Preparation method of corn noodles

A corn noodle and corn technology, which is applied in the field of food processing, can solve the problems of lack of trace elements and unsaturated fatty acids, incomplete nutritional components of corn noodles, rough taste of corn noodles, etc. Reduces the effect of rough taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

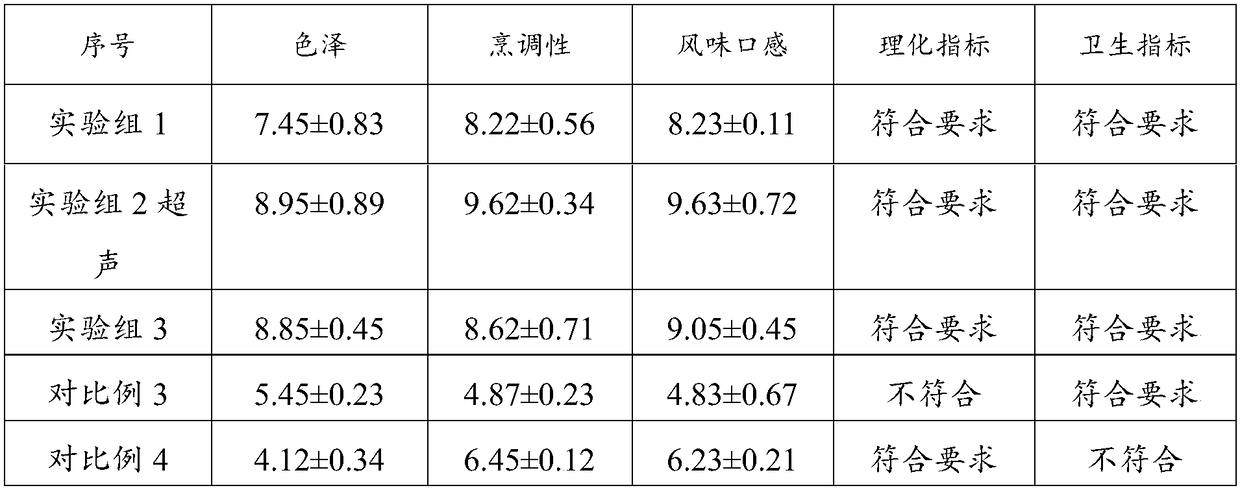

Examples

Embodiment 1

[0039] A preparation method of dried corn noodles, comprising the following steps:

[0040] (1) Get the corn kernels and pulverize them into the corn flour passing through the 0.5mm filter screen, for subsequent use;

[0041] (2) Add 100 parts by weight of corn flour to 55 parts by weight of water and mix evenly, knead the noodles using a double-screw noodle machine at a temperature of 40°C and place them for 40 minutes;

[0042] (3) Expanding at 125°C; the expansion pressure is 15 MPa; the expansion time is 15 minutes.

[0043] (4) Squeeze to form a hot noodle cake and extrude the noodle sheet. The thickness of the hot noodle sheet can be adjusted arbitrarily within 1-3 mm; after cooling to room temperature, cut it into strips according to the thick and thin requirements;

[0044] (5) After cutting according to the long and short requirements, dry it at 55°C for 30 minutes, control the moisture content at 35%, weigh it quantitatively and pack it.

Embodiment 2

[0046] A preparation method of dried corn noodles, comprising the following steps:

[0047] (1) Get the corn kernels and pulverize them into the corn flour passing through the 0.5mm filter screen, for subsequent use;

[0048] (2) Add 55 parts by weight of water to 100 parts by weight of corn flour, and perform ultrasonic treatment. Under the conditions of 300W and 120kHz, the ultrasonic time is 20 minutes, and the mixture is evenly mixed. minute;

[0049] (3) Expanding at 125°C; the expansion pressure is 15 MPa; the expansion time is 15 minutes.

[0050] (4) Squeeze to form a hot noodle cake and extrude the noodle sheet. The thickness of the hot noodle sheet can be adjusted arbitrarily within 1-3 mm; after cooling to room temperature, cut it into strips according to the thick and thin requirements;

[0051] (5) After cutting according to the long and short requirements, dry it at 55°C for 30 minutes, control the moisture content at 35%, weigh it quantitatively and pack it. ...

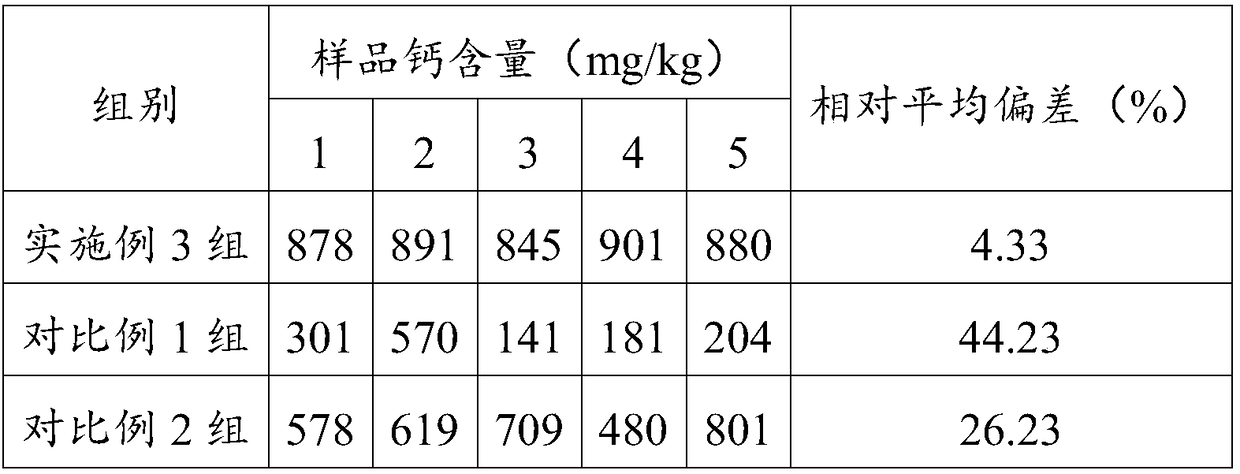

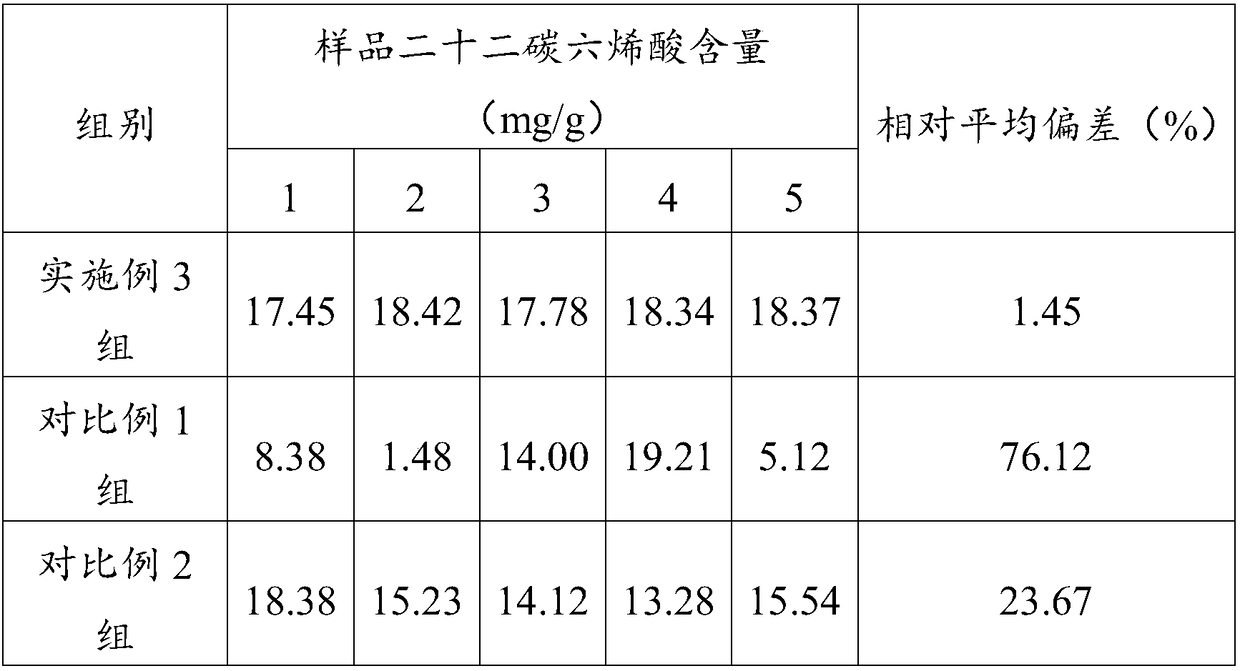

Embodiment 3

[0053] A preparation method of dried corn noodles, comprising the following steps:

[0054] (1) Get the corn kernels and pulverize them into the corn flour passing through the 1mm filter screen for subsequent use;

[0055] (2) Dissolving 0.8 part of calcium gluconate in hot water at 70°C to make a saturated solution of calcium gluconate;

[0056] (3) Mix 1.5 parts of docosahexaenoic acid with 7 parts of olive oil and stir evenly to obtain a mixed oil component;

[0057] (4) Add 60 parts by weight of water to 100 parts by weight of corn flour and the calcium gluconate saturated solution prepared in steps (2), (3) and the mixed oil component mix and carry out ultrasonic treatment. Under the conditions of 300W and 120kHz, the ultrasonic time is 20 Minutes, mix evenly, and use a double-screw drum dough machine at a temperature of 40°C to knead the dough and leave it for 40 minutes;

[0058] (5) Expanding at 130°C; the expansion pressure is 15 MPa; the expansion time is 15 minute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com