manual pressing of the nozzle to actuate the product dispensing device.

[0034] The nozzle also comprises a valve housed in the tube 50, which valve has a needle 1 whose upper end 1a cooperates with the outlet 50a of the turbulence chamber 54, thus forming the ejection nozzle.

[0035] Thus, the end 1a has a pin whose profile matches that of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com