Full-automatic areca nut slicing machine

A slicer, fully automatic technology, applied in the direction of metal processing, etc., can solve the problems of difficult product hygiene quality assurance, difficult management, poor hygiene conditions, etc., to achieve the effect of improving slice processing efficiency, ensuring hygiene quality, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific embodiments of the present invention will be described in detail below in conjunction with the drawings as follows:

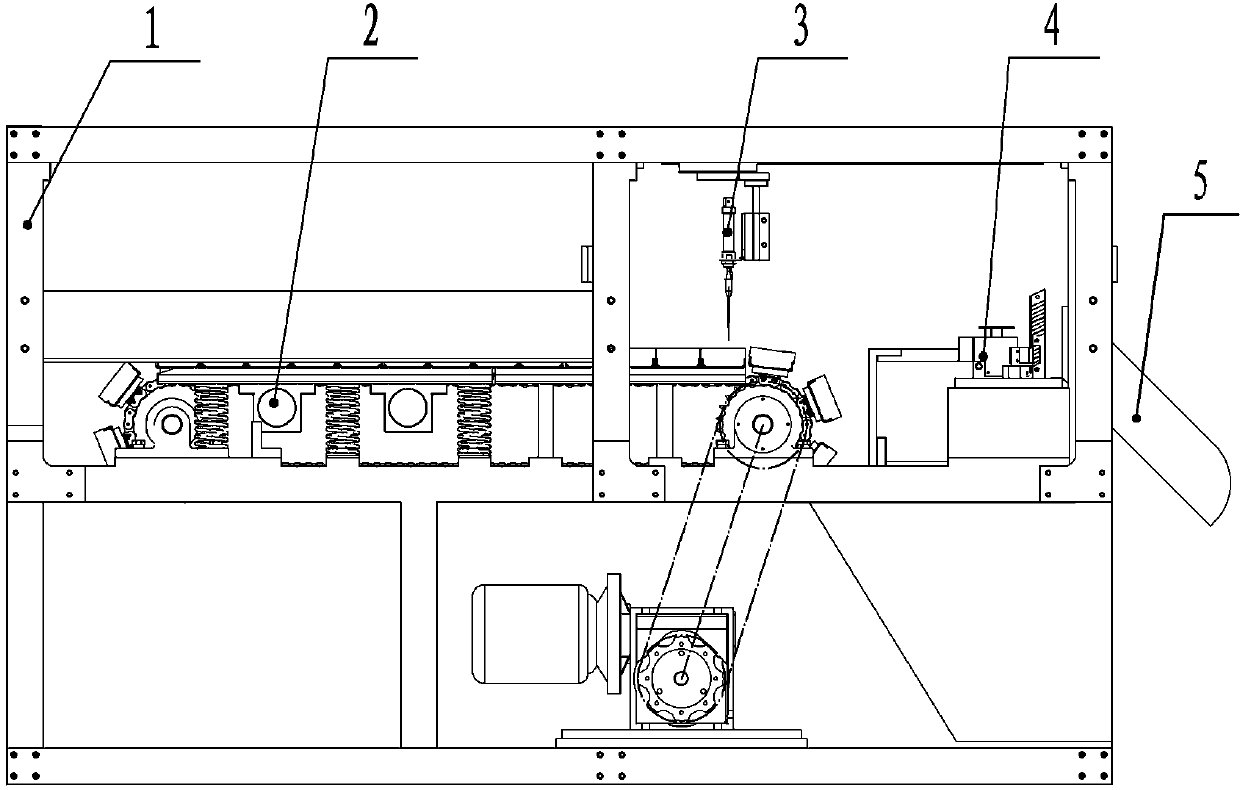

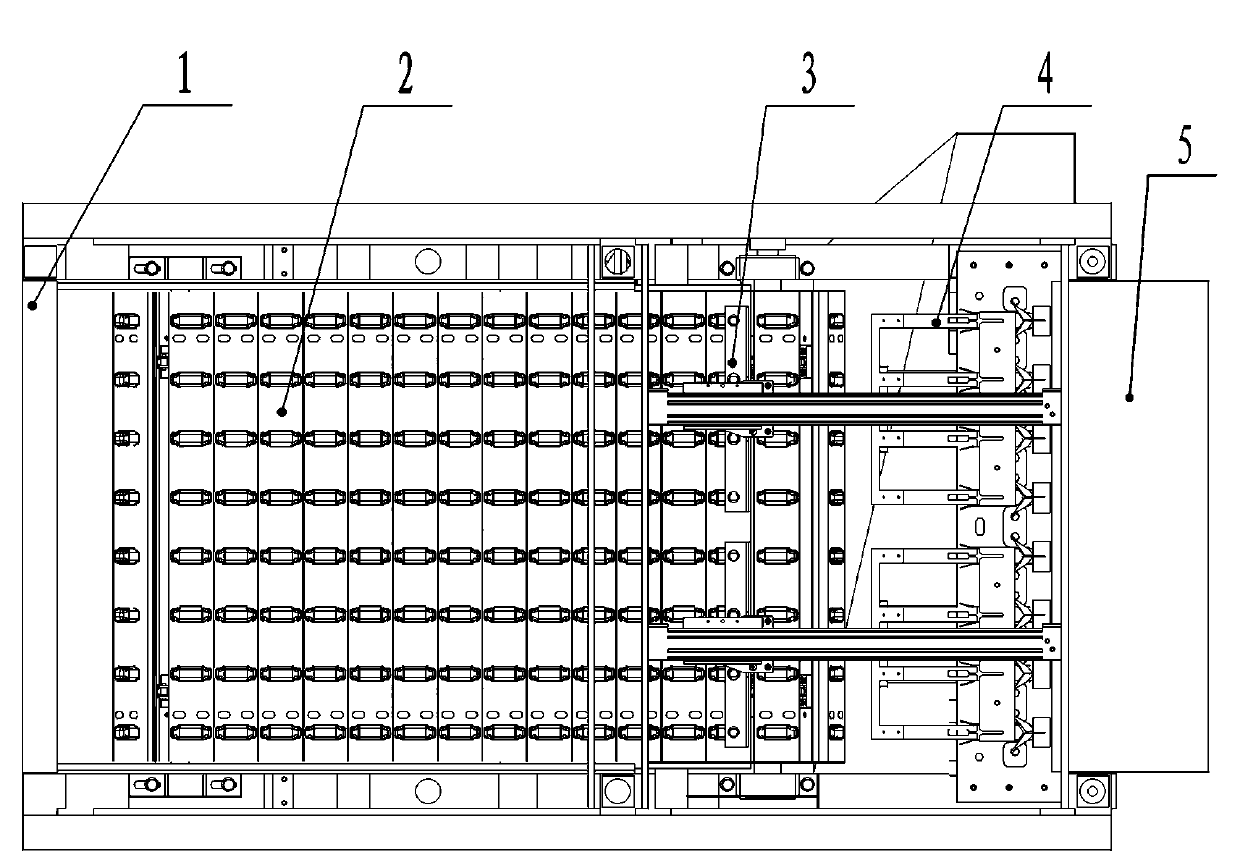

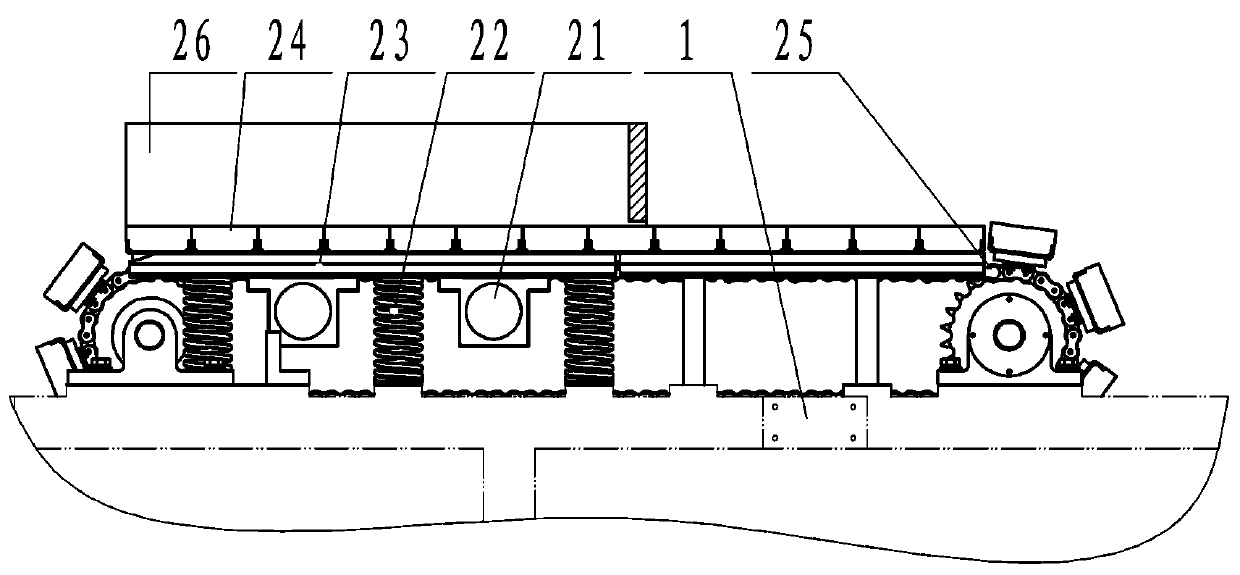

[0028] See attached Figure 1-5 As shown, an automatic betel nut slicer is mainly composed of a frame assembly 1 and a vibration assembly 2, a transfer assembly 3, and a slicing assembly 4 which are installed on the frame assembly and connected in sequence. The vibration assembly is mainly composed of a vibration source 21. The support spring 22, the mold support plate 23, the transmission chain 25, and the material handling mold 24 are connected together. The material handling mold is regularly arranged with multiple rows of betel nut slots 241. The material handling mold is installed on the transmission chain, and the transmission chain is driven by the motor When it rotates, the material handling mold support plate is set at the bottom of the two sides of the material handling mold and connected to the frame assembly through the support sprin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com