Method for raising rehydration performance of far-infrared dried agaricus bisporus by ultrasonic pretreatment

A technology of far-infrared drying and rehydration performance, which is applied in the direction of dry preservation of eggs, etc., can solve the problem of lack and other problems, and achieve the effect of fast rehydration speed, favorable rehydration ratio and rehydration performance, and superior rehydration performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

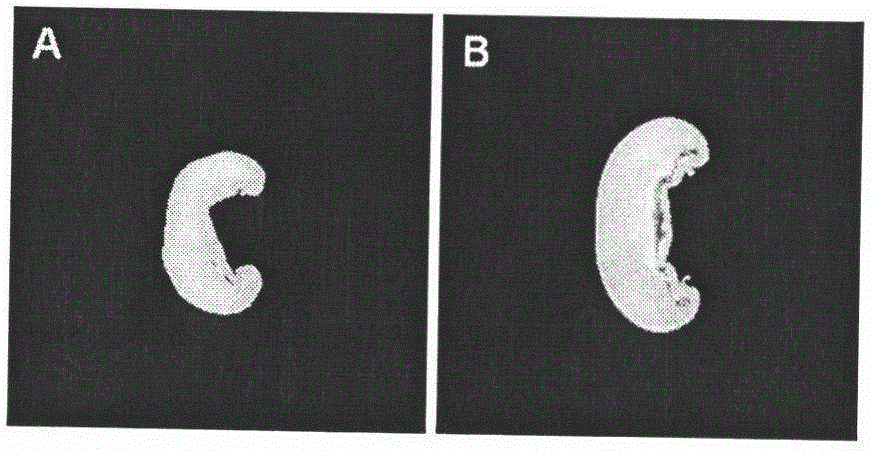

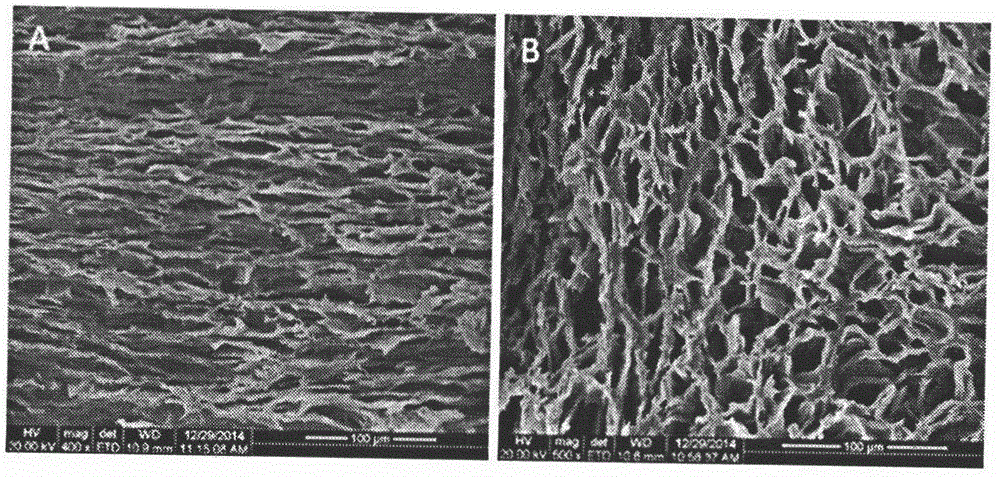

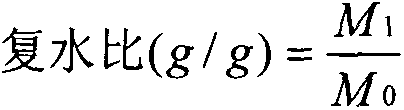

[0024] Commercially purchased fresh Agaricus bisporus with uniform size, cleaned and removed the stalk, and cut into 5mm thin slices longitudinally (along the growth direction). Under normal temperature conditions, the cut Agaricus bisporus slices were put into a digitally controlled ultrasonic cleaner for pretreatment, with a material-to-liquid ratio of 1:4, an ultrasonic frequency of 40kHz, and a power density of 0.367W / cm 2 , The ultrasonic treatment time is 10 minutes, the intermittent time is 3 minutes, and the intermittent frequency is 3 times. After ultrasonic treatment, drain the surface moisture of Agaricus bisporus slices, and then place them in far-infrared drying equipment for drying, with a radiation distance of 150mm and a radiation intensity of 2.1KW / m 2 , so that the water content of Agaricus bisporus is below 5%. The dried Agaricus bisporus slices are filled with nitrogen and packed in a well-sealed aluminum-plastic bag, and stored in a dry place at room temp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Power density | aaaaa | aaaaa |

| Power density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com