Continuous condiment adding device

A technology for adding device and seasoning, which is applied in the fields of food forming, food science, application, etc., can solve the problems of inability to distribute ingredients evenly, continuous discharge, and inability to contact and process ingredients with seasonings.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

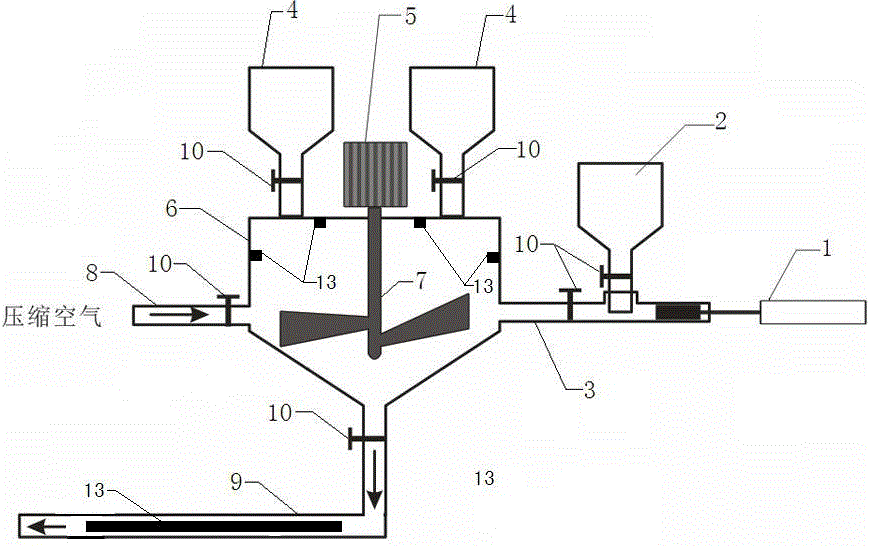

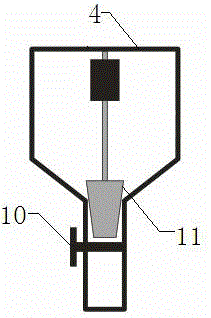

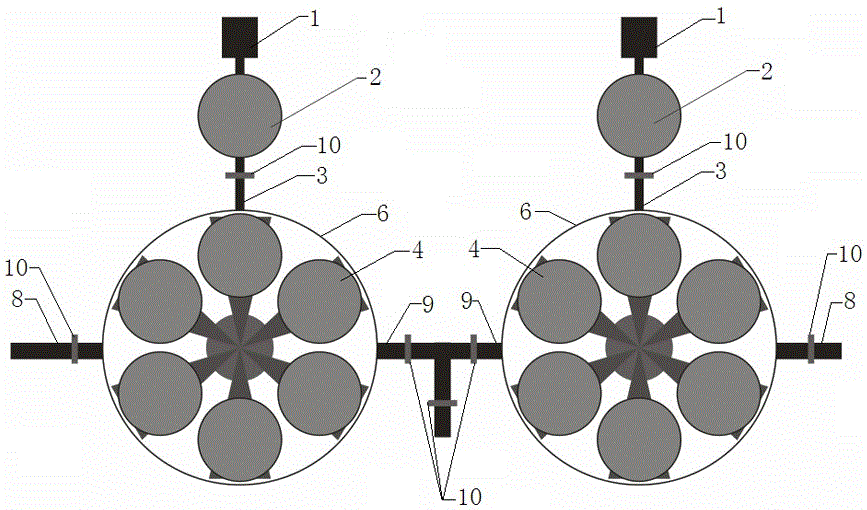

[0023] Such as figure 1 As shown, a continuous seasoning adding device includes a mixing chamber 6, and above the mixing chamber 6 there are several (6 in this embodiment, the specific number can be determined according to actual needs) granular solid seasoning and liquid The seasoning hopper 4 is equipped with a stirring mechanism inside and a discharge pipe 9 at the bottom. The side walls of the mixing chamber 6 are respectively connected with the compressed air pipe 8 and the horizontal feeding pipe 3. The inlet end of the feeding pipe 3 is connected to the piston type The filling machine 1 is connected, and a semi-solid seasoning hopper 2 is provided along the feeding pipe 3, and a flow regulating mechanism is provided on each granular solid seasoning and liquid seasoning hopper 4, and the compressed air pipe 8, feeding Pipe 3, discharge pipe 9 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com