Patents

Literature

55results about "Eggs preservation by drying" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

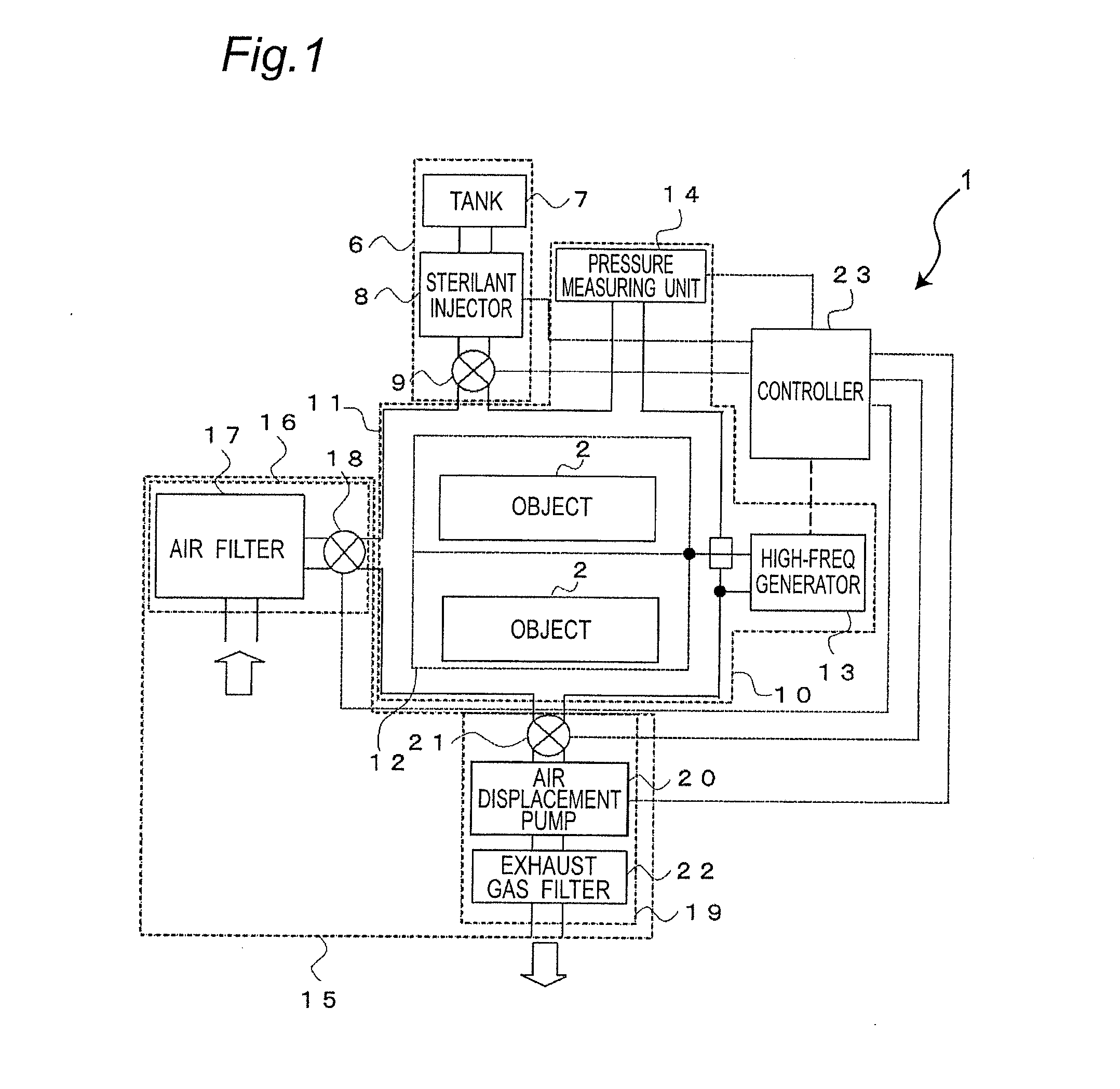

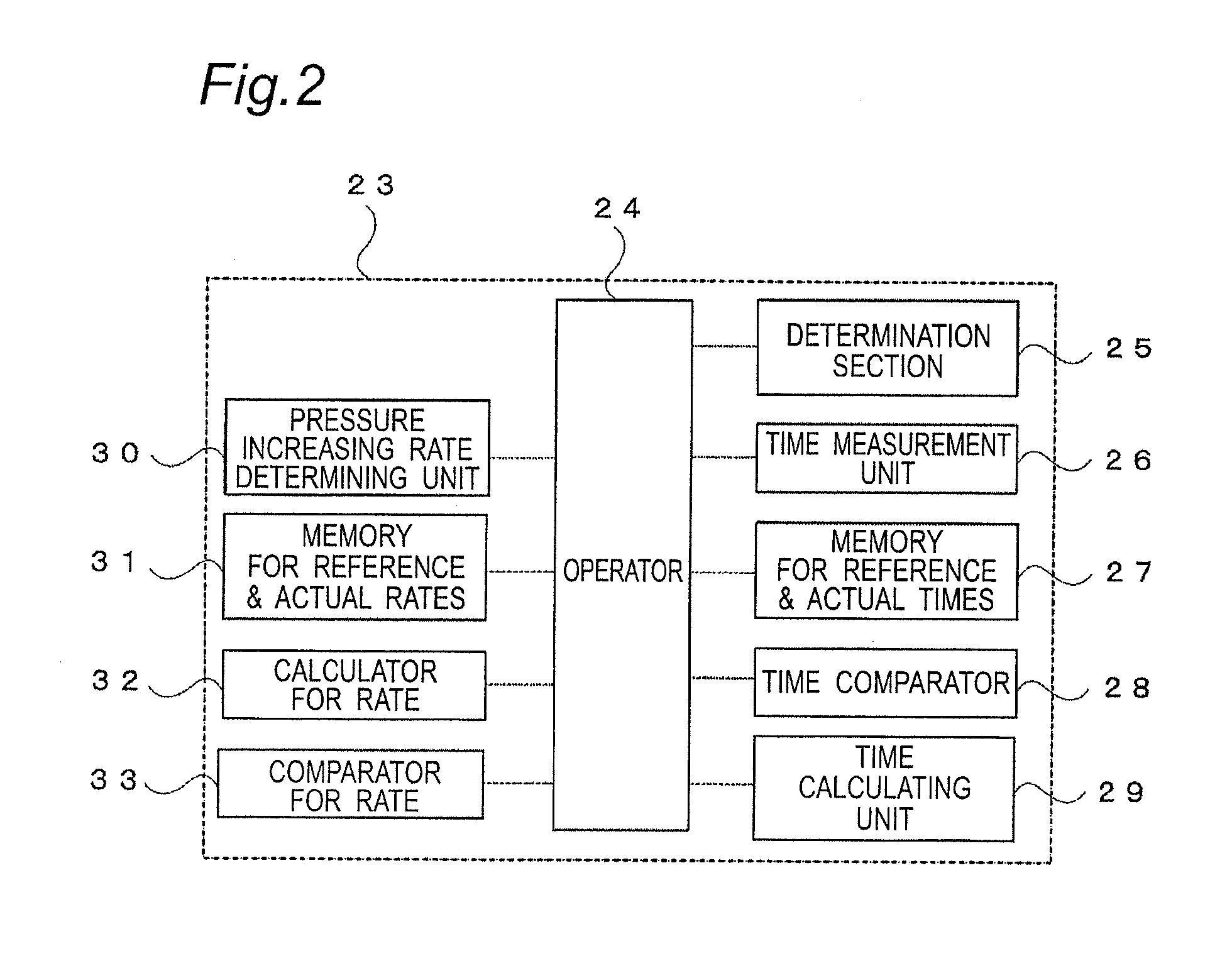

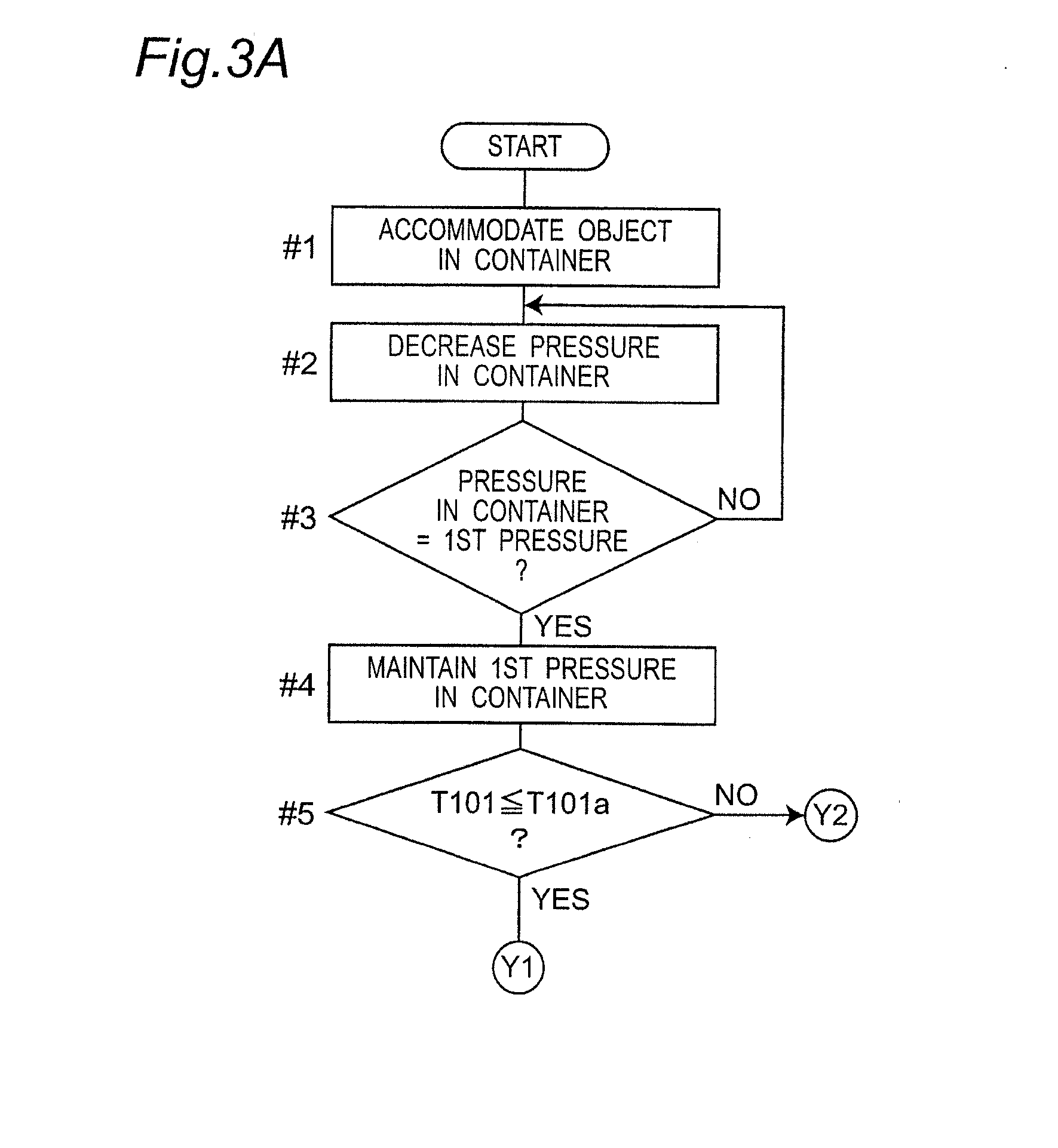

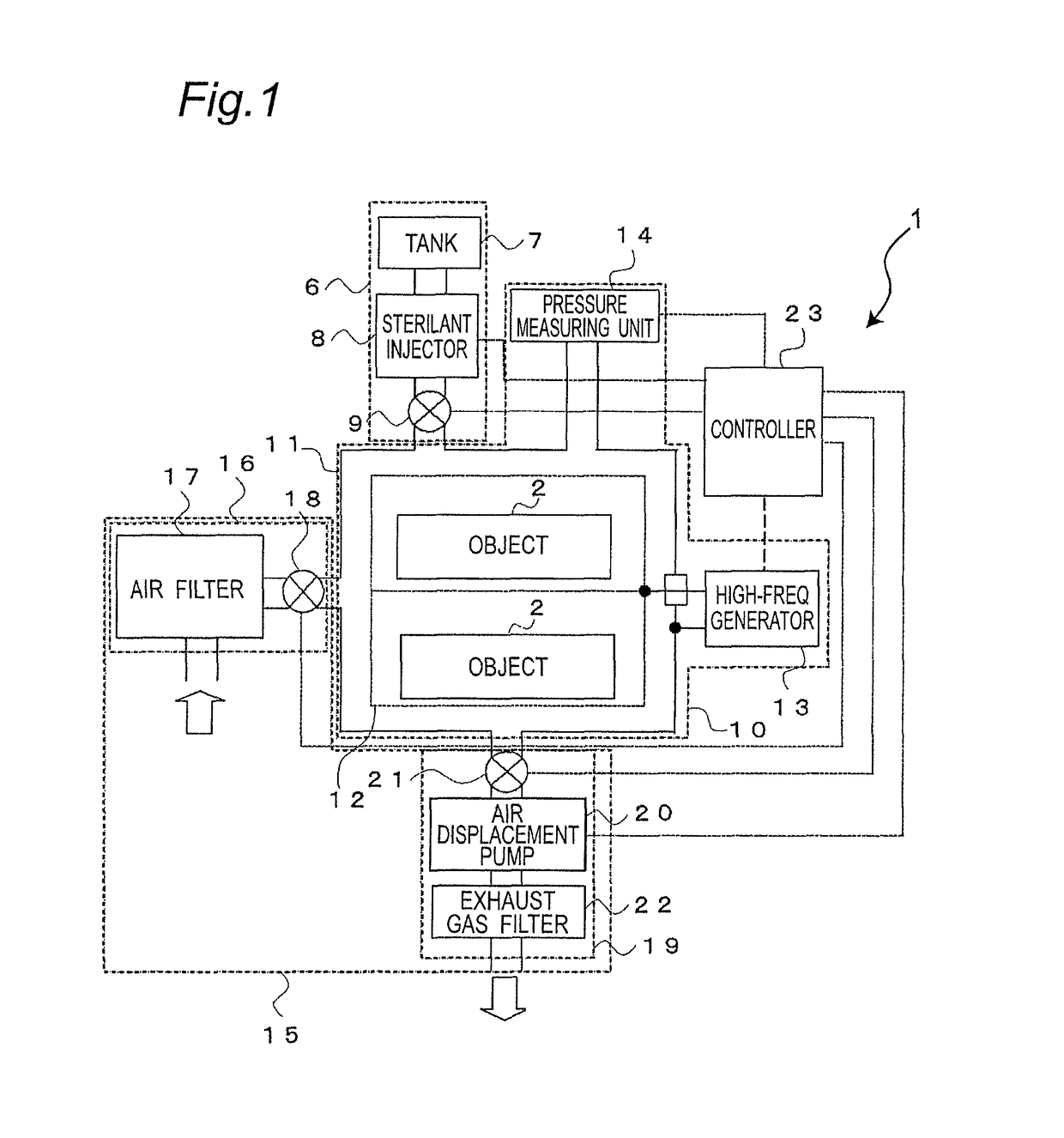

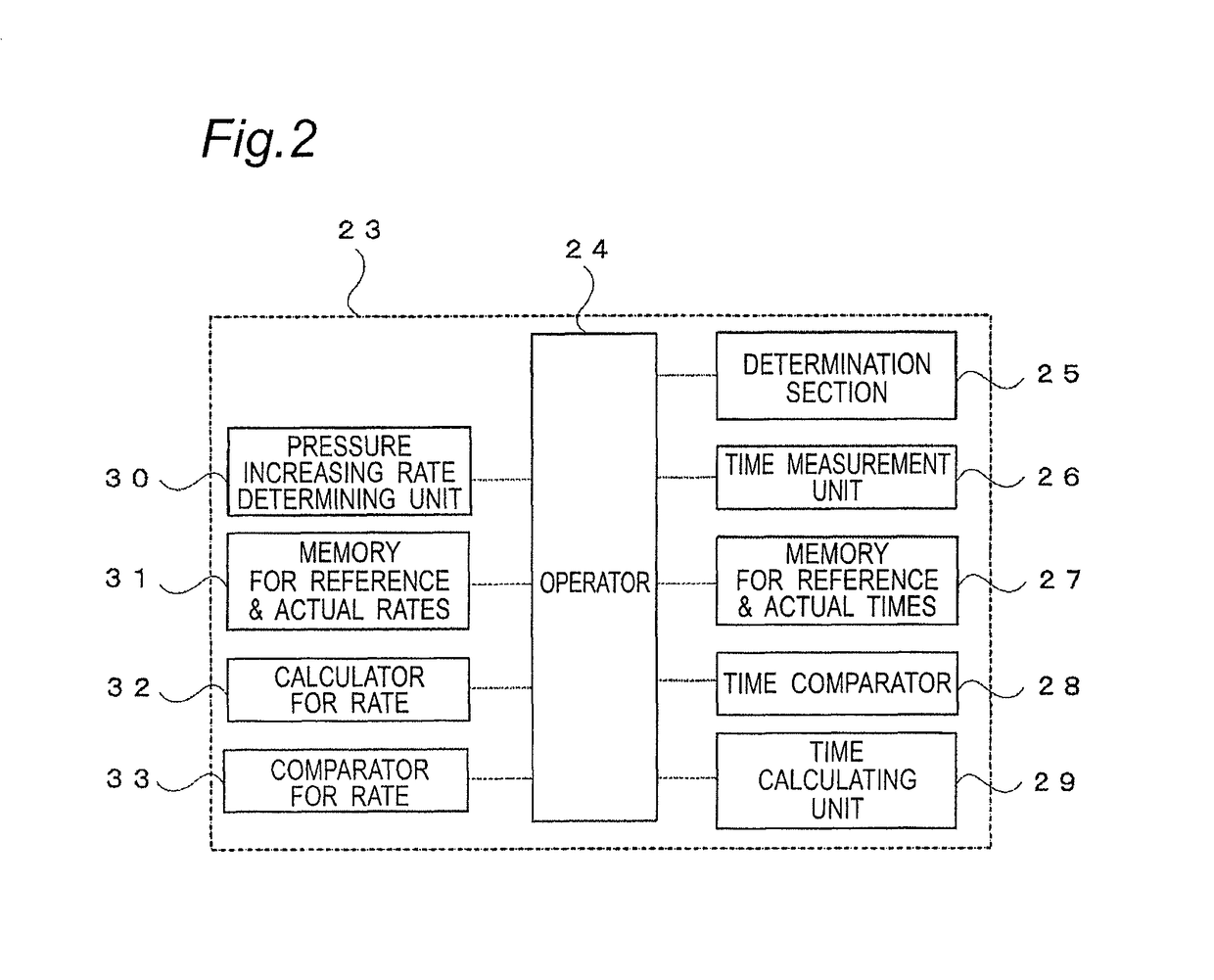

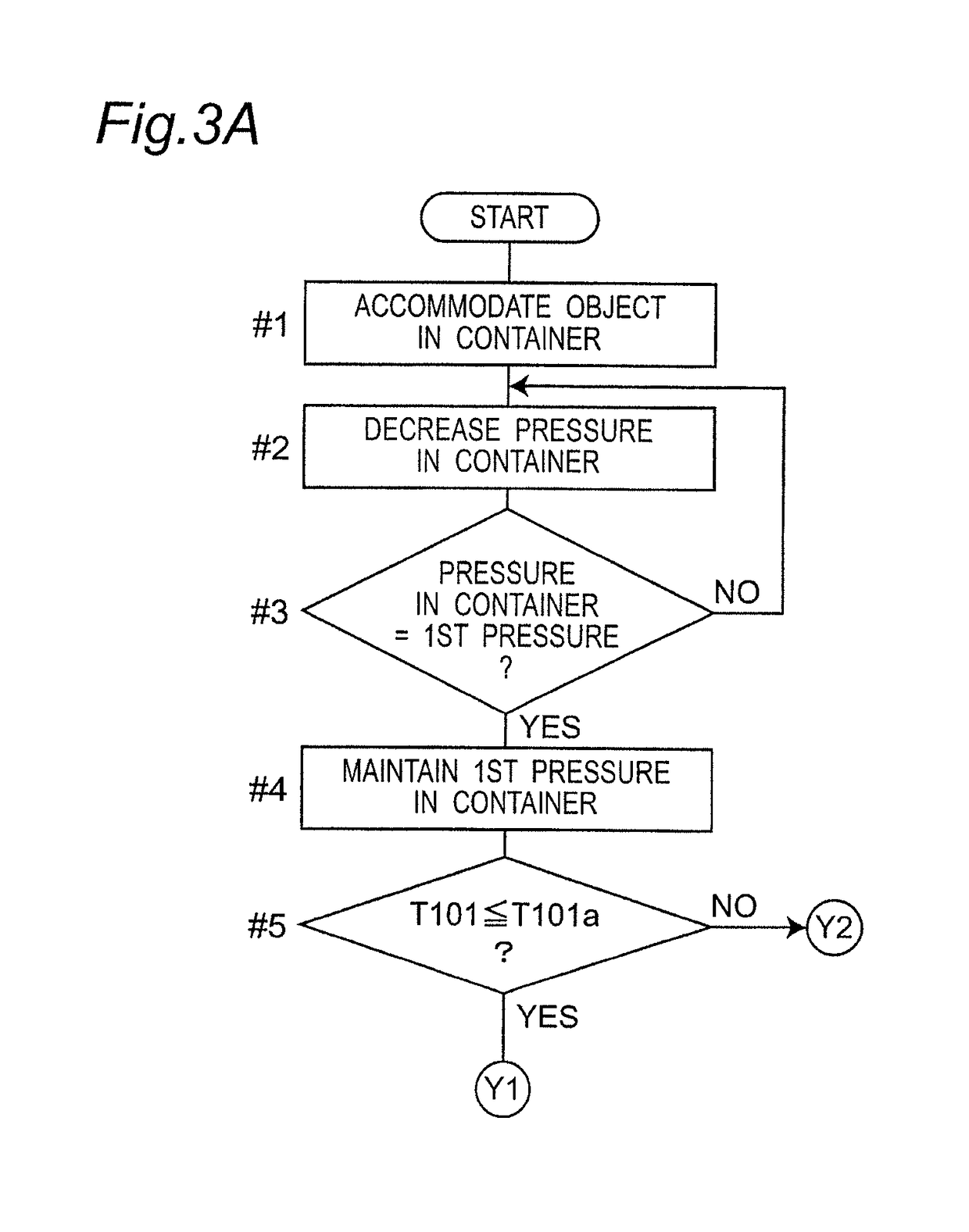

Sterilization method and device

ActiveUS20150313250A1Improve contact efficiencyFully dryExhaust apparatusElement comparisonPressure decreaseProcess engineering

According to the present invention, a sterilant can be injected into a container without residual water on an object to be sterilized. The method includes decreasing a pressure in the container to a pressure higher than the triple point pressure at which water freezes. The method further includes comparing an actual time required for decreasing the pressure and a reference time, or comparing an actual rate of pressure increase and a reference rate to detect residual water on the object. If the residual water is detected, the pressure in the container is increased to the atmospheric pressure or the quasi-atmospheric pressure and the object is heated, and then the pressure is decreased to drain the residual water through the decompression boiling. The step of draining the residual water is repeatedly performed until no residual water is detected on the object and subsequently the sterilant is injected into the container.

Owner:SARAYA CO LTD

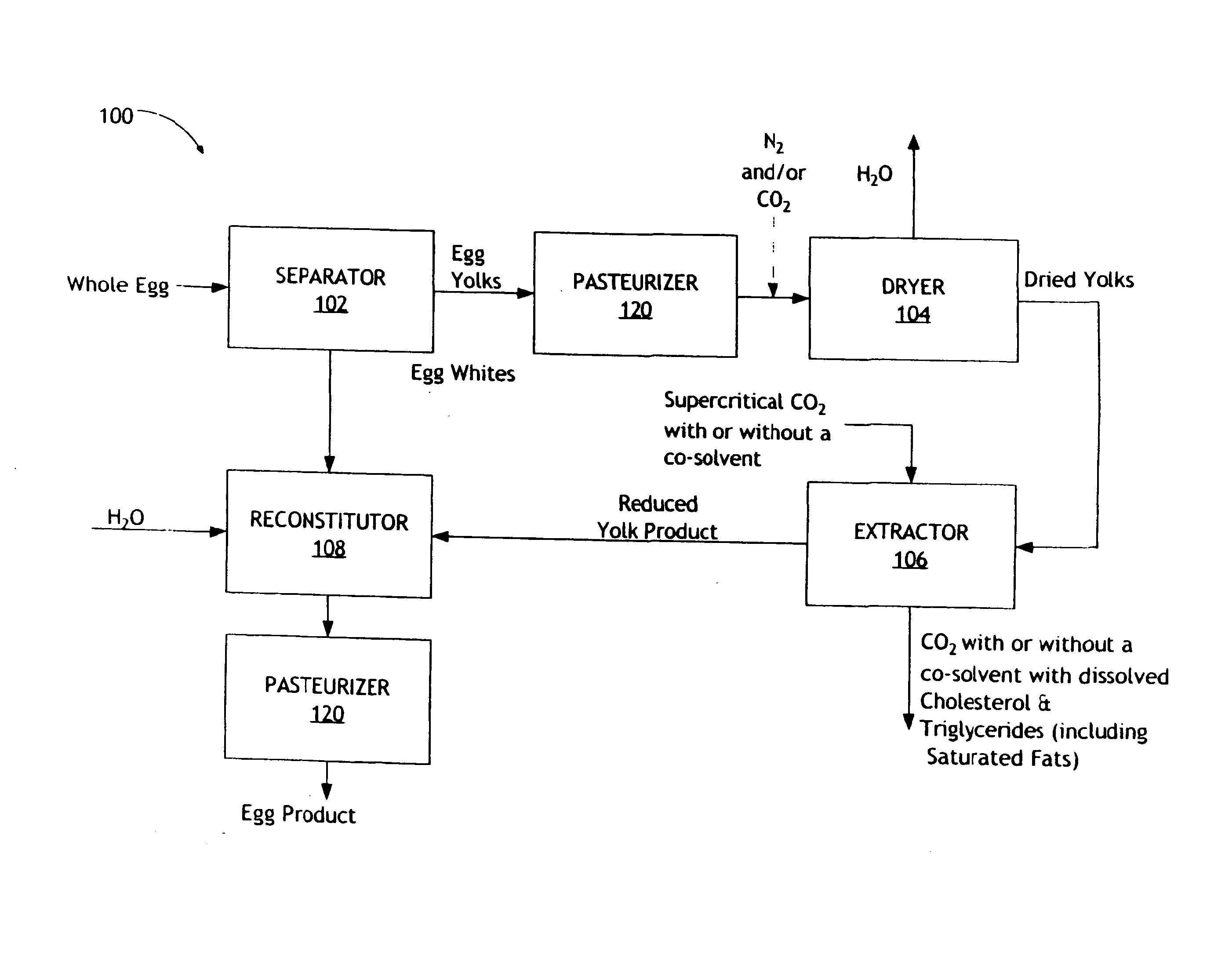

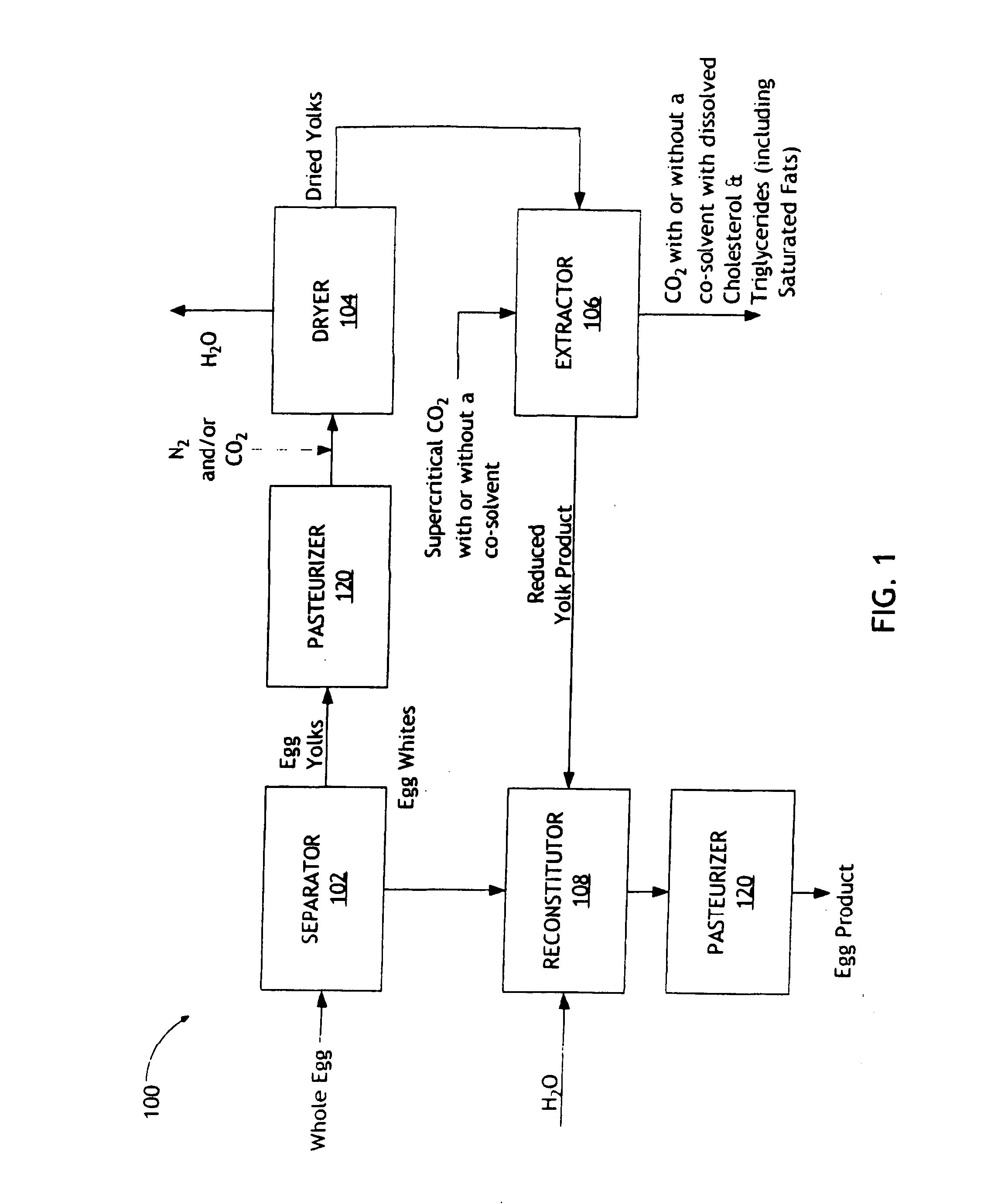

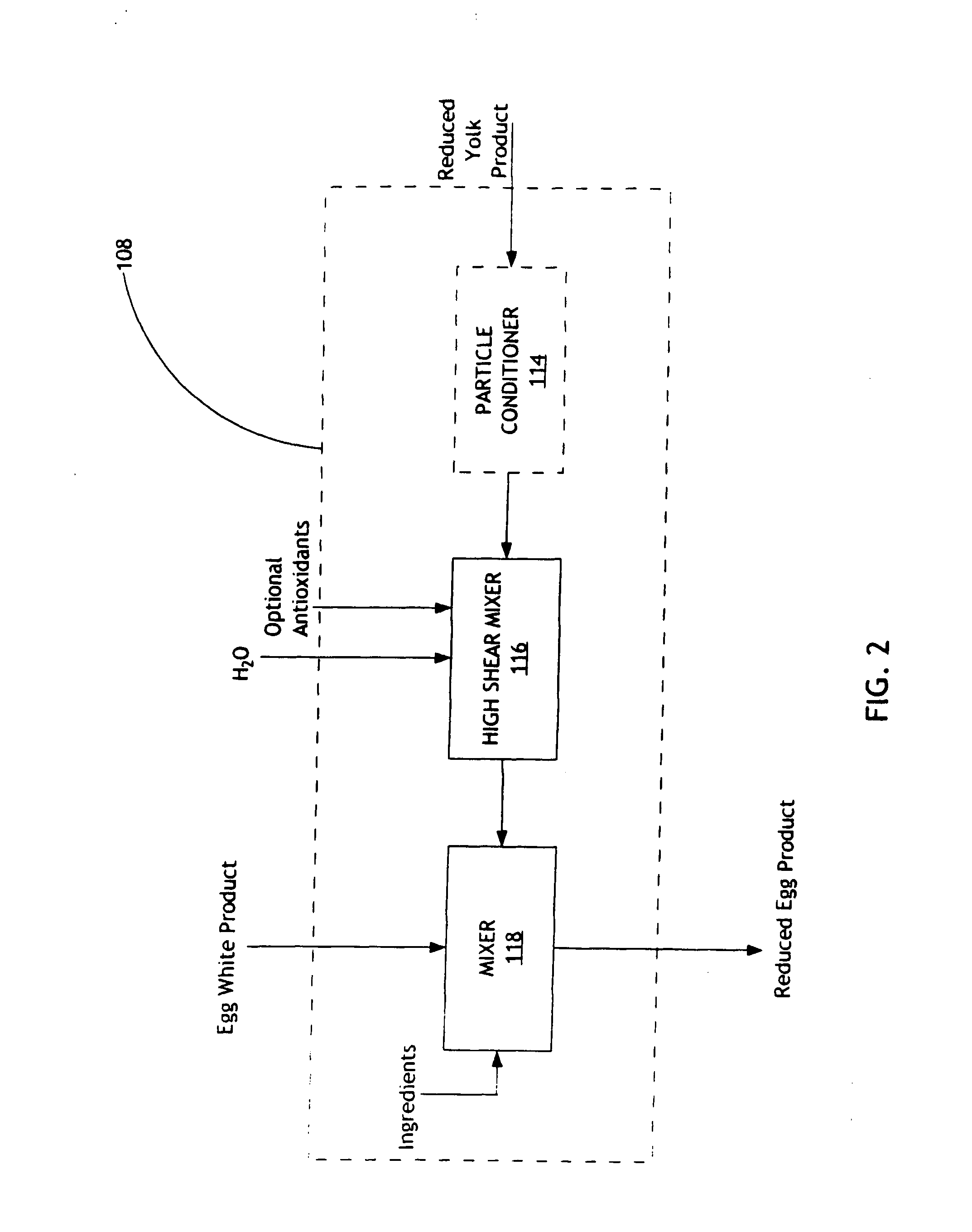

Egg product and production method

InactiveUS20080003335A1Reduce cholesterolLower triglycerides and cholesterolAutomatic control devicesMilk preservationAnimal scienceHoneycomb

A reduced egg product produced by supercritical fluid extraction comprising egg yolk from a whole egg that has a portion of undesired components, such as cholesterol and triglycerides (including saturated fats), selectively removed from the natural egg yolk while the beneficial components, such as phosphotipids, are selectively retained and while the consumer-desired flavor, texture, and / or functionality of the egg yolk is retained. A method for producing the reduced egg product comprises at least one of separating, drying, and extracting and optionally reconstituting. The continuous drying method produces dried egg yolk with a honeycomb type structure or small particle with low densities allowing for effective extraction and reconstitution. Furthermore, the reconstituting method is efficient and the pasteurizing method is capable of pasteurizing triglyceride and fat reduced egg yolk and triglyceride and fat reduced whole egg.

Owner:CONAGRA FOODS

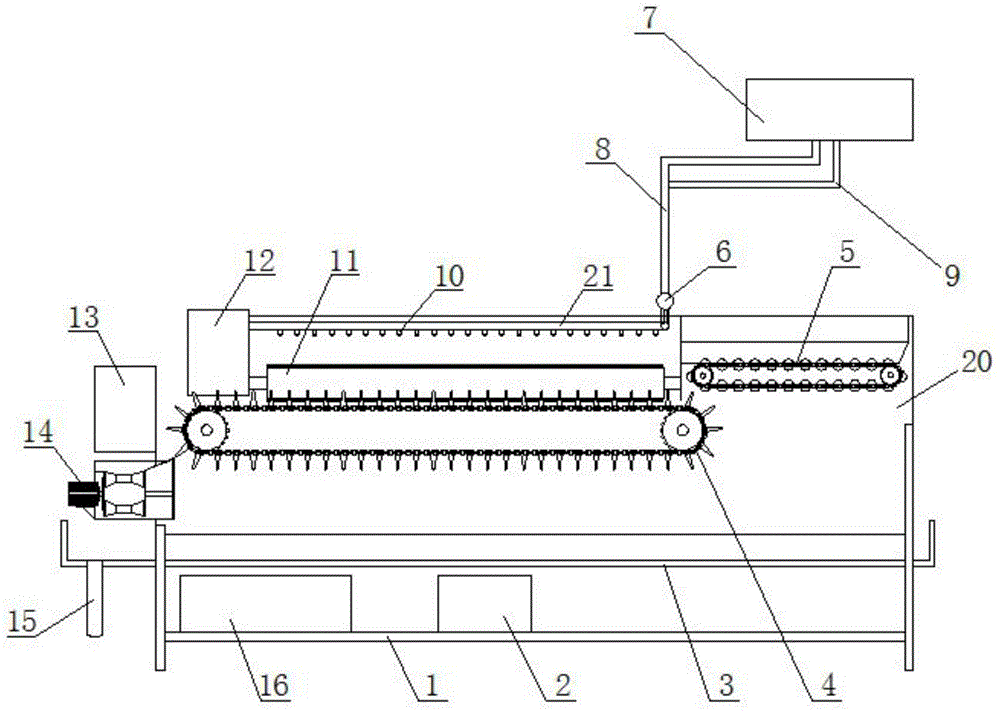

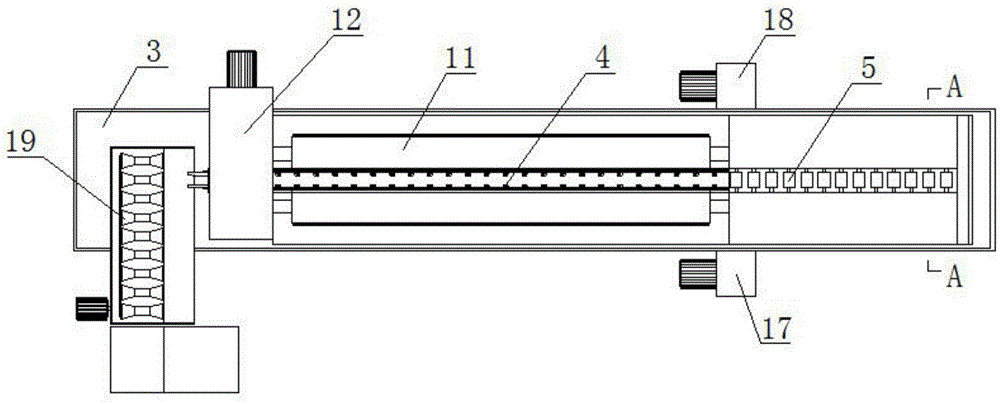

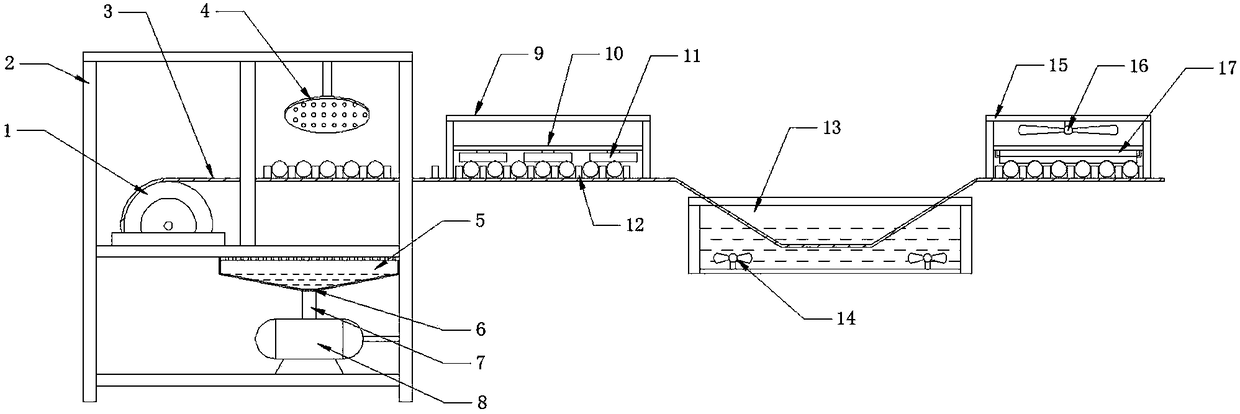

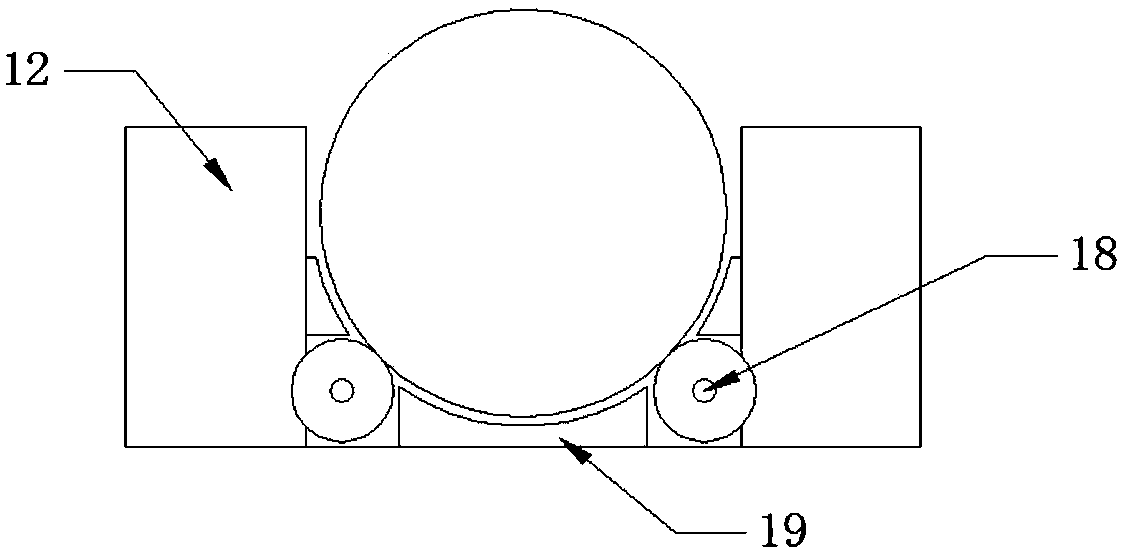

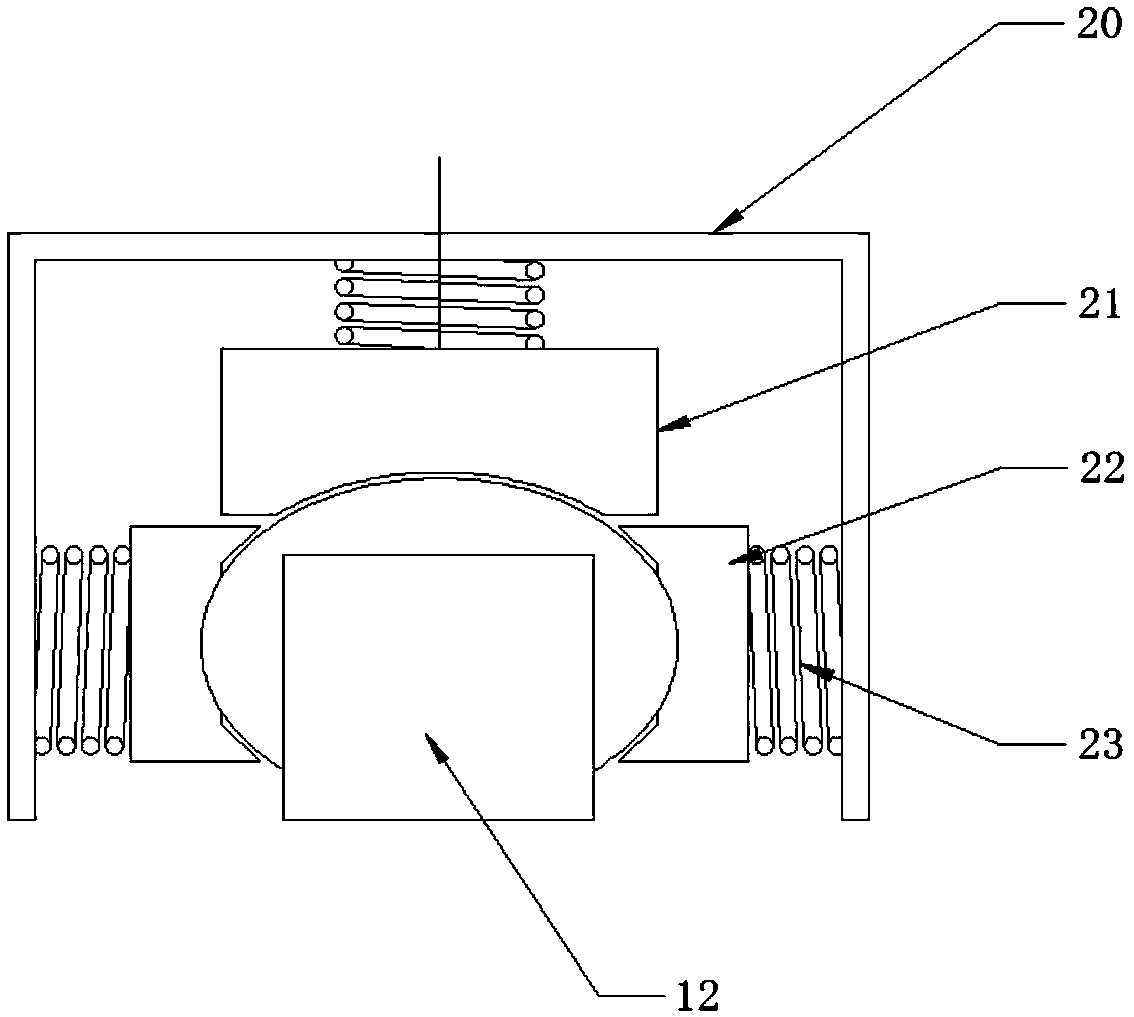

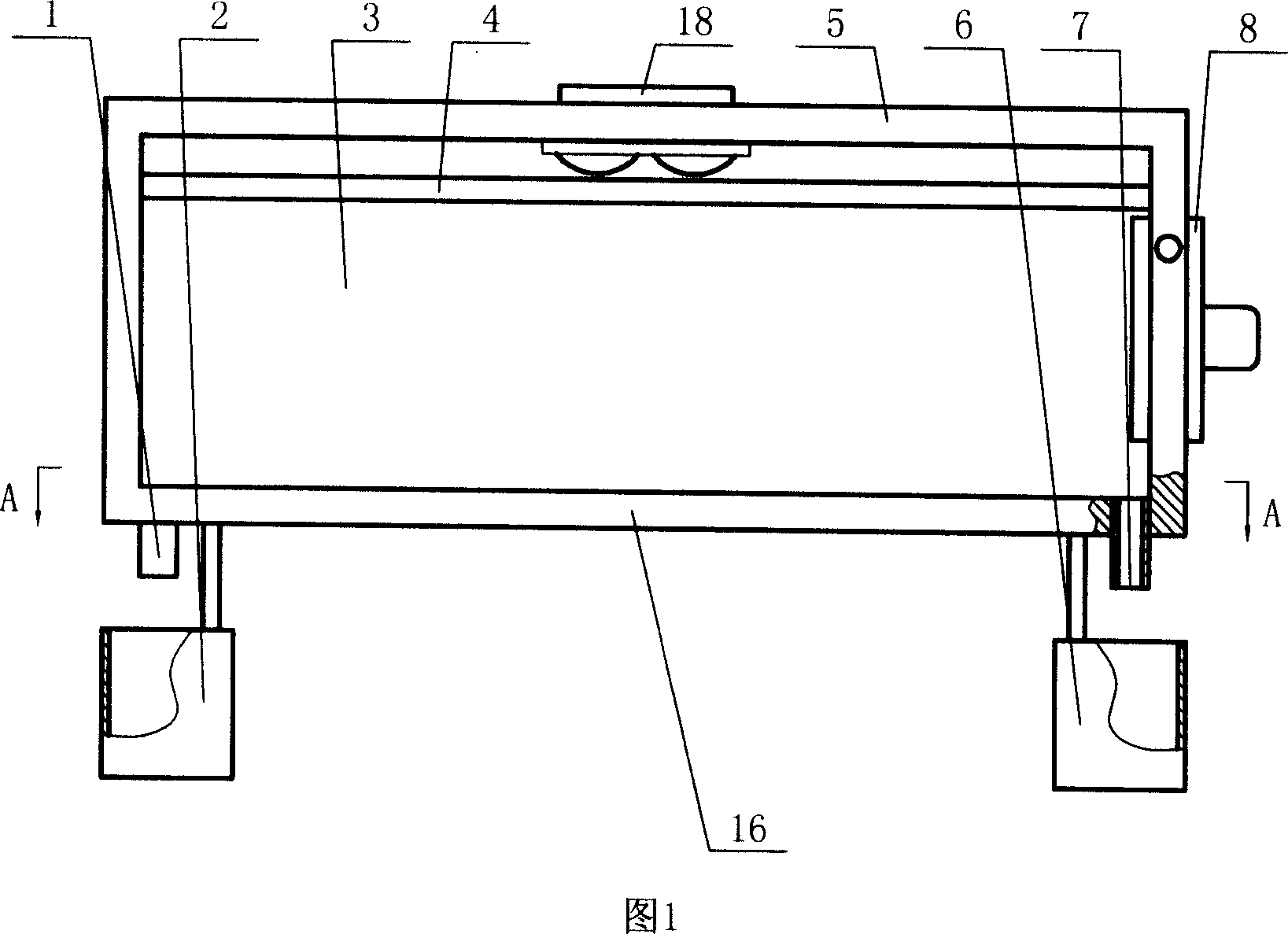

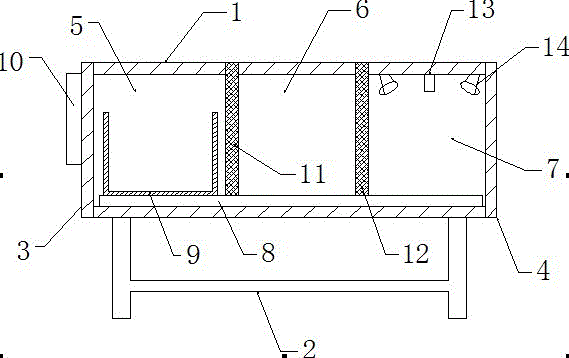

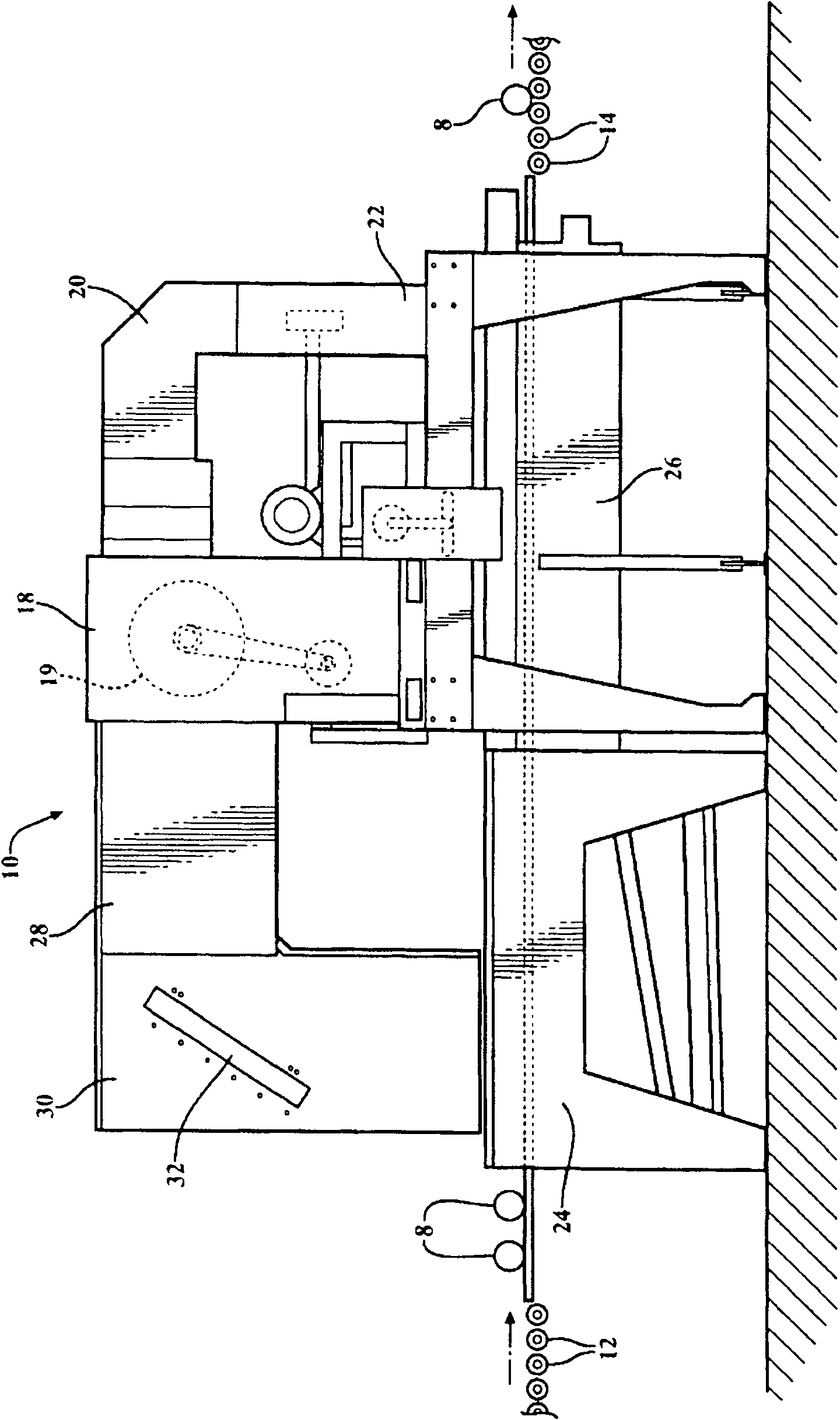

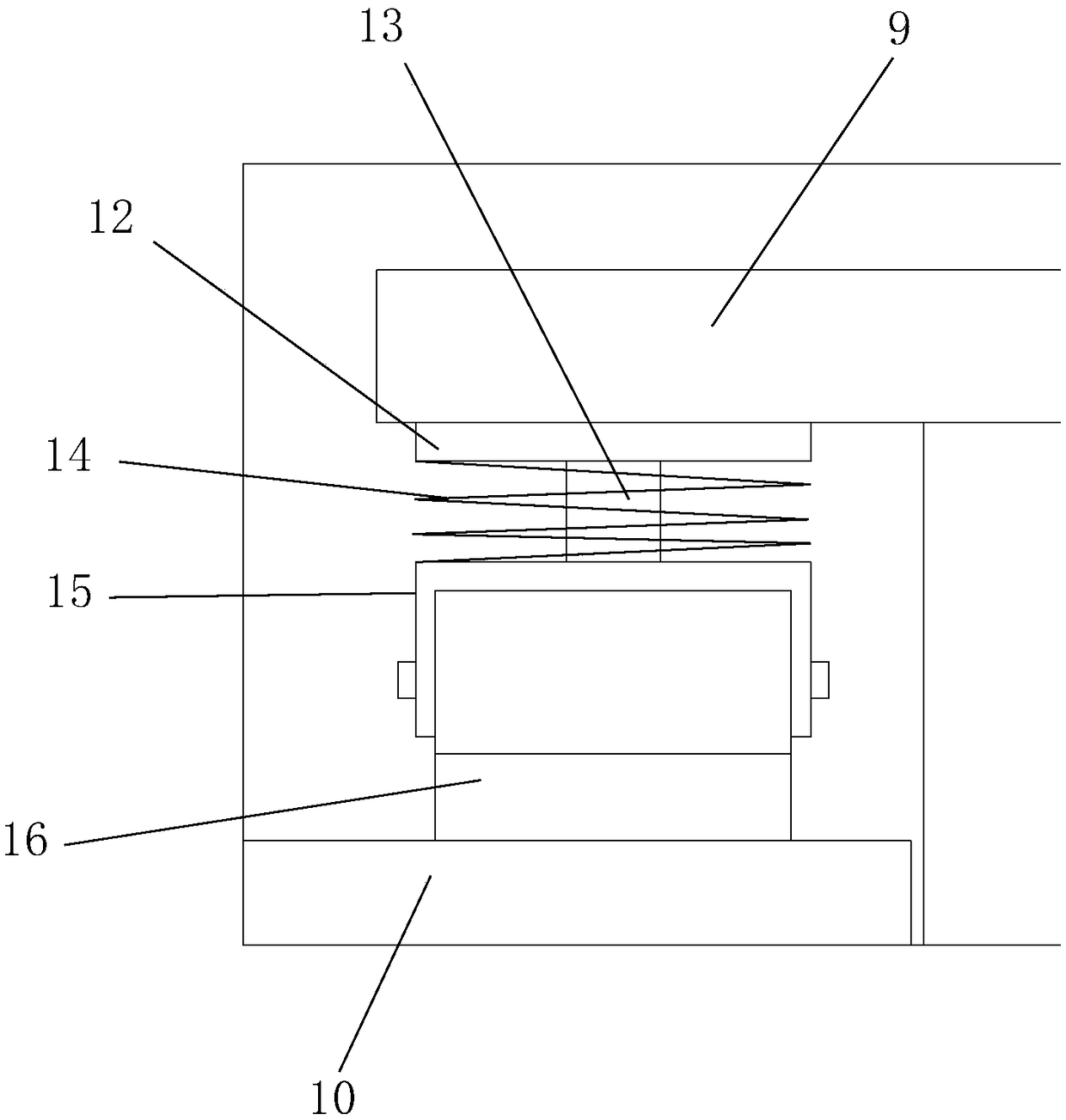

Egg cleaning machine

InactiveCN104982350ARealize automatic deliveryAutomatic delivery is fast and efficientEggs preservation by dryingAvicultureEngineeringElectric control

The invention discloses an egg cleaning machine, belonging to the technical field of poultry egg cleaning. The machine comprises a frame, an electric control box and an egg cleaning machine body, wherein the egg cleaning machine body and the electric control box are respectively arranged on the frame; the egg cleaning machine body comprises a feeding mechanism, an egg cleaning conveying belt and a discharging mechanism; the feeding end of the egg cleaning conveying belt is connected with the discharging end of the feeding mechanism; the feeding end of the discharging mechanism is connected with the discharging end of the egg cleaning conveying belt; a spraying system is arranged right above the egg cleaning conveying belt, and a cleaning mechanism is arranged side above the egg cleaning conveying belt; and an air drying mechanism is arranged right above the discharging mechanism. According to a technical scheme in the invention, through the respective arrangements of the feeding mechanism and the discharging mechanism for automatically conveying eggs at two ends of the cleaning machine, and the arrangement of the egg cleaning conveying belt between the feeding mechanism and the discharging mechanism, chicken manures on the surfaces of the eggs in the egg cleaning conveying belt are rapidly rinsed clean in conveying process; and through the arrangement of the air drying mechanism above the discharging mechanism, rapid air drying of the surfaces of cleaned eggs is realized.

Owner:GUIZHOU LIUJIANG ANIMAL & POULTRY

Egg machining cooking food

InactiveCN101606726AAvoid excessive denaturationNatural fluffy and soft tasteEggs preservation by dryingFood shapingBiotechnologyMicrowave

The present invention relates to an egg machining cooking food. All the while, the convenient character and the long-term storage character of cooked food series processed food are always seek. One method for solving said problems is a cooking food after sterilization, however, the protein of the cooking food is degenerated greatly due to the biocidal treatment under a high temperature and high pressure condition, and the moisture contained in the protein tissue is discharged, thus the mouthfeel of the proteinaceous food becomes very hard, dried and multi-muscle, and the local flavor is deprived. The aim of the invention is to provide a cooking food of egg, capable of avoiding said problems even through cooking and sterilizing. By an egg machining product after microwave puff drying, said problem is solved.

Owner:TAIYO KAGAKU CO LTD

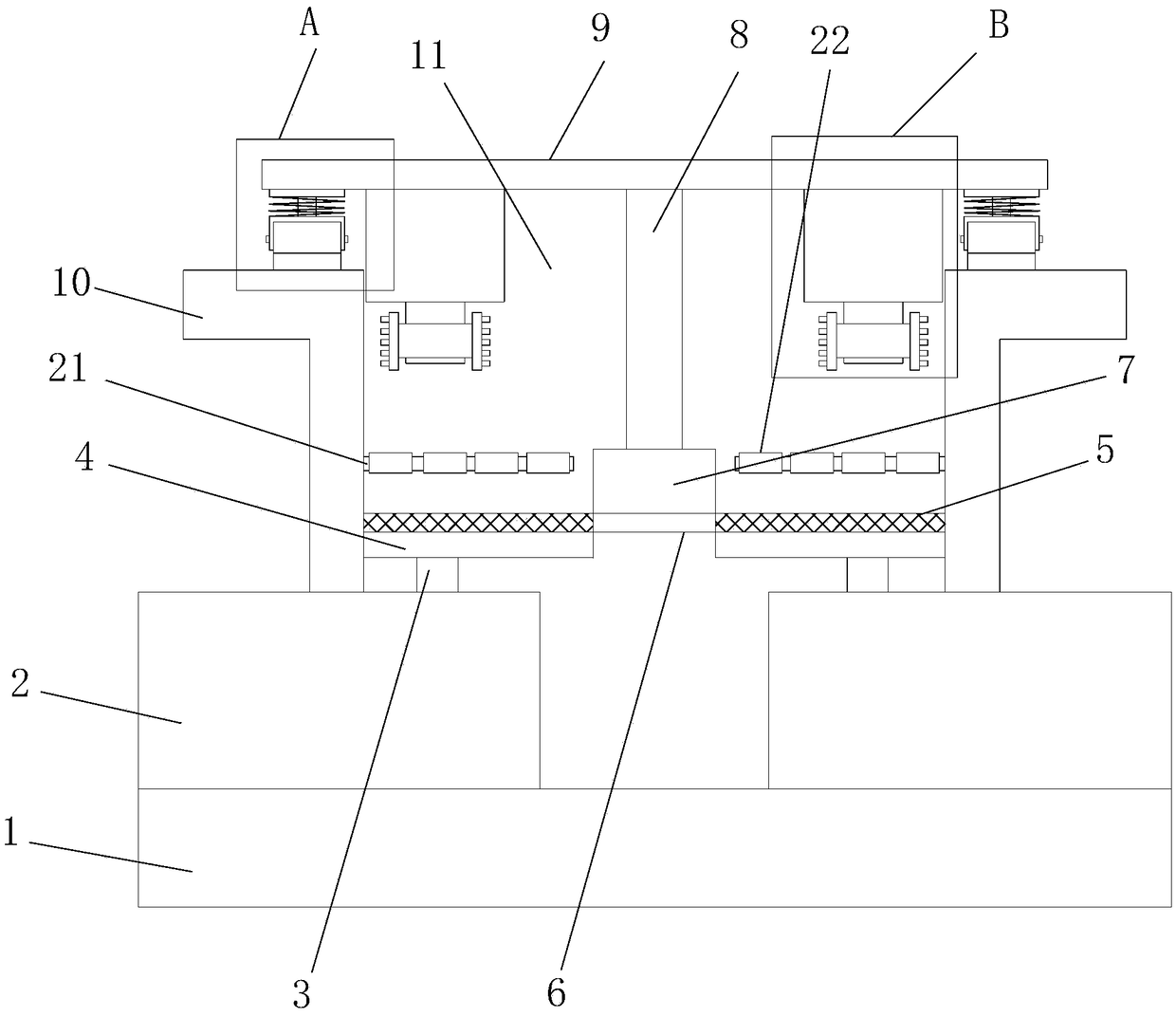

Self-adjusted automatic cleaner

InactiveCN108207706AImprove finished product qualityQuick removalEggs preservation by dryingAvicultureEngineeringConveyor belt

The invention discloses a self-adjusted automatic cleaner belonging to the technical field of automatic equipment, and the problem that poultry eggs which are dried by way of heating and drying of hotair by means of poultry egg cleaning equipment are likely to go bad in the prior art is solved. The cleaner comprises a shower rack, a brushing rack, a cleaning box and a drying rack, which are successively arranged, wherein a transmission wheel is mounted on the shower rack, and the transmission wheel is connected to a conveyor belt. The cleaner is characterized in that placing racks are mountedon the conveyor belt, a spray thrower is mounted above the conveyor belt in the shower rack, a hairbrush is mounted in the brushing rack, a fan and a sponge device are mounted above the drying rack,the sponge device comprises a sponge supporting rack mounted on the outer side of the placing racks, springs are connected to the upper side and the two sides of the sponger supporting rack, the spring above is connected to first sponge, and second sponge is connected to the springs on two sides. The self-adjusted automatic cleaner dries the cleaned poultry eggs by using the fan and the sponge, sothat the poultry eggs are prevented from going bad.

Owner:ZHENGZHOU QISHUO ELECTRONICS TECH CO LTD

High fat to protein ratio egg yolk product and methods for making and utilizing same

ActiveUS20080268124A1Raise the ratioEdible oils/fats ingredientsDough treatmentAnimal scienceHigh fat

The present invention relates to a high fat to protein ratio egg yolk product and a method of preparing same. More particularly, the invention pertains to a dried high fat to protein ratio egg yolk product which substantially maintains the functional characteristics of whole egg yolk, is convenient to use, and has a long shelf life. The present invention also relates to a method of utilizing such a high fat to protein ratio product in making egg containing bakery products, mayonnaise and other food products. A process for preparing a dried high fat to protein ratio egg yolk which comprises: (a) separating an egg yolk from a whole egg; (b) concentrating the fat to protein ratio of the egg yolk so that the ratio is greater than 2.0:1, and (c) drying the concentrated egg yolk.

Owner:IGY IMMUNE TECH & LIFE SCI

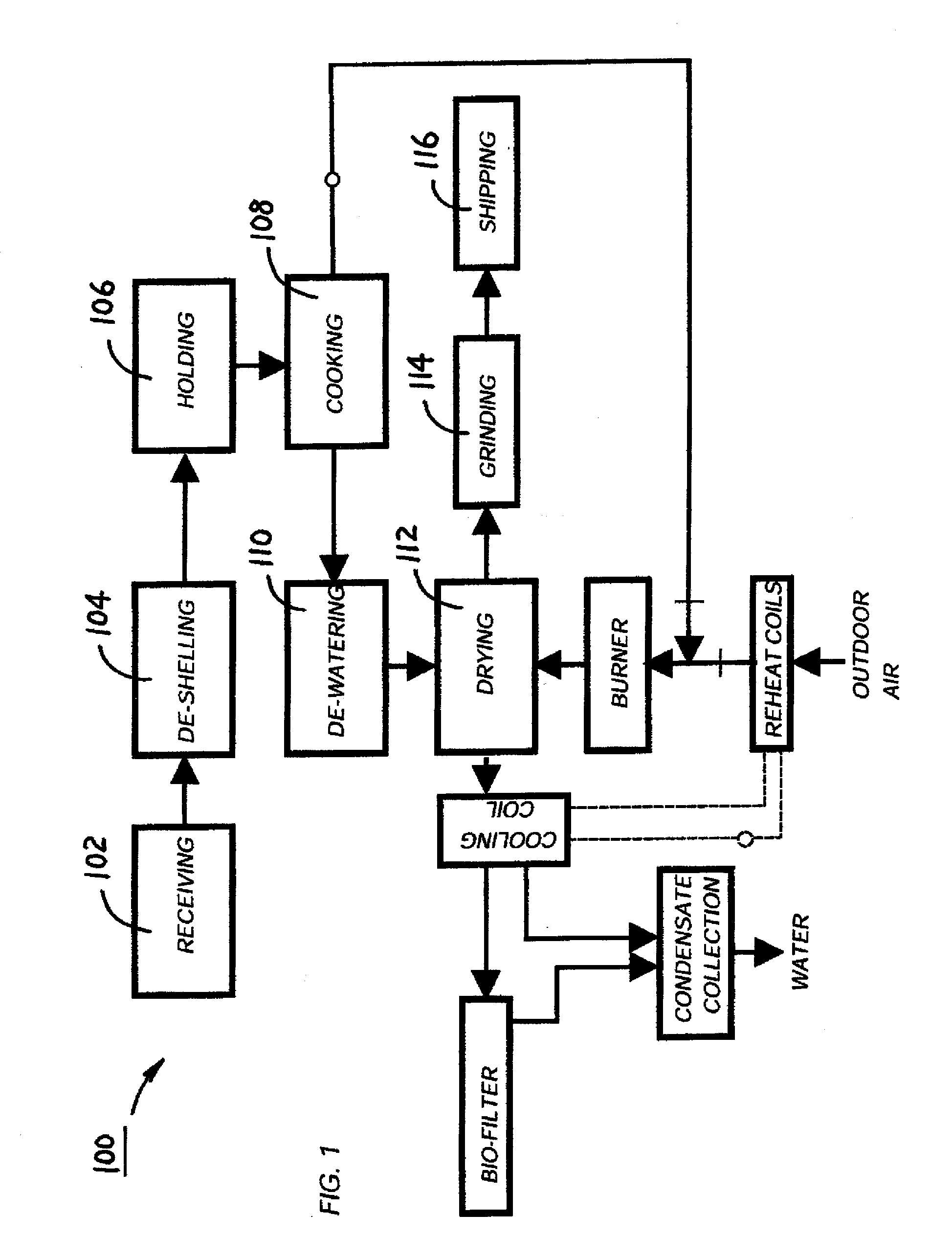

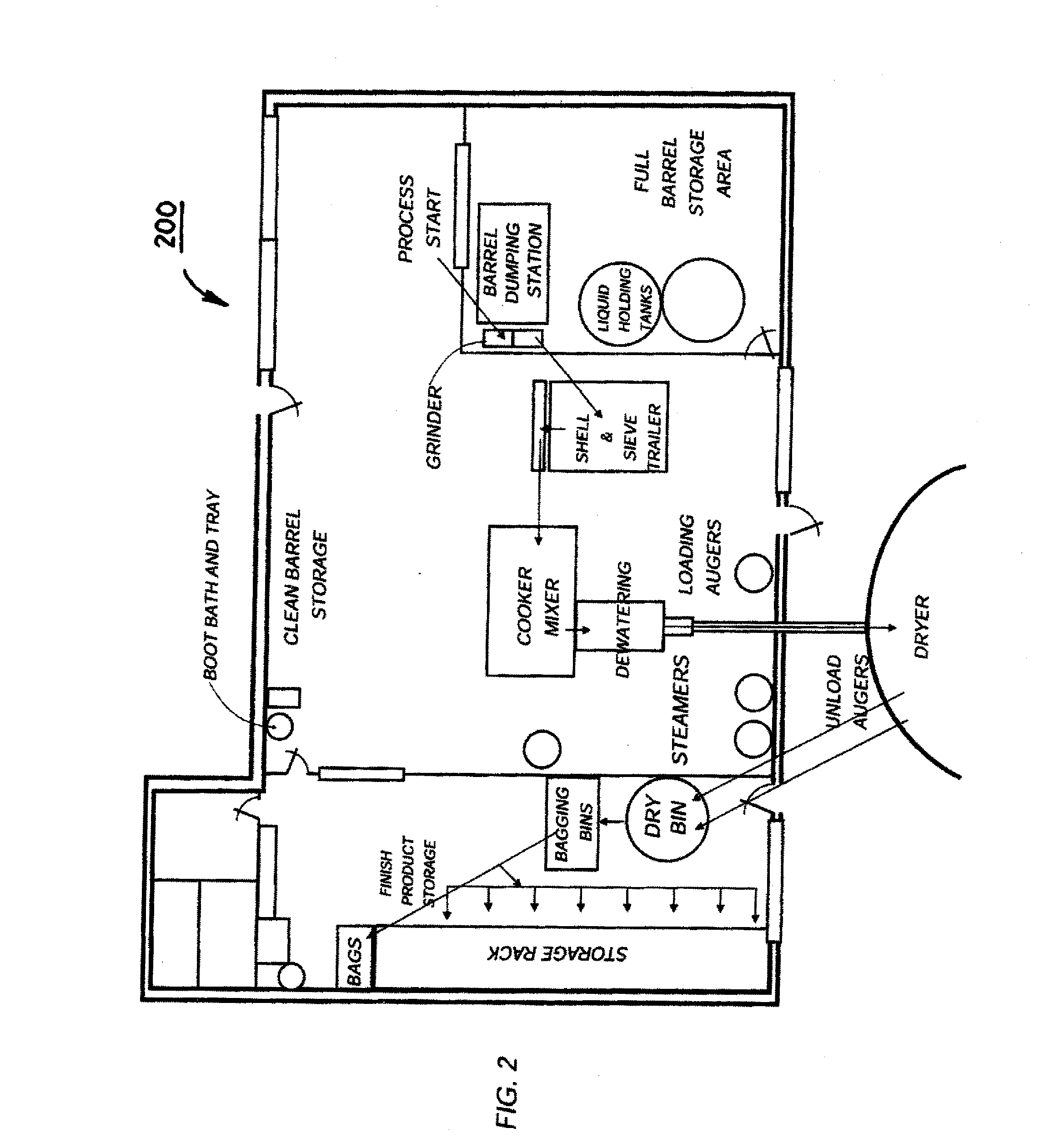

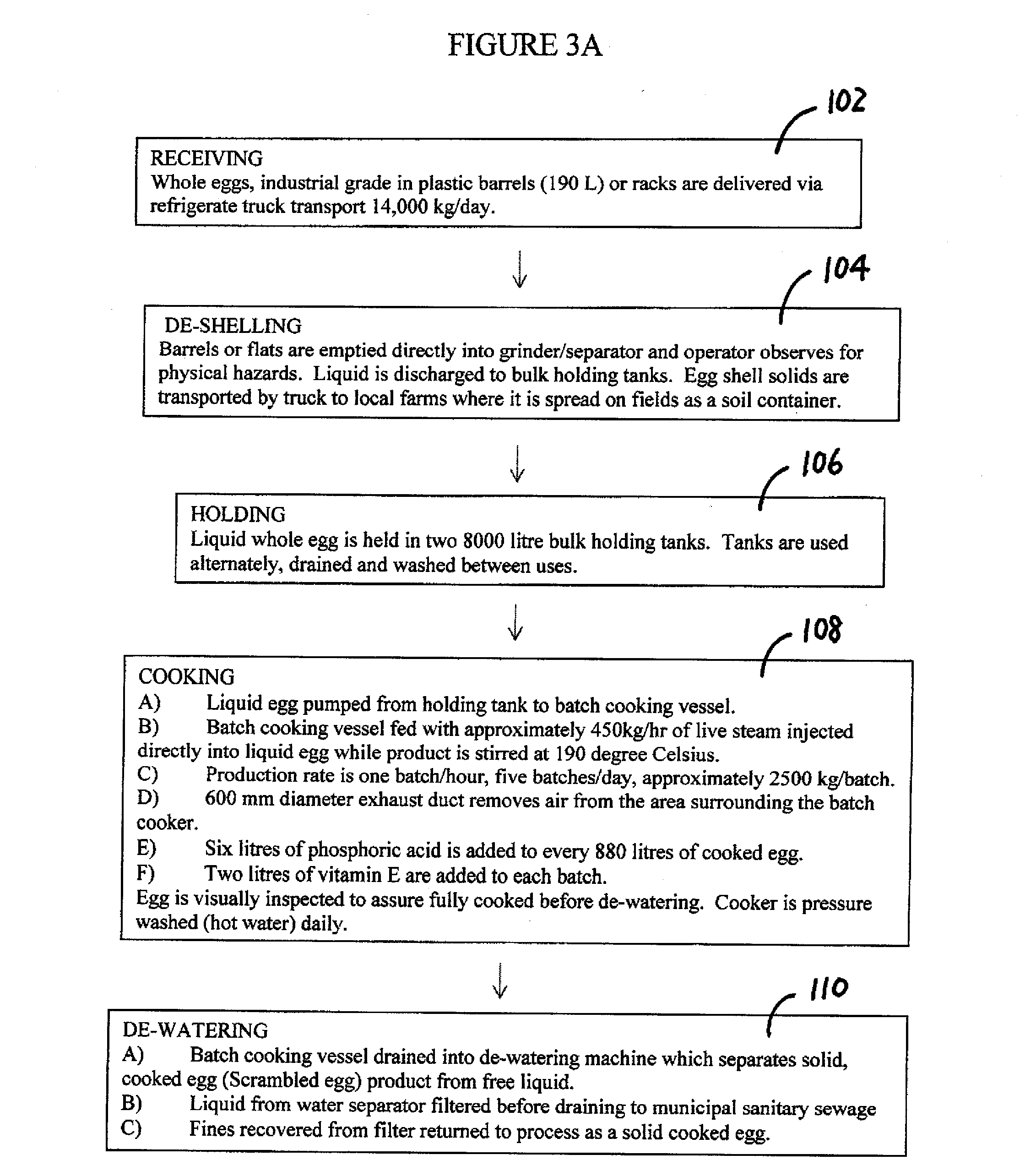

Method and apparatus for producing dried whole egg

The present concept is a method of producing dried whole egg, which includes the steps of de-shelling and separating the shell from the inner egg. Next the egg is cooked with live steam injection, and phosphoric acid is added. Next the cooked egg is dried. Finally the cooked egg is ground to a final particle size.

Owner:SANT STANLEY

Dried egg white, production method therefor, and food containing improved dried egg white

InactiveUS20080226805A1Increase elasticityHigh gel strengthEggs preservation by dryingFood preparationDried egg whiteCarbon dioxide

An improved dried egg white has a pH of 9.5 or more and a carbon dioxide concentration is 1% or less in a sealed 250 ml vial, when 25 g of the product is stored in the vial at 75° C. for 24 hours.

Owner:Q P CORP

Food air drying apparatus

InactiveCN1973640ASpeed up dryingEnsure hygienic qualityEggs preservation by dryingDrying machines with local agitationDried foodFood sanitation

The food air drying apparatus includes one frame with bottom plate, ventilating ports in the sides and top, door hinged to the front and gauzes to avoid air contamination and fly, one shelf inside the frame for hanging the matter to be dried, and one electric fan on the frame to force airflow. It may also be provided with high temperature lamp or other heater to speed the air drying. It is set indoor to dry food and can ensure high quality of the dried food.

Owner:黑伟钰

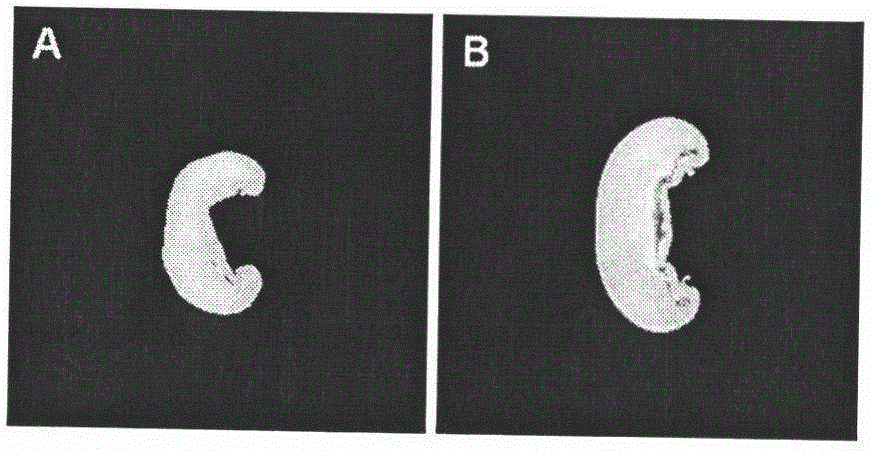

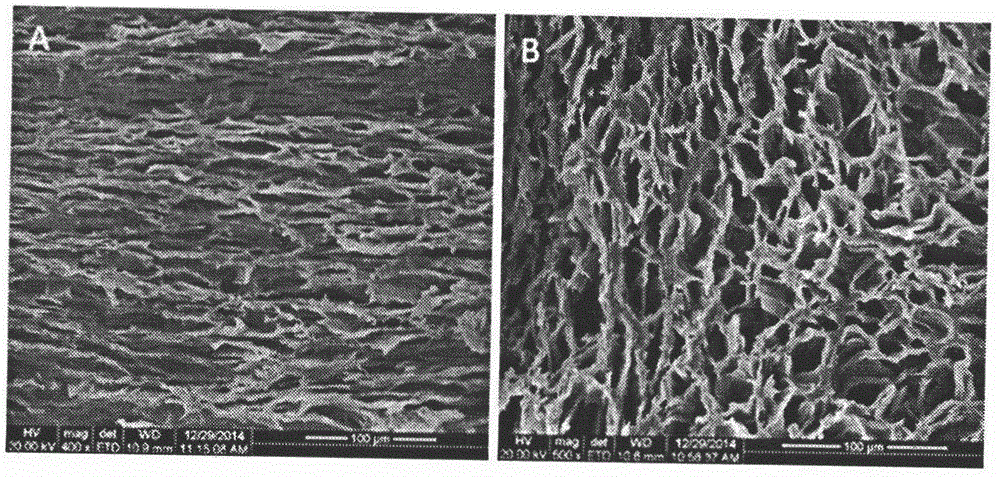

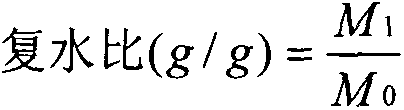

Method for raising rehydration performance of far-infrared dried agaricus bisporus by ultrasonic pretreatment

ActiveCN104938609AFast rehydrationImprove water absorptionEggs preservation by dryingAdditive ingredientFar infrared

The invention relates to a method for raising rehydration performance of far-infrared dried agaricus bisporus by ultrasonic pretreatment and belongs to the field of agricultural products deep processing. The method comprises the following steps: choosing fresh and equally-sized agaricus bisporus, cleaning and removing agaricus bisporus stems, vertically slicing, and carrying out intermittent ultrasonic pretreatment with ultrasonic pretreatment frequency being 20-40 kHz, power density being 0.2-0.5 W / cm<2>, ultrasonic pretreatment time being 3-10 min, intermittent time being 2-5 min and intermittent number of times being 2-6 times; and draining off moisture on the surface of the agaricus bisporus slices which have undergone ultrasonic pretreatment, placing the agaricus bisporus slices in far-infrared drying equipment with radiation distance being 100-200mm and radiation intensity being 1.6-2.9 KW / m<2> and drying until water content of the agaricus bisporus is lower than 5%. By the intermittent ultrasonic pretreatment, internal cells of the agaricus bisporus form micro-channels which are beneficial to enhance rehydration performance of the dehydrated agaricus bisporus slices after drying. Rehydration performance of the dehydrated agaricus bisporus slices which have undergone intermittent ultrasonic pretreatment is raised by 15-22% in comparison with rehydration performance of untreated agaricus bisporus slices. Rehydration performance is enhanced remarkably, and nutritional ingredients are retained effectively.

Owner:JIANGSU ACADEMY OF AGRICULTURAL SCIENCES

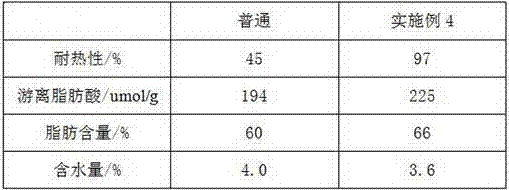

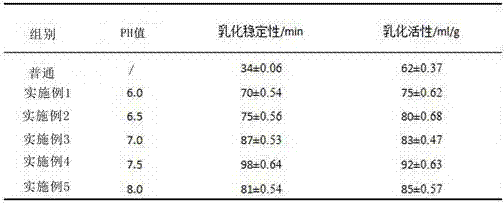

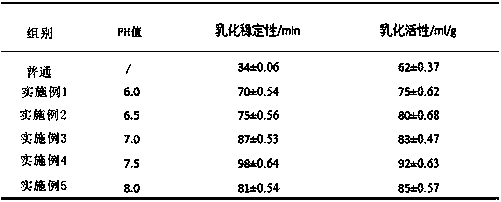

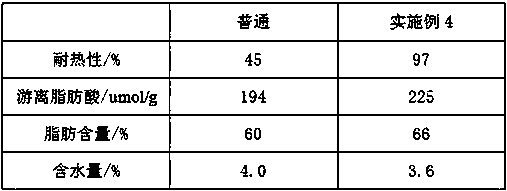

Preparation process of high-emulsifiability egg yolk powder

ActiveCN106901236AGood emulsifying effectStable tasteFood freezingEggs preservation by dryingFlavorStable state

The invention relates to the dry food processing engineering field, and in particular, relates to a preparation process of a high-emulsifiability egg yolk powder. An egg yolk liquid has the pH adjusted for two times in an egg yolk powder preparation process, after first-time pH adjustment, the temperature is increased by heating to make proteins in the egg yolk liquid generate network charges having a rejection or dimerization effect for changing a protein surface layer structure, so that the effect of improving the emulsifiability of the egg yolk powder is achieved. After the egg yolk liquid is cooled to room temperature, the pH is adjusted for the second time to neutral, so the egg yolk powder can maintain a relatively stable state, the obtained product can withstand harsh conditions, the same texture, taste, stability, flavor intensity and rheological properties can be achieved with use of less amount, the cost is saved, and the productive benefits are increased.

Owner:HENAN UNIV OF SCI & TECH

Egg white product and its preparation method

InactiveCN1279848CReduce weightEggs preservation by dryingFood preparationAnimal scienceFood products

A kind of method to produce egg white using the technology of cooling and drying in vacuum includes separating, freezing, drying in vacuum, grinding, and wrapping. And the invention does also provide a product of egg white by the method to produce egg white using the technology of cooling and drying in vacuum. The aim of The invention discloses to provide a handy product. It has a light weight and the excellent smell and taste. Moreover, the taste and the nutrition of the egg white are as well as the original ones. Whenever or wherever you are, you can enjoy it just by using spoiling water to steep it.

Owner:宋述孝

New sterilization device for countryman egg processing

InactiveCN104585295AEnsure safetyEasy to dryEggs preservation by irradiation/electric treatmentEggs preservation by heatingAnimal scienceFood safety

The present invention discloses a new sterilization device for countryman egg processing and the device includes a body frame and a pot body arranged on the top of the body frame. A feed hatch door and a discharge hatch door are arranged at the left and right side of the pot body; a high-temperature sterilization chamber is arranged inside of the pot body and is arranged at the right side of the feed hatch door; a cooling chamber is arranged at the right side of the high-temperature sterilization chamber; an air-drying chamber is arranged between the cooling chamber and the discharge hatch door; an interconnected slide rail is arranged at the bottom of the high-temperature sterilization chamber, the cooling chamber and the air-drying chamber; a feeding car is movably arranged on the slide rail; a PLC controller is arranged on the feed hatch door; the device can kill residual bacteria, quickly air-dry products to enable an easy packaging, improve productivity, and provide an ultraviolet sterilization device to further ensure food safety; the entire sterilization process is controlled by the PLC controller automatically, which improves intellectualization degree; the device has a simple overall structure and is very convenient to operate.

Owner:DENGFENG HUIDA FOOD FACTORY

Beverage additive mixture of trehalose and protein

InactiveUS20060233934A1High glass transition temperatureCleaner flavorEggs preservation by dryingFood ingredient as taste affecting agentFood flavorTrehalose

The invention provides an additive for a beverage. The additive comprises a mixture containing one or more normally bitter / cardboard-tasting proteins and trehalose. Although the additive contains at least one normally bitter / cardboard-tasting protein, the additive unexpectedly has a substantially neutral effect on the flavor of the beverage. The invention also provides for the simplicity of processing and storing the mixture in dehydrated form. The mixture is dehydrated, and then rehydrated before or during its addition to a beverage. The dehydration and subsequent rehydration permits processing, preserving, handling, and storing benefits—with substantially no damage to the protein or to the additive. The invention provides the additive and beverages containing the additive. In addition, the invention provides methods for preparing the additive and methods for preparing a flavored beverage.

Owner:CARGILL INC

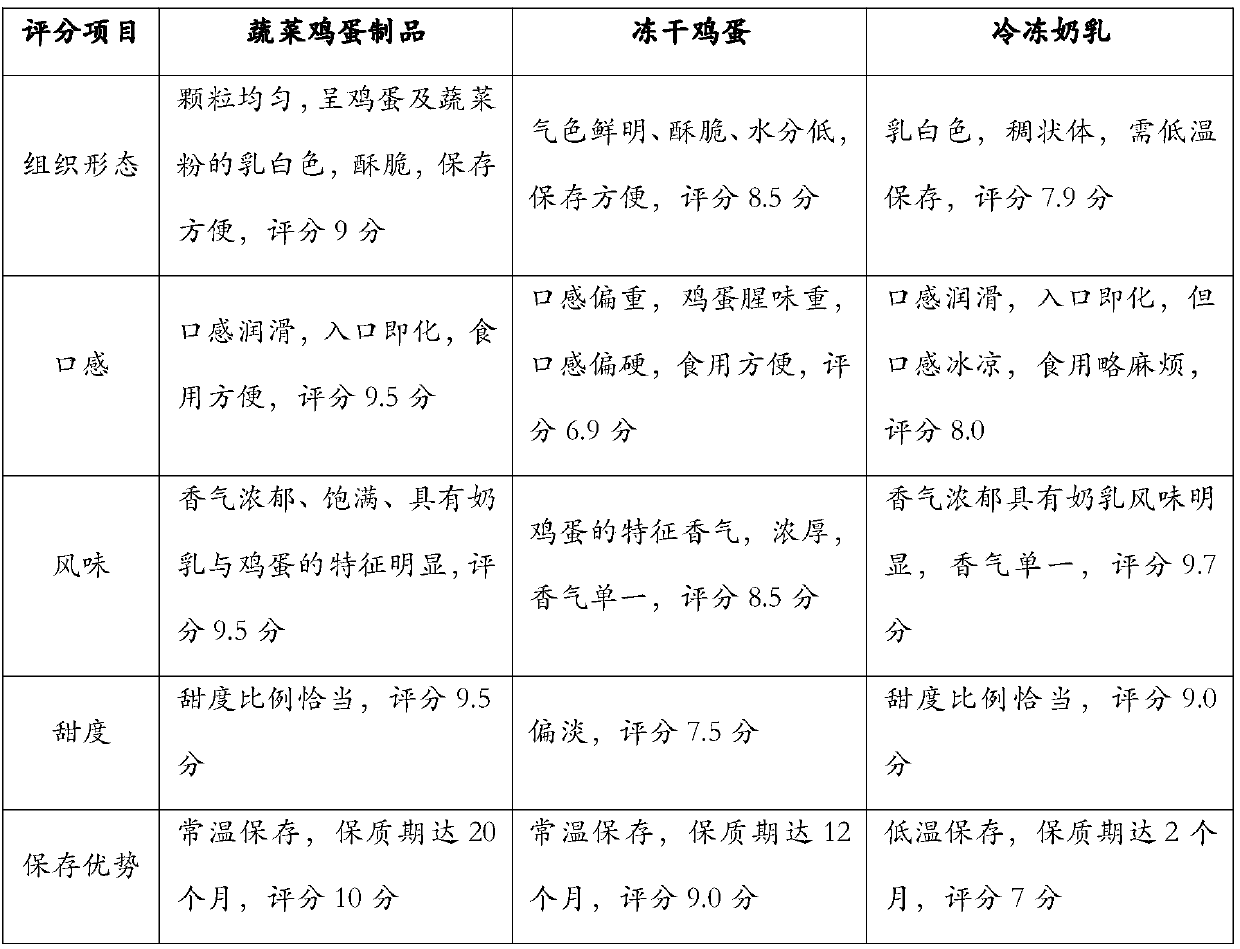

Vacuum-freeze-dried vegetable and egg product and preparation method

PendingCN109567064AGreat tasteAdd flavorFood ingredient as colourEggs preservation by dryingFlavorBiotechnology

The invention provides a vacuum-freeze-dried vegetable and egg product and a preparation method. Raw materials of the vacuum-freeze-dried vegetable and egg product comprise the following components inparts by weight: 70-80 parts by weight of egg, 10-20 parts by weight of vegetable powder, 8-12 parts by weight of white granulated sugar, 0.2-0.5 part by weight of fructo-oligosaccharide and 132-168parts by weight of plain boiled water. According to the vegetable and egg product, an eating mode of existing egg products is changed, the popularization range is extended, the taste and the flavor are improved, a nutrition structure of the product is enriched, the fragrance is obvious, and the vacuum-freeze-dried vegetable and egg product melts in the mouth.

Owner:福建欧瑞园食品有限公司

Method for drying grosvenor momordica fruits

InactiveCN106259844AAvoid skin darkeningAvoid phenomena such as zoomingEggs preservation by dryingAdditive ingredientMomordica

The invention discloses a method for drying grosvenor momordica fruits, which comprises the following steps: 1) perforating the peels of cleaned grosvenor momordica fruits and then drying the grosvenor momordica fruits by microwave for 2-3 h; 2) drying the microwave-dried grosvenor momordica fruits with hot blast at 60-70 DEG C for 30-32 h, drying with hot blast at 70-80 DEG C for 15-18 h, and drying with hot blast at 80-90 DEG C for 4-8 h in sequence. The method is capable of effectively reducing the drying time for grosvenor momordica fruits, and the obtained dried grosvenor momordica fruits are small in color and luster change and low in nutrient loss.

Owner:GUILIN SHILI SCI & TECH COMPANY

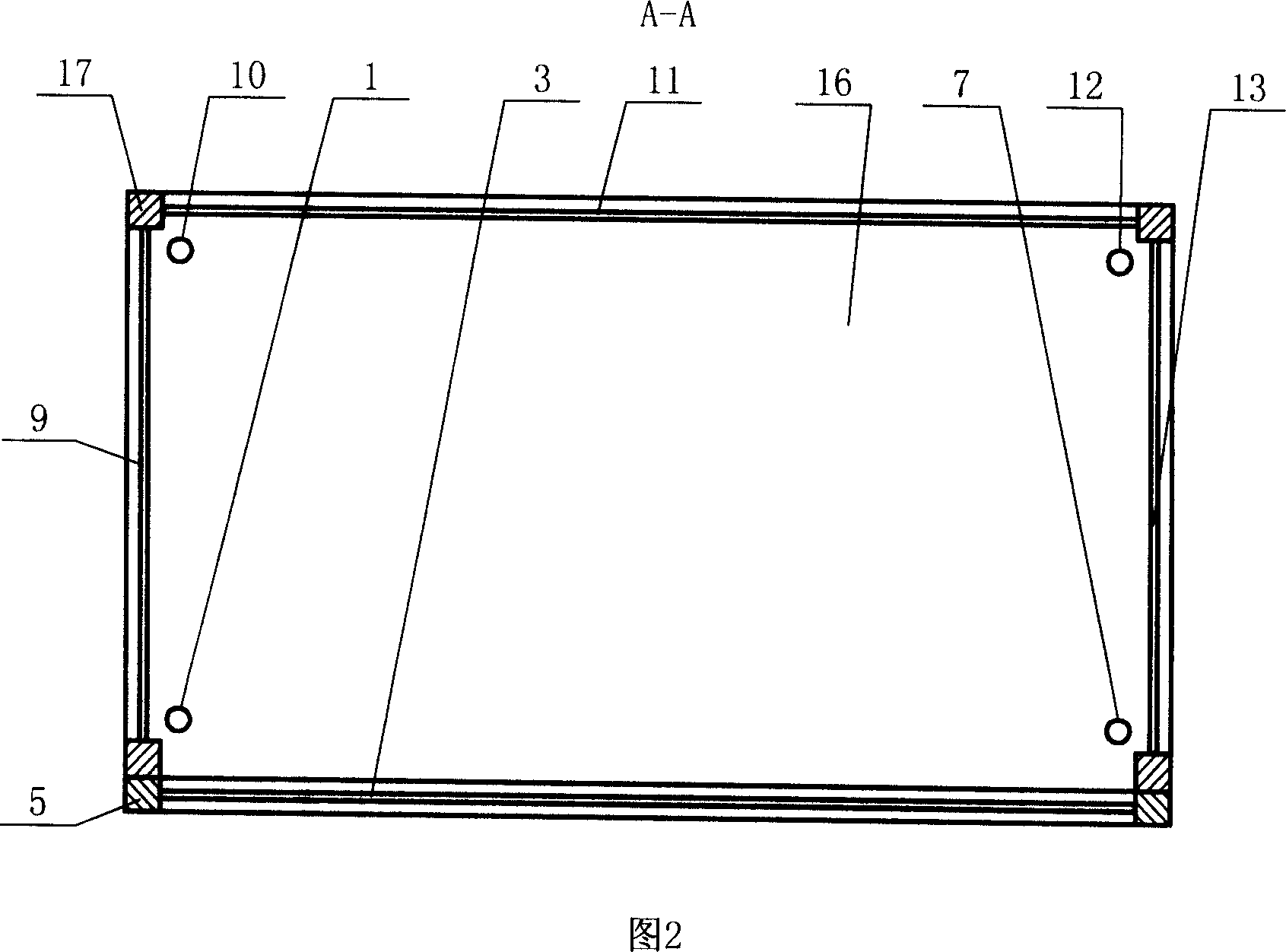

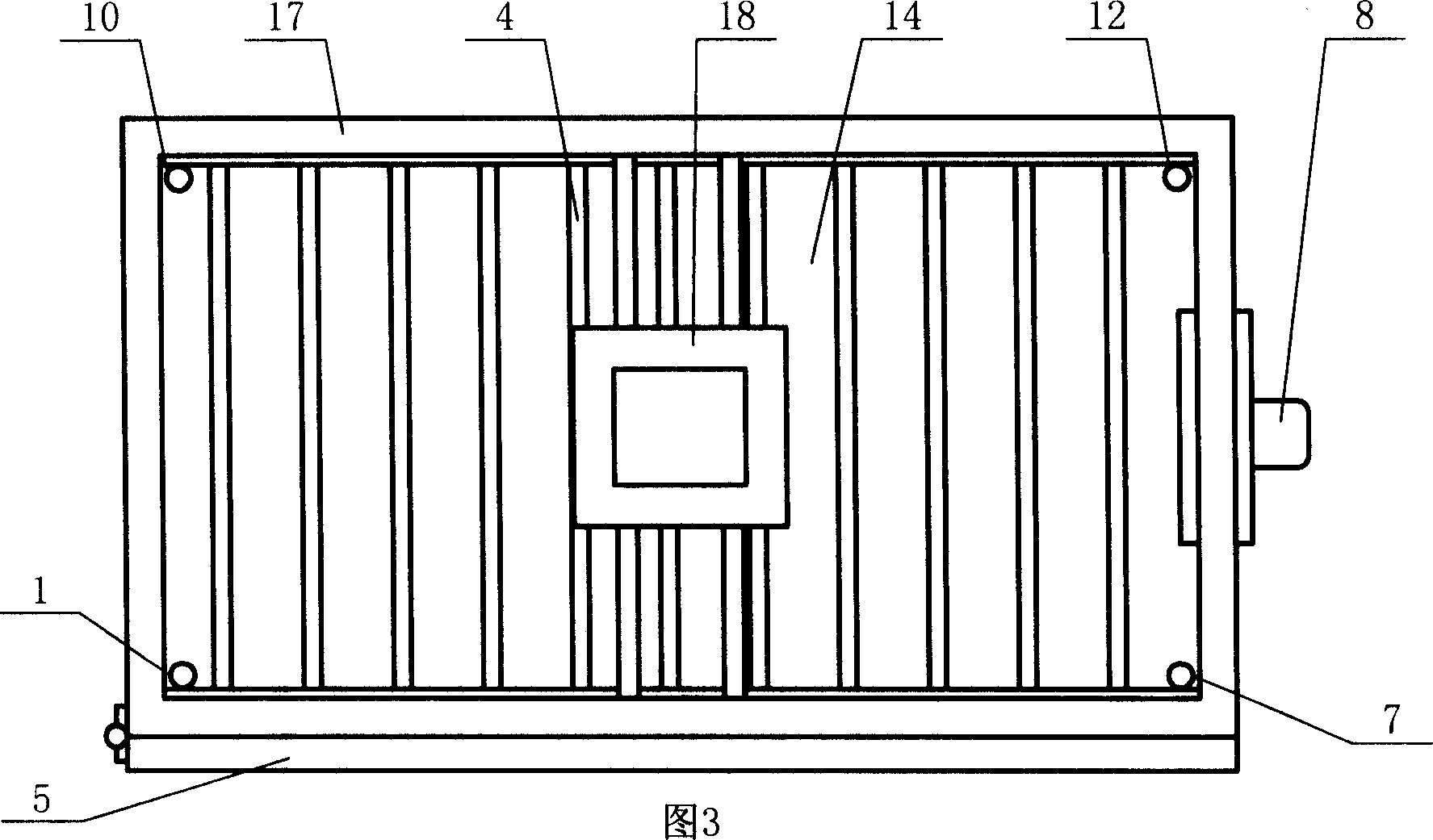

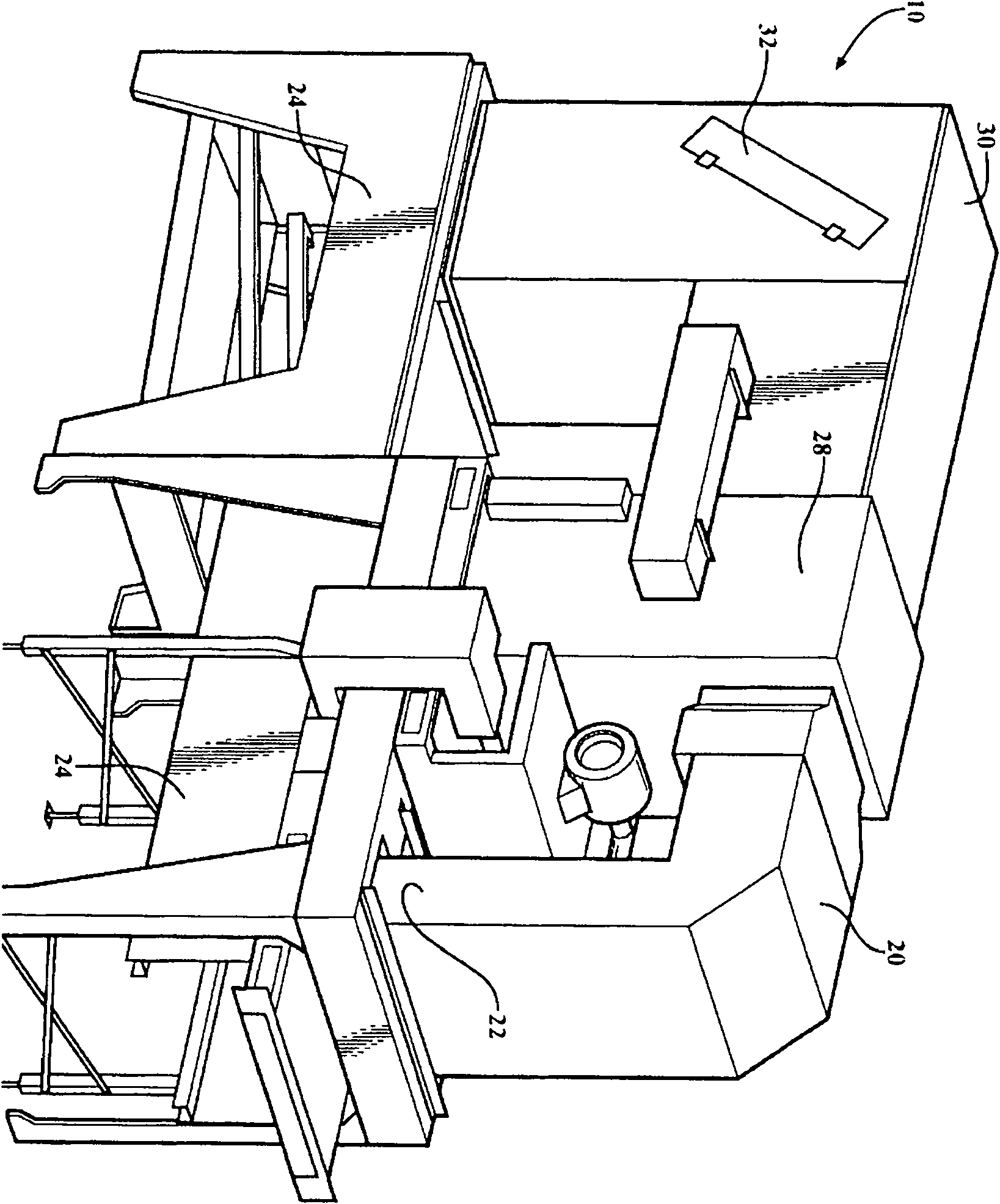

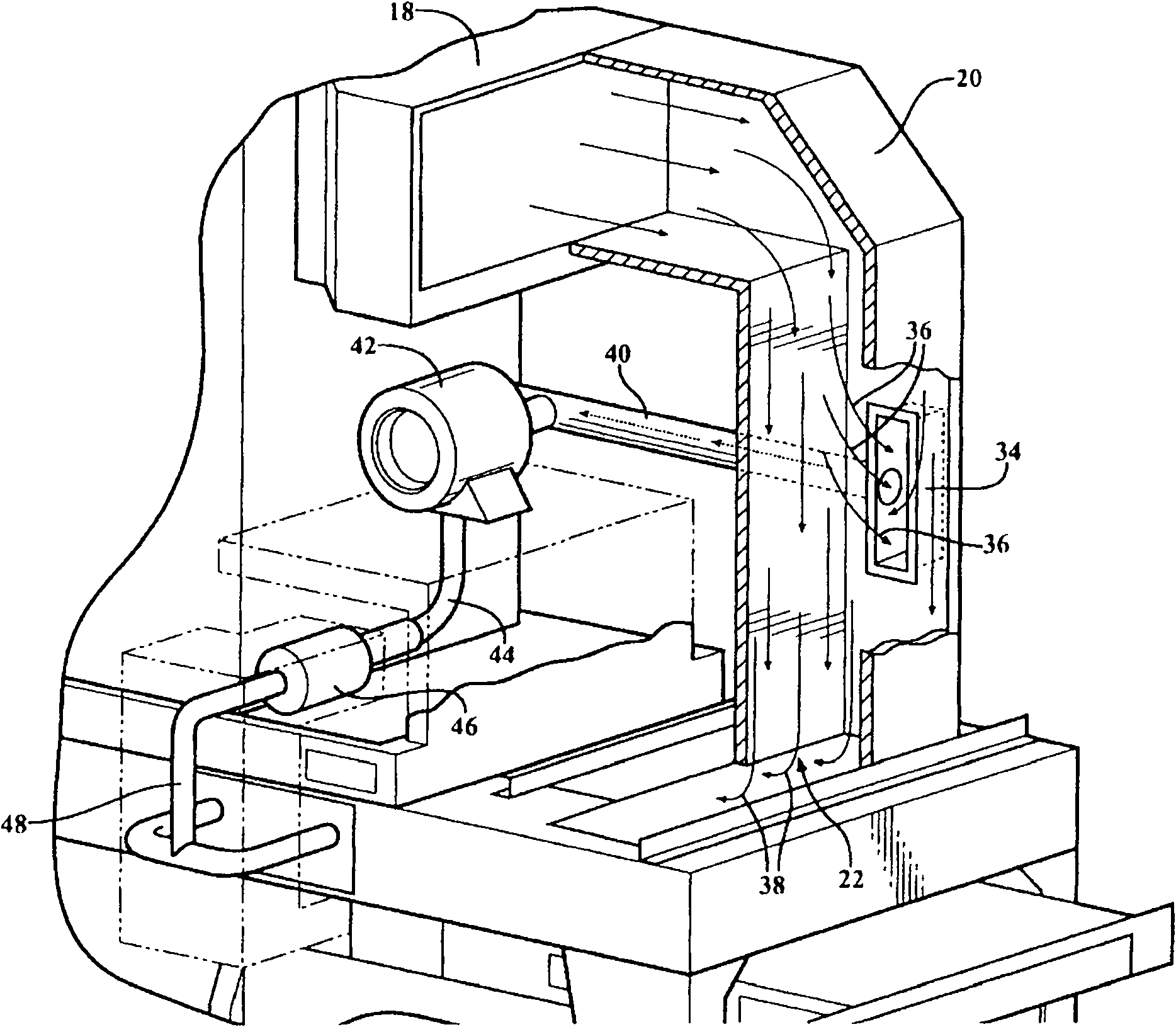

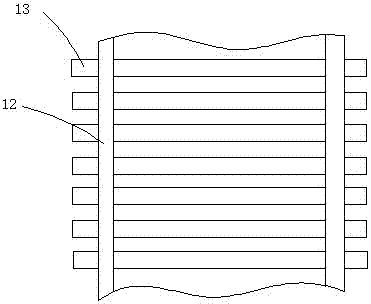

Laminar conditioned egg drying device

InactiveCN102665426ADry fastDrying solid materials with heatDrying gas arrangementsEngineeringHUMID WEATHER

An egg dryer incorporating a rotating spool bar conveyor extending between an inlet end and an outlet end and upon which are supported a plurality of eggs conveyed through the body. An airflow exhibiting a humidity less than that associated with an environment outside the body is directed from the outlet end in a normal and opposing flowing direction relative to a direction of travel of the eggs. Subset flows of heated / desiccated air are also redirected to one or more intermediate header tubes arranged at internal locations of the body in communication with the conveyor and, in combination with impinging baffle plates mounted in proximity to the header tubes, provide additional and targeting drying of such as the ends of the eggs in combination with the overall heated / desiccated airflow.

Owner:FPS FOOD PROCESSING SYST BV

Dehydration method

ActiveUS8187655B2Shelf-life of the dehydrated product is appreciably extendedRehydrate quickly and easilyDrying solid materials with heatDrying solid materials without heatIntact tissueProduct gas

The present invention relates to a method of dehydrating pieces of intact plant or animal tissue, said pieces containing at least 30 wt. % of water, the method comprising (i) contacting the pieces of intact tissue with a pressurized gas to reduce the water content of the pieces by at least 50%, said pressurized gas having a pressure of at least 0.5×Pc and a temperature of at least Tc−60° C., Pc representing the critical pressure of the gas and Tc representing the critical temperature of the gas, and (ii) separating the pressurized gas from the dehydrated pieces, wherein at least 80 wt. %, preferably at least 90 wt. % of the matter removed by the gas from the pieces of intact plant or animal tissue is water. The invention also provides a method of dehydrating a material containing at least 30 wt. % of water, using a method as described before, followed by drying the separated pressurized gas by contacting said pressurized gas with a water absorbent water adsorbent; and recirculating the dried pressurized gas to the partially dehydrated material.

Owner:FEYECON DEV & IMPLEMENTATION

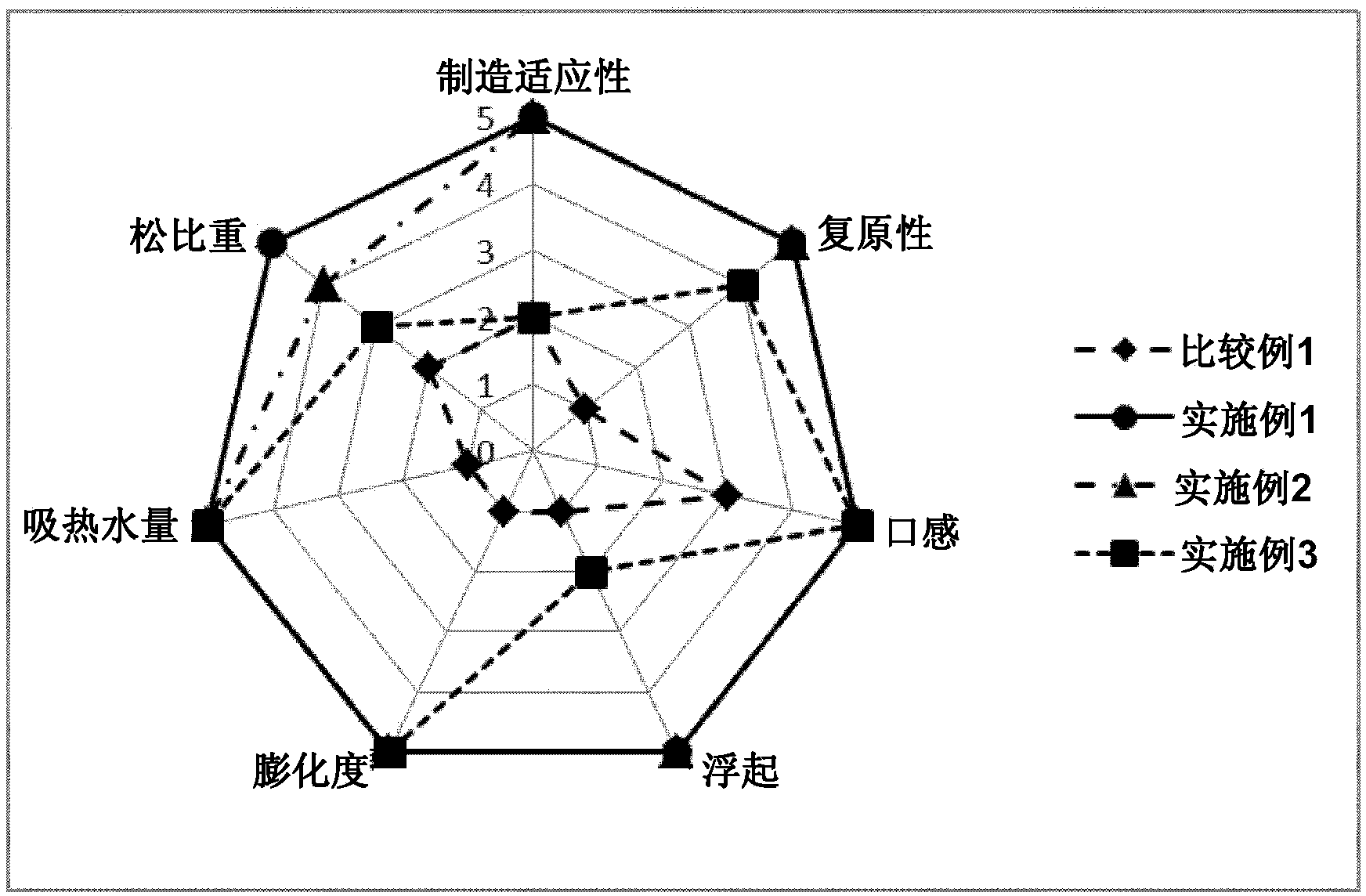

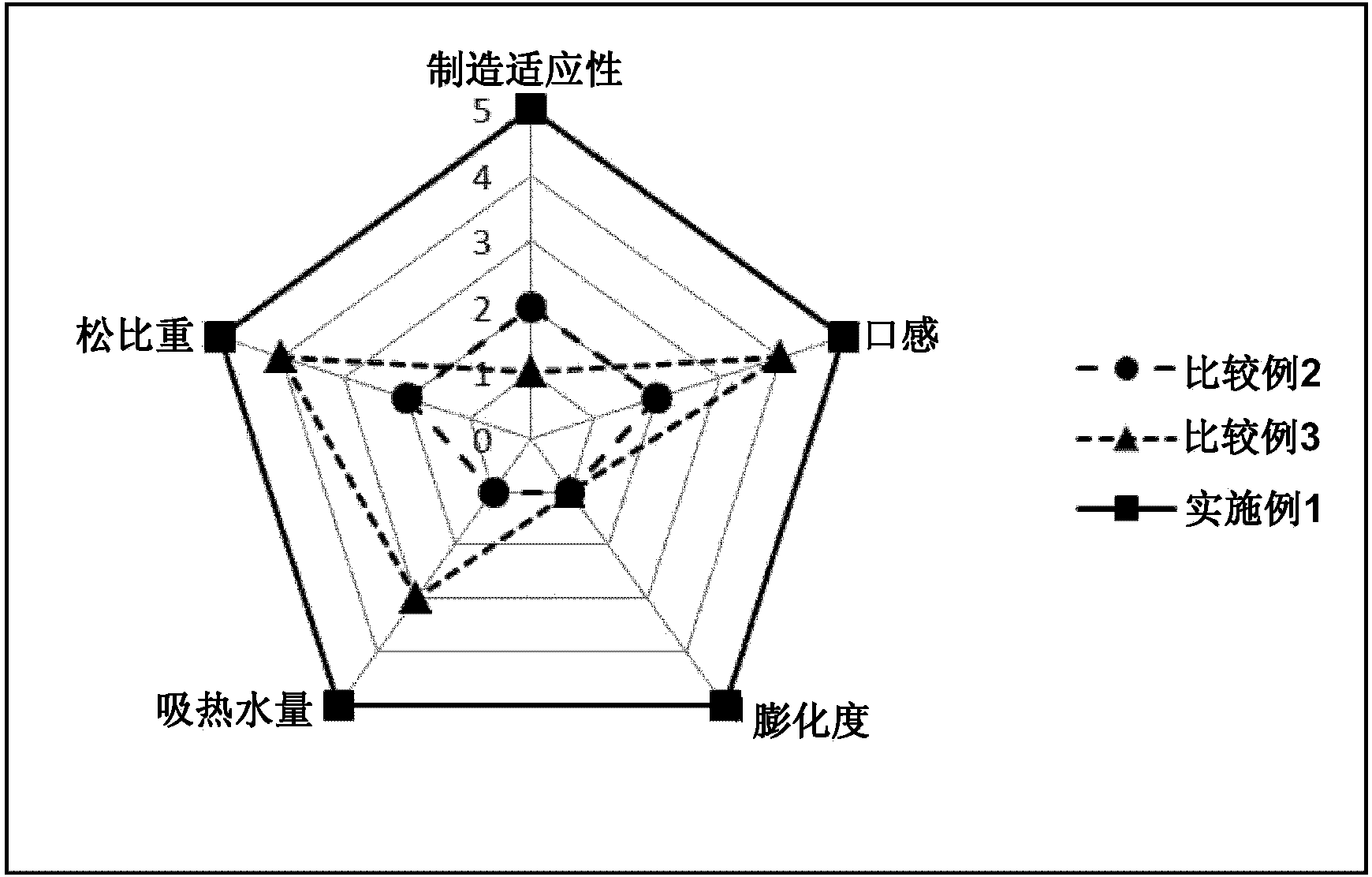

Dry processed protein and process for producing same

InactiveCN104378997AGood lookingAdd flavorProteins working-up by texturisingEggs preservation by dryingFlavorShrimp

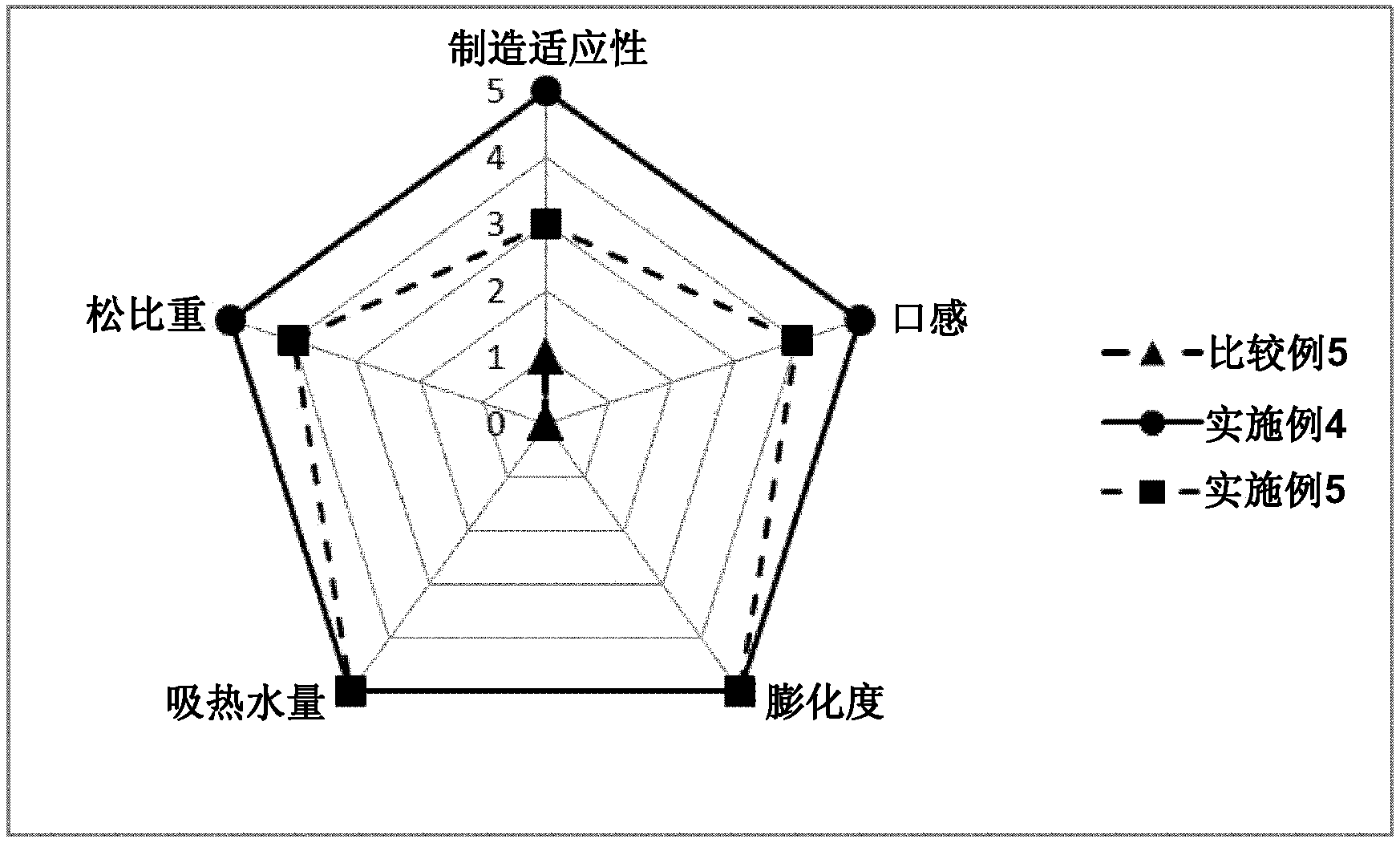

[Problem] To provide: a dry processed protein for use in instant foods which satisfactorily floats when eaten, readily returns to the original state in hot water, and is excellent in terms of texture, appearance, flavor, etc.; and a process for producing the dry processed protein. [Solution] A process for producing a dry processed protein for instant foods, characterized by comprising a small-particle formation step in which dough serving as a raw material and containing a main protein (e.g., egg white) and starch is formed into small particles, a small-particle adhesion step in which the small particles are adhered to one another while keeping the small particles in contact with one another, and a drying step in which the adhered small particles are dried. In some cases, the protein which is to be imitated (including meat, shrimp, cod roe, or the like) can be also added.

Owner:TAIYO KAGAKU CO LTD

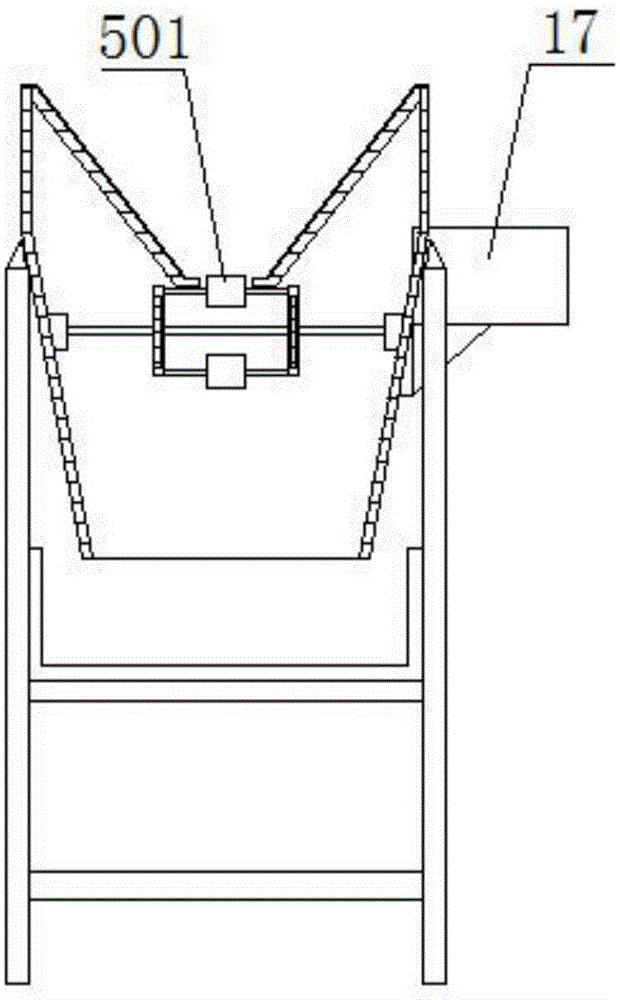

Preserved duck egg cleaning feeding device

InactiveCN108176646AImprove efficiencyRealize multi-directional cleaningEggs preservation by dryingCleaning using liquidsDischarge efficiencyMotor drive

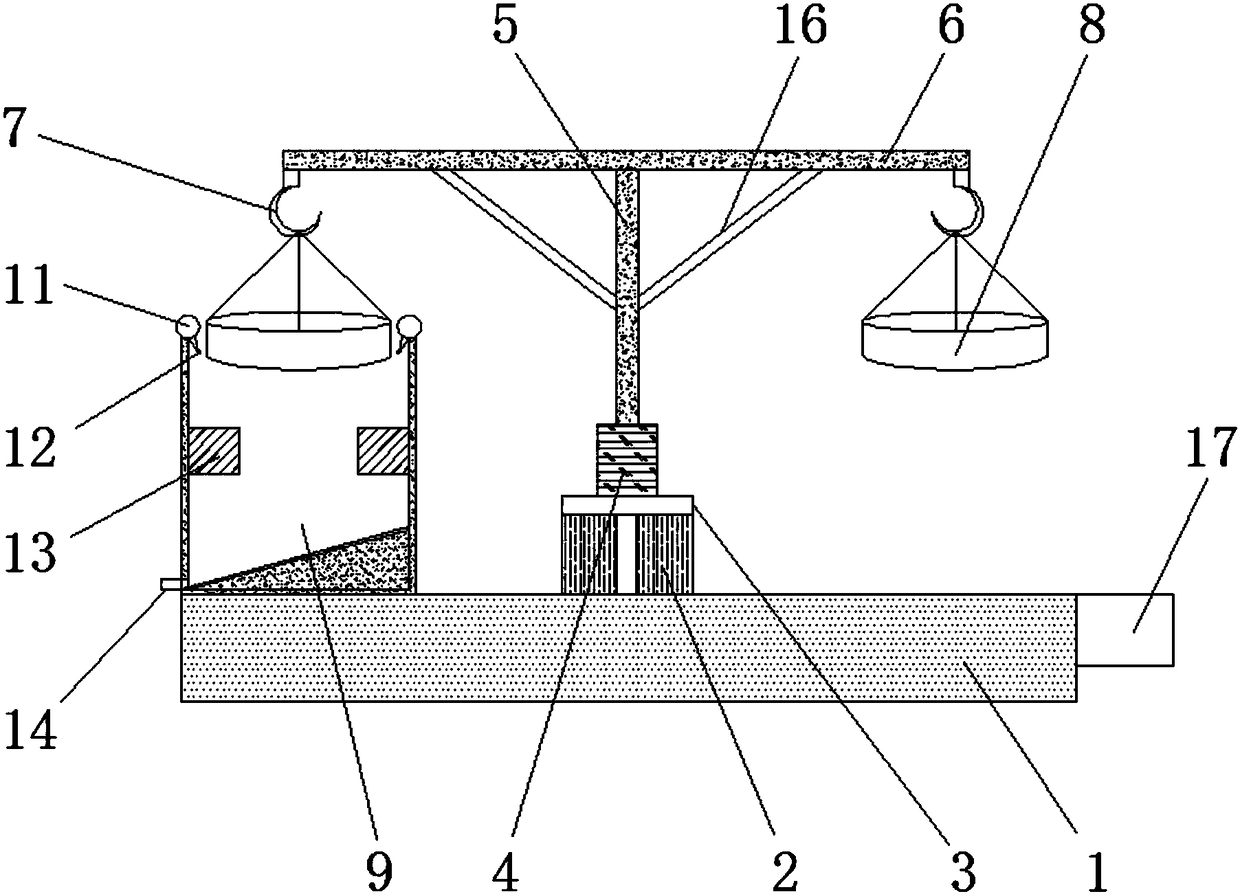

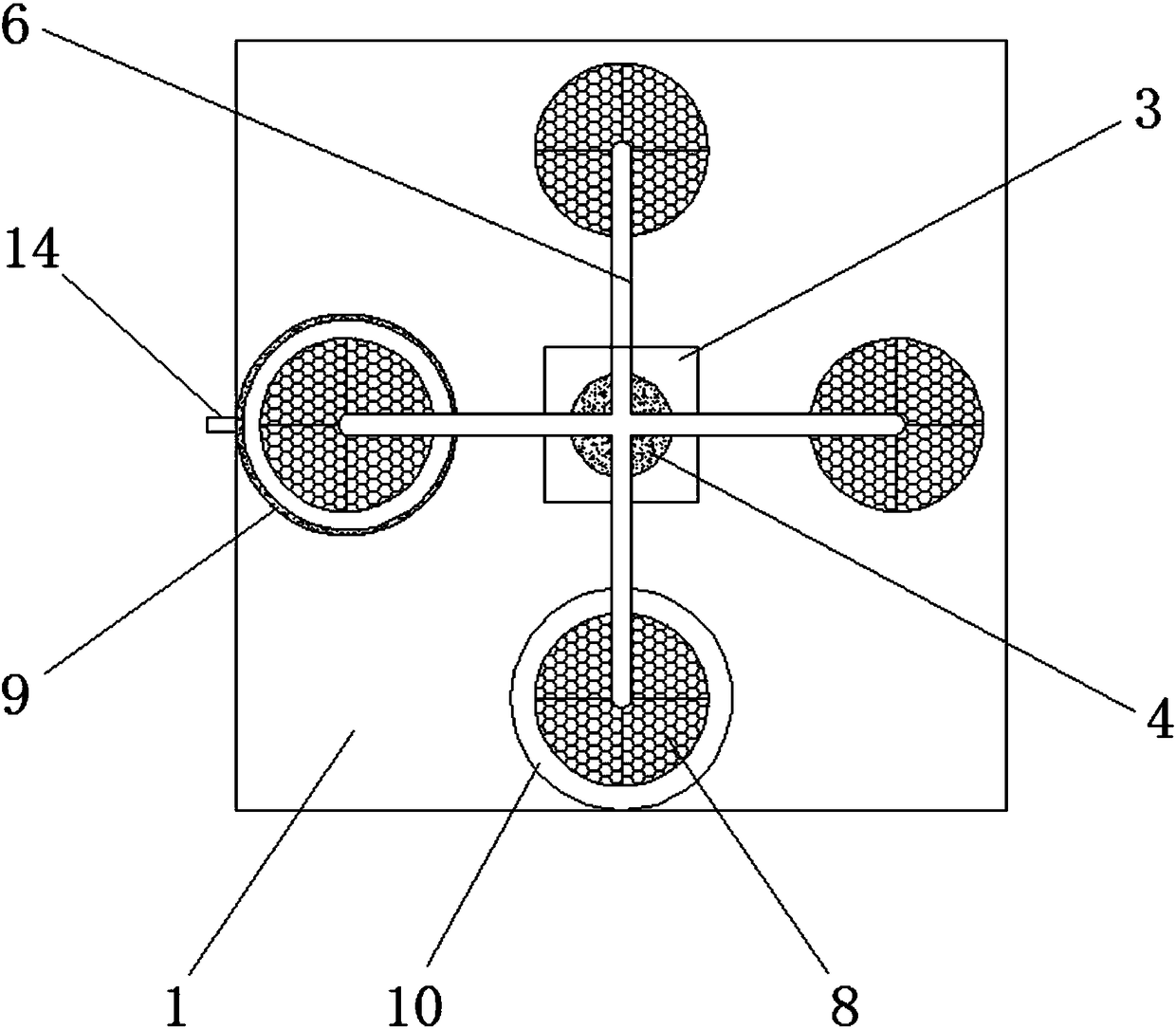

The invention discloses a preserved duck egg cleaning feeding device which comprises a base. An air cylinder is arranged in the center point of the top of the base, a top plate is fixedly connected tothe top of the air cylinder, a motor is fixedly connected to the top of the top plate, a rotary column is fixedly connected to the axis center of the top of the motor, the top of the rotary column isfixedly connected to one end of a transverse rod, the bottom of the end, away from the rotary column, of the transverse rod is provided with a hook, placing baskets is movably connected to the interior of the hook, and the outer surface of each placing basket is sequentially sleeved with a cleaning barrel and a drying barrel. According to the preserved duck egg cleaning feeding device, the air cylinder and the motor drive the four placing baskets to rotate, feeding, cleaning, drying, collection and the like can be simultaneously carried out, and the efficiency is improved; since vibrators arearranged in the cleaning barrels and cooperated with water spray heads, multidirectional cleaning is achieved, and the cleaning effect is improved; and the bottom of each cleaning barrel is inclined,so that the sludge discharge efficiency is improved.

Owner:奉晓梅

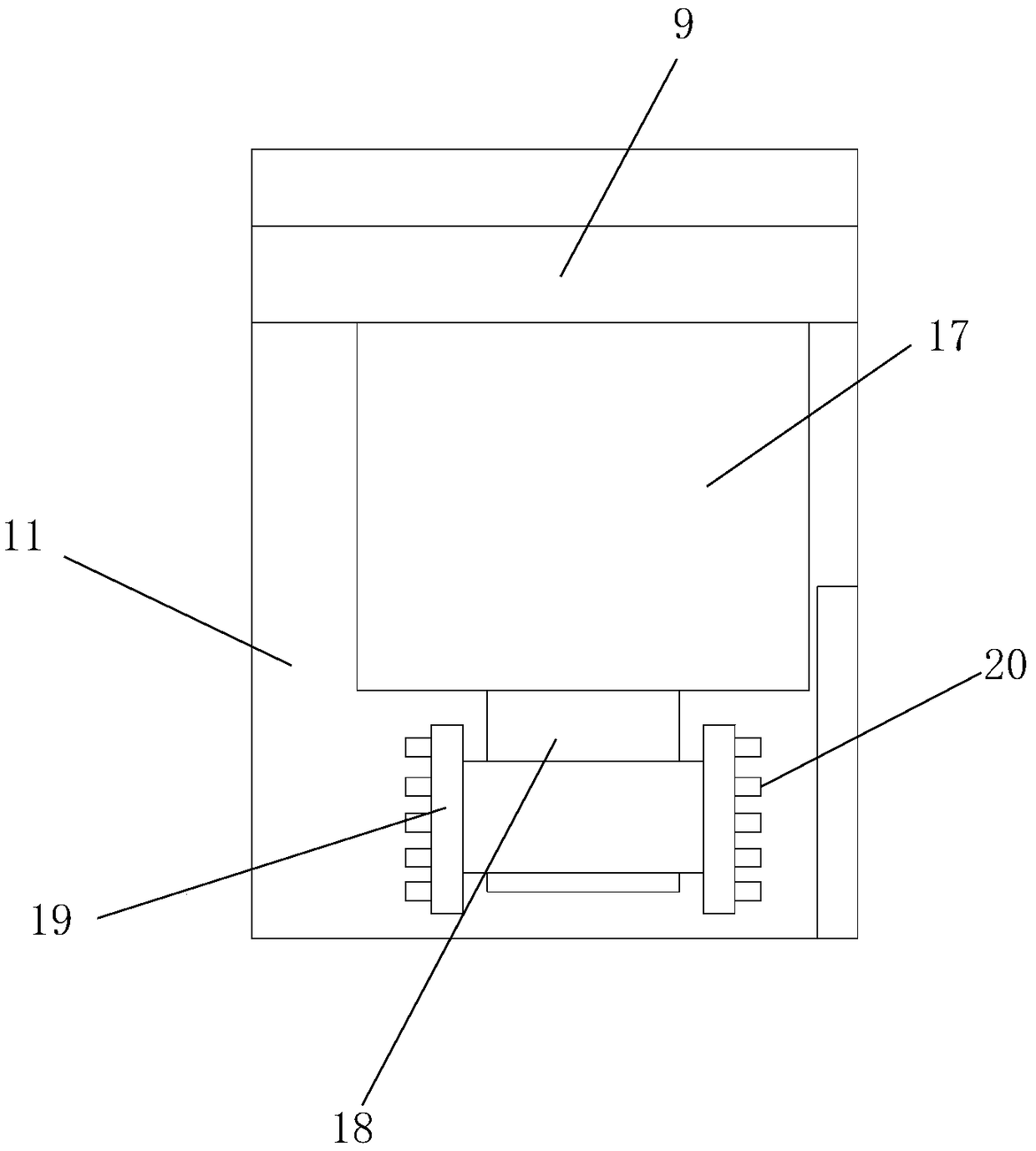

Marinated egg graded-heating device

InactiveCN108739976AImprove efficiencyQuality improvementEggs preservation by dryingFood dryingEngineeringElectrical and Electronics engineering

The invention discloses a marinated egg graded-heating device, which comprises a storage battery and first heating boxes mounted on the storage battery. A chamber is mounted at upper ends of the heating boxes, first transmission pipes are arranged at upper ends of the first heating boxes and mounted in the chamber, a first transmission branch pipe is mounted on each first transmission pipe, a gridis mounted at the upper end of each first transmission branch pipe, a connection plate is mounted between the grids, and the grids, the connection plate and the inner walls of the chamber form a drying cavity. A rotating shaft is mounted on a motor which is mounted at the upper end of the connection plate, second heating boxes are mounted on a mounting plate which is mounted on the rotating shaft, a second transmission pipe is mounted on each second heating box, second transmission branch pipes are mounted on two sides of each second transmission pipe, and a plurality of nozzles are arrangedon each second transmission branch pipe. Mounting shafts are mounted on the inner walls of the chamber and provided with a plurality of carrier plates. The marinated egg graded-heating device is capable of effectively improving marinated egg heating and drying efficiency and quality.

Owner:SUSONG XIANGYUAN POULTRY TRADE

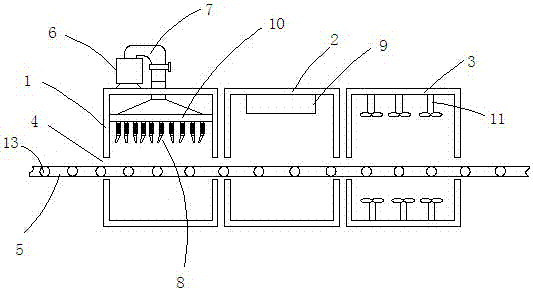

High-efficiency automatic egg drying machine

PendingCN107019027AQuality is not affectedImprove drying efficiencyEggs preservation by dryingThermostatEngineering

The invention discloses a high-efficiency automatic egg drying machine which sequentially comprises a primary thermal drying box, a middle constant-temperature box and a secondary air drying box from front to back. A horizontal conveying belt which horizontally and straightly penetrates through upper openings of the primary thermal drying box, the middle constant-temperature box and the secondary air drying box is arranged in the primary thermal drying box, the middle constant-temperature box and the secondary air drying box; a hot air blower, a hot air pipe and a plurality of flow guide pipes are further arranged at the upper portion of the primary drying box; one end of the hot air pipe is connected with the hot air blower, and an outlet in the other end of the hot air pipe is communicated with and in butt joint with the plurality of the flow guide pipes; a plurality of processing work stations where raw eggs are arranged are arranged on the conveying belt; the position of air outlets of the flow guide pipes correspond to the processing work stations; a constant-temperature device for controlling temperature in a box body is arranged in the middle constant-temperature box; an air blowing device for quickening air flow is arranged in the secondary air drying box. The high-efficiency automatic drying machine not only has a good drying effect, but also has high drying efficiency; the drying effect and the drying efficiency are improved to the maximum degree under situation that egg quality is not affected; the high-efficiency automatic drying machine has high practicability.

Owner:苏州鸿轩蛋业有限公司

Milk-flavored ready-to-eat freeze-dried Chinese chestnut slices and processing method thereof

PendingCN105410821AHigh nutritional valueAvoid it happening againEggs preservation by dryingFood ingredient functionsReady to eatFlavor

The invention relates to the field of food processing, in particular to milk-flavored ready-to-eat freeze-dried Chinese chestnut slices and a processing method thereof. The processing method of the milk-flavored ready-to-eat freeze-dried Chinese chestnut slices comprises the following steps of selecting Chinese chestnuts, cooking the selected Chinese chestnuts, and peeling the cooked Chinese chestnuts; performing whole-fruit color protection on Chinese chestnut pulp; after color protection is finished, cutting the Chinese chestnuts into Chinese chestnut slices, and then performing color protection again; soaking the Chinese chestnut slices after color protection treatment in fresh milk, fishing out the Chinese chestnut slices from the fresh milk, and then pre-freezing the Chinese chestnut slices fished out of the fresh milk; and then freeze-drying the pre-frozen Chinese chestnut slices so as to obtain the milk-flavored ready-to-eat freeze-dried Chinese chestnut slices. According to the processing method of the milk-flavored ready-to-eat freeze-dried Chinese chestnut slices disclosed by the invention, the Chinese chestnut slices are soaked in the milk, so that the mouth feel of the milk-flavored ready-to-eat freeze-dried Chinese chestnut slices is improved, and the nutrient value of the slices is increased; compared with various cooking technologies, a freeze-drying processing technology has the advantage that original nutrient components and original fragrance components of Yanshan Chinese chestnuts are furthest reserved; the prepared milk-flavored ready-to-eat freeze-dried Chinese chestnut slices have the characteristics of being mild in mouth feel, fresh and elegant in flavor, high in palatability and broad in target audiences.

Owner:HEBEI NORMAL UNIVERSITY OF SCIENCE AND TECHNOLOGY

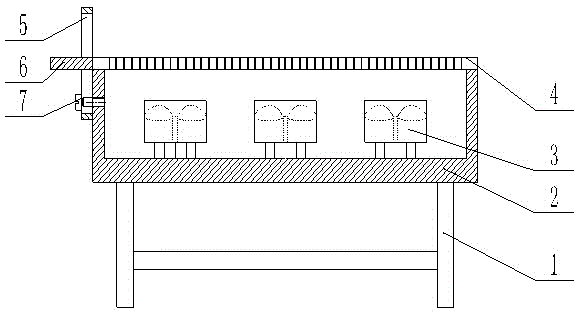

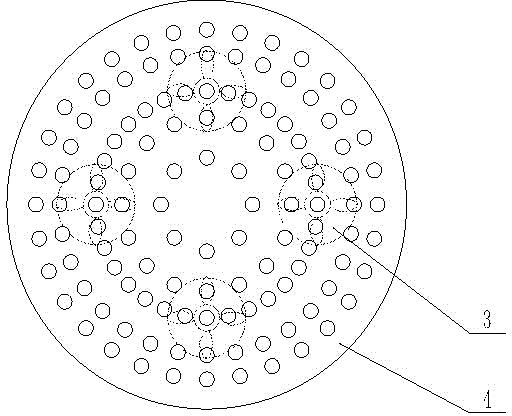

Efficient and simple air drying device for Xiangbalao eggs

InactiveCN105746678AImprove collection efficiencySimple structureEggs preservation by dryingWaste managementAir drying

The invention discloses an efficient and simple air drying device for Xiangbalao eggs. The device comprises a rack, a circular air drying cavity, fans, a circular air drying plate, a slide way, a slide bar, and a screw. Four fans are evenly disposed in the peripheral direction of the circular air drying cavity's bottom. The top of the circular air drying cavity is provided with the circular air drying plate. The slide way is connected to the side of circular air drying cavity through the screw. The slide bar is connected to the side of the circular air drying plate. The slide bar is arranged in the slide way. According to the invention, the four fans are arranged at the bottom of the circular air drying cavity to perform air drying on Xiangbalao eggs on the circular air drying plate equipped with cylindrical through-holes, thus improving the air drying efficiency. At the same time, by setting the slide way and the slide bar, the collection efficiency of the air dried Xiangbalao eggs is improved, and the work efficiency is enhanced. The whole air drying device has the advantages of simple structure and convenient operation.

Owner:DENGFENG HUIDA FOOD FACTORY

Marinated poultry egg processing method based on dry salting

InactiveCN112826046AGreat tasteReduce dosageEggs preservation by dryingFood dryingAnimal scienceSalting

The invention discloses a marinated poultry egg processing method based on dry salting. The processing method comprises the following specific steps: (1) cooking fresh poultry eggs, removing shells, removing egg membranes, and draining for later use; (2) pickling: adding table salt, white sugar and five spice powder into the shelled poultry eggs, and performing dry marination at 4-10 DEG C for 6-9 hours; (3) marination: adding anise, cinnamon, fennel and the like into water, boiling the spices, adding the dry-marinated poultry eggs, and performing cold marinating for 45-60 minutes; (4) baking: baking the marinated poultry eggs at the temperature of 60 to 65 DEG C for 45 to 60 minutes; (6) vacuum packaging; and (7) high-temperature sterilization. After the fresh eggs are subjected to dry marination, the taste easily enters the eggs, flavoring substances enter the eggs to the maximum extent, and the content of auxiliary materials in brine is reduced; the dry marination can also enable the egg white to be elastic and the egg yolk to be sandy and moist; in addition to dry marination , cold marinating is also adopted, so that water loss caused by hot marinating, inconsistent concentration of marinating liquid and difference of products in different batches can be avoided; in addition, the cold marinating can avoid black rings generated due to the fact that the poultry eggs are in a high-temperature environment for a long time, and the egg products are more attractive.

Owner:HUBEI SHENDAN HEALTHY FOOD

Sterilization method and sterilizer

ActiveUS10058106B2Improve contact efficiencyFully dryLavatory sanitoryEggs preservation by dryingTriple pointReference rate

According to the present invention, a sterilant can be injected into a container without residual water on an object to be sterilized. The method includes decreasing a pressure in the container to a pressure higher than the triple point pressure at which water freezes. The method further includes comparing an actual time required for decreasing the pressure and a reference time, or comparing an actual rate of pressure increase and a reference rate to detect residual water on the object. If the residual water is detected, the pressure in the container is increased to the atmospheric pressure or the quasi-atmospheric pressure and the object is heated, and then the pressure is decreased to drain the residual water through the decompression boiling. The step of draining the residual water is repeatedly performed until no residual water is detected on the object and subsequently the sterilant is injected into the container.

Owner:SARAYA CO LTD

Method of Producing Dried Egg White, and Dried Egg White

InactiveUS20200000112A1Easily and stably obtainingHigh gel strengthProtein composition from eggsEggs preservation by heatingBiotechnologyAnimal science

[Object] To provide a method of producing dried egg white capable of easily and stably obtaining dried egg white having high gel strength, and the dried egg white.[Solving Means] In this dried egg white, a proportion of an egg white protein having a molecular weight of not less than 97,400 and not more than 340,000 is not less than 35% of a proportion of an egg white protein having a molecular weight of not less than 20,100 and not more than 340,000

Owner:Q P CORP

Egg particles and preparation method thereof

InactiveCN107874156AFor long-term storageComplete shapeEggs preservation by dryingFlavorBeta-Carotene

The invention provides egg particles and a preparation method thereof. The egg particles are prepared from the following components in percentage by weight: 40-45% of dried whole-egg powder, 18-23% ofcorn starch, 11-15% of white granulated sugar, 4-5% of edible salt, 1-3% of onions, 1.5-3% of garlic, 1.5-2.5% of aginomoto, 0.03-0.05% of beta-carotene, 0.2-0.3% of disodium nucleotide, 0.007-0.013%of vitamin E and 13.9-14.3% of water. The egg particles provided by the invention can be stored for a long time, are excellent in taste and flavor, and also keep the original nutritional components of fresh eggs.

Owner:兴化市华荣食品有限公司

High gel type egg white powder preparation and storage method

InactiveCN105918926ASimple preparation processReduce energy consumptionYeast food ingredientsFood processingWhite powderDextran

The present invention discloses high gel type egg white powder. The high gel type egg white powder is composed of the following raw materials in parts by weight: 20-25 parts of dextran solution, 24-30 parts of galactomannan solution, 10-20 parts of starch, 60-75 parts of compound mineral, 8-15 parts of an emulsifier, 10-16 parts of yeast, and 40-45 parts of water. The prepared egg white powder is subjected to storage by radiation treatment. Compared with the prior art, the high gel egg white powder preparation technology is simple, low in energy consumption, and low in cost. The obtained egg white powder is rich in nutritional value. At the same time, the irradiated egg white powder better maintains the original various physicochemical indexes, excellent functionality, appearance and color. Besides, the nutrients in the egg white powder are affected, and the egg white powder is in line with national food standards and has very good application and promotion prospects.

Owner:QIANSHAN TIANSHENG AGRI ECOLOGICAL TECH DEV CO LTD

A kind of preparation technology of highly emulsifying egg yolk powder

ActiveCN106901236BGood emulsifying effectStable tasteFood freezingEggs preservation by dryingBiotechnologyYolk

The invention relates to the dry food processing engineering field, and in particular, relates to a preparation process of a high-emulsifiability egg yolk powder. An egg yolk liquid has the pH adjusted for two times in an egg yolk powder preparation process, after first-time pH adjustment, the temperature is increased by heating to make proteins in the egg yolk liquid generate network charges having a rejection or dimerization effect for changing a protein surface layer structure, so that the effect of improving the emulsifiability of the egg yolk powder is achieved. After the egg yolk liquid is cooled to room temperature, the pH is adjusted for the second time to neutral, so the egg yolk powder can maintain a relatively stable state, the obtained product can withstand harsh conditions, the same texture, taste, stability, flavor intensity and rheological properties can be achieved with use of less amount, the cost is saved, and the productive benefits are increased.

Owner:HENAN UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com